Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Strong surface hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyphenylene sulfide compound material, and preparation method and application thereof

InactiveCN102391648AStrong surface hardnessHigh strengthPositive displacement pump componentsLiquid fuel engine componentsFiberPolymer science

The invention relates to a polyphenylene sulfide compound material and a preparation method thereof, and a process for preparing an anticorrosion pump overflowing assembly by using the compound material, and belongs to the technical fields of anticorrosion materials and application of the anticorrosion materials. The compound material mainly comprises the following components in part by mass: 100 parts of polyphenylene sulfide, 40 to 100 parts of reinforcement fibers, 18 to 35 parts of hollow glass microspheres, and 25 to 60 parts of polyamide. The compound material is prepared by a melt cladding method. The anticorrosion pump overflowing assembly is prepared by using the compound material and a compression molding process or an injection molding process. The prepared polyphenylene sulfide compound material has high intensity, toughness, surface hardness, corrosion resistance, and small friction coefficients; and the manufactured overflowing assembly has high intensity, wear resistance and corrosion resistance, and long service life and can be used for high-corrosion using conditions where pumps of other materials cannot be used.

Owner:BOSHAN WATER PUMP MFG FACTORY

Environmental protection type paint technique of furniture

InactiveCN101347777AStrong surface hardnessStrong conversion ratePretreated surfacesCoatingsEnvironmental resistanceEmery paper

The invention provides an environment-protection paint process used for furniture, which comprises the steps as follows: A: a blank is ground by an emery paper grinder; B: the ground plate is plastered so as to increase the smoothness of the surface; C: the plate is filled with colorant or transparent putty; D: the primer with high hardness is sprayed once; E: the grinding is subsequently carried out so as to clean the residual plasters and grind the plate to be smooth; F: polyurethane primer is sprayed on the ground plate and the plate is painted and sealed; G: after twice primer spraying and grinding, a novel and environment-protection finishing paint is sprayed for coloring; H: the plate is conveyed to a specially made ultraviolet drying pipeline to carry out the drying and curing, and the drying time is at least 5 minutes. Compared with the prior art, the environment-protection paint process of the invention has the advantages of beautiful appearance, low cost, no polluting to the environment, no harms on human body, etc.

Owner:ZHEJIANG SUNON FURNITURE MFG

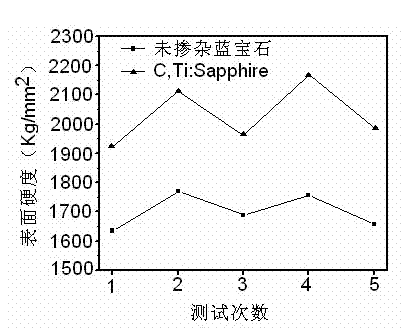

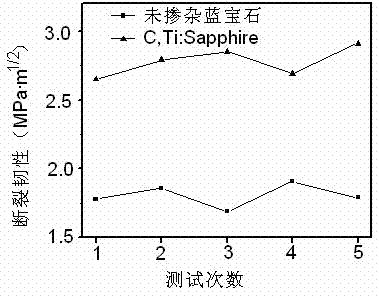

Sapphire crystal with high mechanical property and fabrication method thereof

InactiveCN103046137AIncrease elasticityDoes not impair permeabilityPolycrystalline material growthFrom frozen solutionsTi dopingBreaking strength

The invention relates to a sapphire crystal with a high mechanical property and a fabrication method thereof. The sapphire crystal with the high mechanical property is doped with carbon and titanium; the doping content of the carbon is 1,000-10,000ppm of the total mass of the crystal; and the doping content of the titanium is 500-3,000ppm of the total mass of the crystal. The invention further discloses the fabrication method of the crystal, which comprises the following steps: mixing raw materials at a mixture ratio, grinding, conducting a forming technology, fabricating a crystal growth raw material, and growing the crystal by a temperature gradient method, a descent method or a kyropoulos method. The sapphire crystal doped with the carbon and the titanium is higher in surface hardness, breaking strength and breaking tenacity; and doping ions do not damage optical permeability of the sapphire crystal.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

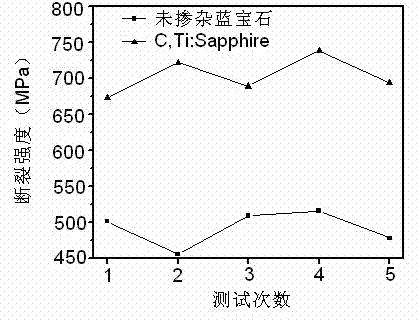

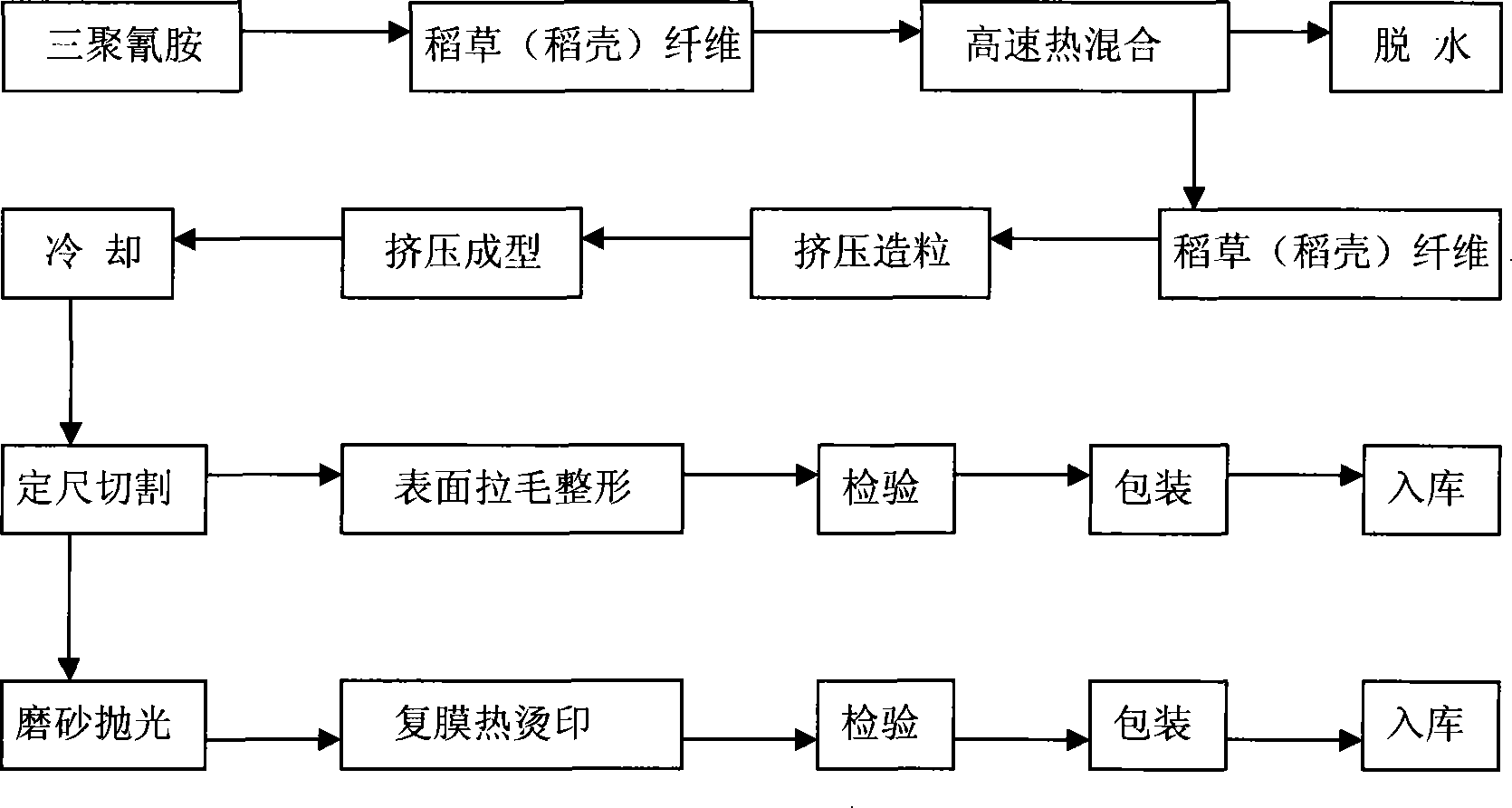

Straw, rice hull fibre base wood-plastic composite material and manufacture method thereof

InactiveCN101245189AAvoid rough surfacesImprove physical and mechanical propertiesRice strawMelamine resin

The invention relates to a wood plastic composite material and a preparation method thereof, in particular to a straw, a rice husk fiber base wood plastic composite material and a preparation thereof. The straw and the rice husk fiber base wood plastic composite material comprise the following components according to weight percentage: melamine resin: 3.5 percent; the straw and the rice husk fiber or the mixture of the straw and the rice husk: 60 percent; polyethylene with low density: 32 percent; solubilizer: 2 percent and lubricant: 2.5 percent. The wood plastic composite type building material of the invention adopts high technology, and utilizes waste plastics and a large amount of straw (rice straw, rice husk) powder to mix and extrude various formed hollow sectional materials of wood plastic at high temperature by fiber strengthening, and the wood plastic composite material is a typical environmental-friendly material. The wood plastic composite material is characterized by sun block, waterproof, anti-moth, anti-freezing and anticorrosion, and the wood plastic composite material without formaldehyde is strong in wood sense, high in surface hardness, strong in wear resistance, good in antiaging, long in service life, easy in processing, is suitable for the preferable material of decoration indoors and outdoors, and is similar to wood in shape but better than wood in property.

Owner:SHAOXING YINYING TEXTILE

Micro-nano composite glaze material

ActiveCN105036558AHas a mineralizing and melting effectSynthesis temperature is lowMicro nanoMullite

The invention belongs to the field of ceramic glaze materials, and particularly relates to a daily micro-nano composite glaze material. The micro-nano composite glaze material comprises, by weight, 30 parts to 60 parts of micro-alpha-Al2O3, 4 parts to 8 parts of nano-TiO2, 3 parts to 9 parts of micro-Ni, 3 parts to 9 parts of nano-ZrO2, 50 parts to 60 parts of nano-TiC, 3 parts to 9 parts of mullite, 20 parts to 30 parts of kaolin, 30 parts to 50 parts of fused alumina, 15 parts to 30 parts of silicon dioxide micro powder, 2 parts to 6 parts of sodium hexametaphosphate, 3 parts to 8 parts of zinc oxide, 6 parts to 15 parts of zirconium carbide, 3 parts to 9 parts of silicon nitride, 3 parts to 9 parts of yttrium carbonate and 7 parts to 15 parts of goethite powder. A glaze prepared through the micro-nano composite glaze material is resistant to the high temperature, abrasion and corrosion; in addition, compared with a common glaze layer, the good tenacity and the good strength are achieved at the same time; in addition, even if the glaze material is illuminated for a long time, bacterial resisting, self cleaning and oxidation resisting of the surface can be achieved.

Owner:LONGQUAN JINHONG PORCELAIN

Steel part surface ultra-hardening treatment process

InactiveCN106435581AGood dispersionUniform particle sizeTransportation and packagingMetal-working apparatusDispersityMetallic materials

The invention relates to a steel part surface ultra-hardening treatment process and belongs to the field of metal material surface treatment. A vacuum cladding method is adopted for cladding an iron-base alloy with a WC composite coating. The steel part surface ultra-hardening treatment process comprises the steps that firstly, coating of the composite coating is prepared, and powder materials which are good in dispersity, uniform in particle diameter and high in strength and abrasion resistance are formed in advance; and then the surface of the steel part is cladded with the obtained spherical materials through the vacuum cladding method, and the steel part with the high surface hardness is obtained.

Owner:大连圣洁热处理科技发展有限公司

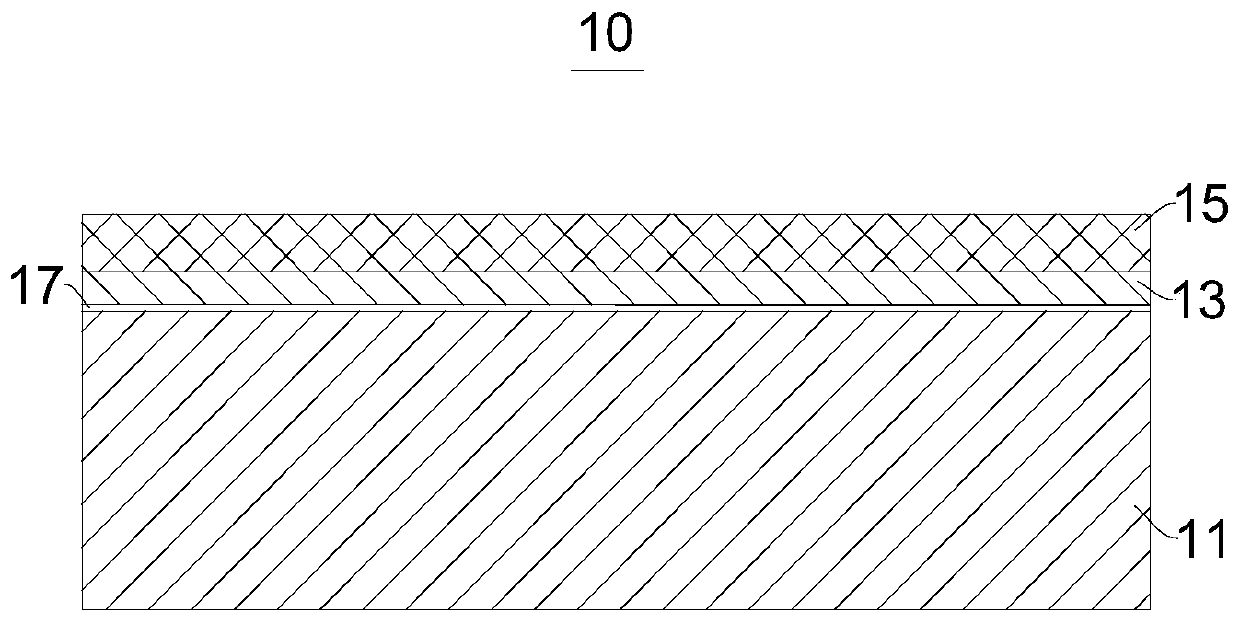

UV ink printed metal gusset plate for ceiling decoration

InactiveCN101906862APromote environmental protectionImprove the three-dimensional effectCovering/liningsGusset plateHardness

The invention discloses a UV ink printed metal gusset plate for ceiling decoration. The UV ink printed metal gusset plate comprises a metal base layer, wherein a varnish coating is coated on the upper surface of the metal base layer; a colored ink layer is printed on the upper surface of the varnish coating; and a transparent UV ink layer is printed on the upper surface of the colored ink layer. A polypropylene or polyethylene protective film is attached to the upper surface of the UV ink layer. The UV ink printed metal gusset plate has the advantages of high plate strength, high environmental protection property, rich colorful patterns, strong third dimension, strong surface texture feel, high surface hardness, scratch prevention, easy cleaning and nonflammability; besides, compared with the currently widely used UV ink metal gusset plate, the UV ink printed metal gusset plate has better decoration effect and protection effect and longer service life.

Owner:SHANGHAI XILV ELECTRICAL APPLIANCES

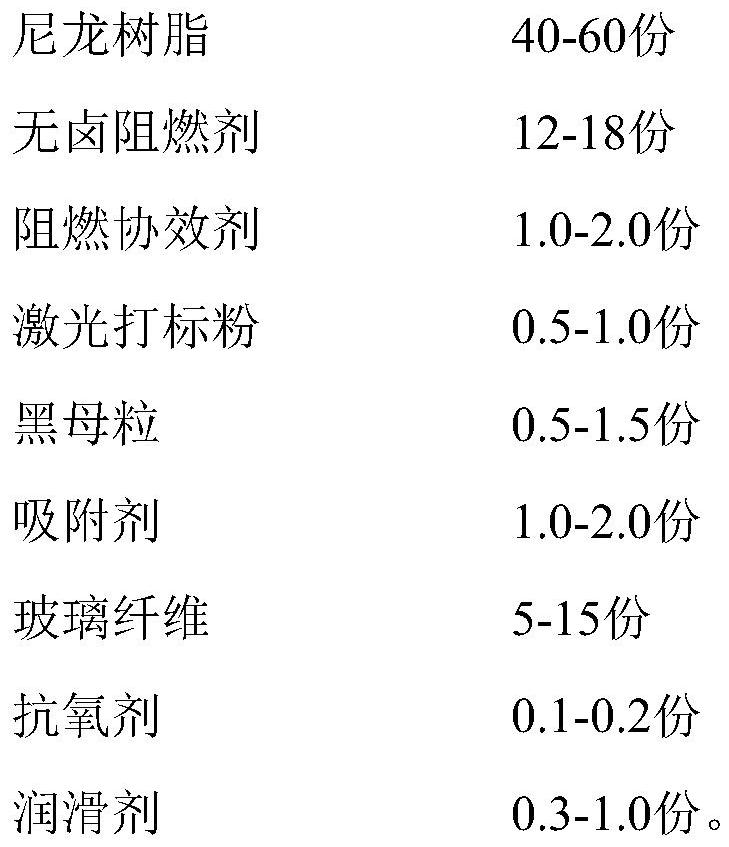

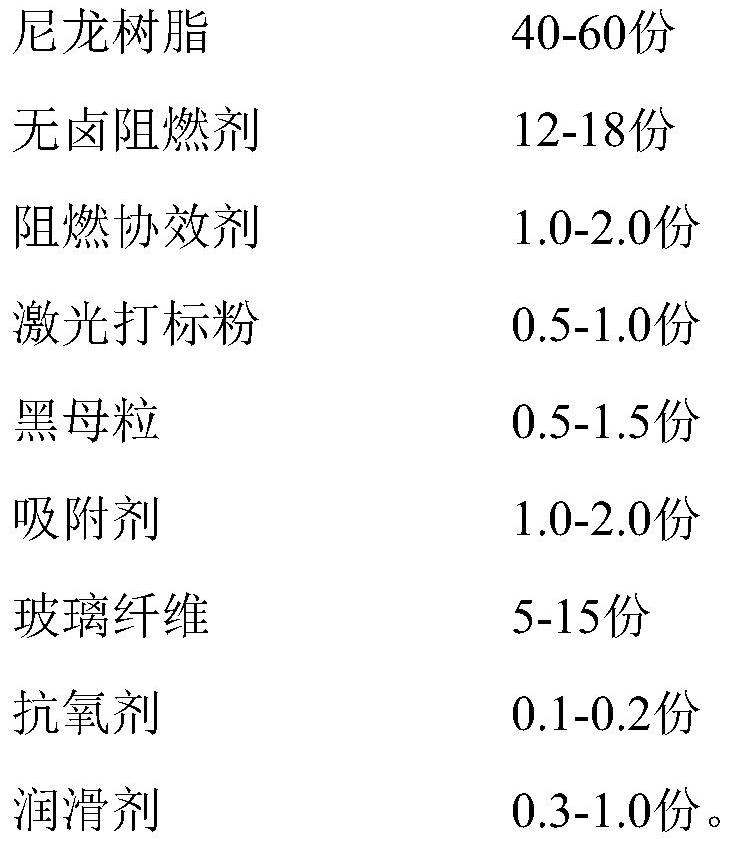

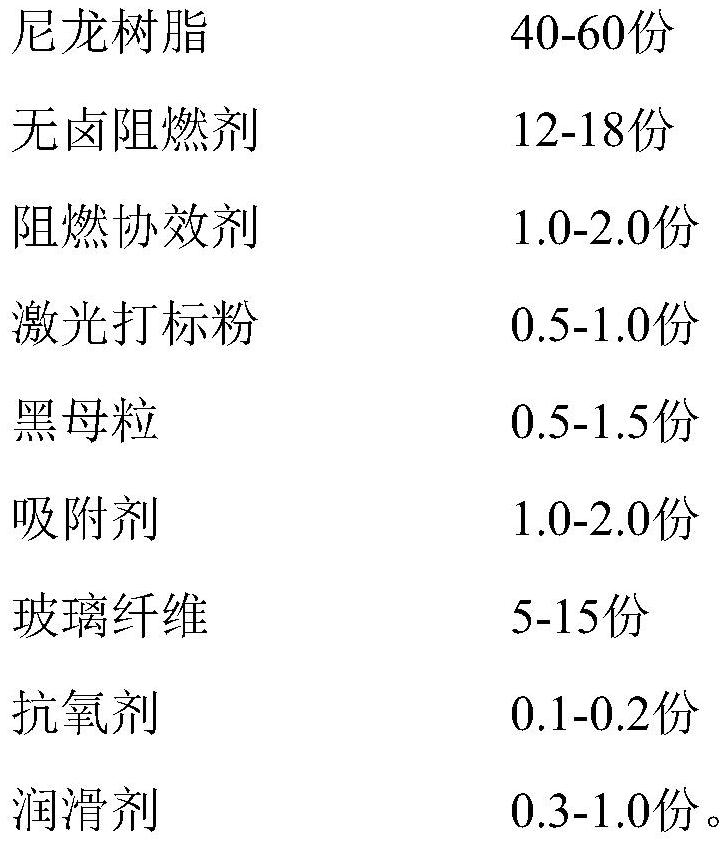

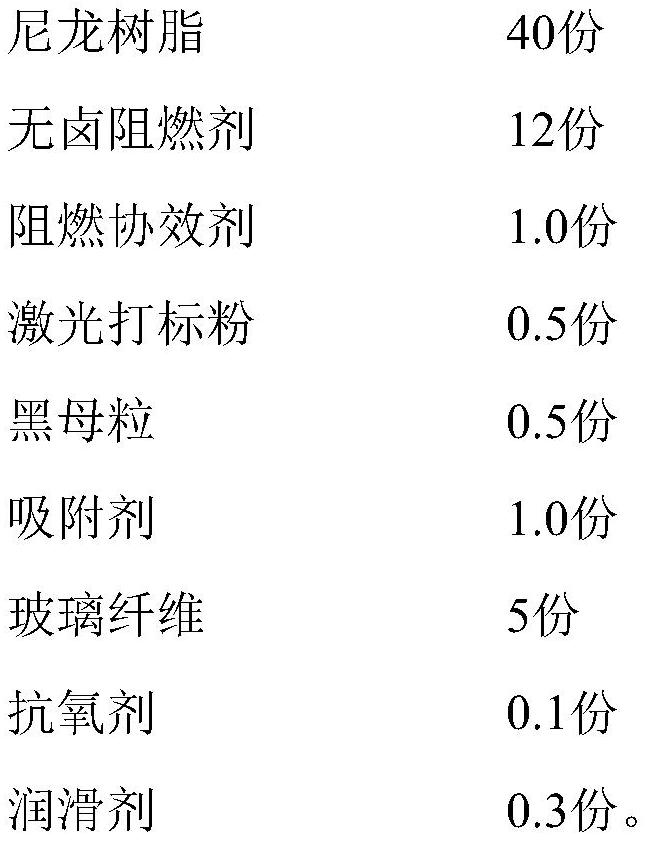

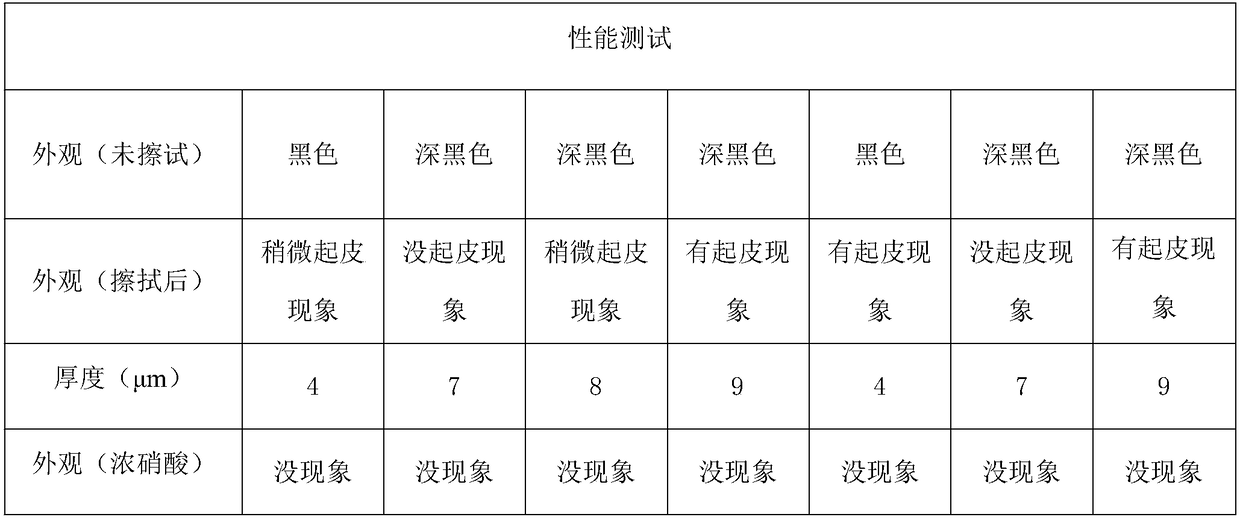

Halogen-free flame-retardant nylon composite material capable of being subjected to laser marking and preparation method thereof

The invention relates to the technical field of laser marking high polymer materials, in particular to a halogen-free flame-retardant nylon composite material capable of being subjected to laser marking and a preparation method thereof. The nylon composite material comprises nylon resin, a halogen-free flame retardant, a flame retardant synergist, laser marking powder, black master batch, an adsorbent, glass fibers, an antioxidant and a lubricant, so that the prepared nylon composite material has excellent flame retardance and high-temperature and high-humidity resistance, relatively good tensile strength and bending strength and a good laser marking effect. The material is simple in preparation process, environment-friendly, clean and low in cost, laser marking can be directly carried out in the product processing process, and continuous and automatic industrial production is realized.

Owner:东莞市东翔塑胶有限公司

Micro-nano composite glaze

ActiveCN105036558BHas a mineralizing and melting effectSynthesis temperature is lowSodium phosphatesMullite

The invention belongs to the field of ceramic glazes, in particular to micro-nano composite glazes for daily use. A micro-nano composite glaze, the glaze is composed of the following raw materials by weight: 30-60 parts of micron α-Al2O3, 4-8 parts of nano-TiO2, 9 parts of micron Ni3-9, 3-9 parts of nano-ZrO2, 50-60 parts of nano-TiC , 3‑9 parts of mullite, 20‑30 parts of kaolin, 30‑50 parts of fused corundum, 15‑30 parts of silica powder, 2‑6 parts of sodium hexametaphosphate, 3‑8 parts of zinc oxide, zirconium carbide 6‑15 parts, 3‑9 parts of silicon nitride, 3‑9 parts of yttrium carbonate, 7‑15 parts of udonite powder. The glaze prepared by the micro-nano composite glaze has high temperature resistance, wear resistance and corrosion resistance, and compared with ordinary glaze layer, it also has good toughness and strength; in addition, even if it is exposed to light for a long time, it can also be antibacterial and self-cleaning on the surface ,anti-oxidation.

Owner:LONGQUAN JINHONG PORCELAIN

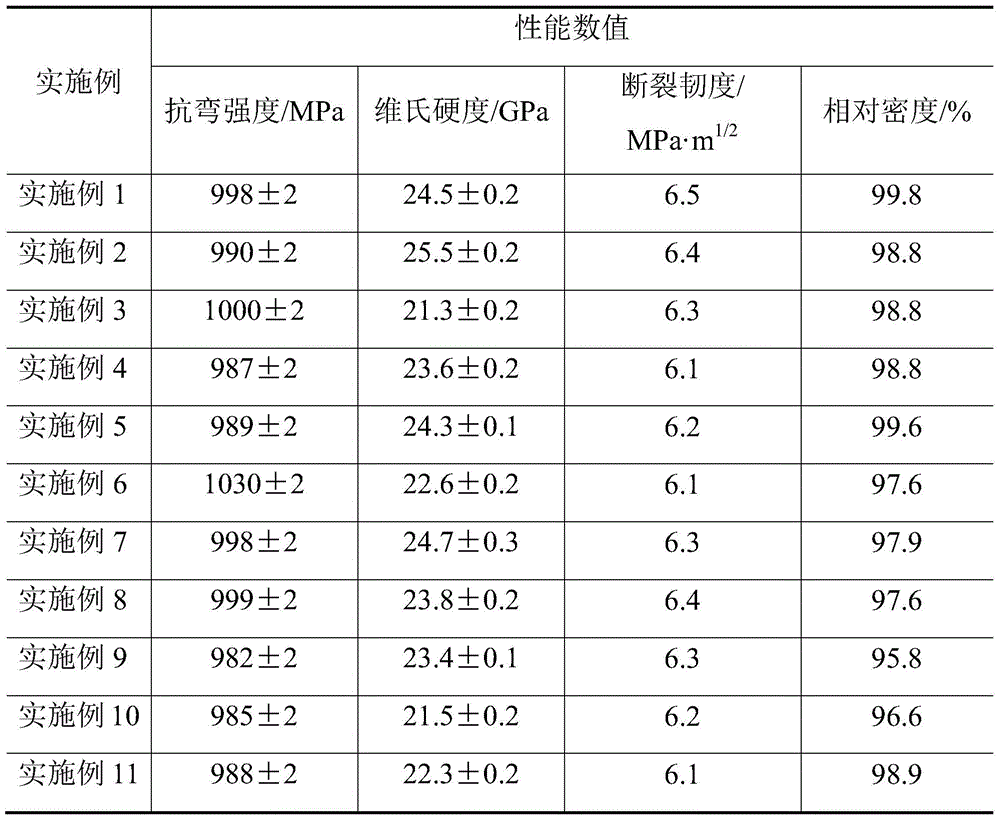

Railway digital signal cable with overall performance

InactiveCN103489519ASelf-lubricatingTimely maintenancePlastic/resin/waxes insulatorsInsulated cablesEngineeringStructural engineering

The invention relates to a railway digital signal cable with overall performance. The railway digital signal cable comprises a cable core located in the center of the whole cable, an outer sheath made of nylon is arranged outside the cable core, a plurality of non-shielding four-wire sets and a plurality of shielding four-wire sets are arranged inside the cable core, the cable core is wrapped by a cable core wrapping belt in a longitudinal or a surrounding mode, a metallic shield pipe is arranged outside the cable core wrapping belt, an inside liner is arranged outside the metallic shield pipe, a steel-tape armoring layer is arranged between the inside liner and the outer sheath, and the non-shielding four-wire sets and the shielding four-wire sets are formed by twisting a plurality of insulating single lines. Gaps between the metallic shield pipe and the cable core wrapping belt and gaps between the cable core wrapping belt and the non-shielding four-wire sets and the shielding four-wire sets are tightly filled with magnesium oxide.

Owner:江苏通鼎光电科技有限公司

Anodic oxidation die-casting aluminum alloy material and preparation method thereof

PendingCN111748714AExpand the scope of applicationImproved surface hardness and mechanical propertiesAnodisationAnodic oxidationCorrosion resistant

The invention discloses an anodic oxidation die-casting aluminum alloy material and a preparation method thereof. The anodic oxidation die-casting aluminum alloy material comprises, by mass percent, 2.5-3.5% of Mg, 0.8-1.2% of Mn, 0.2-0.5% of Co, 0.1-0.2% of Cr, 0.01-0.03%of Sr, less than or equal to 0.2% of Si, less than or equal to 0.15% of Fe, less than or equal to 0.05% of Cu, and the balanceAl. According to the material and the method, by optimizing components of an aluminum-manganese system die-casting aluminum alloy material, the material can achieve a good anodic oxidation effect, thedefects of aluminum alloy surface hardness, wear resistance and the like are overcome, and the application range is expanded; and meanwhile, the preparation method is simple, the corrosion effect ofan aluminum alloy on a casting crucible can be reduced, meanwhile, the plasticity of the aluminum alloy is increased, the generation of defects such as thermal cracks, shrinkage cavities, shrinkage porosity and the like is reduced, a honeycomb porous structure on the surface of an anodic oxidation film generated on the surface of the aluminum alloy through the anodic oxidation process is uniform in dye coloring, and the compact anodic oxidation film formed after pore sealing has high surface hardness, wear resistance and corrosion resistance.

Owner:ANHUI SCI & TECH UNIV

Water paint coating method for white closing of Russian birch door sheets

InactiveCN107159540AStrong glossVOC (xylene) content decreasedLiquid surface applicatorsCoatingsLacquerUltraviolet

The invention discloses a water paint coating method for white closing of Russian birch door sheets. The method is characterized by comprising the steps of: material repair; spraying of water adhesive primer; spraying of UV spraying primer and spraying of UV transparent primer; multiple times of filling and polishing; and multiple times of water paint spraying. Because of no oil paint, but use of water paint, the product is safe and environment-friendly, the VOC content is reduced by 20 times compared with the oil paint, the product has no smell, and is high in surface hardness, difficult to scratch and higher in ultraviolet intensity resistance; and the coated door sheets are higher in surface gloss.

Owner:宁波凤凰杰仑木业股份有限公司

Mold surface ultra-hardening treatment technology

The invention relates to a mold surface ultra-hardening treatment technology, belongs to the field of metal material surface treatment, and provides a technology for spraying a WC composite coating on iron-based alloy through a plasma spraying method. The method comprises the steps that firstly, composite coating paint is prepared and then made to form a powder raw material which is good in dispersity, uniform in particle size and high in strength and wear resistance; secondly, the obtained spherical raw material is sprayed on the mold surface through the plasma spraying method, and a mold with the high surface hardness is obtained.

Owner:大连圣洁热处理科技发展有限公司

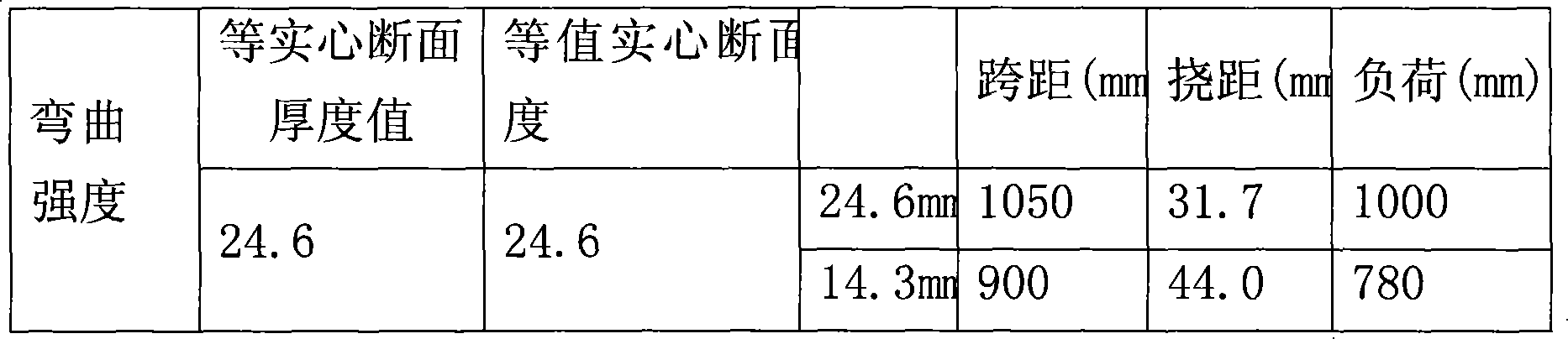

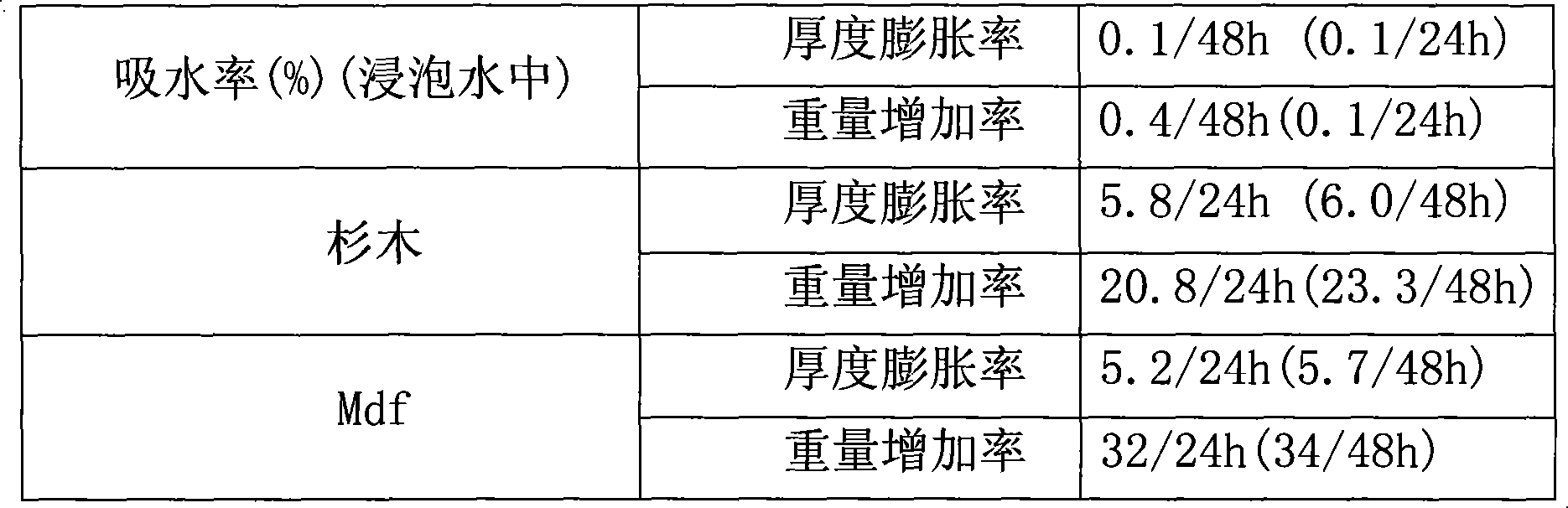

Special veneering pressing and sticking method of melamine impregnated paper

ActiveCN101954657BNon-deformableStrong surface hardnessSurface covering paperWood treatment detailsCompression moldingWear resistant

The invention discloses a special veneering pressing and sticking method of melamine impregnated paper, which comprises the steps of: softening medium density polyethylene fibreboards, improving the formula of the melamine impregnated paper, and compression-molding by adopting a concave and convex matching mould. The method avoids the deficiencies that a traditional door sheet is not wear-resistant, is not stain-resistant, is easy to deform, crack, delaminate, burn, and mildew, and the surface of a traditional door sheet needs cumbersome processing procedures, such as many times of painting or spray painting, and the like.

Owner:JIANGSHAN OUPAI DOOR IND

Method of manufacturing abnormity spinneret

ActiveCN101033561BStrong scratch resistanceHigher than silk surface hardnessHollow filament manufactureVacuum evaporation coatingSputteringElectrochemical micromachining

This invention relates to a manufacturing method for an abnormal spinneret including: 1, spraying metal Ti thin layer and making oxidation process on a glass plate, then throwing off negative etching glue and pre-drying it to form a pattern of the abnormal nozzle etching glue structure, 2, sputtering a Ti-Cu conduction layer, 3, applying an electric deposition technology to carry out deposition of the stress buffer layer, a non-crystal state silking face layer and a die supporting layer to form a complete electric die cast, 4, heat-processing it and cooling it to room temperature, 5, carryingout flatness process to remove the negative glue and Cu stress buffer layer.

Owner:SHANGHAI HUIPU ELECTROMECHANICAL SCI & TECH CO LTD

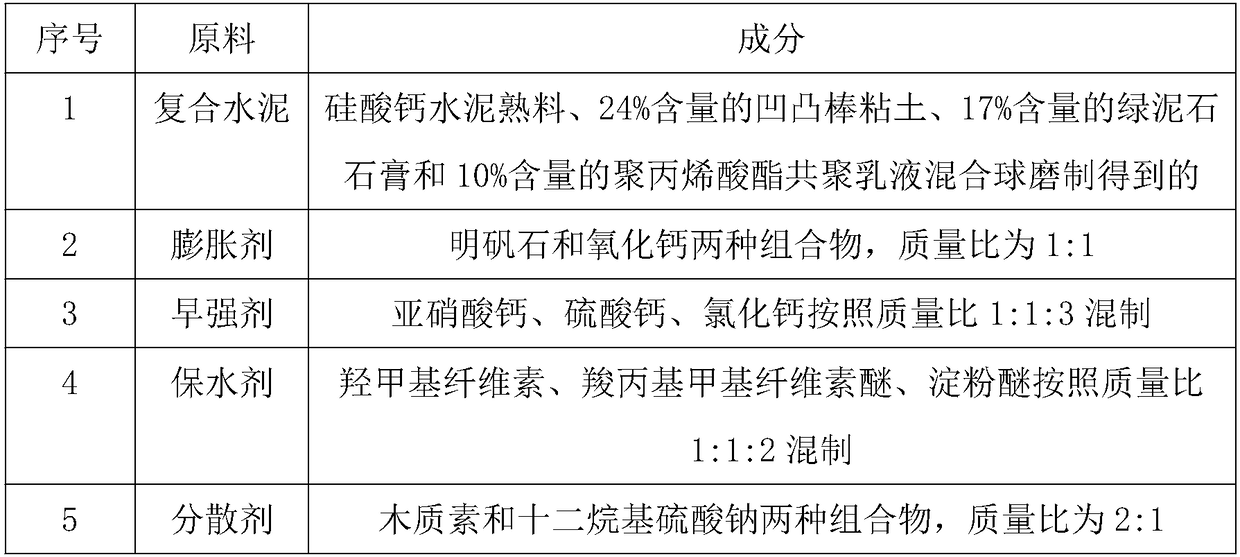

Concrete material for pavement slabs and preparation method thereof

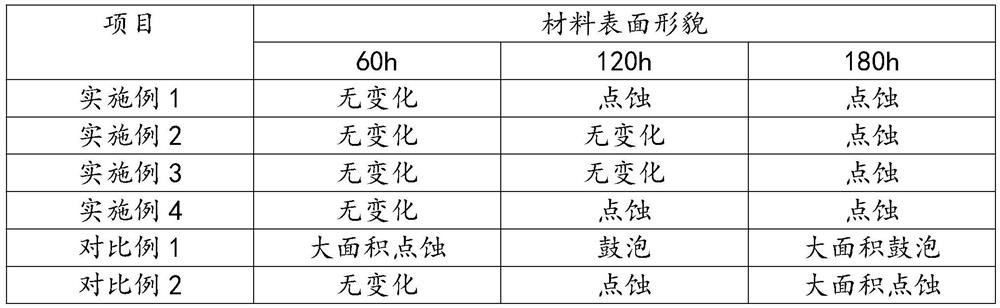

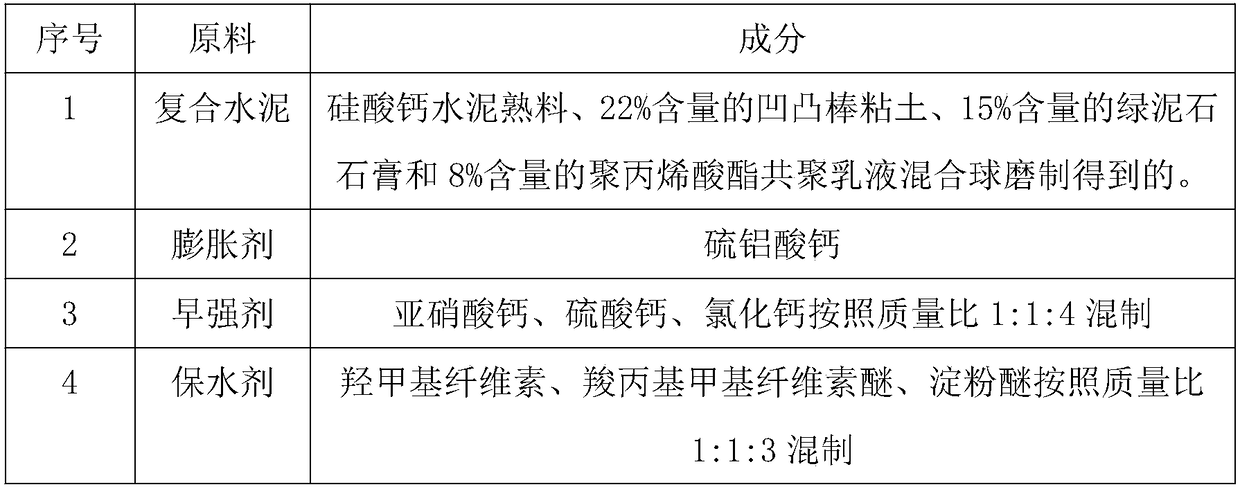

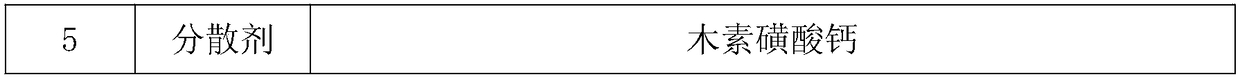

The invention discloses a concrete material for pavement slabs and a preparation method thereof and relates to the technical field of pavement slabs. The concrete material is made from composite cement, clay-grade mica, high-silicon iron tailings, carbide slag, porous zirconia ceramic, rectorite, quartz sandstone, chrysotile fiber, sodium polyacrylate, barium chloride, a swelling agent, an early strength agent, a water-holding agent, and a dispersant. The preparation method herein includes: performing ball milling on raw materials, and stirring and mixing. The concrete material herein is convenient and simple to prepare, is green, has good comprehensive properties, can resist adhesion of adhesive matters, such as chewing gum, is convenient to clean, and provides improved cleanliness and water perviousness for pavement slabs, as well as road environment and city appearance.

Owner:合肥慧林建材有限公司

Door and window profile preparation method based on building energy-saving PVC door and window cross-linking technology

The invention discloses a door and window profile preparation method based on a building energy-saving PVC door and window cross-linking technology and relates to a door and window profile preparation method. The problem that various performance indexes of doors and windows cannot meet the service requirements because door and window profiles of PVC materials are degraded is solved. The preparation method comprises the following steps: 1, by taking high-energy electron rays as a radiation source, performing inner and outer layer co-extrusion on to-be-prepared PVC plastics and an aluminum lining, and adding a cross-linking agent onto an outer surface layer of the to-be-prepared PVC plastics; 2, breaking C-CL bonds of the PVC on the outer surface layer of the to-be-prepared PVC plastics under the action of the radiation source, and forming free radicals; 3, carrying out an auto-polymerization reaction on the free radicals generated by the cross-linking agent under the action of the radiation source, and replacing CL in a PVC long chain of the outer surface layer of the to-be-prepared PVC plastics in the step 2 so as to form effective grafting; and 4, adjusting the intensity of the radiation source, forming a PVC-cross-linking agent-PVC long chain, and finally forming meshed distribution of the cross-linking agent branched chain. The method disclosed by the invention is used for preparing the door and window profiles.

Owner:HARBIN ZHONGDA PROFILE TECH

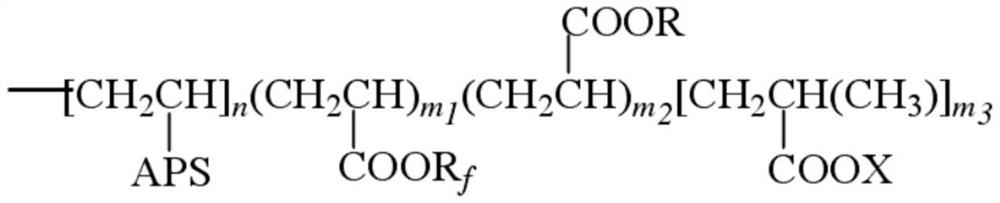

Organic silicon modified fluorinated polyacrylate emulsion, preparation method thereof, prepared unconventional energy drilling and production coating and application thereof

PendingCN114853956AImprove mechanical propertiesHigh strengthChemical industryCoatingsMetallic substrateMaterials science

The invention provides an organic silicon modified fluorinated polyacrylate emulsion, a preparation method thereof, a prepared unconventional energy drilling and production coating and application thereof, and relates to the technical field of unconventional energy drilling and production coatings. The preparation method specifically comprises the following steps: heating and uniformly mixing lauryl methacrylate, perfluoropolyether methacrylate, vinyltriethoxysilane and n-butyl methacrylate, adding an emulsifier to prepare a pre-emulsion, adding an initiator in batches, and heating for reaction to obtain the organic silicon modified fluorinated polyacrylate emulsion. And the organic silicon modified fluorine-containing acrylate is copolymerized with styrene and toluene to obtain the organic silicon modified fluorine-containing acrylate unconventional energy drilling and production coating. Through detection, the coating has excellent hydrophobic scale inhibition performance and good bonding strength, the adhesive force of the coating to a metal substrate can be greatly improved, and the coating has the advantages of high bonding capacity, high surface hardness and good wear resistance and scrubbing resistance. The preparation process is simple to operate and low in energy consumption, the production process is easy to control, and large-batch continuous production can be realized.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

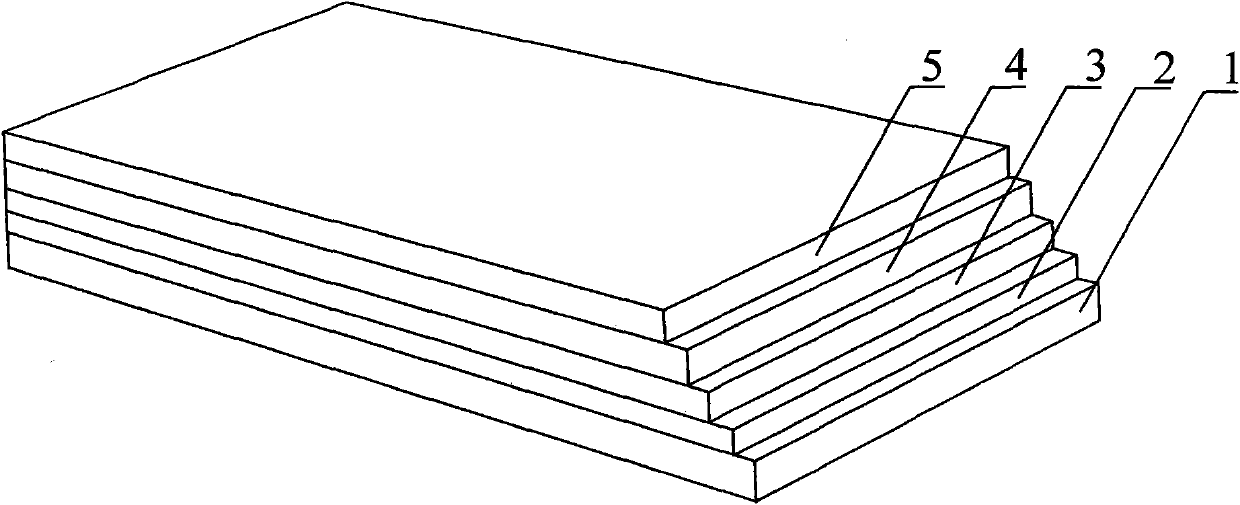

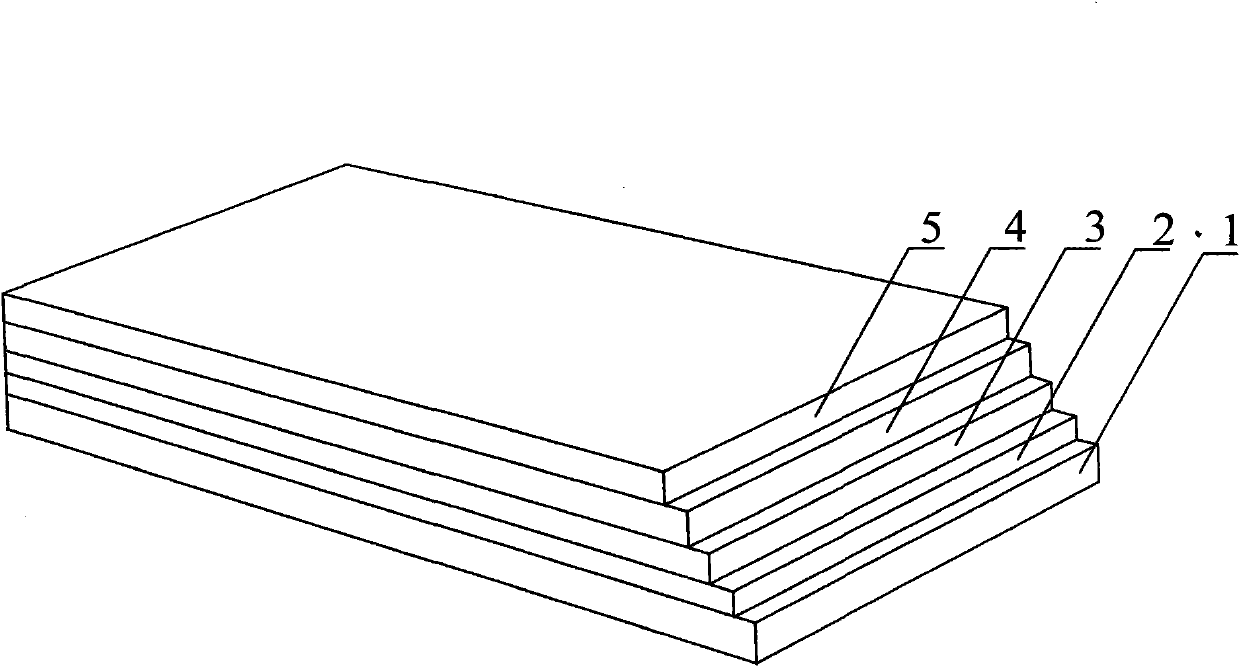

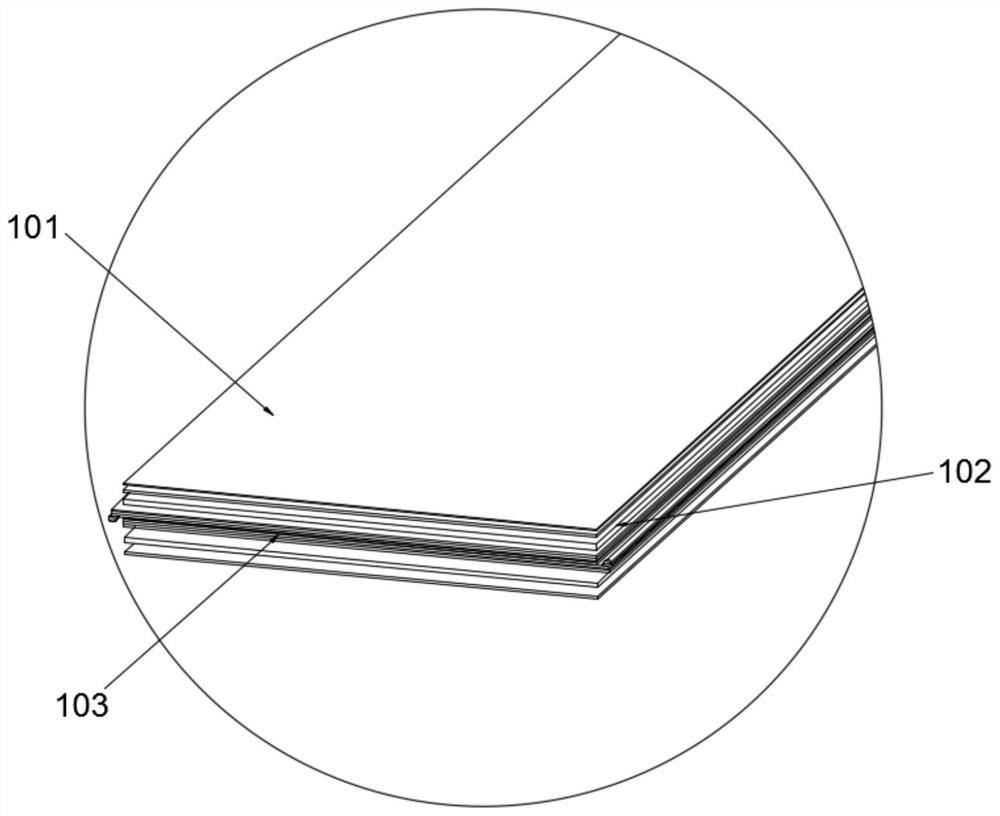

Novel wooden floor and manufacturing method thereof

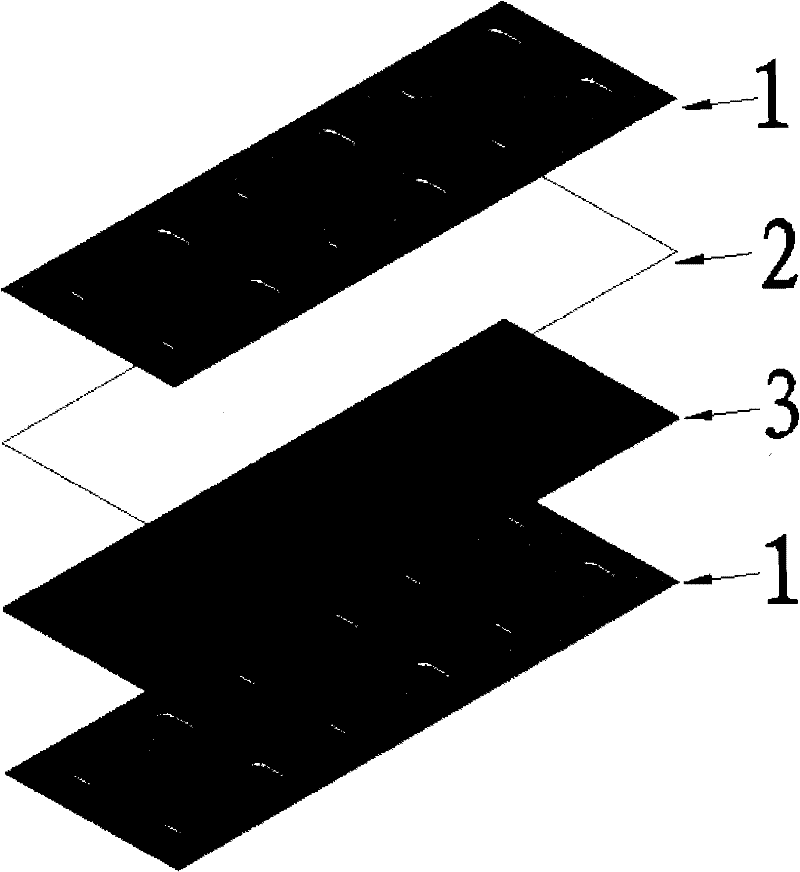

PendingCN112917630AExtended service lifeStrong surface hardnessPaper/cardboard layered productsWood veneer joiningHigh densityUltimate tensile strength

The embodiment of the invention discloses a novel wooden floor and a manufacturing method thereof. The novel wooden floor sequentially comprises a surface board layer, a first strength layer and a base material layer from top to bottom in the thickness direction, wherein the surface board layer, the first strength layer and the base material layer are bonded and compounded with one another, the first strength layer is a high-density fiberboard, and the thickness of the first strength layer is 0.5-3.0 mm. In batch production, it can be effectively guaranteed that the product has a relatively flat decorative surface, the outturn percentage is higher, and the manufacturing cost is lower.

Owner:ZHEJIANG LINGGE WOOD

Thermal transfer PET film UV-curable varnish and preparation method thereof

ActiveCN107365553BImprove adhesionStrong surface hardnessPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

Owner:东周化学工业(昆山)有限公司

A kind of negative ion diatom mud wall decoration material and preparation method thereof

The invention discloses a negative ion diatom ooze decorative material for a wall surface. The negative ion diatom ooze decorative material for the wall surface comprises the following raw materials by weight percent: 30-40% of diatom ooze, 25-35% of zirconium oxide, 15-25% of titanium oxide, 10-14% of kaolin, and 2-4% of chemical fiber powder. A preparation method of the negative ion diatom oozedecorative material specifically comprises the following steps: S1, roasting and pulverizing: roasting the diatom ooze at the high temperature of 1800 DEG C, pulverizing in a pulverizer to obtain a diatom ooze powder; S2, screening: screening and collecting the diatom ooze powder pulverized in the step S1; S3, premixing the materials: stirring and mixing the zirconium oxide, the titanium oxide, the kaolin and the chemical fiber powder in a stirrer to obtain a mixture; S4, stirring through negative ions: putting the diatom ooze powder screened in the step S2 into a negative ion stirrer, addingthe mixture prepared in the step S3 in the process of stirring the diatom ooze powder, mixing the diatom ooze powder and other material mixtures, and finally preparing a finished product.

Owner:浦瑞纺环境技术(上海)有限公司

Negative ion diatom ooze decorative material for wall surface and preparation method of negative ion diatom ooze decorative material fort wall surface

The invention discloses a negative ion diatom ooze decorative material for a wall surface. The negative ion diatom ooze decorative material for the wall surface comprises the following raw materials by weight percent: 30-40% of diatom ooze, 25-35% of zirconium oxide, 15-25% of titanium oxide, 10-14% of kaolin, and 2-4% of chemical fiber powder. A preparation method of the negative ion diatom oozedecorative material specifically comprises the following steps: S1, roasting and pulverizing: roasting the diatom ooze at the high temperature of 1800 DEG C, pulverizing in a pulverizer to obtain a diatom ooze powder; S2, screening: screening and collecting the diatom ooze powder pulverized in the step S1; S3, premixing the materials: stirring and mixing the zirconium oxide, the titanium oxide, the kaolin and the chemical fiber powder in a stirrer to obtain a mixture; S4, stirring through negative ions: putting the diatom ooze powder screened in the step S2 into a negative ion stirrer, addingthe mixture prepared in the step S3 in the process of stirring the diatom ooze powder, mixing the diatom ooze powder and other material mixtures, and finally preparing a finished product.

Owner:浦瑞纺环境技术(上海)有限公司

A kind of antistatic paint and environmental protection antistatic floor

ActiveCN107964326BImprove stabilityImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsFirming agentPolymer chemistry

Belonging to the building field, the invention relates to an antistatic paint and an environment-friendly antistatic terrace. The antistatic paint comprises the a first raw material and a second raw material in a weight ratio of 20-40:60-80, wherein the first raw material comprises a waterborne epoxy curing agent, a dispersant, a conductive agent and deionized water in a weight ratio of 60-80:0.1-0.5:5.1-10.5:9-34.8, and the second raw material includes epoxy resin, an active diluent and a defoamer in a weight ratio of 70-90:9.2-29.8:0.2-0.8. The antistatic paint has excellent electrical conductivity, hardness and antistatic effect. The environment-friendly antistatic terrace includes a concrete base layer, an antistatic primer layer compounded on the concrete base layer, and an antistaticfinishing paint layer compounded on the antistatic primer layer, and the primer used by the antistatic primer layer is the antistatic paint. The environment-friendly antistatic terrace provided by the invention has the characteristics of antistatic properties, strong surface hardness and long service life.

Owner:上海牧桔新型材料有限公司

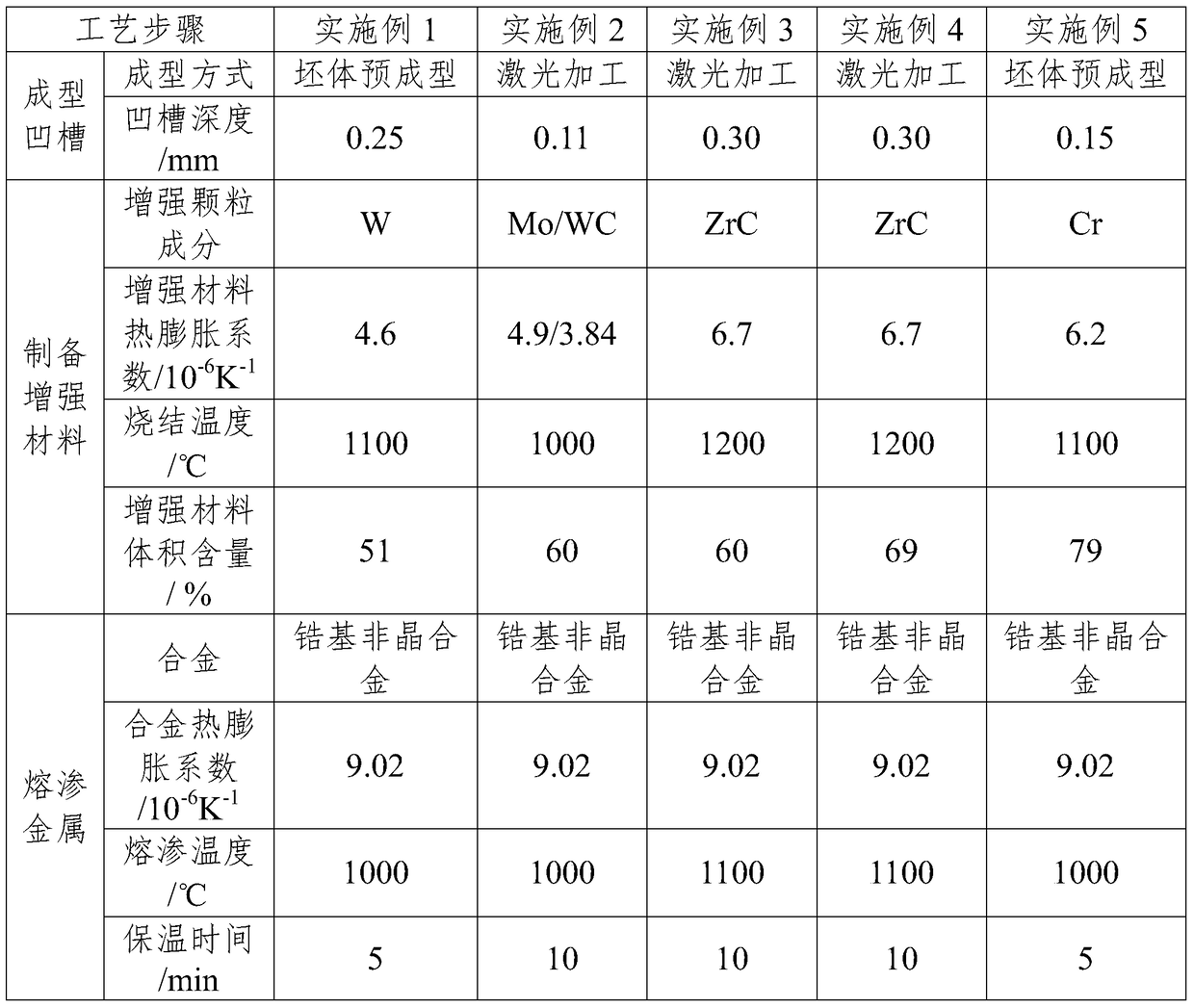

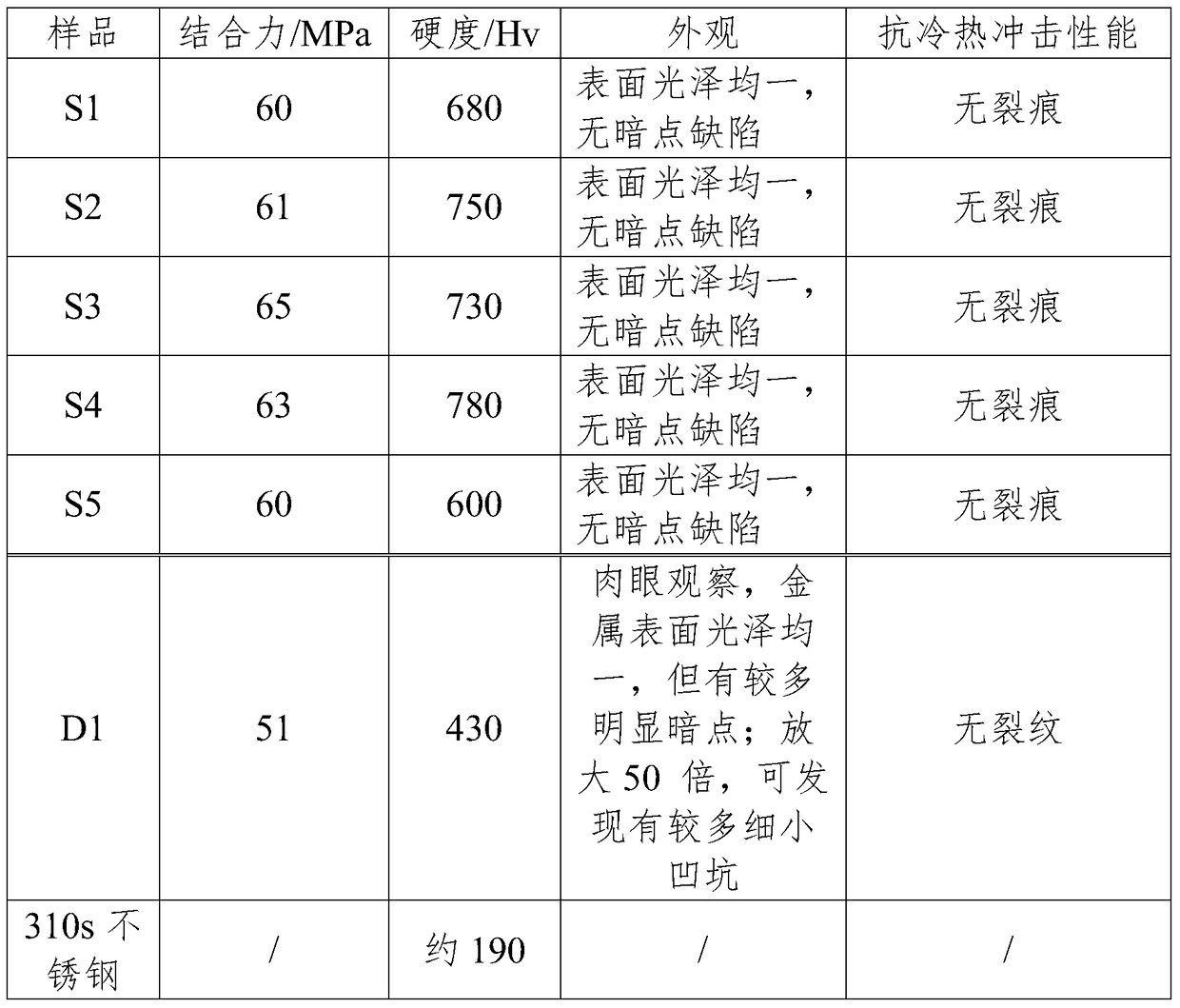

A kind of metal-ceramic composite body and preparation method thereof

For overcoming the problems of low hardness of a metal member, low combination force of the metal member with a ceramic base body, and poor appearance and performance in a metal / ceramic composite body in the prior art, the invention provides a metal / ceramic composite body which comprises a ceramic base body and a metal member, a groove being formed in the surface of the ceramic base body and the metal member being arranged in the groove. The metal member comprises a zirconium-based amorphous alloy base body and a reinforcing material in the amorphous alloy. The reinforcing material is one or more selected from W, Mo, Ni, Cr, stainless steel, WC, TiC, SiC, ZrC or ZrO2. Meanwhile, the invention also discloses a preparation method of the metal / ceramic composite body. In the metal / ceramic composite body, the surface hardness of the metal member is high and the metal member has strong combination force with the ceramic base body. The metal / ceramic composite body is excellent in appearance and performance.

Owner:BYD CO LTD

A halogen-free flame-retardant nylon composite material capable of laser marking and preparation method thereof

The invention relates to the technical field of laser-marked polymer materials, in particular to a laser-markable halogen-free flame-retardant nylon composite material and a preparation method thereof. The nylon composite material includes nylon resin, halogen-free flame retardant, flame retardant synergist, laser marking powder, black masterbatch, adsorbent, glass fiber, antioxidant and lubricant, so that the obtained nylon composite material has the following characteristics: It has excellent flame retardancy and high temperature and high humidity resistance, good tensile strength and bending strength, and good laser marking effect. In addition, the material has a simple preparation process, is environmentally friendly and clean, and has low cost, and can be directly laser marked in the product processing process to realize continuous and automatic industrial production.

Owner:东莞市东翔塑胶有限公司

Graphene wood-plastic micro-foaming material with uniform foam and preparation method of micro-foaming material

The invention discloses a graphene wood-plastic micro-foaming material with uniform foam and a preparation method of the micro-foaming material. The method comprises the following steps: a, washing wood powder by using an alkali, performing draining, performing ultrasonic wave-vacuum synergetic dispersion on the dried wood powder, silicon micropowder and graphene under the protection of an inert gas, performing washing by using water, performing drying, and linking the silicon micropowder, the wood powder and the graphene to form micro fine powder to obtain composite powder under the action ofthe alkali at the surface of the wood powder treated by the alkali; b, mixing the composite powder, resin and a zeolite molecular sieve to prepare a mixed material; c, performing extrusion granulation on the mixed material to obtain mixed granules; and d, adding a foaming agent into the mixed granules, and performing micro-foaming injection molding to obtain the wood-plastic composite material with the uniform foam. The method disclosed by the invention greatly eliminates moisture in the bamboo wood powder, reduces high-temperature damage to the wood powder structure, and has a safe and high-efficiency drying manner; and the obtained bamboo wood powder has good and strong interface bonding performance with the resin, micropores generated by foaming have regular shapes, small pore diameters, uniform distribution, foaming quality is good, so that the composite material has good surface hardness, good toughness, high strength, and a wide application range.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Novel aluminum alloy and surface treatment process thereof

PendingCN113463011AGood compatibilityReduce surface tensionAnodisationMolten spray coatingChromium carbideAnodic oxidation

The invention relates to the technical field of metal surface treatment, in particular to a novel aluminum alloy and a surface treatment process thereof. The novel aluminum alloy comprises an aluminum alloy body, an anodic oxide film layer coating the surface of the aluminum alloy body and a chromium carbide coating sprayed to the surface of the anodic oxide film layer, and nano micropores are formed in the outer surface of the anodic oxide film layer; and the pore size of the nano micropores is 5-10 nm, and the thickness of the anodic oxide film layer is 5-8 mu. According to the novel aluminum alloy, the aluminum alloy body is subjected to anodic oxidation to form the anodic oxide film layer with high adsorption capacity, and the anodic oxide film layer has good adsorption capacity due to the fact that the anodic oxide film layer contains the nano-scale nano micropores, so that the binding force between the anodic oxide film layer and the chromium carbide coating is enhanced conveniently; and compared with a traditional anodic oxidation aluminum alloy, the aluminum alloy has better metal texture and decoration performance. Meanwhile, the mechanical properties such as corrosion resistance and strength of the aluminum alloy base material can be improved by overlapping the anodic oxide film layer and the chromium carbide coating.

Owner:东莞金稞电子科技有限公司

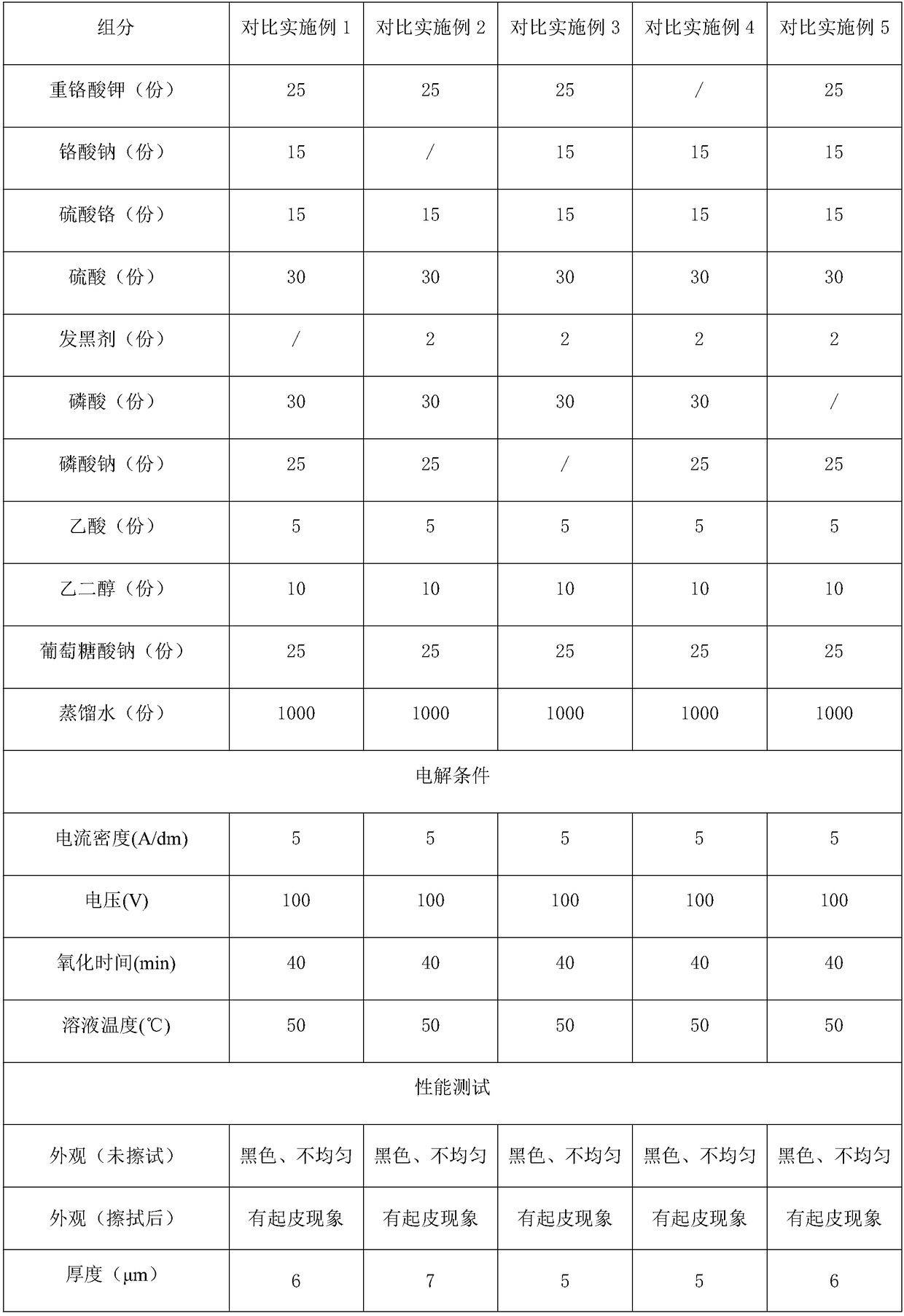

A kind of titanium-magnesium alloy anodic oxidation coloring method

ActiveCN106835238BEasy maintenanceImprove bindingSurface reaction electrolytic coatingPhosphatePhosphoric acid

The invention discloses an anodizing coloring method for a titanium-magnesium alloy. The method comprises steps as follows: (1), pretreatment; (2), anodizing: an anodizing solution is prepared from 20-60 parts by weight of potassium dichromate, 10-30 parts by weight of chromate, 10-20 parts by weight of sulfate, 10-50 parts by weight of sulfuric acid, 2-4 parts by weight of a blackening solution, 25-40 parts by weight of phosphoric acid, 20-40 parts by weight of phosphate, 1-10 parts by weight of acetic acid, 10-20 parts by weight of ethylene glycol, 15-30 parts by weight of sodium gluconate and 700-1,000 parts by weight of distilled water through mixing, a sample is taken as a working electrode, graphite is taken as an auxiliary electrode, the working electrode and the auxiliary electrode are completely soaked in the anodizing solution for anodizing; (3), follow-up treatment. The method is simple and easy, oxidation films with different thicknesses and good compactness can be obtained by controlling different voltage values, pH values of the anodizing solution and power-on time, and the market requirement of anodizing for metal surface treatment is met.

Owner:FOSHAN KEITH TITANIUM TECH CO LTD

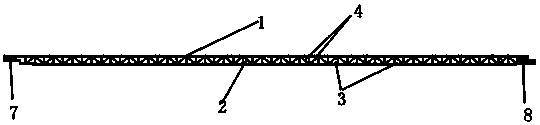

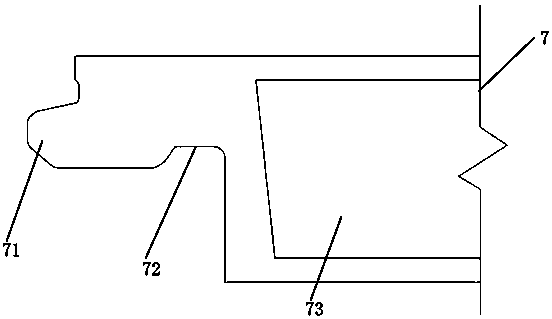

Square-hole hollow bidirectional oblique-pulling-type decorative plate

InactiveCN107654036AEasy constructionRest assuredCovering/liningsFlooringEngineeringMechanical engineering

The invention discloses a square-hole hollow bidirectional oblique-pulling-type decorative plate. The decorative plate comprises a decorative plate body. The decorative plate body is of a hollow structure. The hollow structure is formed by arranging and combining a plurality of square holes with the same structure and size at equal intervals. A diagonal reinforcing tendon is obliquely pulled in each square hole. Obliquely-pulling directions of the diagonal reinforcing tendons in any two adjacent square holes are opposite. One side of the decorative plate body is provided with a male part machined block of a reserved tenon groove fixing part. The other side of the decorative plate body is provided with a female part machined block of the reserved tenon groove fixing part. The decorative plate body, the male part machined block of the reserved tenon groove fixing part and the female part machined block of the reserved tenon groove fixing part are in integral structure. The square-hole hollow bidirectional oblique-pulling-type decorative plate is used in the wall surfaces or roof decoration, the weight is low, the installation speed is high, visual integrity is high, appearance is beautiful, pressure borne by the plate body is high, and the decorative plate further has the advantages of being fireproof, waterproof, green, environment-friendly, formaldehyde-free, odorless, capableof being immediately installed and immediately lived and the like.

Owner:无锡磐石新型建材科技有限公司

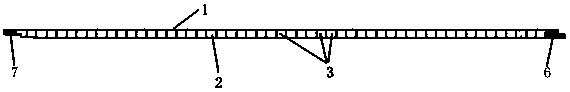

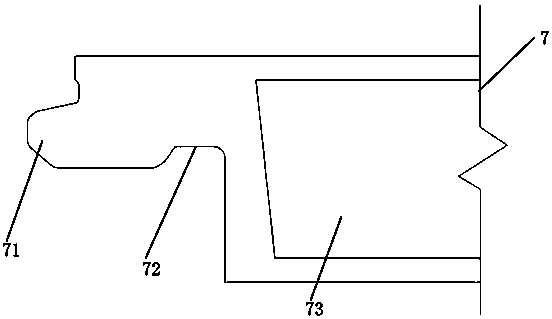

Square hole hollow type decorative sheet

The invention discloses a square hole hollow type decorative sheet. The decorative sheet comprises a decorative sheet body which is of a hollow structure, and the hollow structure is formed by arranging and combining square holes with the same structure and size at equal intervals; one side of the decorative sheet body is the male processing end of a reserved mortice fixing part, and the other side of the decorative sheet body is the female processing end of the reserved mortice fixing part; the decorative sheet body, the male processing end of the reserved mortice fixing part and the female processing end of the reserved mortice fixing part are of an integrated structure. The decorative sheet is applied to decoration of the wall surface or the top, the weight is low, the installation speed is high, the splicing gap is small and can hardly be seen with eyes, the visual integrity is high, the appearance is attractive, and the decorative sheet has the advantages of being resistant to fire and water, green, environmentally friendly, free of formaldehyde and odor, capable of making people live just after decoration and the like.

Owner:无锡磐石新型建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com