Coating for replacing electronic product screen protection film and preparation method

A technology for electronic products and coatings, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as inability to remove well, unsatisfactory protection effect, etc., and achieve good light transmittance, good flexibility, resistance to Good abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

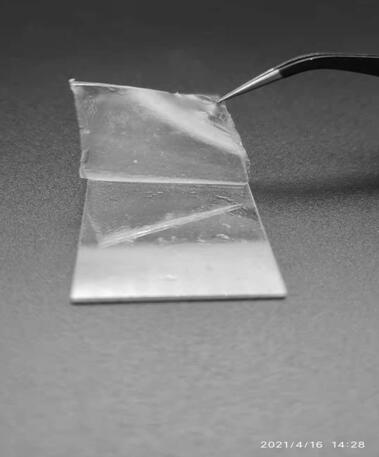

Image

Examples

Embodiment 1

[0036] (1) Mix 35kg PET and 70kg SBS evenly, then knead and extrude through a screw extruder to granulate, then pulverize through a jet mill, and discharge to obtain a composite powder with an average particle size of 6 μm;

[0037] (2) Add 100kg of composite powder into a high-speed mixer, then stir at a constant temperature and high speed, control the temperature at 100°C, control the speed at 1300rpm, stir for 8 minutes, then spray 2kg of ammonia water and 10kg of perhydropolysilazane in sequence, and continue stirring for 25 minutes. Discharging to obtain surface-treated composite powder;

[0038] (3) Mix 12.kg of surface-treated composite powder, 0.8kg of polytetrafluoroethylene powder, 45kg of polyurethane acrylate, and 0.15kg of BYK-333 leveling agent from Germany BYK at high speed, and then add 11kg of tripropylene glycol diacrylate , 1.5kg of α,α'-diethoxyacetophenone, dispersed evenly, and then filled with shading, to obtain a paint that can replace the screen protec...

Embodiment 2

[0040] (1) Mix 35kg PET and 70kg SBS evenly, then knead, extrude and granulate through a screw extruder, then pulverize through a jet mill, and discharge to obtain a composite powder with an average particle size of 3 μm;

[0041] (2) Add 100kg of composite powder into a high-speed mixer, then stir at a constant temperature and high speed, control the temperature at 98°C, and control the speed at 1250rpm, stir for 9 minutes, then spray 1.5kg of ammonia water and 7kg of perhydropolysilazane in sequence, and continue stirring for 22 minutes , discharging to obtain surface-treated composite powder;

[0042] (3) Stir 11kg of surface-treated composite powder, 0.6kg of polytetrafluoroethylene powder, 48kg of polyurethane acrylate, and 0.12kg of BYK-306 leveling agent from Germany BYK at high speed, and then add 10.5kg of tripropylene glycol diacrylate, 1.2kg of 2-hydroxy-2-methyl-1-phenylacetone, dispersed evenly, and then filled with shading, can get a kind of coating that replaces...

Embodiment 3

[0044] (1) Mix 35kg PET and 70kg SBS evenly, then knead, extrude and granulate through a screw extruder, then pulverize through a jet mill, and discharge to obtain a composite powder with an average particle size of 9 μm;

[0045] (2) Add 100kg of composite powder into a high-speed mixer, then stir at a constant temperature and high speed, control the temperature at 102°C, and control the speed at 1350rpm, stir for 7 minutes, then spray 2.5kg of ammonia water and 12kg of perhydropolysilazane in sequence, and continue stirring for 28 minutes , discharging to obtain surface-treated composite powder;

[0046] (3) Stir 14kg of surface-treated composite powder, 0.9kg of polytetrafluoroethylene powder, 42kg of polyurethane acrylate, and 0.18kg of German BYK leveling agent BYK-310 at high speed, and then add 11.5kg of tripropylene glycol diacrylate, 1.8kg of 1-hydroxycyclohexyl phenyl ketone, dispersed evenly, and then filled with shading, can obtain a kind of coating that replaces t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com