Multilayer improved thermal shrinkage preservative film/bag and base material composition thereof

A technology of fresh-keeping film and composition, which is applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of poor acid resistance, difficult granulation and recycling of waste packaging materials, poor dimensional stability, etc., and achieve reduction Or put an end to environmental pollution, improve comprehensive utilization efficiency, and good flexibility and extensibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Prepare each layer of raw materials first;

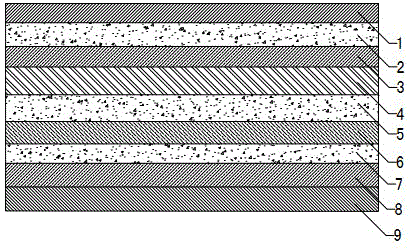

[0038] Surface layer 1: 38kg of ethylene glycol modified polyethylene terephthalate copolymer with a density of 1.30g / cm3; 5kg of maleic anhydride grafted polymer with a density of 0.87g / cm3; 5kg of 1, 2-di(isononyl)cyclohexanedicarboxylate with a density of 0.954g / cm3; 1kg of antioxidant masterbatch and 1kg of SiO 2 Anti-blocking masterbatch;

[0039] The first adhesive layer 2: 50kg of maleic anhydride-modified polyolefin polymer, with a density of 0.87 g / cm3 and a melt index of 2.5g / 10min at 190°C / 2.16kg;

[0040] The first polyolefin layer 3: 15kg of anhydride-modified polyolefin resin with a density of 0.89g / cm3 and a melt index of 4g / 10min at 190°C / 2.16kg; 35kg of ethylene / acrylic acid copolymer resin with a density of 0.94g / cm3, the melt index is 2g / 10min at 190℃ / 2.16kg;

[0041] Resin-based functional layer 4: 40kg of ethylene glycol-modified polyethylene terephthalate copolymer with a density of 1.30g / cm3; 5kg of...

Embodiment 2

[0050] Prepare each layer of raw materials first

[0051] Surface layer 1: the arbitrary ratio mixture of two kinds of ethylene glycol modified polyethylene terephthalate copolymers of 35kg, density is 1.237g / cm3, the maleic anhydride graft polymer of 12kg, density is 0.893g / cm cm3; 1kg of high-purity silicon-based anti-blocking masterbatch; 3kg of flexibility modifier with a density of 0.96 g / cm3;

[0052] The first adhesive layer 2: 50kg of maleic anhydride graft modified polyolefin copolymer, the density is 0.96 g / cm3, and the melt index is 1.2g / 10min under the condition of 190 ℃ / 2.16kg;

[0053] The first polyolefin layer 3: 15kg of ethylene / acrylic acid copolymer resin with a density of 0.878g / cm3 and a melt index of 4.5g / 10min at 190°C / 2.16kg; 35kg of anhydride-modified polyolefin resin with a density of 0.893g / cm3, melt index at 190℃ / 2.16kg;

[0054] Resin-based functional layer 4: 40kg of ethylene glycol-modified polyethylene terephthalate copolymer with a density o...

Embodiment 3

[0061] Prepare each layer of raw materials first;

[0062] Surface layer 1: 38kg of olefin copolymer with a density of 0.904g / cm3, 5kg of metallocene ethylene-propylene copolymer with a density of 0.863g / cm3; 5kg of 1,2-cyclohexanedicarboxylic acid bis(isononyl ) ester softener with a density of 0.966 g / cm3; 1kg containing 10% high-purity silicon-based anti-blocking masterbatch, 1kg containing 5% antioxidant masterbatch;

[0063] The first adhesive layer 2, the second adhesive layer 5, the third adhesive layer 7: 35 kg of maleic anhydride graft-modified polyolefin copolymer, the density is 0.88 g / cm3, and the melt index is at 190 ℃ / 0.95g / 10min under the condition of 2.16kg; 15 kg of anhydride-modified ethylene / acrylate copolymer resin, the density is 0.946g / cm3, and the melt index is 2.0g / 10min ~8g / under the condition of 190℃ / 2.16kg 10min;

[0064] Anti-puncture layer: 45kg of ethylene glycol modified polyethylene terephthalate copolymer with a density of 1.27g / cm3; 5kg of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com