Ceramic catalysis filter pipe

A technology of filter tubes and ceramics, which is applied in the field of ceramic catalytic filter tubes, can solve the problems of complex structure, large footprint, and low dust removal efficiency, and achieve the effects of good filtering effect, wide denitrification temperature range, and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

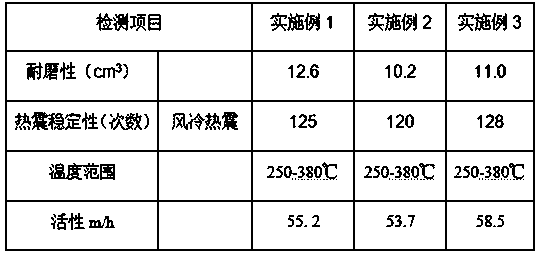

Examples

Embodiment 1

[0024] 1) Mud mixing: Put attapulgite in 7mol / L HCl solution, stir at 80°C for 8 hours, wash and dry, and grind to 400 mesh. Dry mix 22 parts of modified attapulgite, 28 parts of anatase titanium dioxide, 2 parts of γ-alumina, 4 parts of silicon dioxide, and 1 part of tungsten trioxide, add 2 parts of cerium nitrate, metavanadic acid 2 parts of ammonium, 3 parts of manganese nitrate solution with a volume ratio of 50%, and deionized water to prepare a slurry. Add the prepared ammonium metavanadate solution and cerium nitrate solution to the above slurry and stir evenly. The evaporator evaporates under reduced pressure to remove water. Calcinate the completely dried material at a high temperature of 500°C to activate the activity, grind it to 400 mesh, and obtain a catalyst powder; mix 50 parts of catalyst powder, 2 parts of calcium oxide, 2 parts of magnesium oxide, and 0.2 parts of polycarboxylate superplasticizer , 3 parts of carboxymethyl cellulose, 2 parts of stearic acid...

Embodiment 2

[0030] 1) Mud mixing: Put attapulgite in 6mol / L HCl solution, stir at 80°C for 8 hours, wash and dry, and grind to 400 mesh. Dry mix 30 parts of modified attapulgite, 30 parts of anatase titanium dioxide, 3 parts of γ-alumina, 5 parts of silicon dioxide, and 1.5 parts of tungsten trioxide, add 3 parts of cerium nitrate, metavanadic acid 3 parts of ammonium, 6 parts of manganese nitrate solution with a volume ratio of 50%, and deionized water to prepare a slurry. Add the prepared ammonium metavanadate solution and cerium nitrate solution to the above slurry and stir evenly. The evaporator evaporates under reduced pressure to remove water. Calcinate the completely dried material at a high temperature of 500°C to activate the activity, grind it to 400 mesh, and obtain a catalyst powder; mix 80 parts of catalyst powder, 3 parts of calcium oxide, 3 parts of magnesium oxide, and 0.3 parts of polycarboxylate superplasticizer , 7 parts of carboxymethyl cellulose, 3 parts of stearic a...

Embodiment 3

[0036] 1) Mud mixing: Put attapulgite in 6mol / L HCl solution, stir at 80°C for 8 hours, wash and dry, and grind to 400 mesh. Dry mix 25 parts of modified attapulgite, 25 parts of anatase titanium dioxide, 2 parts of γ-alumina, 4 parts of silicon dioxide, and 1.5 parts of tungsten trioxide, add 2 parts of cerium nitrate, metavanadic acid 3 parts of ammonium, 5 parts of manganese nitrate solution with a volume ratio of 50%, and deionized water to prepare a slurry. Add the prepared ammonium metavanadate solution and cerium nitrate solution to the above slurry and stir evenly. The evaporator evaporates under reduced pressure to remove water. Calcinate the completely dried material at a high temperature of 500°C to activate the activity, grind it to 400 mesh, and obtain a catalyst powder; mix 65 parts of catalyst powder, 3 parts of calcium oxide, 2 parts of magnesium oxide, and 0.2 parts of polycarboxylate superplasticizer , 5 parts of carboxymethyl cellulose, 2 parts of stearic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com