Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Have no cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified magnesium oxy-sulfur cement

InactiveCN102924038AImprove mechanical propertiesImprove water resistanceAqueous solutionMaterials science

The invention relates to modified magnesium oxy-sulfur cement. The cement consists of the following raw materials in parts by weight: 100 parts of magnesium oxide, 0.05-10 parts of additive, 50-200 parts of 10%-30% magnesium sulfate aqueous solution and 0-300 parts of filler. The modified magnesium oxy-sulfur cement has excellent mechanical property and water resistance, is temperature-resistant, does not crack, can be used for substituting for a magnesium oxy-chloride cement and can be used for producing materials of mortar, concrete, slabs, crafts and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

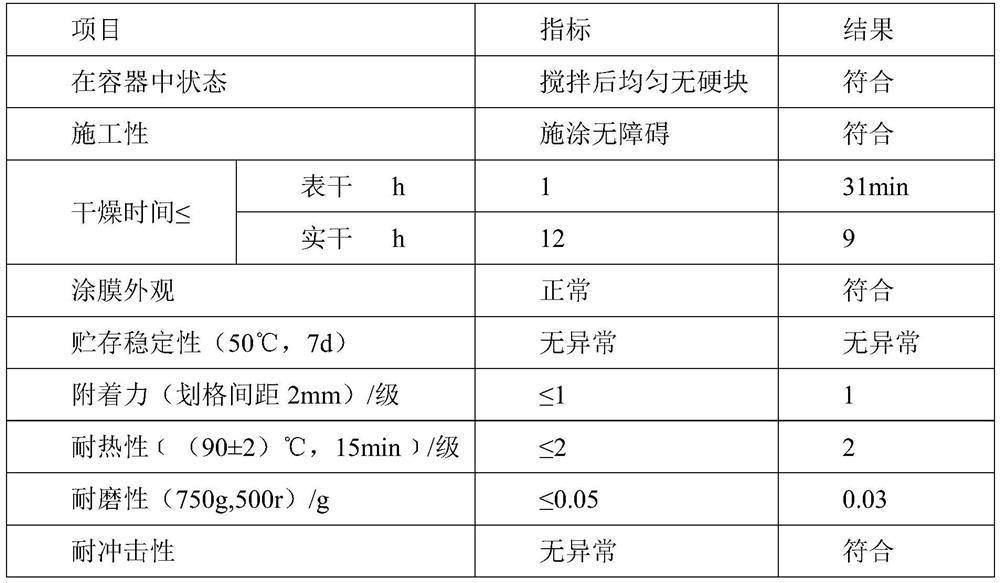

Acid-and-alkali-resistant environment-friendly ink for automotive windscreen and preparing method thereof

The invention relates to the technical field of ink, in particular to an acid-and-alkali-resistant environment-friendly ink for an automotive windscreen.The acid-and-alkali-resistant environment-friendly ink is characterized by being prepared from, by mass, 50%-70% of lead-and-cadmium-free composite glass powder, 8%-20% of inorganic pigment, 20%-40% of varnish, 0.6%-1% of dispersing agent, 0.6%-1% of flatting agent and 0.3%-0.6% of thixotropic agent.The acid-and-alkali-resistant environment-friendly ink for the automotive windscreen is efficient and environmentally friendly, has excellent acid and alkali resistance and suitable sintering temperature, is good in water resistance, high in adhesive force and good in ultraviolet resistance, and has the quite low light transmissivity, and foreign-automobile-windscreen ink products can be replaced with the ink.

Owner:湖南衡义材料科技有限公司

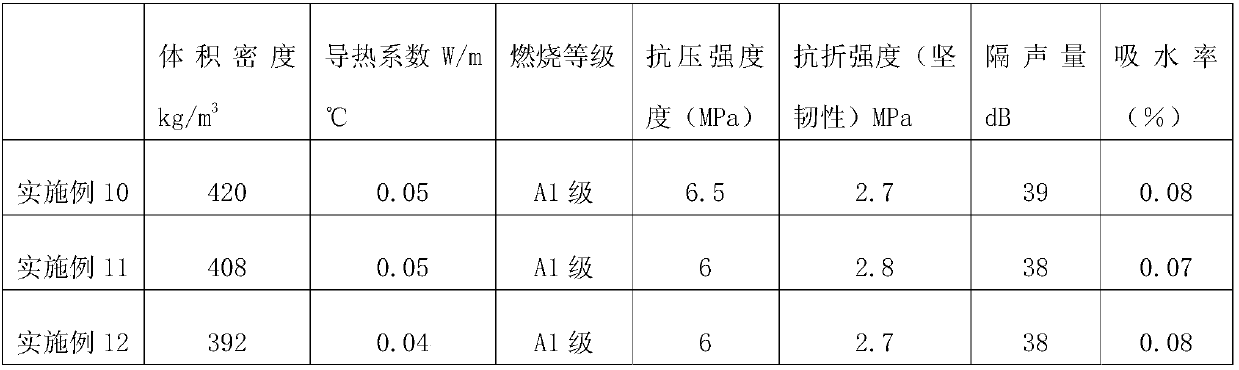

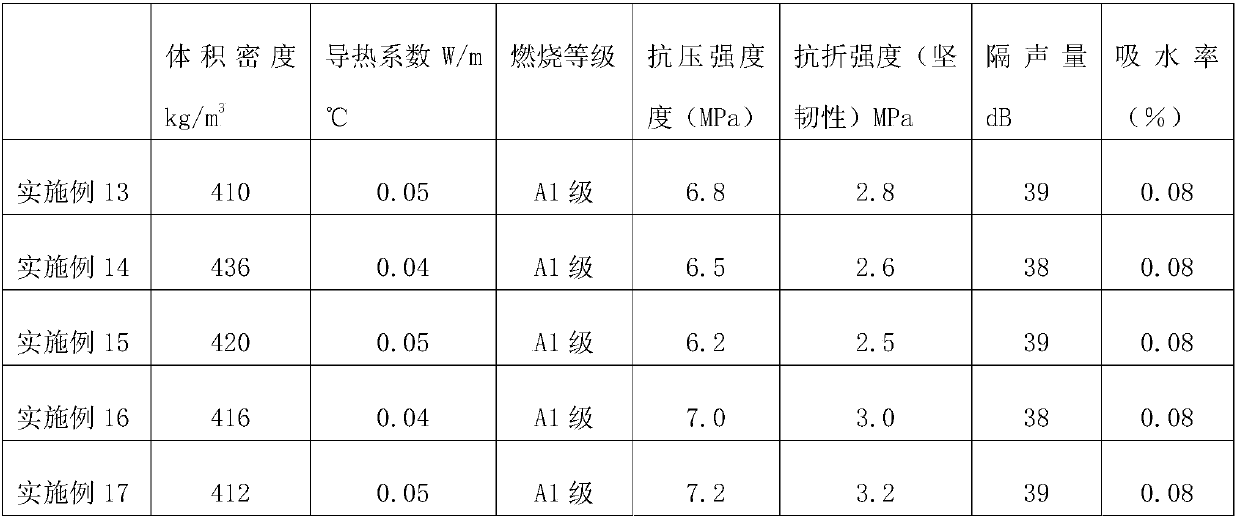

Foaming ceramic heat-insulating wallboard based on graphene and preparation method thereof

InactiveCN107602106AImprove fire insulation and weather resistanceImprove fire performanceCeramicwarePore distributionEnvironmental resistance

The invention provides a graphene-based foamed ceramic insulation wallboard, which is made of the following components: potassium sodium feldspar, ceramic waste residue, graphene, vermiculite, high-temperature co-solvent, expanded graphite, zirconia, clay, stable agent and debonding agent. Using potassium sodium feldspar and ceramic waste slag as the base material, adding graphene and vermiculite to make the board more lightweight, high-strength, thermal insulation, and improve the performance of the board such as fire resistance, insulation and weather resistance, using expanded graphite as a foaming agent, using high temperature The foaming process can better control the density, pore distribution and pore size of the board, achieve better heat preservation and light weight effects, and make a board with remarkable anti-aging, corrosion resistance, heat insulation, sound insulation, waterproof and impervious, fireproof and fireproof. , lightweight, high-strength, non-cracking, green and environmental protection and other comprehensive performance in one foam lightweight wallboard.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

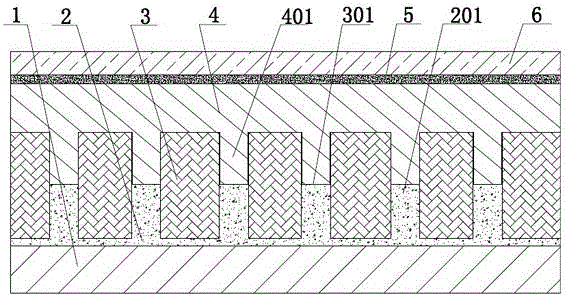

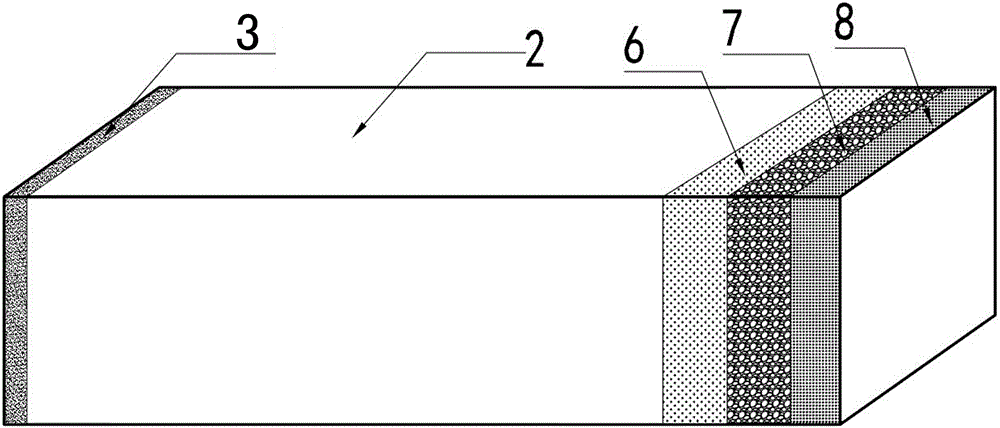

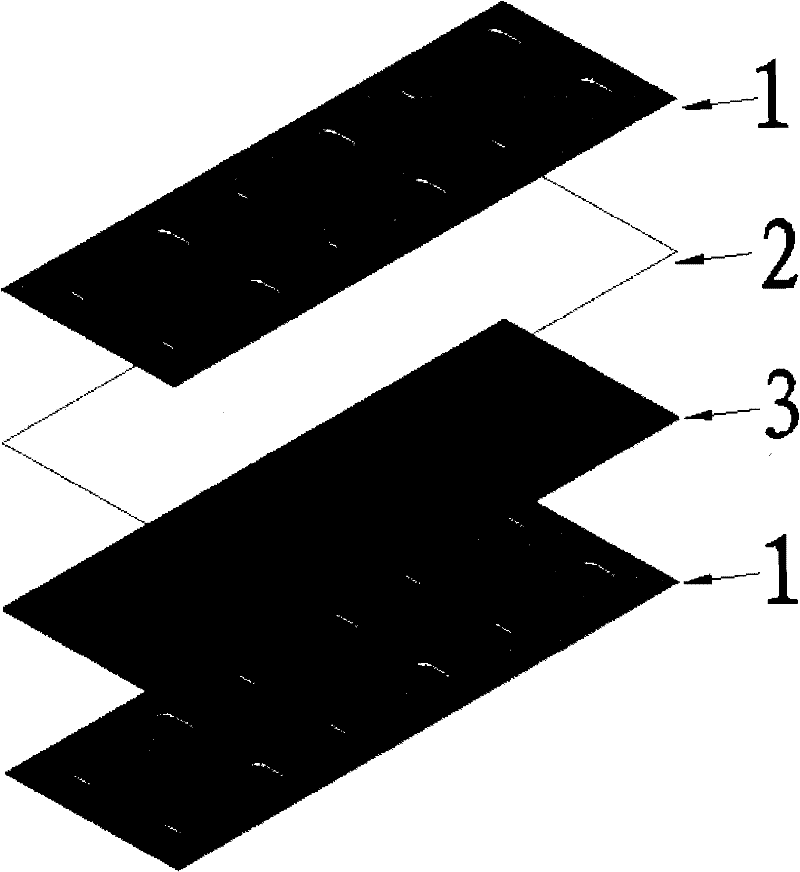

Novel granite facing thermal-insulation integrated plate and construction process thereof

ActiveCN104372908AHave no crackingImprove the decorative effectCovering/liningsLaminationThermal insulationArchitectural engineering

The invention discloses a novel granite facing thermal-insulation integrated plate and a construction process thereof, and belongs to the technical field of construction. The granite facing thermal-insulation integrated plate comprises a baseplate, a polyurethane thermal-insulation plate and the like, wherein the baseplate is connected with the polyurethane insulation plate through an adhesive layer; a cover plate is connected with the polyurethane thermal-insulation plate through inserting a cover plate convex column in a through hole; and an ultrathin granite facing plate is connected with the cover plate through a stone mighty bonding layer. An outer wall decorative material adopts the novel ultrathin granite facing thermal-insulation integrated plate; the plate gap structure and the construction process are precisely adjusted and controlled in a bonding-anchoring combined manner; and the novel granite facing thermal-insulation integrated plate mainly solves the problems of poor appearance quality, poor durability and poor heat-preserving and heat-insulating effects in a traditional outer wall decorative material, greatly improves the construction quality, is short in construction period, is obvious in economic benefit, is specifically suitable for the outer wall outer thermal-insulation decorative construction of various new residential buildings and public buildings, and can satisfy the high-standard requirements of durability of outer walls of the buildings and energy conservation and emission reduction in the use process.

Owner:ZHEJIANG WANDA CONSTR GROUP

Environment-friendly high-strength mildew-proof putty powder

The invention provides environment-friendly high-strength mildew-proof putty powder comprising the following components in percentage by weight: 70-99% of heavy calcium carbonate, 0-30% of ash calcium, 0.5-10% of starch sodium octenylsuccinate, 0.2-5% of hydroxypropyl methylcellulose and 0.5-10% of modified starch, wherein the sum of the weight percentages of all the components is 100%. The putty powder is high in binding strength, greatly improved in mildew resistance and convenient in construction, and has the advantages of no powder falling, no scales, no cracks and no mildews.

Owner:深圳摩盾环保新材料有限公司

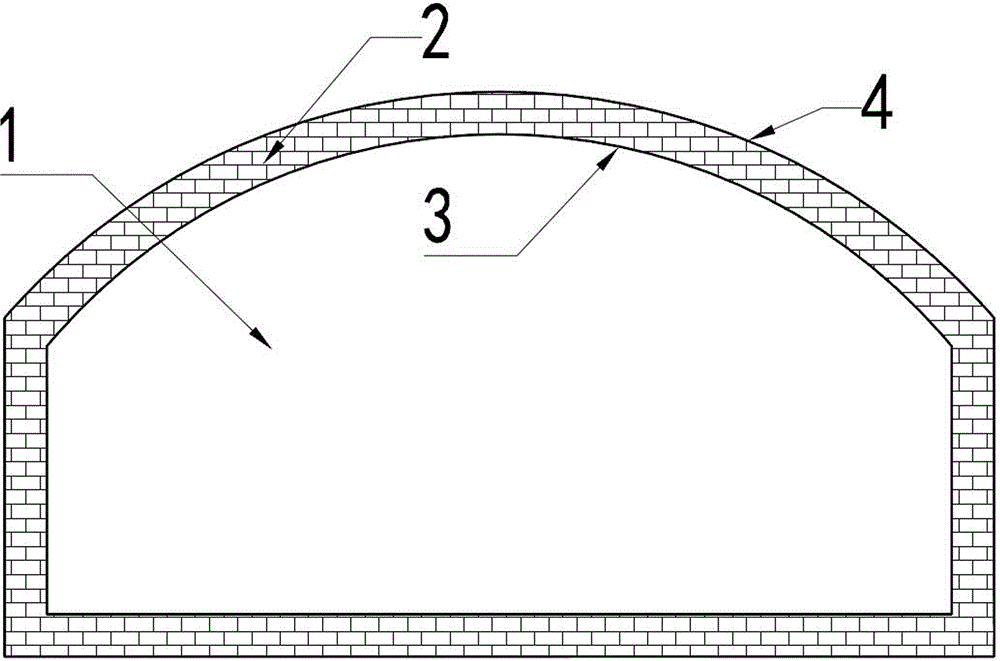

Energy-saving industrial furnace

The invention discloses an energy-saving industrial furnace. The energy-saving industrial furnace comprises a furnace base body, and the furnace base body is made of heatproof fibers, firebricks or a micro-nano material; the outer wall of the furnace base body is coated with a combined heat insulation coating layer, and the inner wall of the furnace base body is coated with an infrared radiation energy-saving coating layer; and the combined heat insulation coating layer comprises an inner heat insulation coating layer, a medium heat insulation coating layer and an outer heat insulation coating layer which are sequentially coated from inside to outside. A reinforced radiation heat transfer combined thermodynamic heat insulation energy-saving technology, which combines the infrared high-radiation technology of the high temperature-resistant infrared-energy saving coating layer with the high-efficiency heat insulation technology of the combined heat insulation coating layer, is applied, so the industrial furnace disclosed in the invention has the characteristics of effective improvement of the heat utilization efficiency, good energy saving effect, long service time, prolonged service life, and generation of the environmental protection effect.

Owner:SHENZHEN TRIUMPH TECH ENG +1

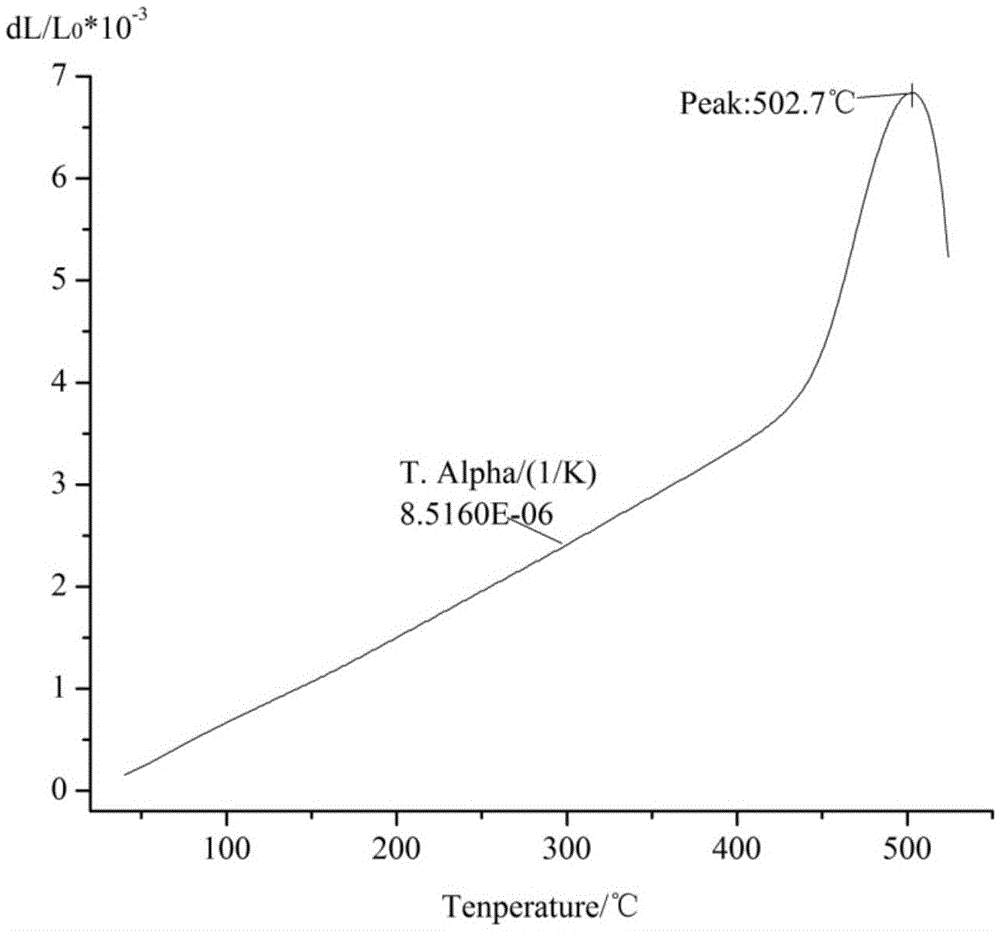

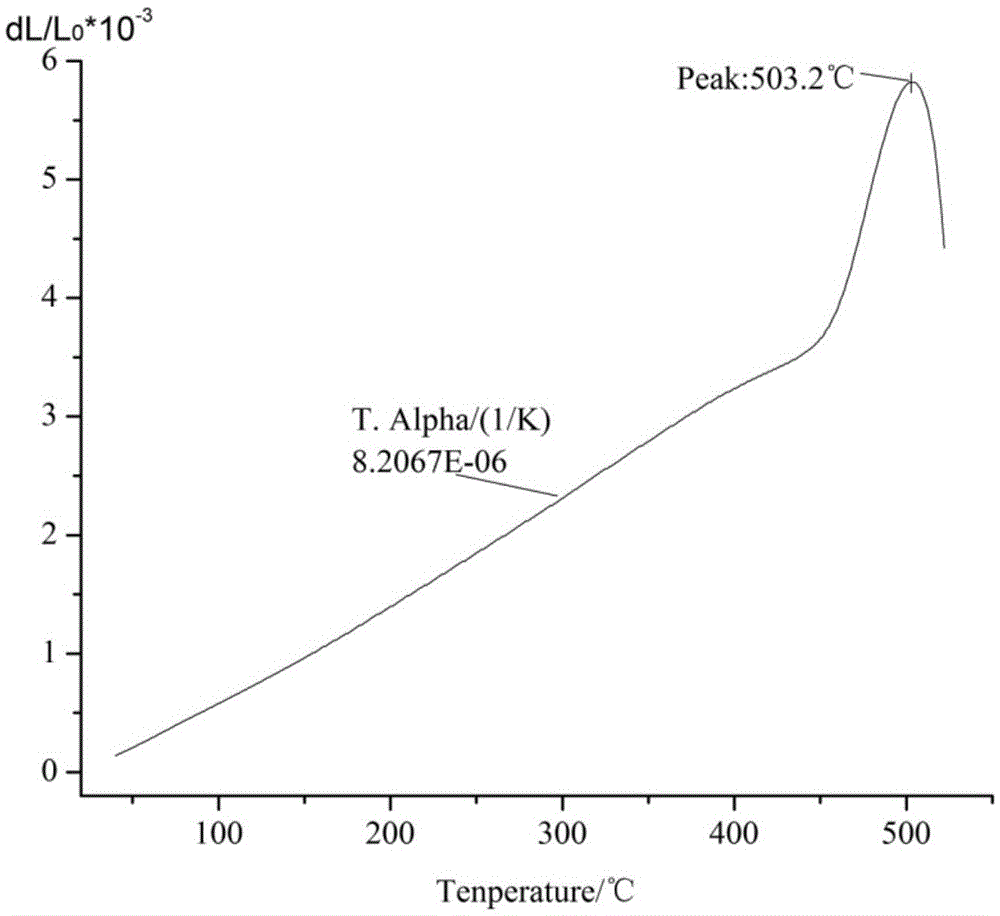

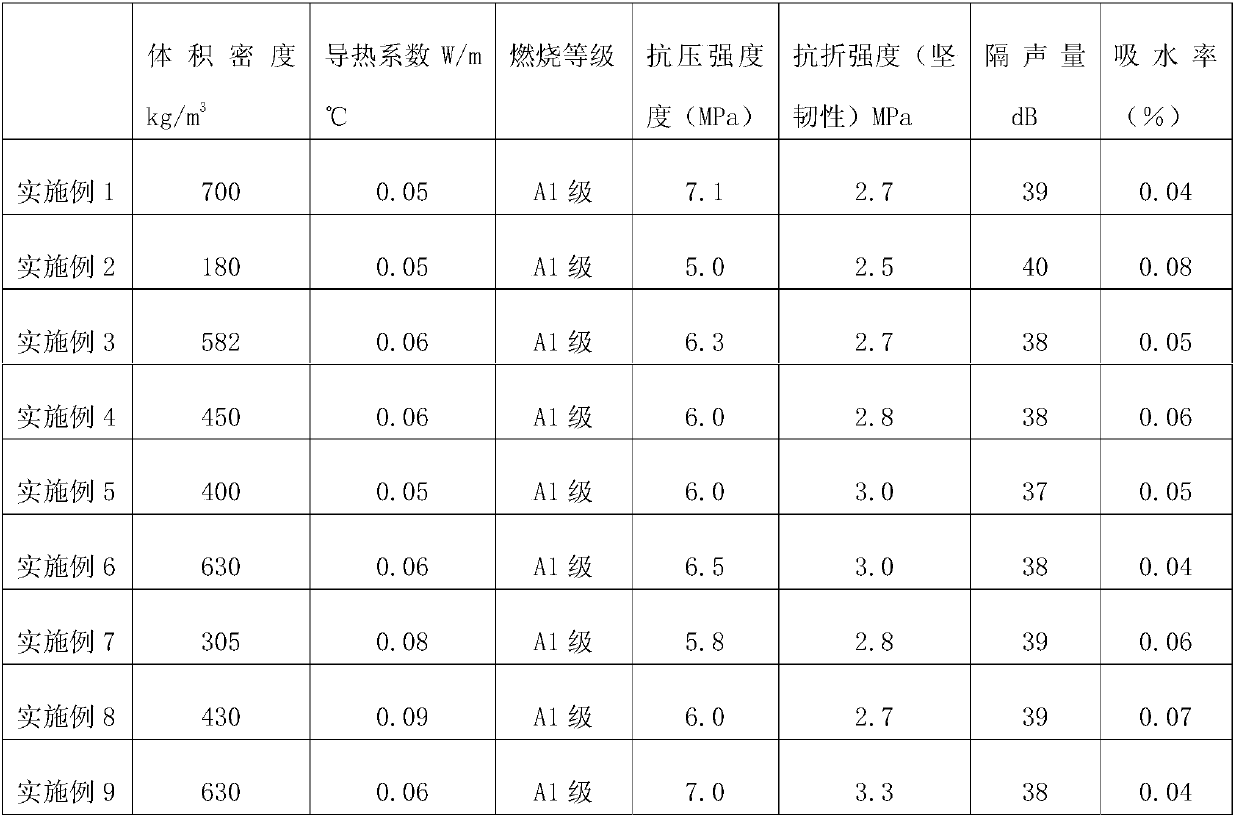

Thick film circuit medium temperature sintered silver electrode slurry for aluminium alloy substrate and preparation method thereof

InactiveCN107068238AAvoid harmSolve urgent problems in the manufacturing industryNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver electrodeOrganic solvent

The invention discloses a thick film circuit medium temperature sintered silver electrode slurry for an aluminium alloy substrate and a preparation method thereof. The electrode slurry comprises an inorganic bonding phase, spherical silver powders, flake silver powders and an organic carrier. The inorganic bonding phase is formed by seven materials which comprise Bi2O3, B2O3, CaO, ZnO, K2O, a nucleating agent and a rare earth oxide. The organic carrier is formed by five materials which comprise an organic solvent, a polymer thickening agent, a dispersing agent, a deforming agent and a thixotropic agent. The preparation method of the electrode slurry comprises the steps of (a) inorganic adhesive phase preparation, (b) organic carrier preparation and (c) electrode slurry preparation. The electrode slurry has good thixotropy and fluidity and low sintering temperature, a sintered electrode has the advantages of a smooth structure, compactness, no crack, no pinhole, no bubble, lead-free and environment-friendliness, and at the same time the sintered electrode has the advantages of strong adhesion, aging resistance, low resistance and excellent printing characteristic and sintering characteristic.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Exterior wall external thermal insulation bonding mortar

ActiveCN104086143AMeet insulation requirementsHigh bonding strengthThermal insulationPhosphoric acid

The invention discloses exterior wall external thermal insulation bonding mortar which is composed of the raw materials of, by weight, 20-30 parts of sulphoaluminate cement, 40-60 parts of quartz sand, 15-25 parts of yellow loam, 12-16 parts of soapstone powder, 2-3 parts of organosilicone powder, 3-5 parts of calcium phosphate, 16-22 parts of granular glass wool, 8-12 parts of rice bran powder, 2-3 parts of magnesium chloride, 0.5-1 part of hydroxyethyl cellulose, 1.5-2.5 parts of urea-formaldehyde resin gum powder, 0.5-1 part of sodium carboxymethyl starch, 1-2 parts of guar gum powder, and 3-6 parts of a composite filling material. The exterior wall external thermal insulation bonding mortar provided by the invention has the characteristics of high bonding strength, good thermal insulation performance, good cracking resistance, low water absorption rate, good water resistance, good weatherability, and the like. With the mortar, an obtained building exterior wall thermal insulation system can resist cracking, hollowing and chalking. The building exterior wall thermal insulation system also has the advantages of high adhesion strength with a wall body, good construction performance, good waterproofing effect, good mildew-resisting effect, and the like. With the exterior wall external thermal insulation bonding mortar, building exterior wall external thermal insulation requirements can be satisfied.

Owner:南通达海澄筑建筑科技有限公司

Manufacturing method of large ink

The invention relates to a manufacturing method of large ink. The manufacturing method mainly comprises the steps of making a pattern, refining smoke, mixing glue, pestling, making ink and molding, sizing and drying the ink, wherein the step of mixing glue means that a smoke material and a sizing material are stirred for 6-8 minutes by using a blender, the step of making ink and molding means that a molded ink blank is put on a mass fire plate, two to four 300W-electric furnaces are arranged under the mass fire plate for heating the mass fire plate to reach 70 DEG C to 90 DEG C, the step of sizing means that compression molding is carried out on the ink blank by using a four-bar ink pressing machine for 0.5-3 hours, and the step of drying ink means that the ink is dried for 6-12 months in a natural indirect ventilation condition. The ink manufactured by the method is larger in appearance, different in shape and convenient to enjoy and store; and the additional value of the product is improved.

Owner:HUANGSHAN SHEXIAN JUMOTANG INK IND

An addition of blast furnace slag building inside and outside the wall thermal insulation putty

The invention discloses a method for preparing the inner and outer wall insulation putty of blast furnace slag, which is prepared by the following raw materials: cement, hollow glass beads, tetraethyl orthosilicate, anhydrous ethanol, 1mol / L hydrochloric acid, template agent F127, emulgator OP 10 portions, sodium bicarbonate, silica sol, ammonium persulfate, light sand, titanium dioxide, blast furnace slag, brucite fiber, gypsum, polyethylene glycol fatty acid ester, tourmaline powder, polystyrene prepolymer, sodium alginate, azodiisobutyronitrile and a proper amount of deionized water. The putty powder of this invention has the advantages of low cost, good adhesive property, good abrasion resistance, good washing resistance, and also has anti-cracking, no corrosion, no cracking, environmentally friendly, tasteless, no harm to the human body and so on.

Owner:高绍彬

Novel high-performance composite material for cable and preparation method

InactiveCN106633524AReduce pollutionHigh strengthPlastic/resin/waxes insulatorsFiberDecabromodiphenyl ether

The invention discloses a novel high-performance composite material for a cable and a preparation method thereof. The novel high-performance composite material is prepared from the following raw materials in parts by weight: 50 to 60 parts of polyvinyl chloride resin, 20 to 30 parts of acrylonitrile-butadiene-styrene resin, 8 to 12 parts of polycarbonate, 5 to 7 parts of trioctyl trimellitate, 4 to 6 parts of decabromodiphenyl ether, 5 to 7 parts of epoxidized soybean oil, 10 to 12 parts of anilmomethyl triethoxy silane, 5 to 10 parts of bacterial cellulose, 3 to 5 parts of nano calcium carbonate, 4 to 6 parts of mercaptoethanol, 1 to 3 parts of pineapple fibrilia, 5 to 7 parts of flint clay powder and 5 to 10 parts of compound additive. The novel high-performance composite material for the cable, disclosed by the invention, has the comprehensive characteristics of fire resistance, low-high temperature resistance, acid-alkaline corrosion resistance, impact resistance, wear resistance, oil resistance, water resistance and no cracking, each mechanical index meets the requirement of a cable material, and degradation is easy.

Owner:ANHUI TIANYUAN CABLE

Waterproof sizing agent for buildings

The invention discloses a waterproof sizing agent for buildings. The waterproof sizing agent comprises a waterproof emulsion and waterproof powder. The waterproof powder comprises mountain flour, sand, cement, a water reducing agent, a defoaming agent, an anti-crack agent, a reinforced adhesive, a dispersing agent and an assistant. The assistant comprises one or more of a gelatinizing agent, a water retaining agent, an anti-alkaline agent, a retarder and a mildew preventive. The waterproof emulsion refers to an alkali-resistant waterproof emulsion. The waterproof sizing agent for the buildings has the advantages that the mountain flour serves as a maim raw material of the waterproof sizing agent, so that the problem of mountain flour polluting the environment in the stone industry can be solved effectively, conventional building construction raw materials can be replaced, and pollution and damage to natural resources can be reduced; the stone industry is prevented from damaging and influencing surrounding environments, water sources, natural resources and human living; the obtained waterproof sizing agent has excellent performance such as easiness in painting, high adhesion force, high breathability, high toughness, and high resistance to corrosion, ageing, water, permeation, dampness and crack.

Owner:陈谓清

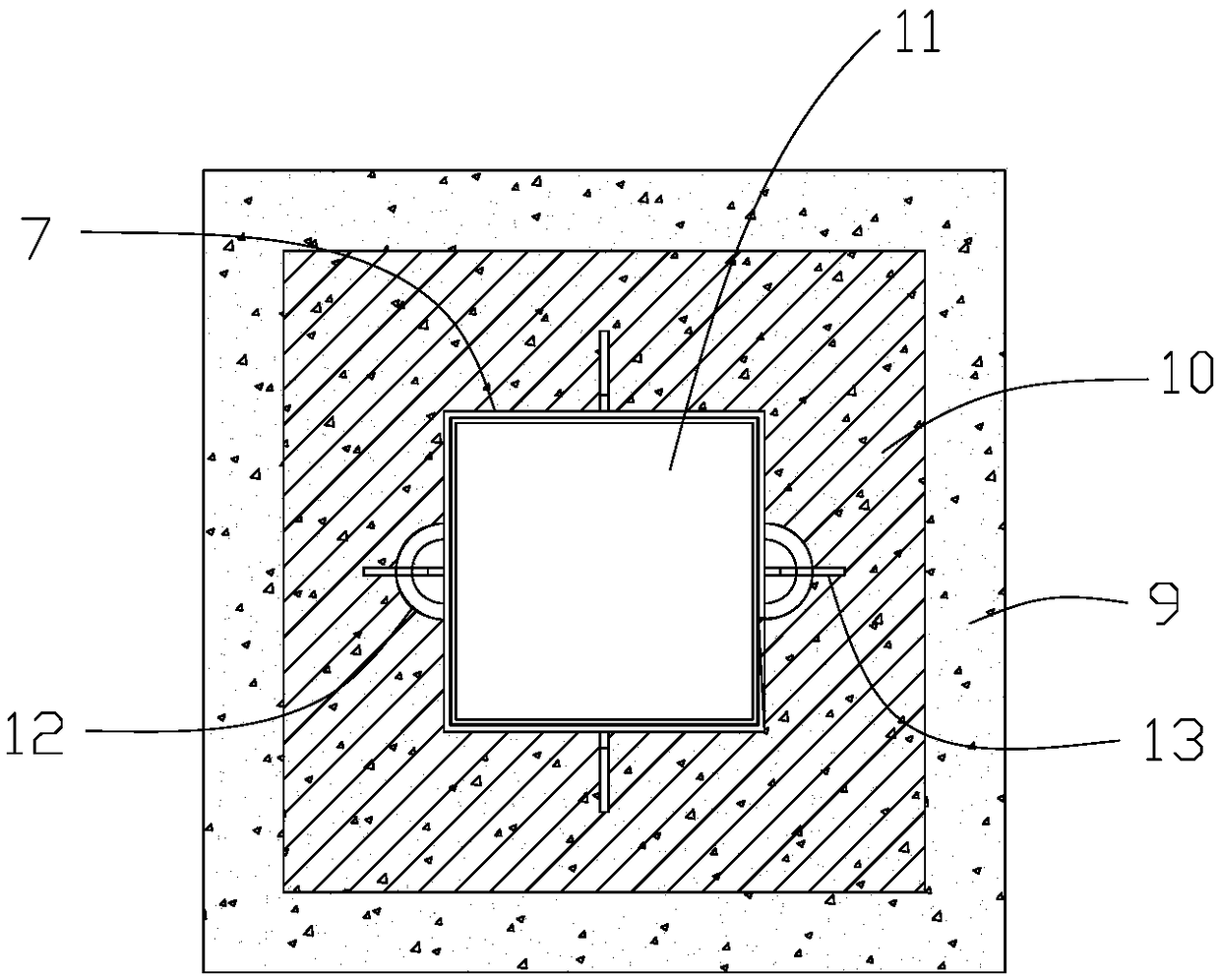

Novel fabricated building system and assembly method thereof

ActiveCN107761990AReduce construction costsEasy constructionWallsFoundation engineeringEarthquake resistanceCrack resistance

The invention provides a novel fabricated building system and further provides an assembly method of the novel fabricated building system. The novel fabricated building system comprises a prefabricated foundation, a structural supporting frame, at least one prefabricated floor and a plurality of wallboards. The structural supporting frame comprises prefabricated reinforcing columns and prefabricated beams, and the prefabricated reinforcing columns are connected with the prefabricated foundation. The prefabricated beams comprise main beams and inserting pieces, and the main beams are connectedwith the prefabricated reinforcing columns. The inserting pieces are connected with the main beams, the prefabricated floors and the main beams are connected through prefabricated connecting pieces and / or adhesives, and every two adjacent wallboards are mutually spliced or glued. The wallboards and the prefabricated reinforcing columns are connected through anchoring steel structures, inserting parts are arranged on the wallboards, and the inserting parts and the inserting pieces are connected in an inserted mode and fixed through adhesives. The wallboards are light wallboards based on graphene and nonmetal foaming and have the advantages of corrosion resistance, heat preservation, heat insulation, fire resistance, water resistance, impermeability, earthquake resistance, cracking resistance, low weight, high strength and the like. The assembled construction method adopted by the building system can shorten the construction period and is safe and efficient.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Double-layer steel net mineral cotton perlite sandwich composite lightweight wall plate

InactiveCN101191359ALight weightCondensation effect is strongBuilding componentsNon toxicitySandwich board

The present invention relates to a double-deck steel mesh mineral cotton perlite sandwich compound light wallboard; an upper cover coat and a lower cover coat are both double-deck steel meshes; a middle sandwich layer consists of a perlite lath, a mineral cotton lath and a perlite lath which are compounded; the compound middle sandwich layer is clamped and fixedly connected to form a grid sandwich board through the double-deck steel meshes of the upper cover coat and the lower cover coat. The invention has light volume weight, heat preservation, heat insulation, shock resistance, good sound absorption effect, non-toxicity and non-radioactivity, firmness, wear resistance, non-cracking and energy-saving and consumption-reducing performance, thereby the invention is an ideal fireproof and environment-friendly building material.

Owner:长沙市天心区广用珍珠岩建材厂

Mechanically sprayed dry-mixed plastering mortar

The invention discloses a mechanically sprayed dry-mixed plastering mortar, which is composed of the following components by weight: 12-22% of cement, 5-10% of fly ash, 40-50% of baked sand less than 5mm, 28-35% of mining powder, and 1-3% of mortar modifier. The mechanically sprayed dry-mixed plastering mortar is suitable for a mechanically sprayed interior-wall plastering engineering, and is different from the traditional plastering mortar due to the addition of the fly ash and the mining powder; when the mortar is used for a novel wall material and other substrates, the wall can be not soaked, an interface agent can be not coated in advance, the maintenance is unnecessary after completion, the wall surface processed with the mortar has the characteristics of no hollowing, no crack and water resistance, the mortar can be used for the interior and exterior walls, the construction is easy, and the construction speed is increased by 50% than that of the site mixed mortar.

Owner:JIAXING BOHONG NOVEL BUILDING MATERIALS

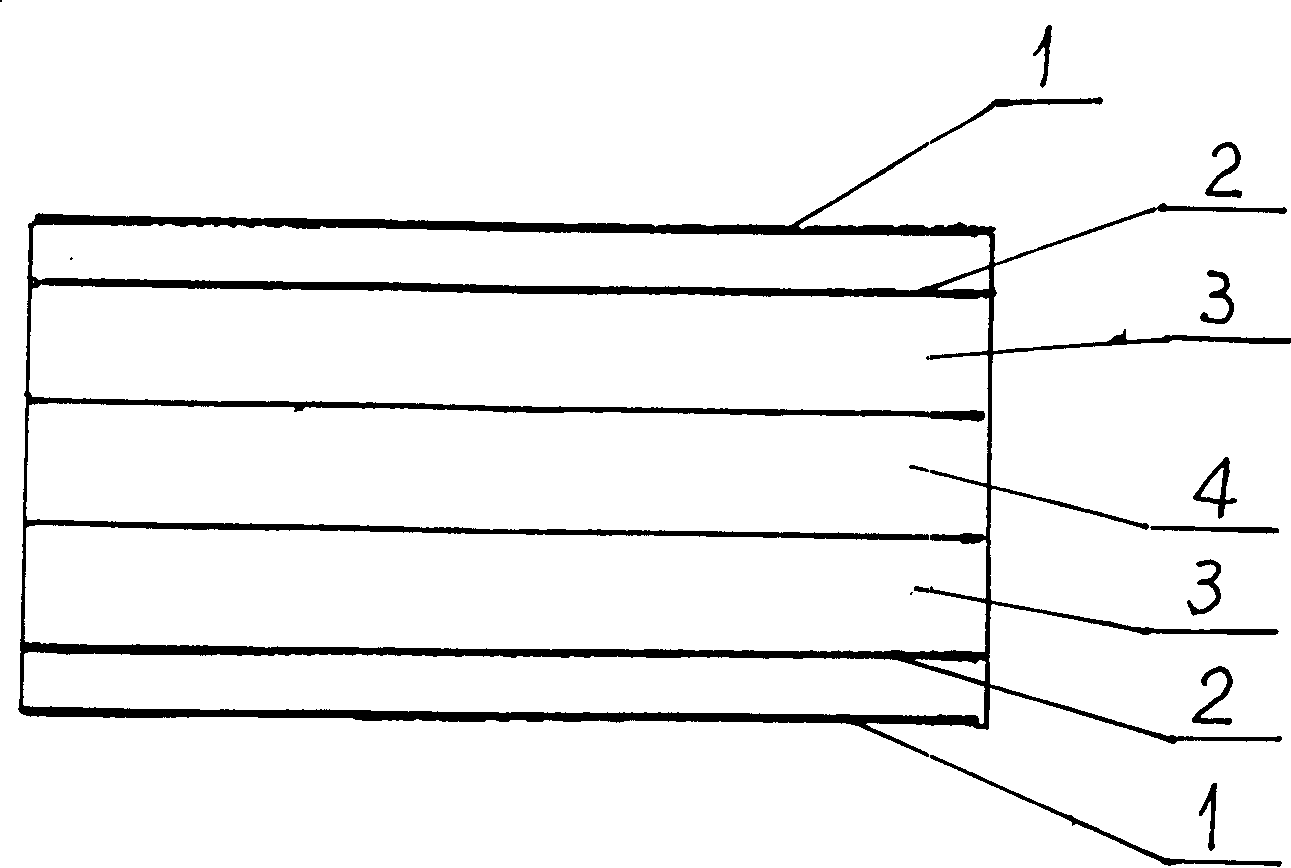

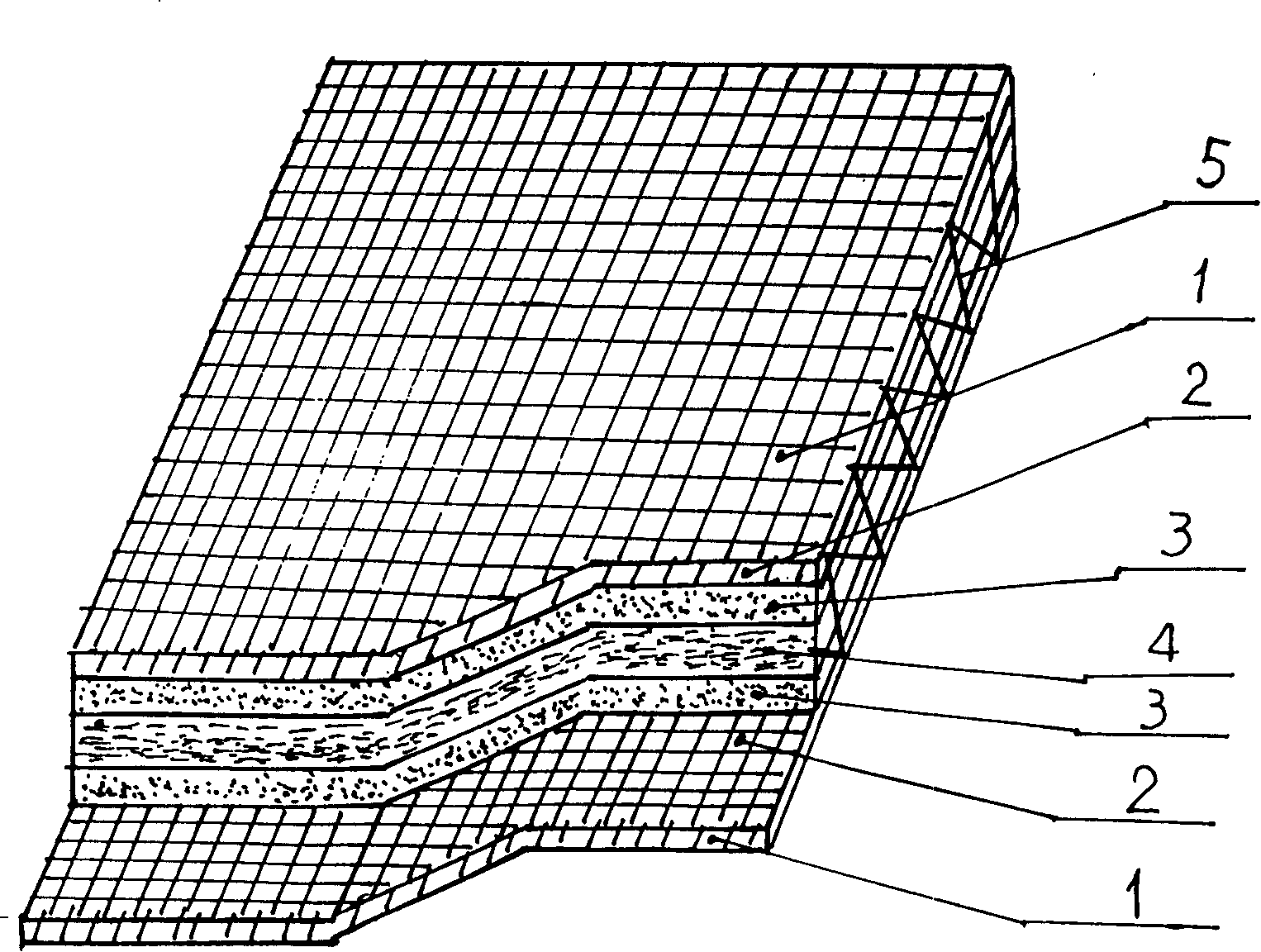

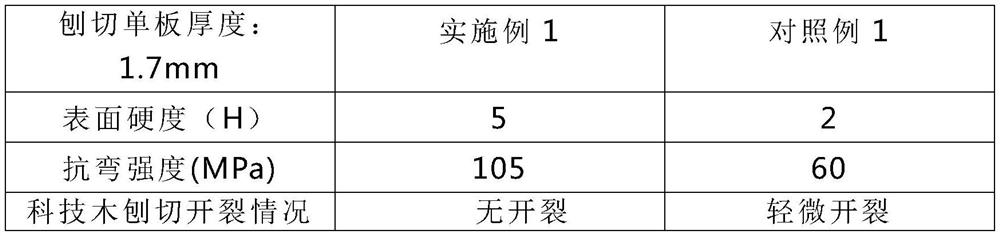

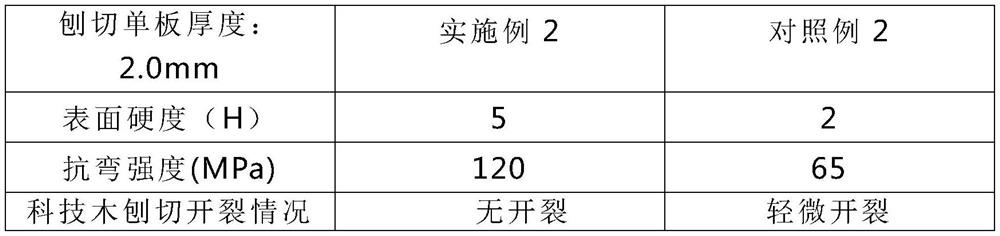

Technical wood material impregnation liquid, preparation method, treatment method and manufacturing process

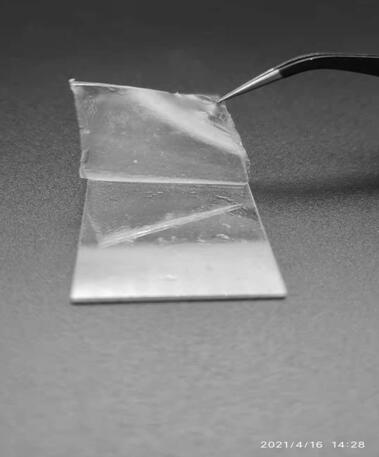

InactiveCN112123489AHigh densityHave no crackingOther plywood/veneer working apparatusRadiation/waves wood treatmentWood veneerPolymer science

The invention belongs to the technical field of technical wood veneer treatment, and particularly relates to technical wood material impregnation liquid, a preparation method, a treatment method and amanufacturing process. The problems that sliced veneers or veneers are prone to cracking and the like in the prior art are solved. The technical wood material impregnation liquid comprises the following material components: silicone acrylic emulsion, a light screening agent, an ultraviolet light absorber, a histamine free radical scavenger and an emulsifier, wherein the weight part ratio of the silicone acrylic emulsion to the light screening agent to the ultraviolet light absorber to the histamine free radical scavenger to the emulsifier is 100: (10-15): (1-5): (1-5): (1-3): (1-4). The technical wood material impregnation liquid has the advantages that the artificial fast-growing soft wood veneer is treated through cooperation of the impregnation liquid and ultrasonic vibration impregnation, so that the prepared sliced veneer or sliced veneer with the small thickness has the advantages of being large in density and free of cracking, fading and yellowing.

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

Coating for replacing electronic product screen protection film and preparation method

InactiveCN113122127AIncrease elasticityImprove rigidityPolyurea/polyurethane coatingsPolyester coatingsTetrafluoroethylenePolysilazane

The invention relates to the technical field of functional coatings, and provides a coating for replacing an electronic product screen protection film and a preparation method thereof.The coating is prepared by uniformly stirring surface-treated composite powder, polytetrafluoroethylene powder, urethane acrylate and a flatting agent at a high speed, then adding a reactive diluent and a photoinitiator, and uniformly dispersing; and the surface-treated composite powder is prepared by the following steps: mixing PET and SBS, extruding and granulating, crushing to obtain composite powder, stirring at a high speed at a constant temperature, and sequentially spraying ammonia water and perhydropolysilazane for stirring. The coating provided by the invention has the excellent characteristics of high hardness, good flexibility, no cracking, wear resistance, drop resistance and the like, has a release effect, can be integrally peeled off for re-coating, is convenient to replace, is hydrophobic and oleophobic, is clean and stain-resistant, and can well replace a current electronic product screen protection film.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Special veneering pressing and sticking method of melamine impregnated paper

ActiveCN101954657BNon-deformableStrong surface hardnessSurface covering paperWood treatment detailsCompression moldingWear resistant

The invention discloses a special veneering pressing and sticking method of melamine impregnated paper, which comprises the steps of: softening medium density polyethylene fibreboards, improving the formula of the melamine impregnated paper, and compression-molding by adopting a concave and convex matching mould. The method avoids the deficiencies that a traditional door sheet is not wear-resistant, is not stain-resistant, is easy to deform, crack, delaminate, burn, and mildew, and the surface of a traditional door sheet needs cumbersome processing procedures, such as many times of painting or spray painting, and the like.

Owner:JIANGSHAN OUPAI DOOR IND

Water-resistant and fire-resistant type paint coating

InactiveCN105017900AImprove the decorative effectWith insulationFireproof paintsStarch dervative coatingsAcrylic resinPulverized fuel ash

The invention discloses a water-resistant and fire-resistant type paint coating. The water-resistant and fire-resistant type paint coating is composed, by weight, of 45-60 parts of acrylate emulsion, 25-30 parts of thermoplastic acrylic resin, 4-6 parts of modified starch, 25-30 parts of pulverized fuel ash, 4-5 parts of gypsum, 6-7 parts of methyl cellulose, 2-4 parts of sodium citrate, 4-5 parts of acylic acid type flatting agents, 6-8 parts of dipropylene glycol dibenzoate, 8-10 parts of epoxy palm oil, 3-5 parts of diphenylamine, 5-6 parts of a silane coupling agent KH550, 2-4 parts of potassium sorbate and 1-3 parts of ethylparaben. According to the water-resistant and fire-resistant type paint coating, the produced coating has the advantages of being good in decorative effect, capable of preserving heat, resistant to fire and water, high in strength, uncracking, long in service life, simple in construction and the like, and the water-resistant and fire-resistant type paint coating has the fire retardant effect on fires of furniture and wall decorations and is suitable for repairing wall surfaces with paint prone to disengagement; meanwhile, the water-resistant function is effectively achieved, the materials are simple, the preparation cost is low, and the application range is wide.

Owner:HEFEI LANTIAN FURNITURE MAKING CO LTD

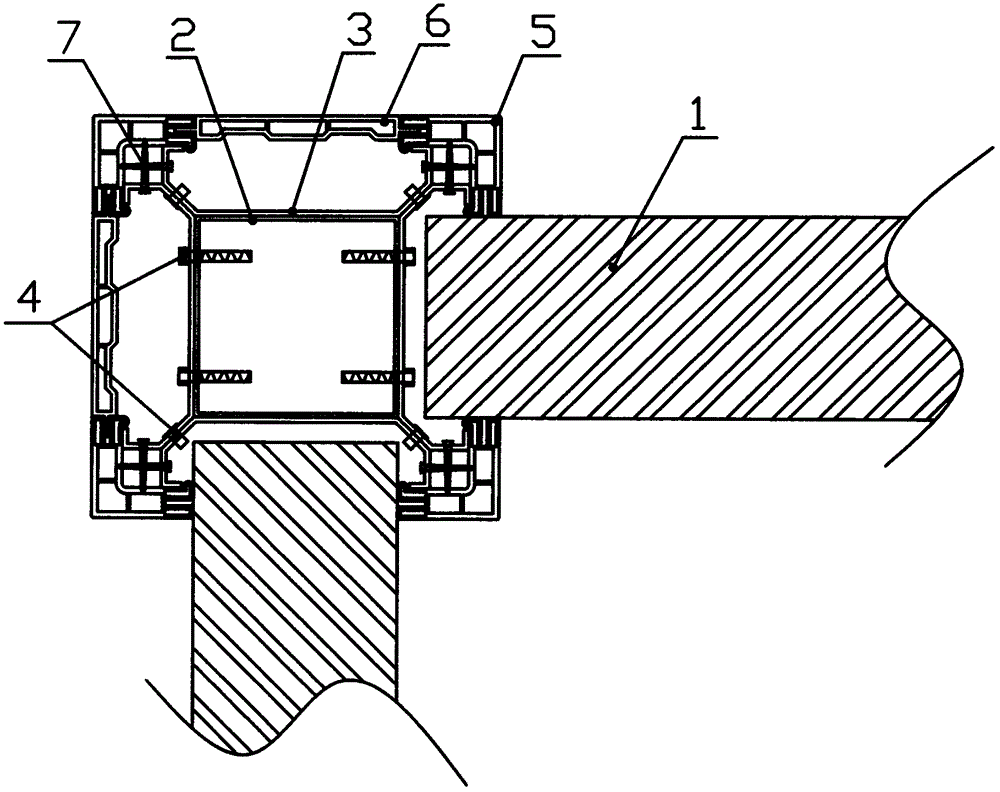

Movable assembly type house

The invention provides a movable assembly type house. The movable assembly type house comprises a galvanized steel pillar (2) and wall boards (1), wherein pillar assembly pieces (3) are fixed to the periphery of the galvanized steel pillar (2) and connected with L-shaped angle boards (5) arranged on four corners of the galvanized steel pillar (2), the wall boards (1) are clamped between every two corresponding adjacent L-shaped angle boards (5), the adjacent L-shaped angle boards (5) between which no wall board (1) is arranged are connected through insertion boards (6), windows are connected to the wall boards (1) through multifunctional corner boards (8), roof girder steel (10) where a roof is laid is connected to the top ends of the wall boards (1), and the periphery of the roof is fixedly connected with eave closing-in boards through eave closing-in C-shaped galvanized steel (11). The house has the advantages of being environmentally friendly, good in heat insulation effect, high in air permeability, resistant to water and corrosion, free of cracking, resistant to flaming, high in anti-seismic grade, easy to install and flexible in design.

Owner:陈光南

Composite material with polyurethane foam coated with plant fibers as well as preparation method and application thereof

PendingCN112644106ALow hygroscopicityFast curingLamination ancillary operationsSynthetic resin layered productsCorrosion resistantContinuous production

The invention discloses a composite material with polyurethane foam coated with plant fibers. According to the composite material, polyurethane rigid foam serves as a core material, and resin-based plant fibers serve as an outer coating layer; and a resin system in the resin-based plant fibers is prepared from the following raw materials: a composite initiator which is 2-5% of unsaturated polyester resin and a release agent which is 3-6% of the unsaturated polyester resin, wherein the unsaturated polyester resin serves as a benchmark. The product provided by the invention has the characteristics of low hygroscopicity, high corrosion resistance, high dimensional stability, light weight and continuous production, and also can improve the strength and environmental protection property.

Owner:江苏集萃复合材料装备研究所有限公司

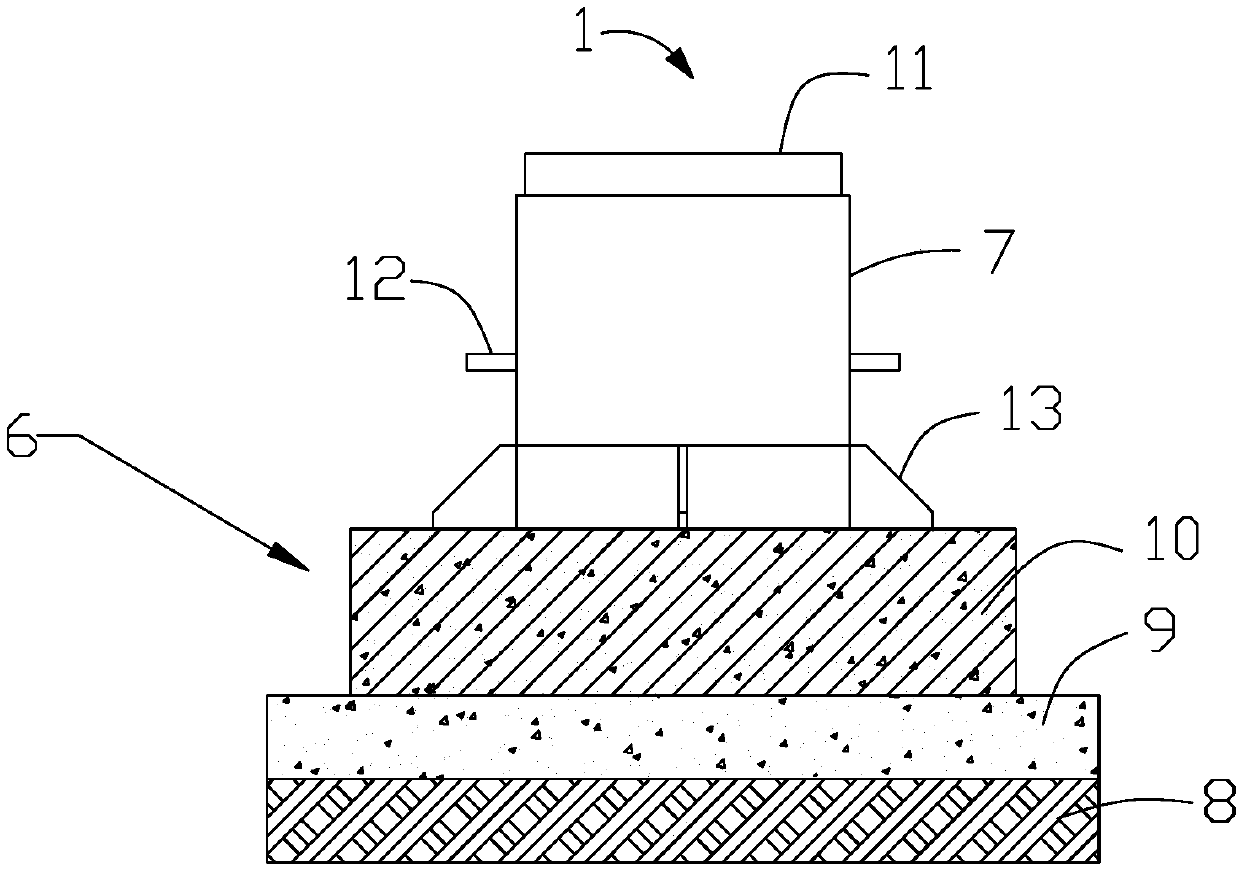

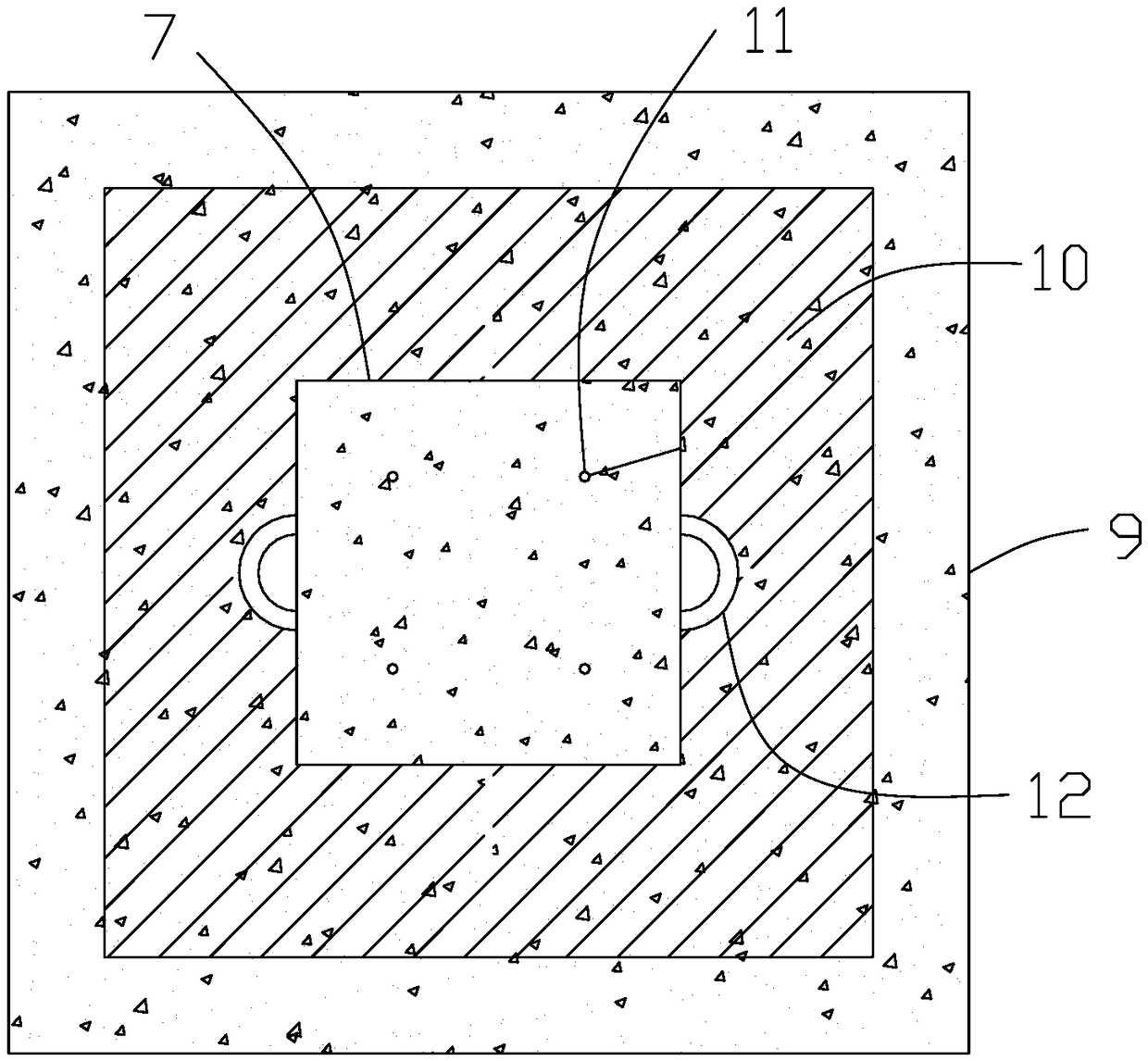

Prefabricated building system with concrete structure and assembly method thereof

ActiveCN107761963BReduce construction costsReduce pollutionHeat proofingProtective buildings/sheltersGrapheneFire prevention

The invention provides a novel assembly type building system with a concrete structure. The novel assembly type building system comprises a prefabricated foundation, a structural supporting frame, a prefabricated floor and a plurality of wall plates; the structural supporting frame comprises concrete prefabricated reinforcing columns and prefabricated beams; the concrete prefabricated reinforcingcolumns are connected with the prefabricated foundation; the prefabricated beams comprise concrete main beams and inserting pieces; the concrete main beams are connected with the concrete prefabricated reinforcing columns; the inserting pieces and the prefabricated floor are connected with the concrete main beams; the wall plates and the concrete prefabricated reinforcing columns are connected through anchoring steel structures; the wall plates are provided with inserting parts; the inserting parts and the inserting pieces are in inserted connection and fixed in a cast-in-place mode. The wallplates are foamed light wall plates based on graphene and nonmetal and have the excellent advantages of corrosion resistant, heat preservation and insulation, fire prevention, water prevention, anti-permeability, anti-earthquake, anti-crack, small weight, high strength and the like. According to the assembly type construction mode adopted by the building system, the construction period can be shortened, and safety and high efficiency are achieved. The invention further provides an assembly method of the novel assembly type building system with the concrete structure.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Thick coating type PE clear primer

ActiveCN111808509AGood anti-sag performanceHigh transparencyPolyether coatingsPolyester coatingsSolid woodPolymer science

The invention provides a thick coating type PE clear primer. The thick coating type PE clear primer comprises a component A, a component B, a component C and a component D, wherein the component A iscomposed of, in parts by weight, 65 to 75 parts of unsaturated polyester resin, 2 to 3 parts of polyether resin, 0.2 to 0.3 part of a dispersing agent, 18 to 25 parts of a filling agent, 0.3 to 0.5 part of an antifoaming agent, 0.3 to 0.5 part of a leveling agent, 0.1 to 0.2 part of an anti-greening agent and 3 to 5 parts of an unsaturated solvent; the component B is a diluent; the component C isketone peroxide; and the component D is a curing accelerator. By adopting the combination of the unsaturated polyester resin and polyether resin, the coating has the advantages of favorable sinking resistance, favorable transparency, high filling property, no cracking and the like, and can be widely used for primer coating of high-grade solid wood and customized furniture.

Owner:四川巴德士新材料有限公司

A kind of preparation method of wood grain paper

ActiveCN106049175BAvoid health hazardsReduce printingMechanical working/deformationPaper coatingWater basedCrazing

The invention discloses a method for preparing woodgrained paper. The method includes the following steps of a, printing, wherein primary-color kraft paper is printed through water-based ink; b, gum dipping, wherein the printed primary-color kraft paper is subjected to gum dipping with modified melamine resin or modified phenolic resin, the modified melamine resin is modified through a plasticizer, and the modified phenolic resin is modified through melamine; c, drying, wherein the primary-color kraft paper subjected to gum dipping is dried; d, hot pressing molding. According to the method, the primary-color kraft paper is adopted, health hazards and environment pollution in the bleaching process of existing products are avoided, the woodgrained paper prepared with the method has the advantages of being heatproof, resistant to flame, free of warping and crazing and easy to clean, color and varieties are various, patterns are rich and attractive, and the color is fresh and bright.

Owner:DYNEA GUANGDONG

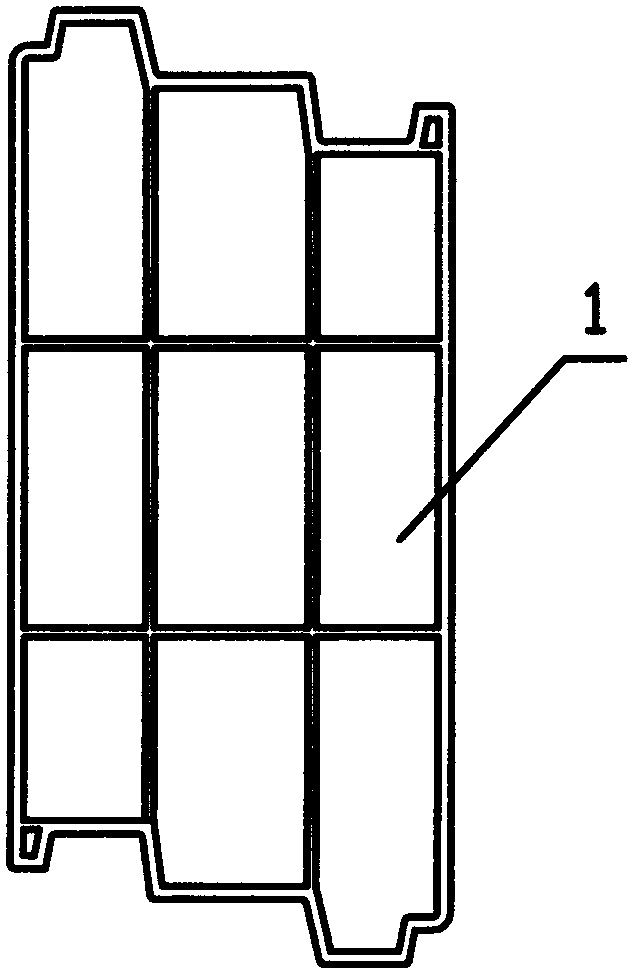

Production method of bamboo rib plate double-layer cavity building module

InactiveCN112606152AEasy to implement production modeIncrease profitCane mechanical workingWood working apparatusArchitectural engineeringStructural engineering

The invention relates to a production method of a bamboo rib plate double-layer cavity building module. The production method comprises the following steps of processing bamboo into bamboo chips, removing inner bamboo partitions, reserving outer bamboo joints, drilling row holes in the bamboo chips, and perforating plastic screw rods and bamboo rods serving as ribs in a staggered manner to prepare bamboo rib plates; and using the bamboo rib plates as an inner plate, a middle plate and an outer plate of the double-layer cavity building module, enabling a plurality of partition plates to be fixed with the inner plate, the middle plate and the outer plate in a double-layer manner between the plates through glue and nails, and manufacturing the bamboo rib plate double-layer cavity building module in a composite manner. According to the production method of the bamboo rib plate double-layer cavity building module, the super-long and super-large building module can be produced, and the bamboo rib plate double-layer cavity building module has the multiple properties of being free of deformation and cracking, low in cost, high in heat preservation and high in strength; and the bamboo rib plates are not only suitable for production of double-layer cavity building modules, but also suitable for production of materials for supporting plates, base plates and frame structures.

Owner:白建国

Method for producing heat-insulation decoration board by using semi-dry type pressing and granulating iron tailings and albite powder co-firing method

The invention discloses a method for producing a heat-insulation decoration board by using a semi-dry type pressing and granulating iron tailings and albite powder co-firing method, and relates to thetechnical field of foaming ceramics. The method adopts the preparation technology with the following steps of firstly, mixing the foaming ceramic raw material of the iron tailings for 1h in a dry way, spraying misty water, enabling a paired roll granulator to produce particles, paving the albite powder with diameter smaller than 0.074mm in a fire-resistant die cushioned with ceramic fiber paper,forming thickness of 3 to 8mm, enabling a material distributor to uniformly add and distribute the particles onto the albite powder, and firing in a roller kiln or a tunnel kiln to form the heat-insulation decoration board, wherein a glass layer with thickness of 3mm is formed on the fired albite powder. The preparation method has the advantages that the preparation method is simple; in the firingprocess, the glass layer with thickness of 3mm on the fired albite powder is tightly bonded with the foaming ceramic material fired by the tailing formula, and the stripping and cracking are avoided;the heat conduction coefficient of the produced heat insulation decoration board is 0.08W / (m.0C), and the index requirements of the heat-insulation decoration board of an outer wall are met.

Owner:辽宁罕王环保科技有限公司

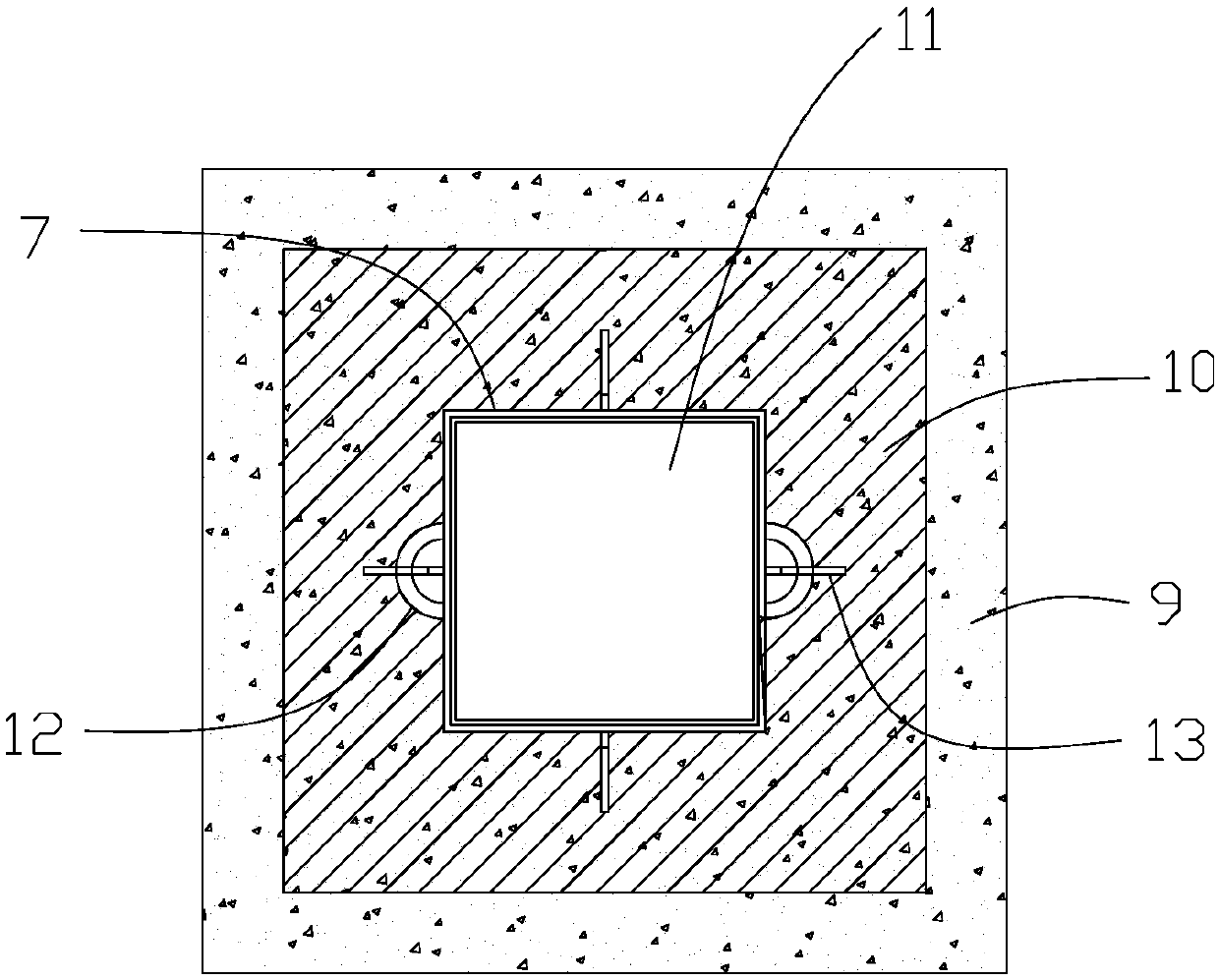

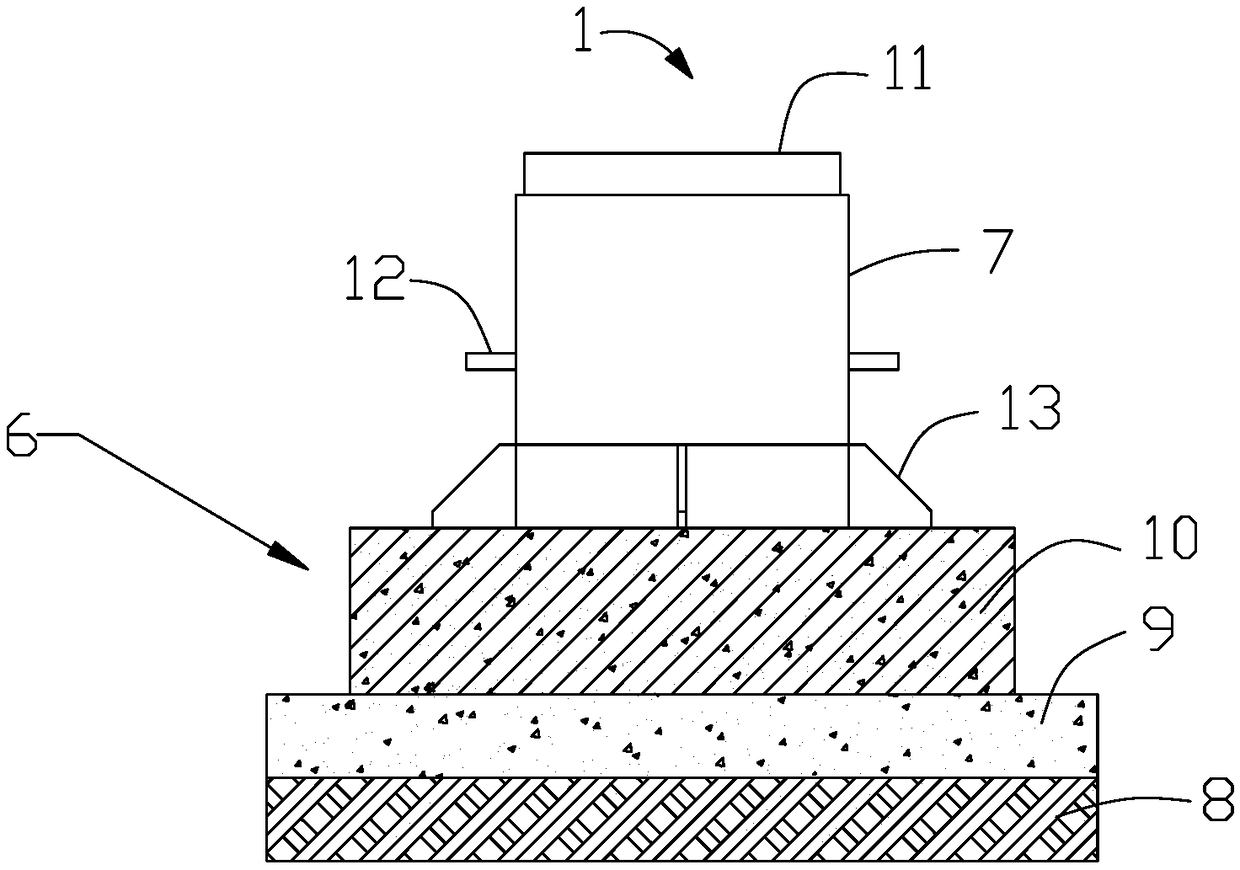

Steel structure prefabricated building system and assembly method thereof

ActiveCN107816130BReduce construction costsReduce pollutionBuilding constructionsCeramic materials productionCrack resistanceEngineering

The invention provides a steel structure novel assembly type building system which comprises a prefabricated base, a structure support frame, prefabricated floors and a plurality of wall boards; the structure support frame comprises steel structure prefabricated reinforcing columns and prefabricated beams, and the steel structure prefabricated reinforcing columns are connected with the prefabricated base; the prefabricated beams comprise steel structure main beams and insertion pieces, and the steel structure main beams are connected with the steel structure prefabricated reinforcing columns;the insertion pieces are connected with the steel structure main beams, and the prefabricated floors are connected with the steel structure main beams; anchoring steel components are used for connecting the wall boards and the steel structure prefabricated reinforcing columns; insertion parts are arranged on the wall boards, and the insertion parts and the insertion pieces are inserted and fixed by a binding agent. The wall boards are based on graphene and nonmetal foaming light wall boards and have the advantages of corrosion resistance, heat preservation and heat insulation, fire proofing, water proofing, permeation resistance, seismic resistance, crack resistance, light weight, high strength and the like. When the building system adopts the assembly type construction manner, the construction period can be shortened, and green energy saving and environment protection can be realized. The invention further provides an assembly method of the steel structure novel assembly type buildingsystem.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

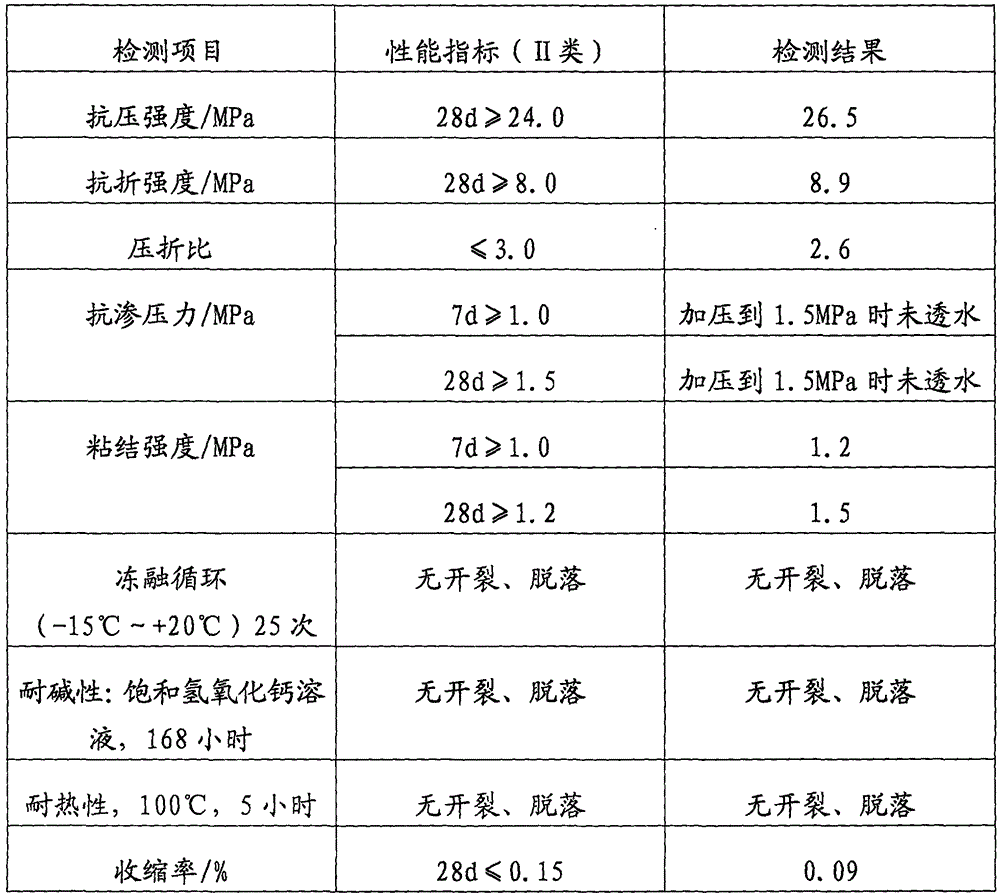

Waterproof, moisture-proof and mildew-proof construction technology for villa basement

ActiveCN107059947BSolve damp and moldyHave no crackingProtective foundationProof constructionArchitectural engineering

The invention provides a waterproof damp-proof and mould-proof construction technology for a villa basement. According to the waterproof damp-proof and mould-proof construction technology for the villa basement, firstly, the leakage condition is detected, and whether leakage stoppage is needed or not is determined according to the leakage condition; secondly, a waterproof crack-proof microcrystal layer is smeared for resisting seepage, and the waterproof crack-proof microcrystal layer has the advantages of being free of cracking, free of an empty drum, good in seepage resistance and cohesiveness, durable and environmentally friendly; and finally, mould resisting and damp resisting are conducted, the wall is painted with waterproof damp-proof and mould-proof microcrystal mortar three times, paste sweeping is conducted on the ground with waterproof damp-proof and mould-proof microcrystal pure cement paste, a waterproof damp-proof and mould-proof microcrystal fine aggregate concrete leveling layer is then manufactured on the ground, the waterproof damp-proof and mould-proof microcrystal mortar, the waterproof damp-proof and mould-proof microcrystal pure cement paste and the waterproof damp-proof and mould-proof microcrystal fine aggregate concrete all contain a waterproof damp-proof and mould-proof microcrystal additive, and the waterproof damp-proof and mould-proof microcrystal additive has good waterproof, damp-proof and mould-proof functions and is environmentally friendly and durable. In this way, the waterproof damp-proof and mould-proof construction technology for the villa basement can permanently solve the problems of leakage, dampness and mould of the villa basement.

Owner:上海微晶防水材料有限公司

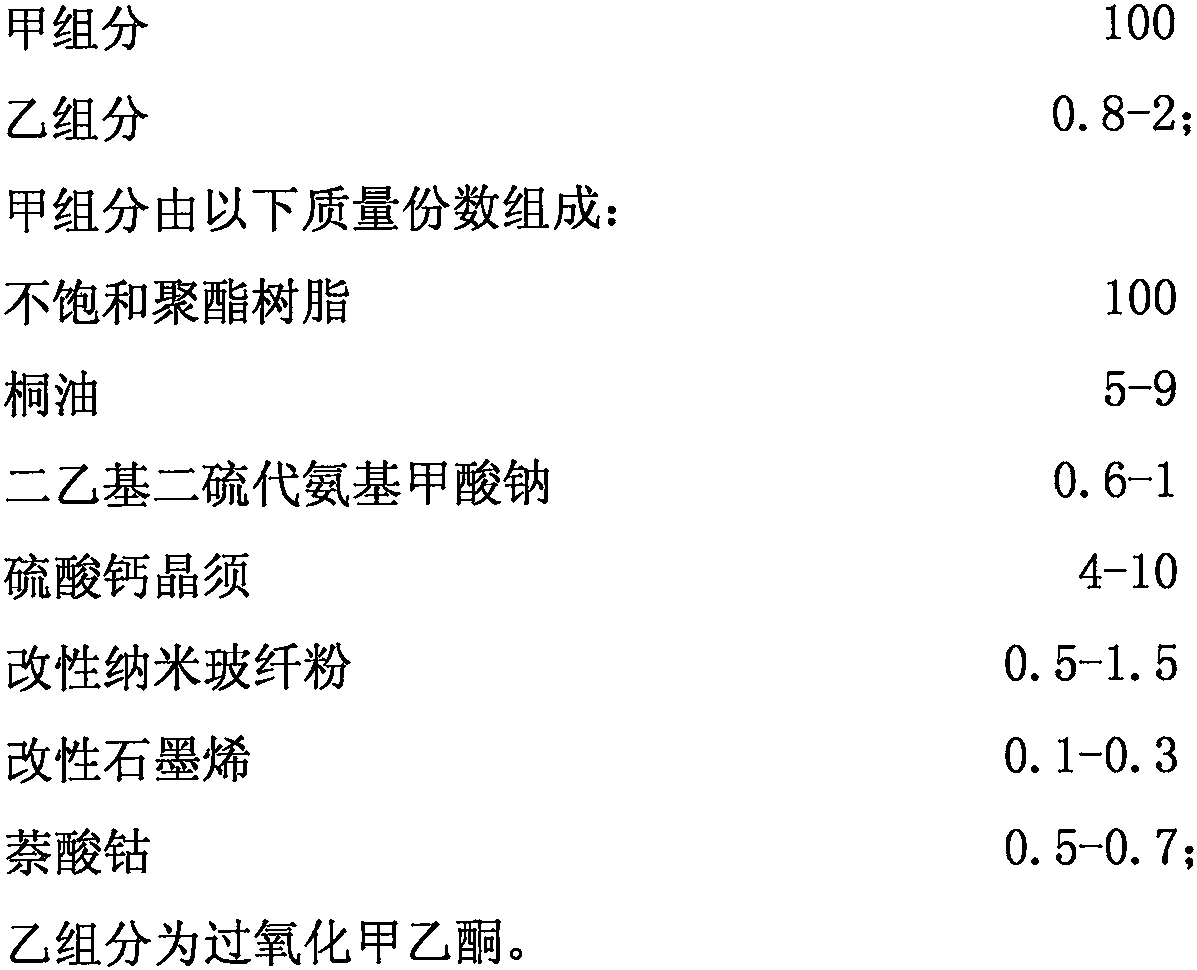

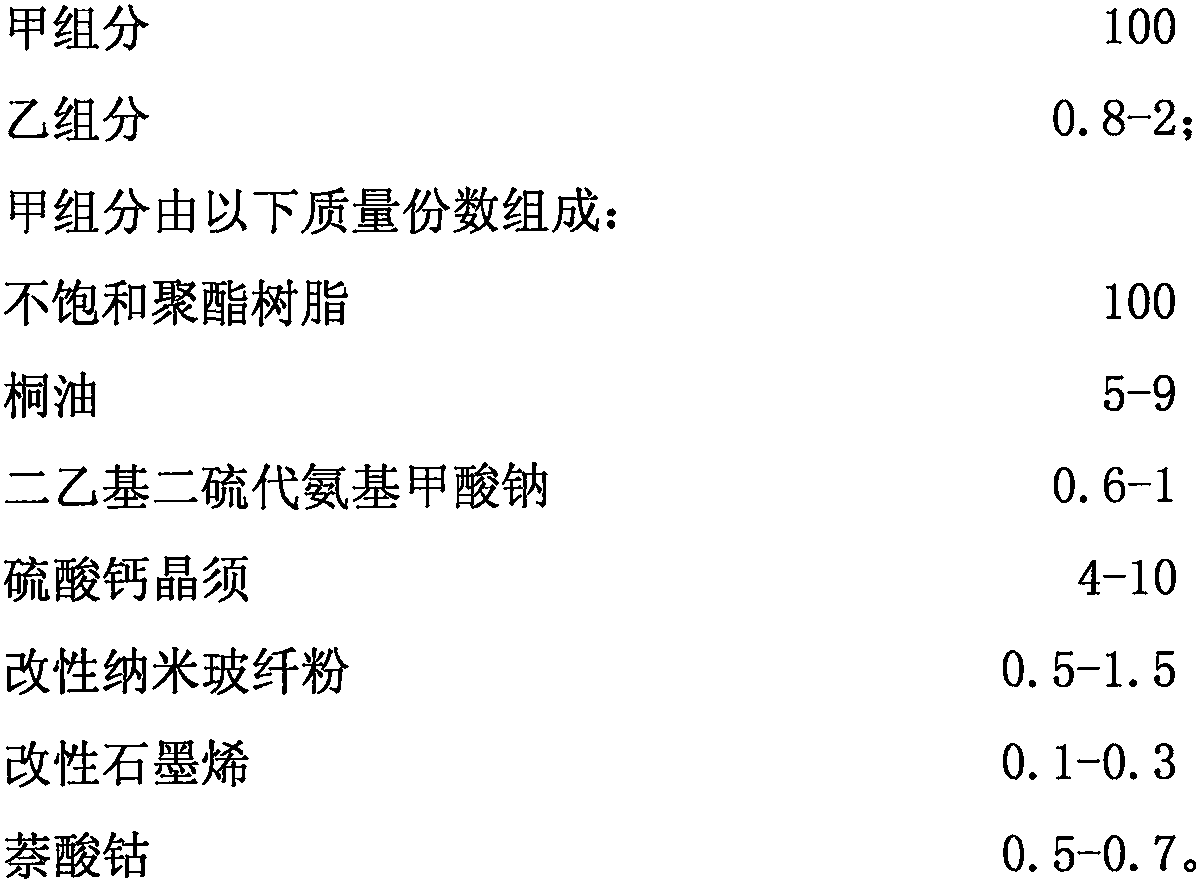

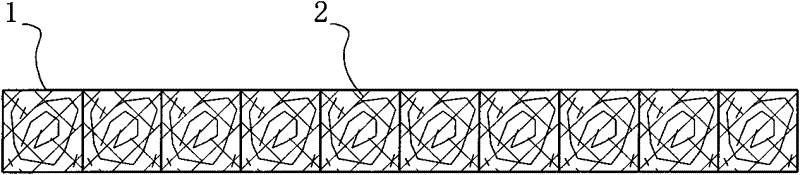

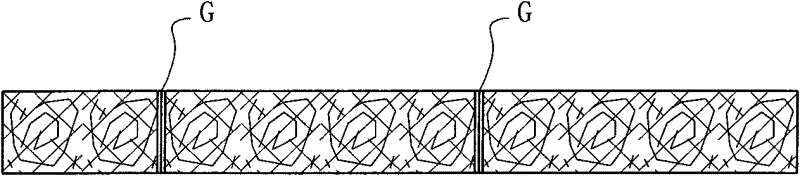

Graphene modified unsaturated polyester resin adhesive and production method thereof

InactiveCN110903746AEasy to produceGood flexibilityAnti-corrosive paintsPolyester coatingsGlass fiberPolymer science

The invention relates to a graphene modified unsaturated polyester resin adhesive, which comprises a component A and a component B, wherein the component A is prepared from a unsaturated polyester resin, tung oil, sodium diethyldithiocarbamate, calcium sulfate whiskers, modified nanometer glass fiber powder, modified graphene and cobalt naphthenate, and the component B is methyl ethyl ketone peroxide. According to the invention, the graphene modified unsaturated polyester resin adhesive is easy to produce and manufacture, can be directly brushed and the like only by uniformly mixing the component A and the component B during use, can further be used for producing glass fiber reinforced plastics and other subsequent products, and is convenient to operate; and the graphene modified unsaturated polyester resin adhesive can resist the erosion of chemical mediums in a use process, and has the characteristics of good flexibility, no cracking, aging resistance and the like.

Owner:扬州润友复合材料有限公司

Method for manufacturing high-density glue permeated plate in mould pressing solid wood

InactiveCN102615689AGuaranteed infiltrationHave no crackingPressure impregnationFlat articlesSolid woodFiber

The invention discloses a method for manufacturing a high-density glue permeated plate in mould pressing solid wood, which belongs to the technical field of processing of artificial plates and relevant equipment. The method is characterized in that a low-density wood plate or wood strip is placed in a high-pressure container to realize supercharging glue permeation via pressure higher than atmosphere pressure, glue permeation time can be shortened, further, glue can assuredly permeate into seams among fiber tissues of the wood effectively, the wood plate or wood strip dried at low temperature is placed in a hot pressing machine to be compressed into a medium and high-density plate in a mould pressing manner according to a proper compression ratio, and accordingly a finally manufactured medium and high-density glue permeated plate in the solid wood really has performances of no crack, waterproofness and fire protection which do not belong to the solid wood, is high in woodiness feeling and nail-holding ability, has excellent stability, and can be used for replacing increasingly deficient hard wood.

Owner:李启山

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com