Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "High strength wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

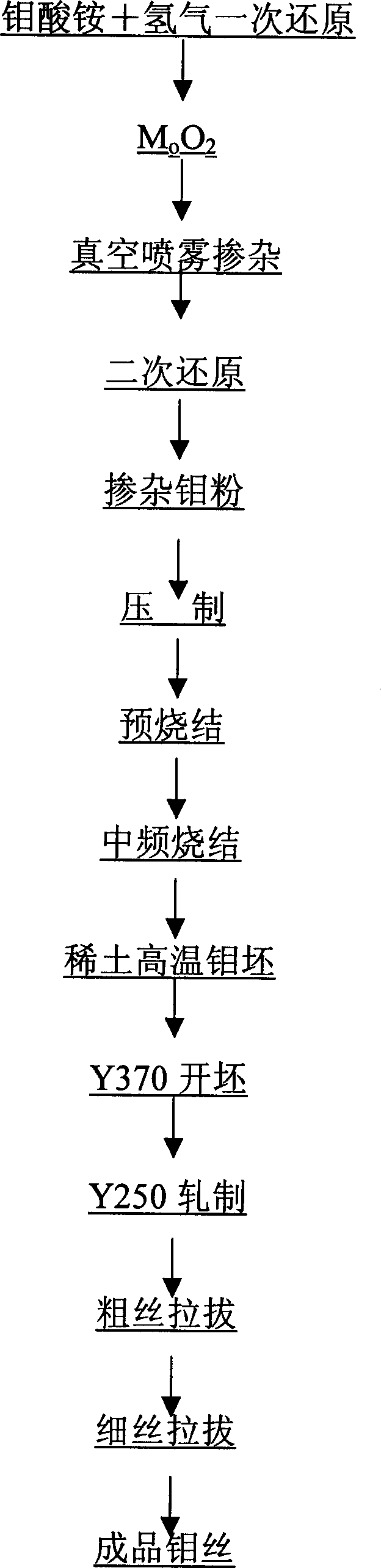

Rare earth molybdenum alloy wire and preparation method thereof

InactiveCN1876875ARaise the recrystallization temperatureHigh strengthTemperature control deviceHeat treatment process controlRare earthAlloy

The invention relates to a rare-earth molybdenum alloy wire and its process for preparing. The invention is characterized in that the said alloy wire contains two rare-earth oxides including lanthanum oxide and Y oxide(mass %) which is 0.4 %-1.0% of the alloy amount and the proportion by weight of lanthanum oxide and Y oxide is 4:1. The process for preparing is different from the traditional powder metallurgy productive technology, which includes performing double-cone vacuum drying and liquid-solid doping at molybdenum dioxide stage, then performing secondary reduction to prepare binary rare-earth doping molybdenum powder, finally preparing rare-earth doping molybdenum wire with Mo-La-Y of 0.5-0.8mm diameter by impression, agglomeration and pressure processing procedure. Compared with the pure molybdenum, the product is of good high-temperature behavior and high recrystallization temperature which increases by 300-500 DEG C than the pure molybdenum, and is of high intensity and abrasive resistance, low ductility and long durability, which has wide application in the mechanical process industry.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Novel-structure wear-resistant bit tooth

InactiveCN102108866AWear-resistanthigh-strengthReduce the number of replacementsSlitting machinesTunnel engineeringWear resistant

At present, a bit tooth is prepared from an alloy-structure steel material; because the alloy-structure steel has low rigidity and is not wear-resistant, a hard alloy cylindrical tooth is broken and falls off early; the service efficiency of the precious hard alloy cylindrical tooth is only 30 percent, and the waste is great; a diamond cylindrical tooth prepared from a superhard material has higher requirement on wear resistance of the bit tooth; the upper end of the bit tooth is provided with a hard alloy sleeve to solve the problem of low wear resistance, but the hard alloy sleeve is broken after being impacted, and cannot protect the diamond cylindrical tooth; moreover, the hard alloy sleeve is high in price and the waste is great. The invention adopts a technical scheme that: a novel-structure wear-resistant bit tooth is characterized by consisting of a bit tooth made of alloy-structure steel, and a wear-resistant body at the upper end of the bit tooth made of the alloy-structure steel, wherein the wear-resistant body is made of die steel or high-speed steel. The hard alloy cylindrical tooth or diamond cylindrical tooth can be effectively protected; and the novel-structure wear-resistant bit tooth is widely applied to coal mines, metallurgy and tunnel engineering.

Owner:闵利新 +1

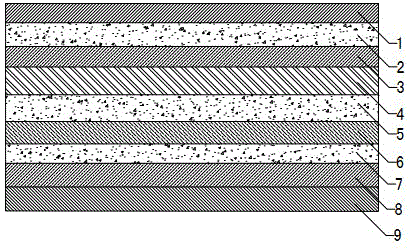

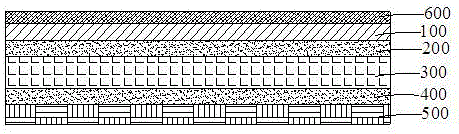

Multilayer improved thermal shrinkage preservative film/bag and base material composition thereof

ActiveCN104608451ALow costReduce wasteSynthetic resin layered productsWater vaporPolyethylene glycol

The invention relates to a multilayer improved thermal shrinkage preservative film / bag and a base material composition thereof, belonging to the technical field of preservative films. The multilayer improved thermal shrinkage preservative film / bag is characterized in that according to the formula, the base material composition comprises the following materials in percentage by weight: 60%-90% of ethanediol modified polyethylene glycol terephthalate copolymers, 5%-20% of ethylene acrylic acid copolymers or maleic anhydride graft polymers and 5%-20% of a soft improver; the preservative film is prepared by adopting the base material composition of the multilayer improved thermal shrinkage preservative film as a resin-based functional layer (4), and at least one functional layer and at least one adhesive layer are co-extruded on the upper surface and the lower surface of the resin-based functional layer (4) so as to form a multilayer layered structure. The multilayer improved thermal shrinkage preservative film / bag disclosed by the invention contains no chloride, is free of crosslinking and has excellent puncture resistance and oxygen and water vapor obstruction property.

Owner:轩福君

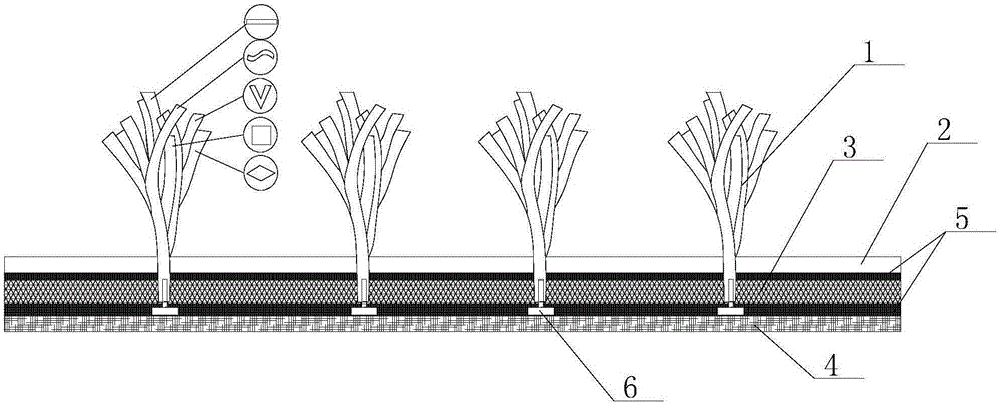

Seven-color artificial leisure turf and processing method thereof

The invention discloses seven-color artificial leisure turf. The turf comprises artificial fiber grass clusters and a base material, wherein the artificial fiber grass clusters are mounted and inserted in the base material, the base material comprises a rubber layer, a base cloth layer and a glass fiber cloth layer, and the base cloth layer is bonded to the rubber layer and the glass fiber cloth layer through adhesive layers. Shapes and colors of grass filaments of the turf are diversified, the grass filaments are close to natural grass in the field in appearance, have various characteristics and have colors similar to those of newly grown grass and grown grass, curved filaments used as bottom contrasts have light colors as well as yellow colors and are closer to newly germinated grass and withered grass in the field, and the grass filaments are closer to outdoor natural weeds.

Owner:江蘇聯創人造草坪股ふん有限公司

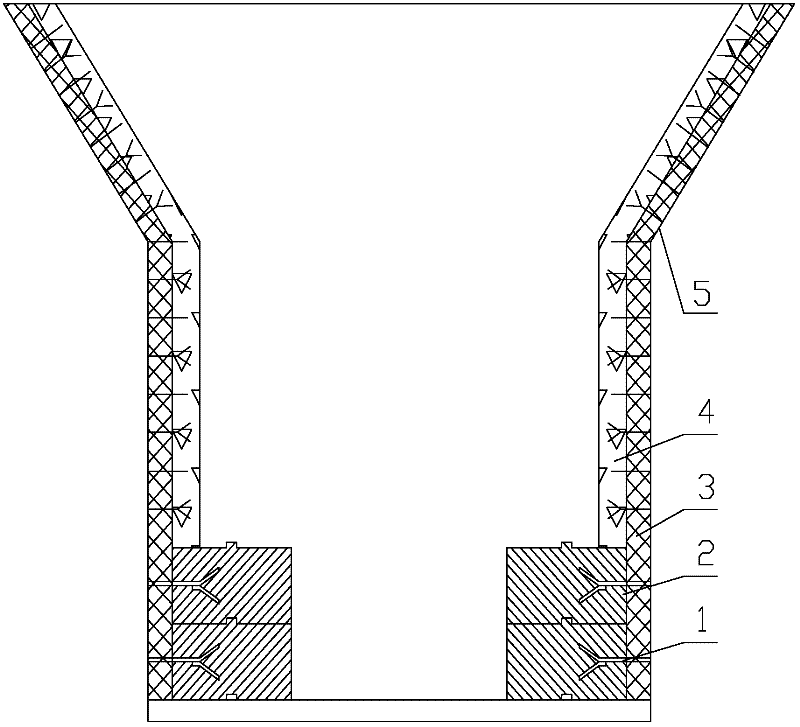

Wear-resistant prefabricated brick for cement-kiln grate-cooler low wall

The invention relates to a wear-resistant prefabricated brick for a cement-kiln grate-cooler low wall, which comprises a metal anchoring nail and a prefabricated-brick body, wherein one end of the metal anchoring nail is preliminarily placed in the prefabricated-brick body; and the wear-resistant prefabricated brick has the advantages that: the wear-resistant prefabricated bricks for the cement-kiln grate-cooler low wall are piled up on site, so that the working procedures of site construction are decreased, for example, anchoring-nail welding, molding, pouring, demoulding, curing and roasting are not needed, the construction time is shortened, and the requirement of a cement plant for short maintenance time is met; and after the roasting of the wear-resistant prefabricated brick, a product has high strength and strong high-temperature resistant and abrasion-resistant performances, the use effect and the service life of the cement-kiln grate-cooler low wall are respectively improved and prolonged, and the wear-resistant prefabricated brick is more convenient to maintain and replace.

Owner:长兴兴鹰新型耐火建材有限公司

Artificial turf with diffuse reflection function and preparation method thereof

ActiveCN104988831AWith diffuse reflectionLow reflexGround pavingsConjugated synthetic polymer artificial filamentsArtificial turfEngineering

The invention discloses an artificial turf with a diffuse reflection function. The artificial turf with the diffuse reflection function comprises a bottom base cloth, artificial fiber grass clusters and an adhesive layer. The artificial fiber grass clusters are arranged on the bottom base cloth, the adhesive layer is arranged at the lower end of the bottom base cloth, each cluster of bottom base cloth is composed of multiple grass filaments and a fixing base plate, a base body is further laid on each artificial fiber grass cluster, a non-woven fabric layer is further arranged between each base body and the bottom base cloth, a glass fabric layer is further arranged at the lower end of the adhesive layer, each base body is lattice structure formed by interweaving crisscross braided threads, the artificial fiber grass clusters are inserted and planted in the lattices of the base bodies, the non-woven fabrics layer is formed by overlaying three layers of structures, the second layer is a melt-blowing cloth, and the first layer and the third layer are spunbonded nonwovens. The invention further designs a preparation method of the artificial turf with the diffuse reflection function. The artificial turf is simple in structure, has high temperature resistance, abrasion resistance and good diffuse reflection functions, and is long in service life, convenient to produce and manufacture, low in production energy consumption, and free of environment pollution.

Owner:江蘇聯創人造草坪股ふん有限公司

Anti-static decorative board and production process thereof

The invention discloses an anti-static decorative board and a production process thereof, and relates to the technical field of decorative materials. The anti-static decorative board is prepared from the following raw materials in parts by weight, 100 parts of PVC (polyvinyl chloride) resin powder, 1-4 parts of stabilizers, 0.5-2 parts of internal lubricants, 0.2-2 parts of external lubricants, 1.0-4.0 parts of processing agents, 0.1-4 parts of foaming agents, 10-50 parts of fillers and 0.1-2.8 parts of graphene. The anti-static decorative board solves the problem that an existing PVC board easily generates static electricity in the use process, and the electrical resistivity of the board is modified from about 1010 ohms to 106-107 ohms. Besides, the anti-static decorative board solves the problems of low strength, low wear resistance, low temperature resistance, low cold resistance and the like of a PVC decorative board, the strength of the PVC decorative board is greatly improved, and the service life of the PVC decorative board is greatly prolonged.

Owner:JIANGSU GOLDEN MATERIAL TECH

Method for processing eight-color leisure artificial turf

ActiveCN105019334AImprove the lubrication effectPrevent production impactGround pavingsAdhesivesFiberGlass fiber

The invention discloses a method for processing eight-color leisure artificial turf. The method comprises the steps of processing yarn of four colors in one time through four-die-head production equipment, gathering the yarn according to specification requirements for plying and mixing, after the tufting process is conducted, forming a bunch of artificial fiber grass, and bonding a T-shaped nail at the bottom end of each bunch of artificial fiber grass for standby application; coating adhesion agents on the upper side and the lower side of a base cloth layer, placing a rubber layer and a glass fiber cloth layer at the upper side and the lower side of the base cloth layer respectively, extending one end of the bunch of artificial fiber grass, and fixing and connecting the T-shaped nail onto the glass fiber cloth layer through the adhesion agents. The shape and color of yarn are diversified, the characters of the yarn are similar to those of natural grass in the filed from the appearance, the color of the yarn is similar to that of newly-grown grass and mature grass, the color of the yarn serving as bottom lining is light and brown which are more like the newly-grown grass and withered grass in the filed, and the yarn looks like outdoor natural 'weeds'.

Owner:江蘇聯創人造草坪股ふん有限公司

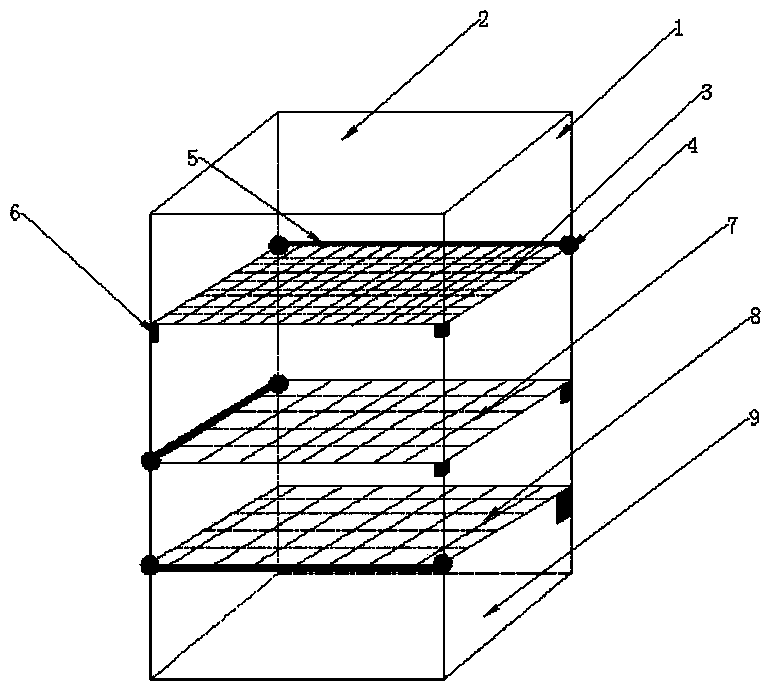

Novel combined filtering unit

InactiveCN103433195AHigh strength wear resistanceReferred to separation efficiencySievingScreeningEngineeringWear resistance

The invention relates to a novel combined filtering unit which comprises a square barrel, a feeding port, a top-layer filter screen, a middle-layer filter screen, a bottom-layer filter screen, rotating shafts, supporting pieces and a discharge port. The square barrel is made of stainless steel materials and used for providing a mineral filtering channel; the feeding port is located in the upper portion of the square barrel, and minerals can enter the barrel from the feeding port; the top-layer filter screen, the middle-layer filter screen and the bottom-layer filter screen are located at the upper end, middle end and lower end of the barrel respectively, one side of the top-layer filter screen, one side of the middle-layer filter screen and one side of the bottom-layer filter screen are linked to the rotating shafts on the wall face of the rectangular filtering unit, the other side of the top-layer filter screen, the other side of the middle-layer filter screen and the other side of the bottom-layer filter screen are supported through the supporting pieces, and all the filter screens are located on the horizontal direction; the rotating shafts are fixedly arranged on the wall face of the square barrel and serve as movable rotating shafts of the filter screens; the discharge port is located in the bottom of the square barrel, and materials are discharged from the discharge port. A plurality of filter screens with different meshes are arranged in the novel combined filtering unit, the minerals can be separated in a multi-grade mode in the different filter screens, and the novel combined filtering unit has the advantages of being high in abrasive resistance, good in adjustment performance, simple in structure, and convenient to manufacture.

Owner:天津聚贤达科技有限公司

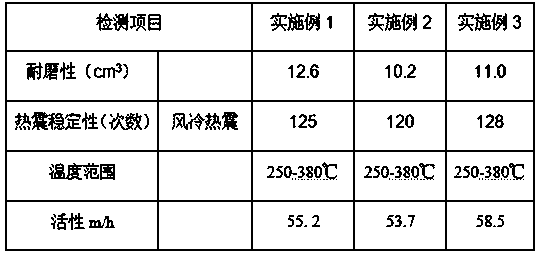

Ceramic catalysis filter pipe

ActiveCN110052164AImprove denitrification efficiencyWide temperature range for denitrificationDispersed particle filtrationTransportation and packagingMicrometerUltimate tensile strength

The invention provides a ceramic catalysis filter pipe which is characterized by comprising a ceramic catalysis support and a catalyst ceramic film wrapping the outer surface of the ceramic catalysissupport, vent holes with the hole diameters of 5-30 micrometers are distributed in the surface of the ceramic film, conical holes with the hole diameters of 0.5-1 millimeters are horizontally and uniformly distributed in the ceramic catalysis filter pipe, and the hole diameter of one end, close to the a catalyst ceramic film, of each conical hole is smaller. The ceramic catalysis filter pipe is stable in denitration efficiency, wide in denitration temperature range, high in mechanical strength, strong in wear resistance, good in filtering effect and quite high in efficiency, and can simultaneously perform denitration and filtration.

Owner:XIAN XIKUANG ENVIRONMENTAL PROTECTION

Dust removal packaging machine and application method thereof

PendingCN109279058AAvoid contaminationPrevent inaccurate feedingSolid materialEngineeringScrew conveyor

The invention relates to a dust removal packaging machine and an application method thereof, and belongs to the technical field of packaging equipment. The dust removal packaging machine comprises a shell, a feeding device, a conveying device and a sealing device; an air inlet and an air outlet are formed in the two opposite face side walls of the shell, an ion fan is arranged on the air inlet, the feeding device comprises a feeding hopper, a spiral conveyor and a feeding pipe, a rotating shaft is horizontally arranged in the feeding hopper, and is fixedly connected with a breaking roller, the conveying device comprises a first conveying belt and a second conveying belt, partition boards are arranged on the first conveying belt evenly at intervals, the sealing device comprises a telescopic air cylinder and two swing arms, the two swing arms are hinged, telescopic rods are fixedly connected to the lower ends of the two swing arms, hot pressing rollers are arranged at the top ends of the telescopic rods, and compression springs are arranged between the hot pressing rollers and the swing arms. The ion fan of the dust removal packaging machine can neutralize material surface static electricity, the particle materials can be effectively prevented from being tainted with dust in the packaging link, and the interior of the shell can be subjected to dust removal.

Owner:南京钢诺智能装备有限公司

High-strength abrasion-resistant alloy material for wiring harness terminal and preparation method of high-strength abrasion-resistant alloy material for wiring harness terminal

The invention relates to the technical field of alloy preparation, in particular to a high-strength abrasion-resistant alloy material for a wiring harness terminal and a preparation method of the high-strength abrasion-resistant alloy material for the wiring harness terminal. Raw materials of the alloy material for the wiring harness terminal comprise 0.02%-0.07% of Cr, 0.01%-0.2% of Mg, 0.01%-0.2% of Ti, 0.02%-0.3% of Zn, 0.02%-0.3% of Fe, 0.02%-0.3% of Sn and the balance Cu and other inevitable impurities. According to the high-strength abrasion-resistant alloy material for the wiring harness terminal and the preparation method of the high-strength abrasion-resistant alloy material for the wiring harness terminal, after various components of the alloy material for preparing the wiring harness terminal are subjected to smelting, hot rolling, annealing and cooling treatment, the obtained alloy material for the wiring harness terminal is high in strength and hardness, the preparation method is simple, and raw materials are easy to obtain.

Owner:WUHU EXCELLENCE WIRE HARNESS SYST

Automotive dashboard fireproof heat-insulating plate

InactiveCN106476720AImprove wear resistanceGuaranteed to workSuperstructure subunitsCompression moldingSurface layer

The invention discloses an automotive dashboard fireproof heat-insulating plate which is characterized by comprising a surface layer, a first buffer layer, a support frame plate, a second buffer layer and a base resin layer; the first buffer layer is connected to the upper surface of the support frame plate through adhesive, the second buffer layer is connected to the lower surface of the support frame plate by compression molding, the surface layer is connected to the upper surface of the first buffer layer by hot melting, the base resin layer is connected to the lower surface of the second buffer layer by hot melting, and an anti-UV coating is also sprayed to the upper surface of the surface layer. In this manner, the automotive dashboard fireproof heat-insulating plate is nontoxic and odorless, is tolerant to corrosion and high temperature, has high wear-resistant strength and excellent flame retardancy and self-extinguishing property, and allows a faulted dashboard to normally operate at high temperature, with the precision of instruments not affected.

Owner:JIANGSU HAOSHENG PLASTIC IND TECH CO LTD

A kind of low-carbon equivalent high-strength wear-resistant steel plate and its production method

InactiveCN101748333BHigh strengthHigh hardnessTemperature control deviceElectric furnaceBrinellingHardness

The invention discloses a low-carbon-equivalent high-strength wear-resistant steel plate, which is prepared from the following components in percentage by weight: 0.15 to 0.18 percent of C, 0.20 to 0.40 percent of Si, 1.30 to 1.40 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.040 to 0.050 percent of V, 0.017 to 0.030 percent of Nb, 0.020 to 0.040 percent of Al, 0.15 to 0.25 percent of Cr, 0.18 to 0.28 percent of Mo, 0.017 to 0.026 percent of Ti, 0.0015 to 0.0030 percent of B, and the balance of Fe and inevitable impurities. The thickness of the steel plate is 8 to 60mm. The high-strength wear-resistant steel plate has the yield strength over 1,000MPa, the Brinell hardness between 380 and 430HBW, the carbon equivalent between 0.41 and 0.49 percent, the maximum tensile strength of 1,280MPa, good low temperature toughness, and the maximum thickness of 60mm.

Owner:WUYANG IRON & STEEL +1

A seven-color leisure artificial turf and its processing method

Owner:江蘇聯創人造草坪股ふん有限公司

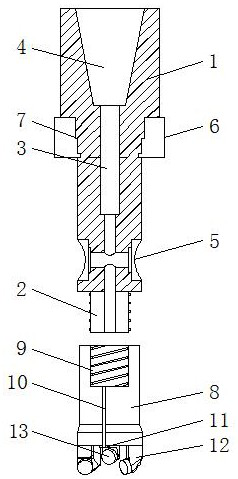

Compact bearing high-pressure jet grouting drill bit

PendingCN112412343ASimple and reasonable structureImprove cutting speed and effectDrill bitsDrilling rodsDrill holeGeotechnical engineering

The invention discloses a compact bearing high-pressure jet grouting drill bit. The compact bearing high-pressure jet grouting drill bit comprises a drill rod body and a drill bit body. The drill rodbody is of a shaft-shaped structure. A connecting block is fixed to the bottom of the drill rod body, and the drill rod body and the connecting block are integrally formed through casting. A jet grouting water conveying channel is formed in the center of the interior of the drill rod body. The compact bearing high-pressure jet grouting drill bit is simple and reasonable in structure, jet groutingcutting at the drilling position can be achieved through the arrangement of a jet grouting compact high-pressure cutting tool bit and a nozzle at the front end of the drill bit body, a first cutting tool bit and a second cutting tool bit are used in cooperation, the first cutting tool bit cuts the outer ring of the drilling position, the second cutting tool bit cuts the inner ring of the drillingposition, and therefore the cutting speed and effect during drilling are improved; and due to the arrangement of a lateral nozzle on the outer side of the drill rod body and a nozzle at the front end,a coaxial and non-concentric cutting nozzle process is adopted, high-pressure jet cutting can be conducted on the side wall of a drilled hole and the front end of a drill bit at the same time, and the high-pressure jet grouting effect is improved.

Owner:史彦

Composite ceramic-phase anti-seepage wear-resistant material produced from polysilicon wastes and used for copper chute

The invention discloses an SiC / Si3N4 composite ceramic material with small thermal expansion coefficient, low porosity, good thermal shock stability and wear resistance, excellent copper slag, aluminum slag and chemical gas permeation resistance, good integrity and long service life and a preparation method thereof. According to the invention, a raw material of the SiC / Si3N4 composite ceramic material is prepared by the following steps: drying and grinding a waste residue obtained by precipitating a polycrystalline silicon slicing waste liquid, carrying out nitridation treatment at 1100-1300 DEG C, adding a certain amount of SiC as a supplementary material, adding a composite additive and water, carrying out pouring, carrying out maintaining at normal temperature, and carrying out heatingand baking at 200-300 DEG C. The SiC / Si3N4 composite ceramic material not only prolongs the production chain of the polycrystalline silicon industry, but also solves the bottleneck problem of development of refractory materials in the non-ferrous metal smelting industry, and is easy for large-scale industrial popularization and application and for industrialization.

Owner:洛阳市科创绿色建材研究院 +1

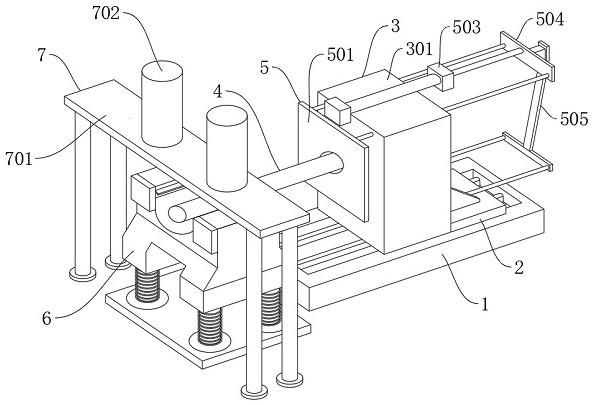

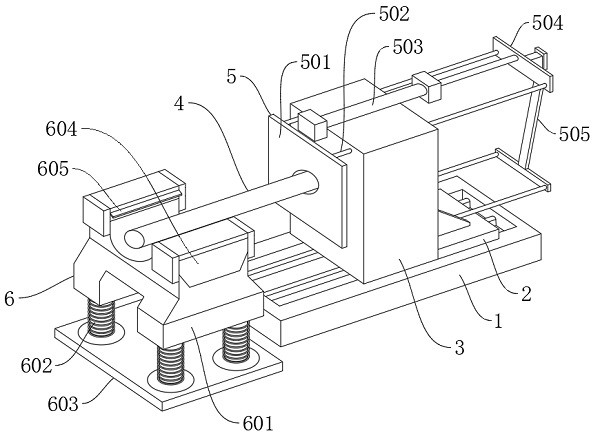

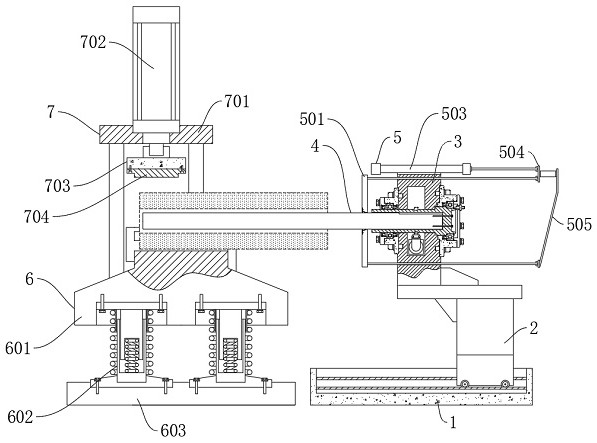

High-strength wear-resistant hydraulic oil cylinder block forging device and forging method thereof

InactiveCN113084062ARealize the collectionRealize automatic unloadingPower hammersCleaning using toolsGear wheelCylinder block

The invention relates to the technical field of post-machining equipment, in particular to a high-strength wear-resistant hydraulic oil cylinder block forging device and a forging method thereof. The high-strength wear-resistant hydraulic oil cylinder block forging device comprises a device base, a supporting plate is arranged at the top end of the device base, a rotating assembly is arranged at the top end of the supporting plate and comprises a shell, a connecting sleeve is arranged inside the shell in a sleeve mode, a limiting block is arranged at the right end of the connecting sleeve, the outer surface of the shell is sleeved with a bearing ring, the outer surface of the bearing ring is sleeved with a bearing sleeve, a first air cylinder is arranged at the position, close to the lower portion of the connecting sleeve, inside the shell, a transmission rod is arranged at the output top end of the first air cylinder, a gear ring is arranged on the outer surface of the connecting sleeve, and a guide rail is fixed to the inner wall of the shell. According to the high-strength wear-resistant hydraulic oil cylinder block forging device and the forging method thereof, forging is more uniform, a cylinder block finished product is high in strength and resistant to abrasion, the finished product is not prone to abrasion during discharging, meanwhile, a scrap collecting mechanism is arranged, and environmental pollution and resource waste are avoided.

Owner:南京金满园机械制造科技有限公司

Automatic powder feeding device

The invention discloses an automatic powder feeding device which comprises a level indicator device, a screw conveyor, an ash conveying pipeline, a high-pressure fan, an observation window access hole, a crawling ladder, a powder feeding protection device, a feed cylinder, and a powder feeding guardrail. The crawling ladder is arranged on the side of a support frame; one end of the crawling ladderis connected with the support frame; the other end of the crawling ladder is connected with the crawling ladder and the powder feeding protection device; the level indicator device, the screw conveyor, the ash conveying pipeline, the high-pressure fan, the observation window access hole, a speed reducer, an ash hopper and a tank are arranged in the support frame; the side of the top end of the support frame is connected with the top end of the ash hopper; the observation window access hole and the level indicator device are arranged on an outer side panel of the ash hopper; the speed reduceris arranged under the ash hopper; and the screw conveyor is connected to the side of the speed reducer. According to the automatic powder feeding device provided by the invention, when a deduster works, a lime powder feeder is arranged according to the system parameters, and the powder feeding rate per hour is set according to the demand of an owner, so that the automatic powder feeding device isstable to work, high in efficiency and convenient to use.

Owner:东莞市宇晨机械科技有限公司

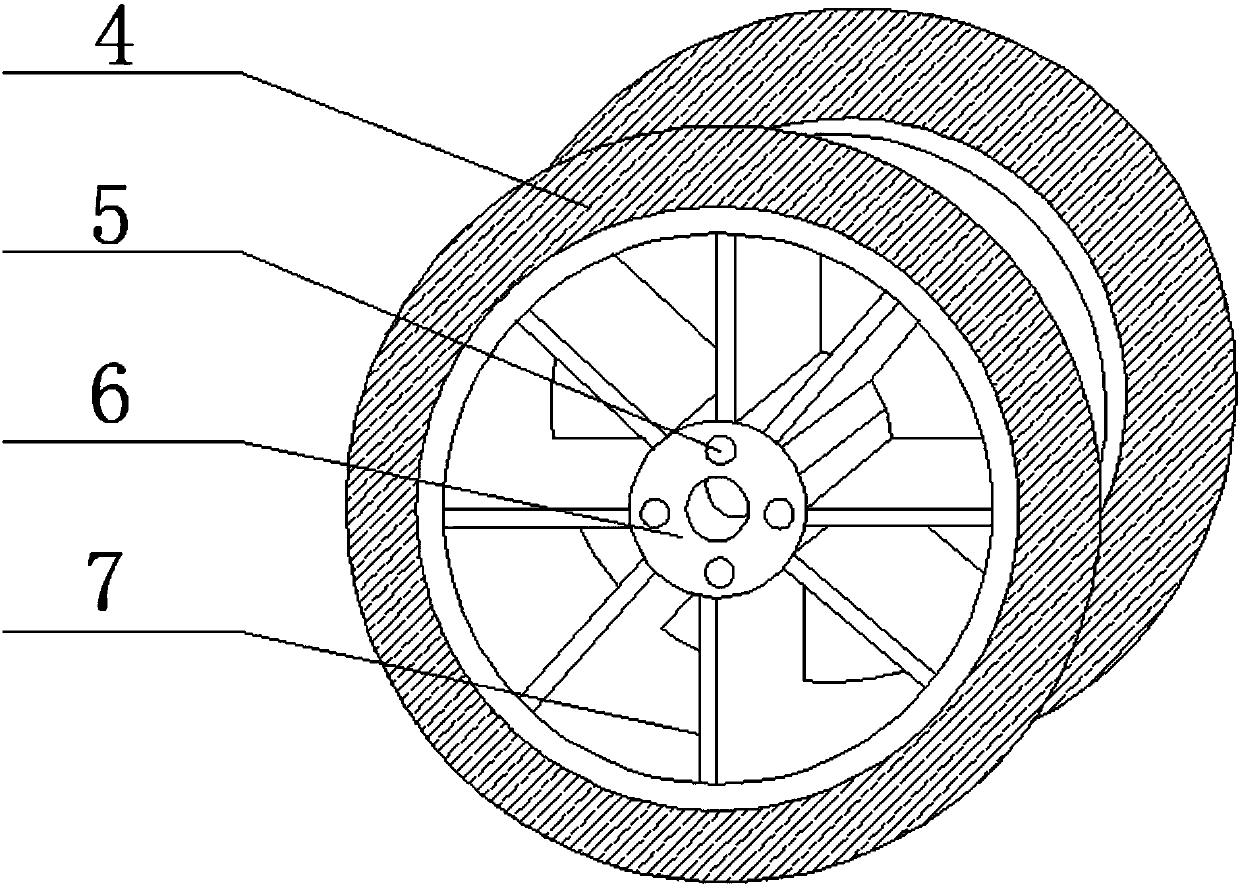

Polyurethane rubber composite special tire and preparation method thereof

InactiveCN109572328AHigh elastic propertiesIncrease elasticitySpecial tyresTyresRubber materialThermal insulation

The invention discloses a polyurethane rubber composite special tire and a preparation method thereof. The tire includes polyurethane patterns, rubber patterns, a tire body, a wheel rim, screw holes,a bearing, spokes, a crown protection layer, an insulating layer and an airtight layer. The beneficial effects of the tire and preparation method are as follows: the surface of the provided tire bodyis formed by polyurethane and rubber which are interlaced and uniformly arranged on the surface of the tire body, so that the tire can have performance of the polyurethane material such as high-strength wear resistant performance, oil resistant performance and high temperature resistance, and have characteristics of high hardness and high strength, and the tire can also reserve the advantages of the rubber material of strong elastic properties, acid and alkali resistance and strong buffering capabilities; that drawing on the strong points of others to make up for one's own weak points can be realized by combining the two materials; and the tire is added with the crown protection layer, the insulating layer and the airtight layer from the external layer to the internal layer, so that the tire can have advantages of deep corrosion resistant performance, good thermal insulation effects and strong airtight performance.

Owner:江苏润昌橡胶科技有限公司

A multi-layer improved heat-shrinkable plastic wrap/bag

ActiveCN104608451BGood weather resistanceGood dimensional stabilitySynthetic resin layered productsPolymer scienceWater vapor

The invention relates to a multilayer improved thermal shrinkage preservative film / bag and a base material composition thereof, belonging to the technical field of preservative films. The multilayer improved thermal shrinkage preservative film / bag is characterized in that according to the formula, the base material composition comprises the following materials in percentage by weight: 60%-90% of ethanediol modified polyethylene glycol terephthalate copolymers, 5%-20% of ethylene acrylic acid copolymers or maleic anhydride graft polymers and 5%-20% of a soft improver; the preservative film is prepared by adopting the base material composition of the multilayer improved thermal shrinkage preservative film as a resin-based functional layer (4), and at least one functional layer and at least one adhesive layer are co-extruded on the upper surface and the lower surface of the resin-based functional layer (4) so as to form a multilayer layered structure. The multilayer improved thermal shrinkage preservative film / bag disclosed by the invention contains no chloride, is free of crosslinking and has excellent puncture resistance and oxygen and water vapor obstruction property.

Owner:轩福君

A processing method of eight-color leisure artificial turf

ActiveCN105019334BImprove the lubrication effectPrevent production impactGround pavingsAdhesivesYarnGlass fiber

Owner:江蘇聯創人造草坪股ふん有限公司

Automobile stamping die insert and laser strengthening manufacturing method thereof

PendingCN112442691AExtended service lifeImprove performanceMetallic material coating processesManufacturing technologyTempering

The invention provides an automobile stamping die insert and a laser strengthening manufacturing method thereof, and belongs to the technical field of die insert preparation. The method comprises thefollowing steps of: tempering, and hardening and tempering a die insert; preparing cladding layer alloy powder which is composed of C, Si, Cr, Ni, Mo, Mn, Co, V, B and the balance Fe; placing the dieinsert on a workbench to be clamped and positioned, and performing laser cladding on the outer surface of the die insert by using the alloy powder; and performing machining treatment on the die insertcoated with a reinforcing layer. According to the laser strengthening manufacturing method of the automobile stamping die insert, common forged steel or an ineffective die serves as a base material,the latest laser cladding manufacturing process is adopted, deformation of the die insert due to excessive heat input is avoided, precision is greatly improved, and meanwhile, production cost and material waste are reduced. The laser strengthening manufacturing method is simple, convenient and flexible in operation and has great popularization and application values in the field of automobile stamping die inserts.

Owner:重庆机电增材制造有限公司

UHMWPE composite double-wall corrugated pipe

PendingCN113402801AHigh strength wear resistanceImprove wear resistanceRigid pipesHigh-density polyethylenePolymer chemistry

The invention relates to the field of plastic pipes, and provides a UHMWPE composite double-wall corrugated pipe, which comprises an inner wall and an outer wall. The inner wall is prepared from the following raw materials in parts by weight: 100 to 120 parts of low-density polyethylene, 3 to 5 parts of color master batch, 4 to 6 parts of a moisture absorbent and 4 to 6 parts of antioxidant master batch. The outer wall is prepared from the following raw materials in parts by weight: 30 to 40 parts of ultra-high molecular weight polyethylene, 70 to 80 parts of high-density polyethylene, 10 to 20 parts of reinforced master batch, 1 to 2 parts of a nucleating agent, 3 to 5 parts of black color master batch, 4 to 6 parts of antioxidant master batch and 4 to 6 parts of a moisture absorbent. According to the UHMWPE composite double-wall corrugated pipe, the ring stiffness and the wear resistance are improved, and the application field of the pipe is expanded.

Owner:福建亚通新材料科技股份有限公司

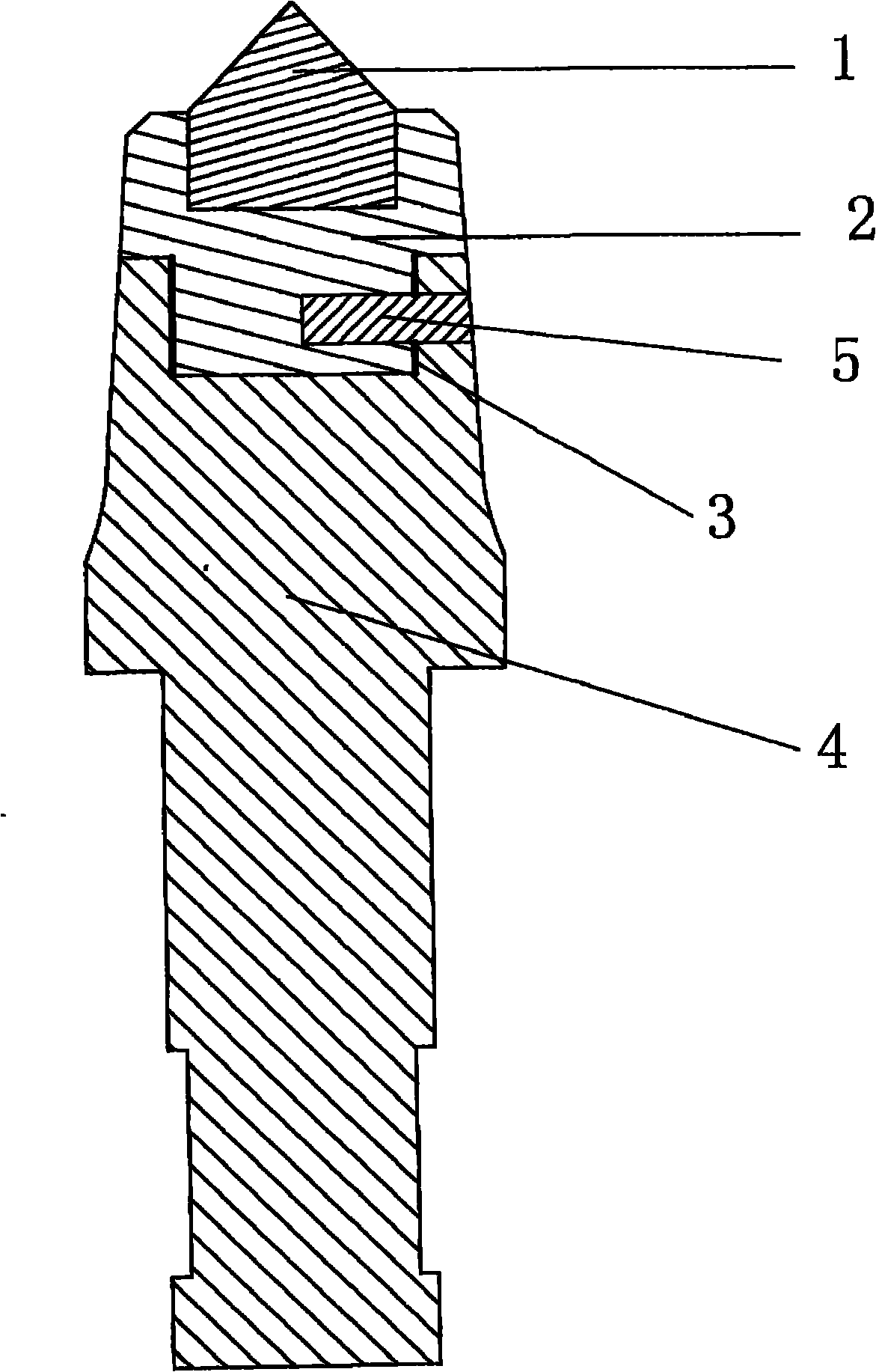

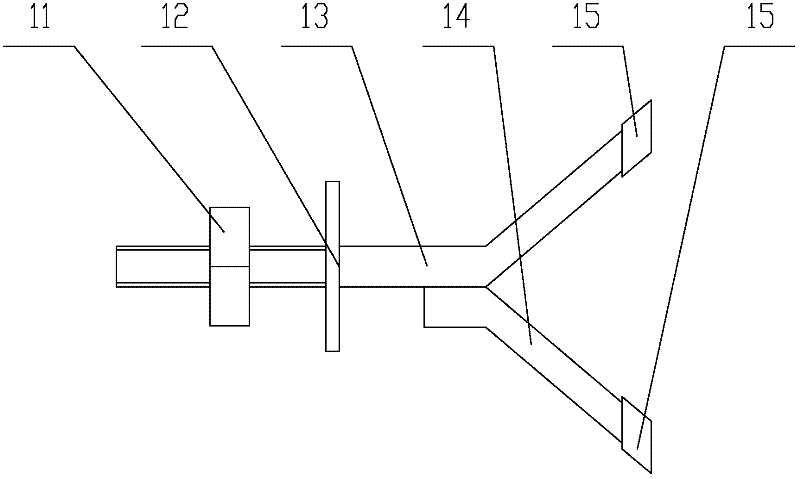

75t heavy forklift truck half axle

The invention discloses a 75t heavy forklift truck half axle which is characterized by comprising a half axle body (1), a half axle flange (2), a flange disk matching surface (3), a positioning pin hole (4), a high-frequency quenching region (5), a flange disk center hole (6), bolt holes (7), a flange disk neck part (8), a spline shaft (9), a spline quenching region (10), a spline tooth (11), a center hole (12) and a detaching screw hole (13), wherein the bolt holes (7), the positioning pin hole (4) and the detaching screw hole (13) are formed in the end part of the half axle flange; eight bolt holes (7) are uniformly formed in the flange disk matching surface, and the aperture of each bolt hole is 14.5mm; the positioning pin hole (4) and the detaching screw hole (13) are formed in the flange disk matching surface; an included angle between the positioning pin hole (4) and the detaching screw hole (13) is 90 degrees; the high-frequency quenching region (5) is arranged at the root of the flange disk neck part; a quenching layer is 1.5mm deep, and the hardness HRC is 45; a high-frequency quenching layer of the spline quenching region on the spline shaft (9) is 2mm deep, and the hardness HRC is 47.

Owner:韩传怀

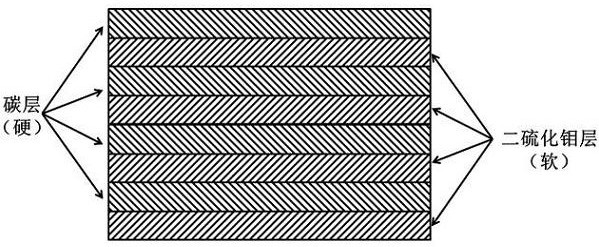

A method for preparing sub-10 nanometer-scale biomimetic structure molybdenum disulfide-carbon multilayer film

ActiveCN111485212BImprove performanceGood serviceVacuum evaporation coatingSputtering coatingCarbon layerPlasma-immersion ion implantation

The invention relates to a method for preparing a molybdenum disulfide-carbon multilayer film with a bionic structure of sub-10 nanometers. The method refers to: preparing a molybdenum disulfide layer by using a high-power pulse unbalanced magnetron sputtering method on a treated base part, Using high-pressure plasma immersion ion implantation technology, CH with a purity greater than 99.99% 4 Plasma is injected onto the molybdenum disulfide layer to form a carbon layer, and the cycle is repeated for 40 to 80 cycles, and the thickness of each layer is controlled below 10nm, that is, alternately deposited on the base component to form a sub-10nm biomimetic structure Molybdenum disulfide-carbon multilayer films. The process of the present invention is simple, and the prepared 10 nanometer level bionic structure molybdenum disulfide-carbon multilayer film has excellent comprehensive properties such as ultra-low friction coefficient, ultra-low wear, high elastic recovery, high binding force, etc., and can greatly improve the space components. quality and service life.

Owner:LANZHOU UNIV OF ARTS & SCI

Porous color matching agent and preparation method thereof

The invention relates to a porous color matching agent and a preparation method thereof, and solves the problems that the process is complicated, the period is long, and a produced porous color matching agent is poor in mechanical strength in an existing porous color matching agent. Porous color matching agent particles are prepared by adopting a multiple emulsion method. The preparation method comprises the steps of adding a pore generator and a pore supporting article in a first hydrophilic colloid solution, carrying out shear dispersing on the pore generator and the pore supporting article in an organic phase solution to form a water-in-oil type first turbid liquid, then carrying out the shear dispersing on the water-in-oil type first turbid liquid in a second hydrophilic colloid solution to obtain and oil-in-water-water-in-oil type second turbid liquid, and preparing the color matching agent of a porous structure by utilizing a limit polymerization process. The process is simple, the feasibility is high, and the production period is short. The produced porous color matching agent has an excellent porous structure, high-strength abrasion resistance and good mechanical strength, the strength requirement of the subsequent processing flow can be met, the produced color matching agent is unlikely to break, the quality of a printed image can be improved, the photographic fixing temperature and printing consumption of the color matching agent can be reduced, and the printing and copying page yield can be increased.

Owner:HUBEI DINGLONG CO LTD

Aging-resistant butyronitrile emulsion adhesive for non-woven fabrics

InactiveCN106221612AImprove bond strengthGood insulationNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesChemistryEmulsion

The invention discloses aging-resistant butyronitrile emulsion adhesive for non-woven fabrics. The aging-resistant butyronitrile emulsion adhesive comprises, by weight, 24-50 parts of nitrile rubber, 8-10 parts of ethylene propylene diene monomer rubber, 16-25 parts of phenolic resin, 50-80 parts of ethyl alcohol, 8-15 parts of borax, 10-15 parts of carbon black, 8-15 parts of triphenyl phosphate, 6-12 parts of zinc oxide, 0.8-1.8 parts of oleic acid, 3-8 parts of anti-aging agents and 2-8 parts of coupling agents. The invention further provides a method for preparing the aging-resistant butyronitrile emulsion adhesive for the non-woven fabrics. The aging-resistant butyronitrile emulsion adhesive for the non-woven fabrics and the method have the advantages that the aging-resistant butyronitrile emulsion adhesive is high in adhesive strength and excellent in insulation and aging-resistant performance; the triphenyl phosphate is added into the aging-resistant butyronitrile emulsion adhesive in a formula, accordingly, the stability, the flame retardance and the antioxidant property of the aging-resistant butyronitrile emulsion adhesive can be effectively improved, and the aging-resistant butyronitrile emulsion adhesive has excellent light stability functions and is excellent in toughness; raw materials for the aging-resistant butyronitrile emulsion adhesive are safe and are free of pollution, processes are easy to implement, production procedures are environmentally friendly, the aging-resistant butyronitrile emulsion adhesive is low in preparation cost, and accordingly the aging-resistant butyronitrile emulsion adhesive and the method can be widely applied.

Owner:SHANDONG CHENGTAI CHEM IND

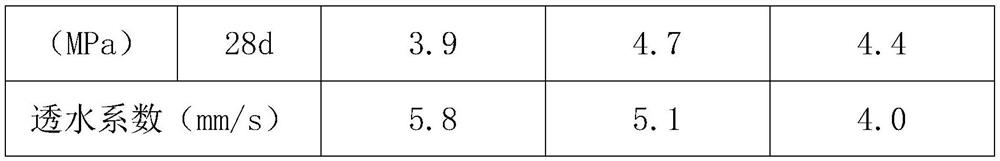

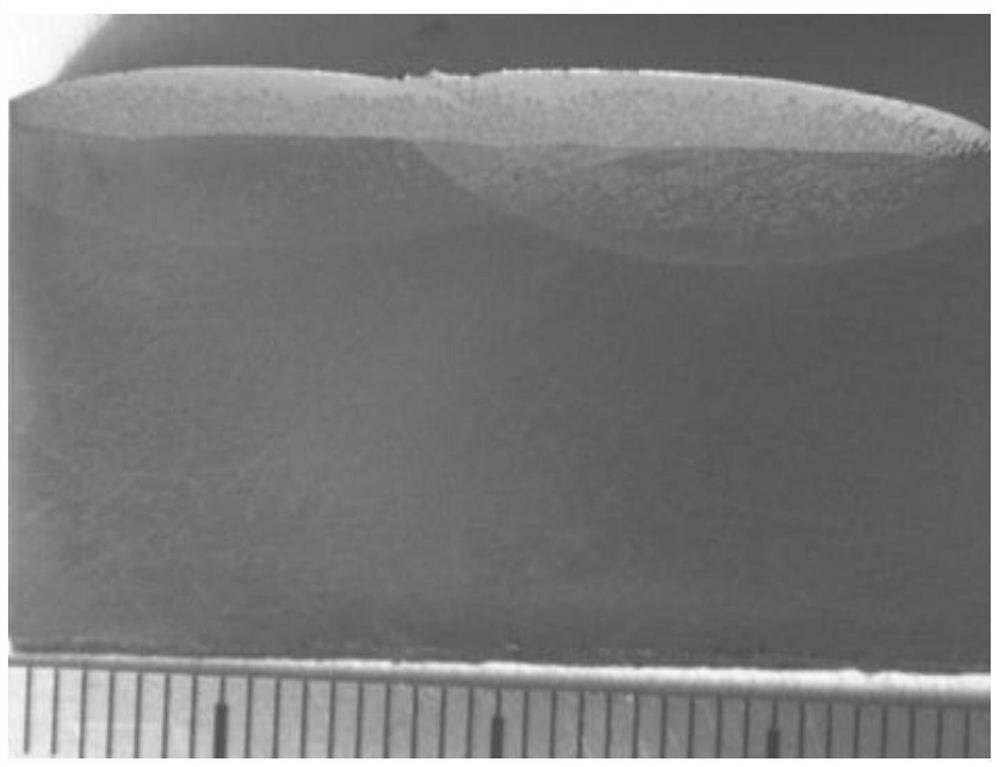

Nano inorganic polymer permeable pavement performance enhancer

PendingCN113563006ASimple preparation processGuaranteed performanceSolid waste managementBreaking strengthPolymer science

The invention discloses a nano inorganic polymer permeable pavement performance enhancer. The nano enhancer comprises the following raw materials: nano silicon dioxide, a modifier, a surfactant, a dissolution promoter, a coupling agent, a foaming agent, a stabilizer and deionized water. The raw materials in parts by weight are as follows: 35-60 parts of nano-silica, 0.5-3 parts of the modifier, 0.3-2 parts of the surfactant, 0.5-2 parts of the dissolution promoter, 5-10 parts of the coupling agent, 0.2-1 part of the foaming agent, 0.1-0.5 part of the stabilizer and 30-60 parts of the deionized water. The nano inorganic polymer permeable pavement performance enhancer provided by the invention mainly has the characteristics of convenience in popularization, high compression resistance and breaking strength, large self-contraction strain, air permeability, water permeability and light weight, and is good in use effect, high in wear resistance and high in practicability.

Owner:禹智环保科技(深圳)有限公司

Cobalt-based plasma powder surfacing material, preparation method and application thereof

ActiveCN112831706BHigh strengthImprove wear resistanceMetallic material coating processesPlasma welding apparatusHigh wear resistanceCemented carbide

The invention relates to a cobalt-based plasma powder surfacing material, a preparation method and application thereof. The cobalt-based plasma powder surfacing material uses sintered WC-Co hard alloy particles of 60-100 meshes as a wear-resistant phase, and has a particle size of 100-100 mesh. The 325 mesh cobalt-based alloy powder is a binder phase, wherein the weight percentage of the wear-resistant phase is 20-60%, and the weight percentage of the binder phase is 40-80%. The cobalt-based plasma powder surfacing material provided by the present invention has a perfect combination of wear resistance and impact resistance, and is especially suitable for surface strengthening of sealed bearings with particularly high wear resistance requirements, and can also be used in open environments with particularly high loads. Abrasion resistance.

Owner:KINGDREAM PLC CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com