Compact bearing high-pressure jet grouting drill bit

A technology of high-pressure rotary spraying and composite sheet, which is applied in the direction of drill bits, drilling with liquid/gas jets, drill pipes, etc. It can solve the problems of inconvenient removal of drill bits and slow drilling speed, etc., so as to improve the cutting rate and effect, improve the effect, Simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

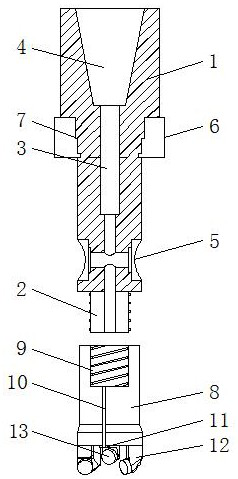

[0024] combine Figure 1-4 , The present invention is a high-pressure jet jet drill bit with a composite sheet bearing, including a drill pipe body 1 and a drill bit body 8 . The drill pipe body 1 is in the shape of a shaft. The bottom of the drill pipe body 1 is fixed with a connecting block 2, and the drill pipe body 1 and the connecting block 2 are integrally cast. The stability between the drill pipe body 1 and the connection block 2 is strengthened. A rotary jet water delivery channel 3 is opened at the center of the inside of the drill pipe body 1 , and the bottom end of the rotary jet water delivery channel 3 runs through the connecting block 2 . The top end of the drill pipe body 1 is provided with a conical interface 4, and the bottom of the conical interface 4 communicates with the rotary jet water delivery channel 3. The bottom of the outer side of the drill pipe body 1 is symmetrically provided with side nozzles 5 , and the side nozzles 5 communicate with the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com