UV ink printed metal gusset plate for ceiling decoration

A technology of ink printing and ceiling decoration, which is applied in the field of building decoration materials, can solve the problems of low production efficiency, large environmental pollution, poor paint film performance, etc., and achieve the effects of high production efficiency, low equipment investment and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

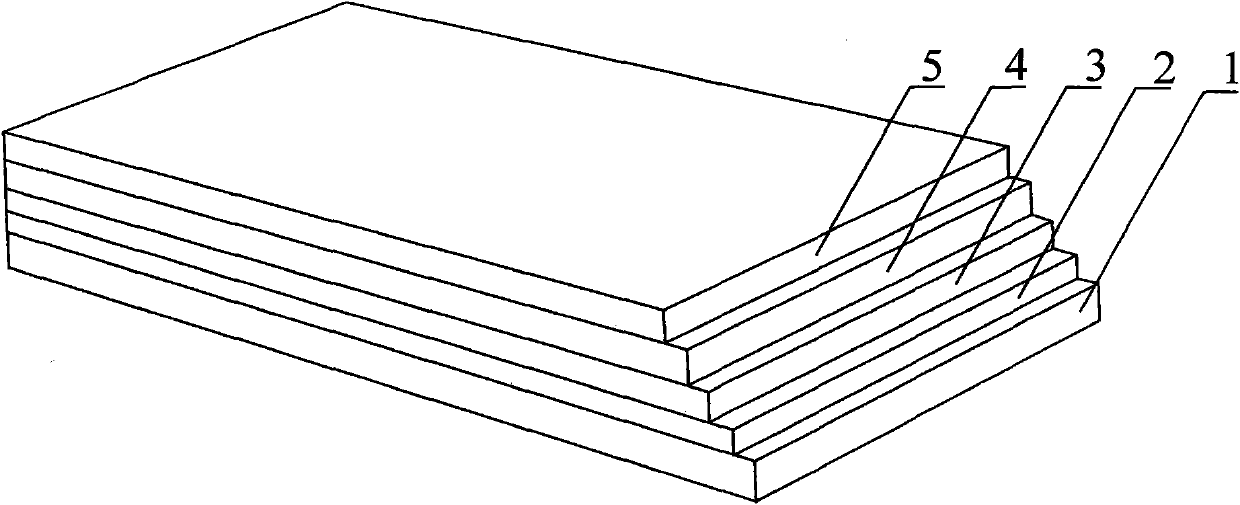

[0026] Example 1. Brown Low, Vitreous Layer Metal Gusset

[0027] The metal base is a wire-drawn aluminum plate. Now tear off the film of the base 1 and remove the dust on the surface, and then roll-coat a layer of varnish 2 with a thickness of 30um on the surface of the metal base, and then enter it into two 9.6kw ultraviolet lamps (high-pressure mercury lamps) ), in a light curing machine with a transmission speed of 20 m / min, after curing, brush a layer of brown UV ink 3 on the surface of the varnish (the thickness of the coating is 60um, and the gloss is 30 degrees). Stay flat for 1 minute, enter the light curing machine equipped with 2 9.6kw iodine lamps and 2 9.6kw ultraviolet lamps (high-pressure mercury lamps), and the transmission speed is 20 m / min. One layer of transparent UV ink 4 is printed on the surface of the brown UV ink, (the thickness of the ink layer is 150um, and the glossiness is 90), and two 9.6kw iodine marriage lamps and two 9.6kw ultraviolet lamps (hig...

Embodiment 2

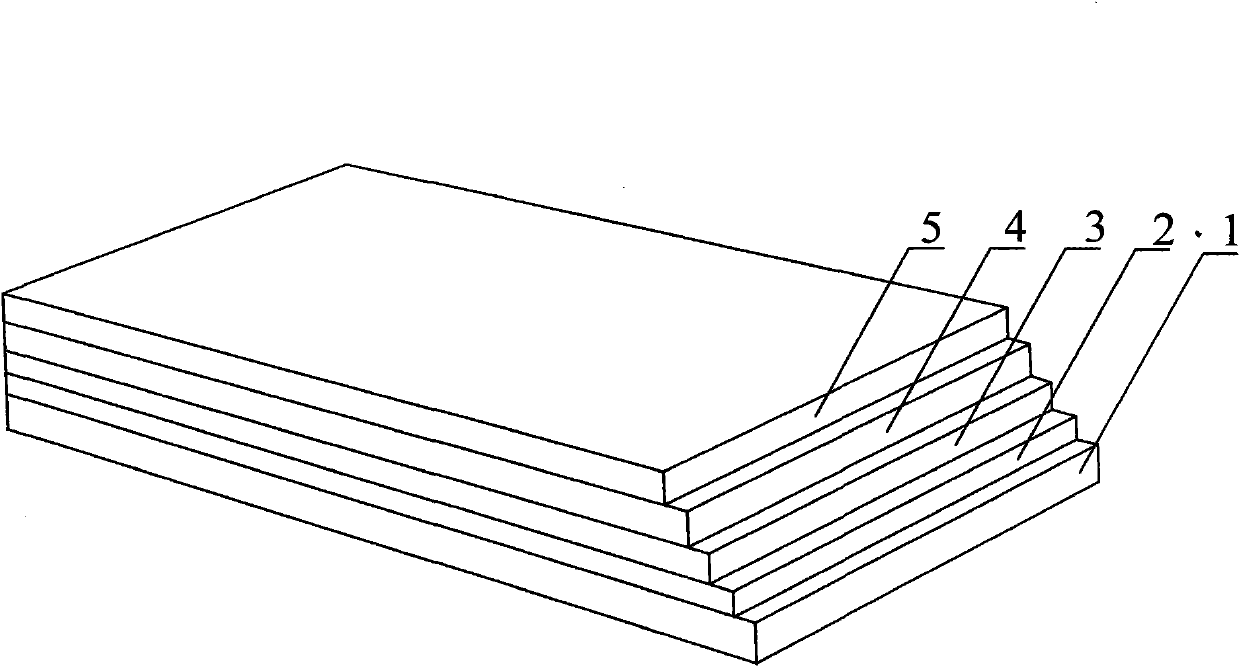

[0031] Example 2. Silver, Vitreous Layer Metal Gusset

[0032] The metal base layer is an alumina plate. Now tear off the film of the substrate 1 and remove the dust on the surface. Brush a layer of silver UV ink 2 on the surface of the substrate (the thickness of the coating is 60um and the gloss is 30 degrees). Stay flat for 1 minute, enter the light curing machine equipped with two 9.6kw iodine lamps and two 9.6kw ultraviolet lamps (high-pressure mercury lamps), and the transmission speed is 20 m / min. After curing, the brown color is cured by ultraviolet light. A layer of transparent UV ink 3 is printed on the surface of the UV ink, (the thickness of the ink layer is 150um, the glossiness is 90), and two 9.6kw iodine marriage lamps and two 9.6kw ultraviolet lamps (high pressure mercury lamps) are installed in it, and the transmission speed is 20 In the light curing machine of m / min, after curing, the inspection index reaches the qualified standard, and the polypropylene fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com