Automobile stamping die insert and laser strengthening manufacturing method thereof

A technology for stamping dies and manufacturing methods, which is applied in the field of automobile stamping die inserts and its laser-intensified manufacturing, which can solve the problems of limited service life of die inserts, deformation of die inserts, and high manufacturing costs, so as to improve service life and increase strength , high wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

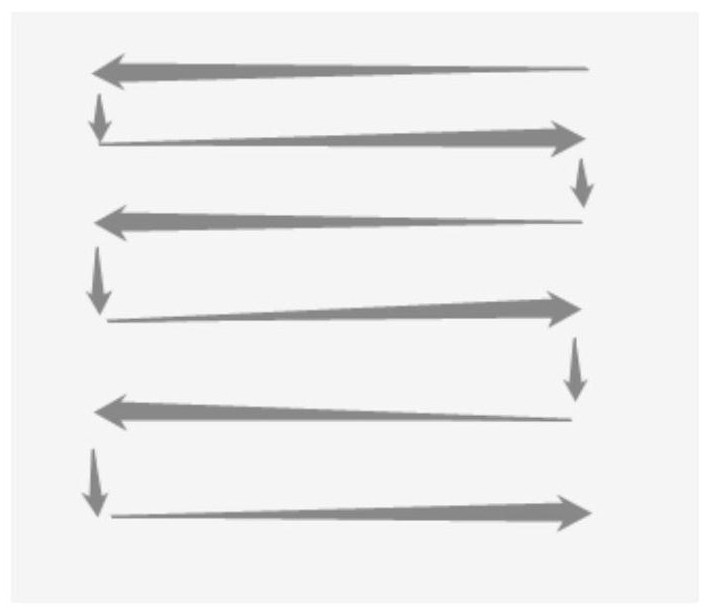

Image

Examples

Embodiment 1

[0028] A laser strengthening manufacturing method for an automobile stamping die insert, comprising the following steps:

[0029] 1) Use ordinary 45# forged steel as the base material of the insert, machine the mold insert of the final working size on the base material, and process the working surface of the mold insert to 1mm below the final working size, that is, remove the mold by machining The surface layer with a thickness of 1mm on the surface of the insert is then tempered and tempered at 550°C;

[0030] 2) Prepare high-strength, wear-resistant alloy powder, the alloy powder is composed of the following components by weight percentage: C: 0.16%; Si: 0.01%; Cr: 18%; Ni: 0.27%; Mo: 0.3% ; Mn: 0.1%; Co: 0.02%; V: 0.03%; B: 0.18%, and the rest is Fe; wherein, the alloy powder is spherical particles with a particle size of 50-150 μm, and the alloy powder is dried in a vacuum oven at 80 ° C After keeping warm for 6 hours, add it to the powder feeding bucket to prepare for la...

Embodiment 2

[0036] A laser strengthening manufacturing method for an automobile stamping die insert, comprising the following steps:

[0037] Process the working surface of the waste mold insert (that is, the invalid mold insert) to 1mm below the final working size, that is, remove the surface layer with a thickness of 1mm on the surface of the waste mold insert by mechanical processing, and then return to the surface at 600°C. Fire quenching and tempering treatment, the hardness after quenching and tempering is 22-34HRC, and the comprehensive mechanical properties are improved at the same time;

[0038] Prepare high-strength, wear-resistant alloy powder, which is composed of the following components by weight percentage: C: 0.16%; Si: 0.01%; Cr: 18%; Ni: 0.27%; Mo: 0.3%; Mn : 0.1%; Co: 0.02%; V: 0.03%; B: 0.18%, and the rest is Fe; among them, the alloy powder is spherical particles with a particle size of 50-150 μm, and the alloy powder is kept in a vacuum oven at 80°C After 6 hours, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com