A kind of metal-ceramic composite body and preparation method thereof

A metal-ceramic and composite technology, applied in the field of metal-ceramic composite and its preparation, can solve the problems of weak bonding force of ceramic matrix, poor appearance performance, low hardness of metal parts, etc. , the appearance of the perfect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing a metal-ceramic composite, comprising:

[0028] S1, providing a ceramic substrate, the surface of the ceramic substrate has grooves;

[0029] S2. Fill the groove with reinforcing particles, and then sinter at 1000°C-1200°C in a protective atmosphere to form a skeleton-shaped reinforcing material in the groove; the reinforcing particles are selected from W, Mo, Ni, Cr, Stainless steel, WC, TiC, SiC, ZrC or ZrO 2 one or more of

[0030] S3, infiltrating the molten amorphous alloy in the groove filled with the reinforcing material, and obtaining a metal-ceramic composite body after cooling.

[0031] As mentioned above, the coefficient of thermal expansion of the ceramic matrix obtained above is preferably 7-10×10 -6 K -1 . Specifically, the above-mentioned ceramic matrix is preferably made of zirconia ceramics.

[0032] According to the present invention, the surface of the ceramic substrate used to prepare...

Embodiment 1

[0060] This example is used to illustrate the cermet composite and its preparation method disclosed in the present invention.

[0061] (1) Weigh 300g W powder (particle size D50 is 1μm, thermal expansion coefficient is 4.6×10 -6 K -1 ) and 1.2g of silane coupling agent 9116 were dissolved in 25g of methyl silicone oil, and the two were stirred for about 2 hours to mix evenly, and defoamed in a vacuum oven for 30 minutes to obtain a W-containing slurry, which was coated on the blank Zirconia ceramics with a depth of 0.25 mm and a width of 0.5 mm formed during body preforming (the coefficient of thermal expansion is 10×10 -6 K -1 ) on the surface groove, fill the groove, and defoam again in the vacuum drying oven for 30 minutes, then put the zirconia ceramics into the vacuum resistance furnace for sintering, raise the temperature to 600°C at 2°C / min, and Keep it warm for 1h, then raise the temperature to 1100°C at 10°C / min, and keep it warm for 1h to form a skeleton-like rein...

Embodiment 2-5

[0064] This example is used to illustrate the cermet composite and its preparation method disclosed in the present invention.

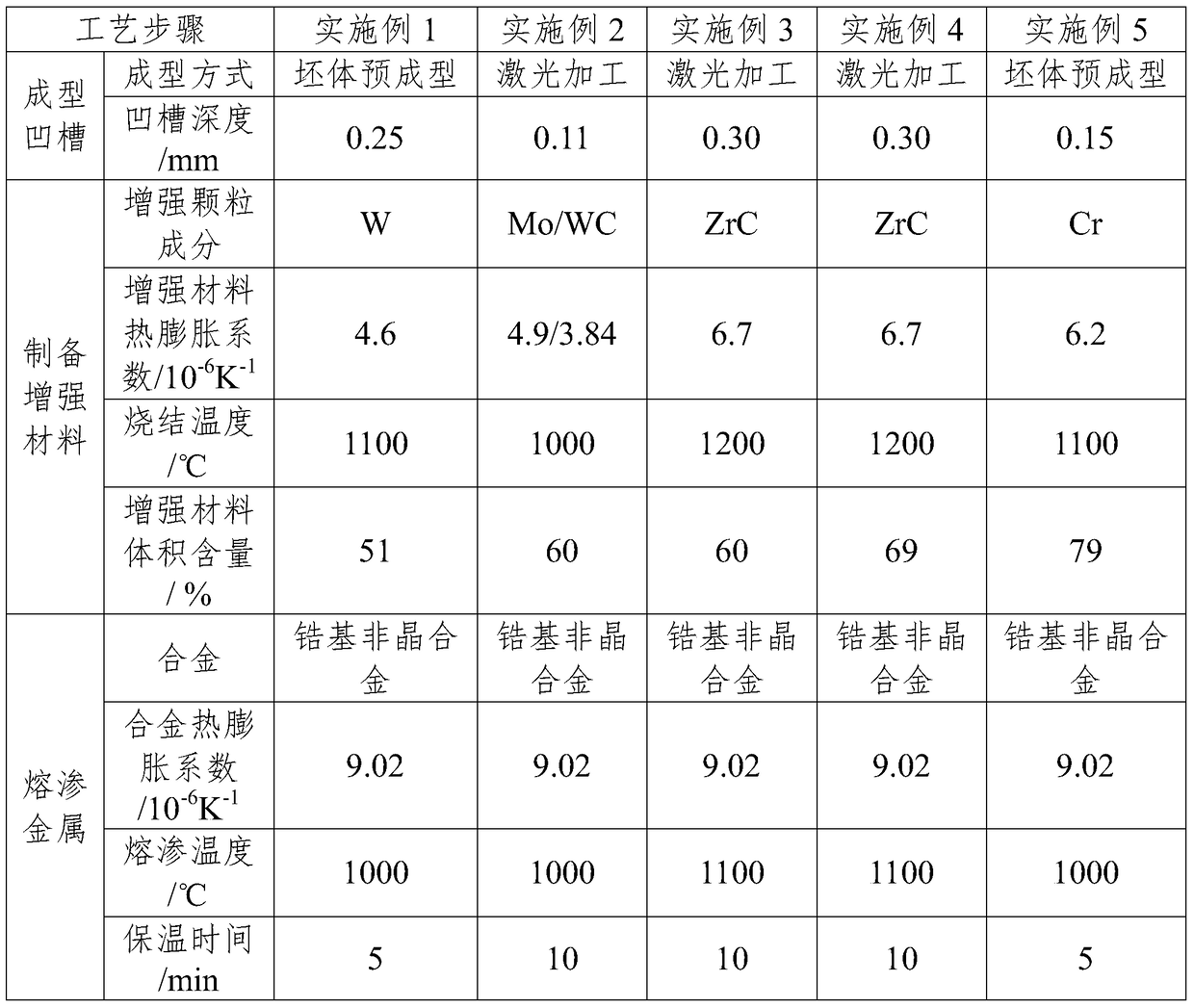

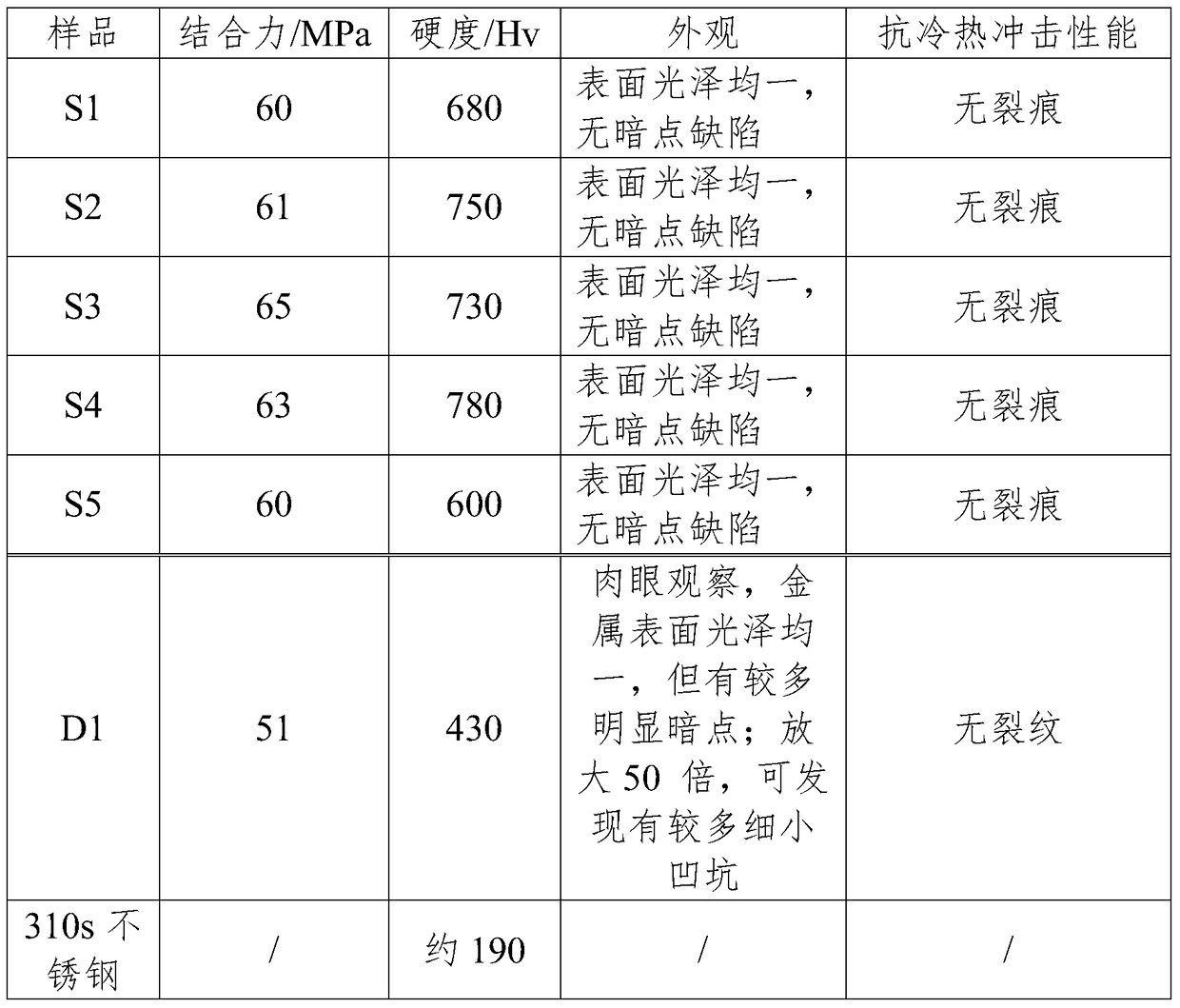

[0065] Using the same method as in Example 1 to prepare metal-ceramic composite samples S2-S5,

[0066] The different specific parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com