Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

248results about How to "Guaranteed weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh-strength atmospheric-corrosion resistant steel

The invention discloses a hyperstrength atmospheric corrosion-tolerant steel, which comprises the following parts: 0.01-0.07% C, 0.25-0.50% Si, 1.60-2.00% Mn, not more than 0.018% P, not more than 0.008% S, 0.20-0.50% Cu, 0.40-0.75% Cr, 0.25-0.60% Ni, 0.03-0.08% Nb, 0.10-0.40% Mo, not more than 0.02 Ti, not more than 0.035% Als, not more than 0.003% B and Fe and impurity.

Owner:武钢集团有限公司

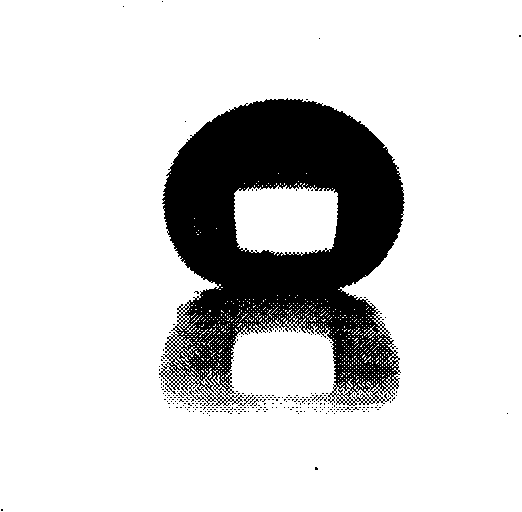

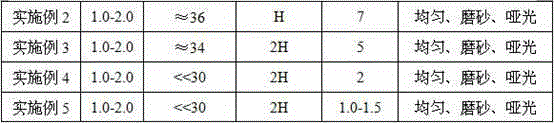

Ultra-discharging water-soluble fluor-silicon-acrylic coatings with nano particles

InactiveCN101307210AWide variety of sourcesInexpensive and easy to obtainEmulsion paintsMechanical propertyNuclear chemistry

The invention discloses a super-hydrophobic water fluorine silicone / acrylic paint containing nanoparticles. The paint is prepared by mixing the compositions by weight percentage: 30 to 65 percent of water, 10 to 40 percent of silicone-acrylate emulsion, 10 to 40 percent of water fluoro-polymer emulsion, 1 to 10 percent of nano-meter oxid particles, 1 to 15 percent of inorganic hole compound and a small quantity of inorganic acid used for adjusting the pH value. The invention also discloses a super-hydrophobic water fluorine silicone / acrylic coating prepared by the paint. The water static wrapping angle of the coating is more than 150 degrees and a rolling angle is lower than 5 degrees. The coating prepared by the paint has the advantages of super-hydrophobicity, excellent mechanical property and easy process, etc. and has the self-cleaning function similar to a lotus leaf.

Owner:胡硕

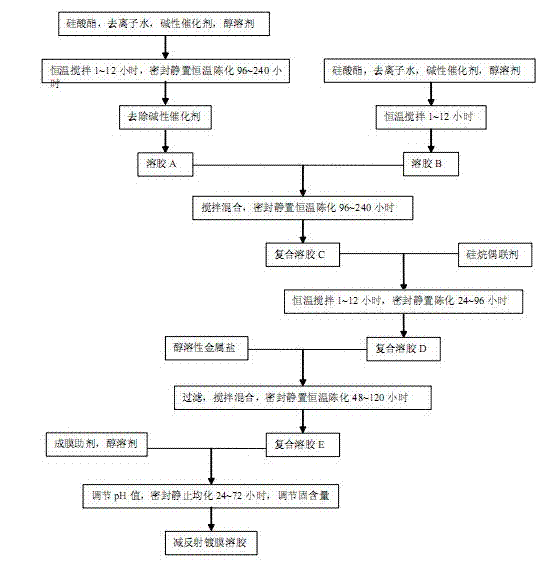

Composite sol for anti-reflection coating and anti-reflection coated photovoltaic glass

InactiveCN102850894AHigh mechanical strengthImprove smoothnessCoatingsColloidal chemistry detailsWeather resistanceSolar cell

The invention relates to the field of manufacture of packaging glass for solar cells, and especially relates to a multi-step catalyzed composite sol for anti-reflection coating, and anti-reflection coated photovoltaic glass manufactured by the composite sol. The composite sol for anti-reflection coating is prepared from the following raw materials by the following method which comprises steps of: preparing sol A, preparing sol B, preparing composite sol C, preparing composite sol D, preparing composite sol E, and preparing the composite sol for anti-reflection coating. An anti-reflection film coated by the sol only needs coating once; therefore the production cost is low, and the process is high-efficient and easily-controlled; the composite sol of the invention is suitable for large-area coating production of photovoltaic glass; the coated product can pass related examinations, such as film hardness, adhesion, and weatherability.

Owner:杭州美格玻璃有限公司

POSS (Polysilsesquioxane)-containing antireflective film coating liquid and preparation method and application thereof

The invention discloses a POSS (Polysilsesquioxane)-containing antireflective film coating liquid and a preparation method and application thereof, and belongs to the field of film coating liquids. The preparation method of the POSS-containing antireflective film coating liquid comprises the following steps of: adding the following raw materials in percentage by weight: 0.01%-20% of POSS derivatives, 0-10% of nanometer silicon dioxide granules, 0%-10% of hollow silicon dioxide, 0%-5% of non-silicon nanometer oxide granules, 0%-10% of organic silicon compounds, 0%-50% of deionized water and 0%-2% of catalysts into a solvent; and reacting at 20-150 DEG C for 0-45 hours to obtain the POSS-containing antireflective film coating liquid. The POSS-containing antireflective film coating liquid disclosed by the invention can be applied to photovoltaic glass, display screen base plate glass, building glass and automobile glass; and the obtained antireflective film has the advantages of good film layer uniformity, high adhesive force and rigidity and good weather resistance.

Owner:武汉绿凯科技有限公司

Building thermal insulation dry powder mortar

A building thermal insulation dry powder mortar belongs to a building thermal insulation material. The weight ratio of a dry powder to water is 1: 1.5. The dry powder is prepared by mixing 450 parts by mass of ordinary portland cement, 70 parts by mass of a calcined gypsum powder, 37.5 parts by mass of a redispersible emulsion powder, 15 parts by mass of fine xylem fibers, 13 parts by mass of polypropylene staple fibers, 10 parts by mass of slaked lime, 10 parts by mass of sierozem, 10 parts by mass of heavy calcium carbonate, 3 parts by mass of hydroxypropyl methyl cellulose, 364 parts by mass of a calcined expanded perlite and 17.5 parts by mass of a premixed auxiliary agent. The thermal insulation building dry powder mortar has the advantages of strong thermal insulation, strong bond with walls, high compressive strength, strong drawing force, excellent weather resistance, and environmental protection, and also has the advantages of fire resistance, cracking resistance, leakage resistance, moisture resistance, sliding resistance, earthquake resistance and the like.

Owner:王荣

Matt release film

ActiveCN105348946ASolve technical problems caused by residuesHigh residual adhesionCoatingsPolymer scienceAcrylic resin

The invention relates to a matt release film. The matt release film comprises a base film and a matt release coating layer arranged at one side of the base film; and the matt release coating layer is formed by coating a fluorine-containing thermosetting coating, and the coating comprises fluorine series resin, acrylic resin, aldehyde ketone resin, a curing agent system, an assistant, a delustering agent and a mixed solvent. The matt release film has the advantages of low surface tension, good adhesiveness and overcoatability, excellent heat and solvent resistance, and high residual adhesion rate and excellent matt effect after peeling when the matt release film is used in the field of electron manufacturing.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

Transparent protective coat for concrete

The invention belongs to the technical field of anticorrosive materials and discloses a transparent protective coat for concrete. According to a three-layer matched scheme of a combined action principle of physical shielding and chemical sealing, the transparent protective coat for concrete comprises a base coat, a floating coat and a topcoat, wherein the base coat is alkyl alkoxy silane, the floating coat is a cationic acrylic polymer emulsion film-forming system; the topcoat is a water-based fluorocarbon resin and polyurethane associative thickener system with pH value of 8-9; the content of the water-based fluorocarbon resin is not less than 20%; the minimum film-forming temperature is not less than 27 DEG C. The transparent protective coat for the concrete has high permeability and excellent sealing property for the concrete, is simple and convenient to construct, transparent in coating and excellent in stain resistance, avoids water dampness and discoloration of the concrete, inhibits nonuniform absorption of the concrete, effectively prevents the concrete surface from blackening, keeps the natural surface effect of the concrete, and is suitable for the protection and application field of various reinforced concrete structures.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

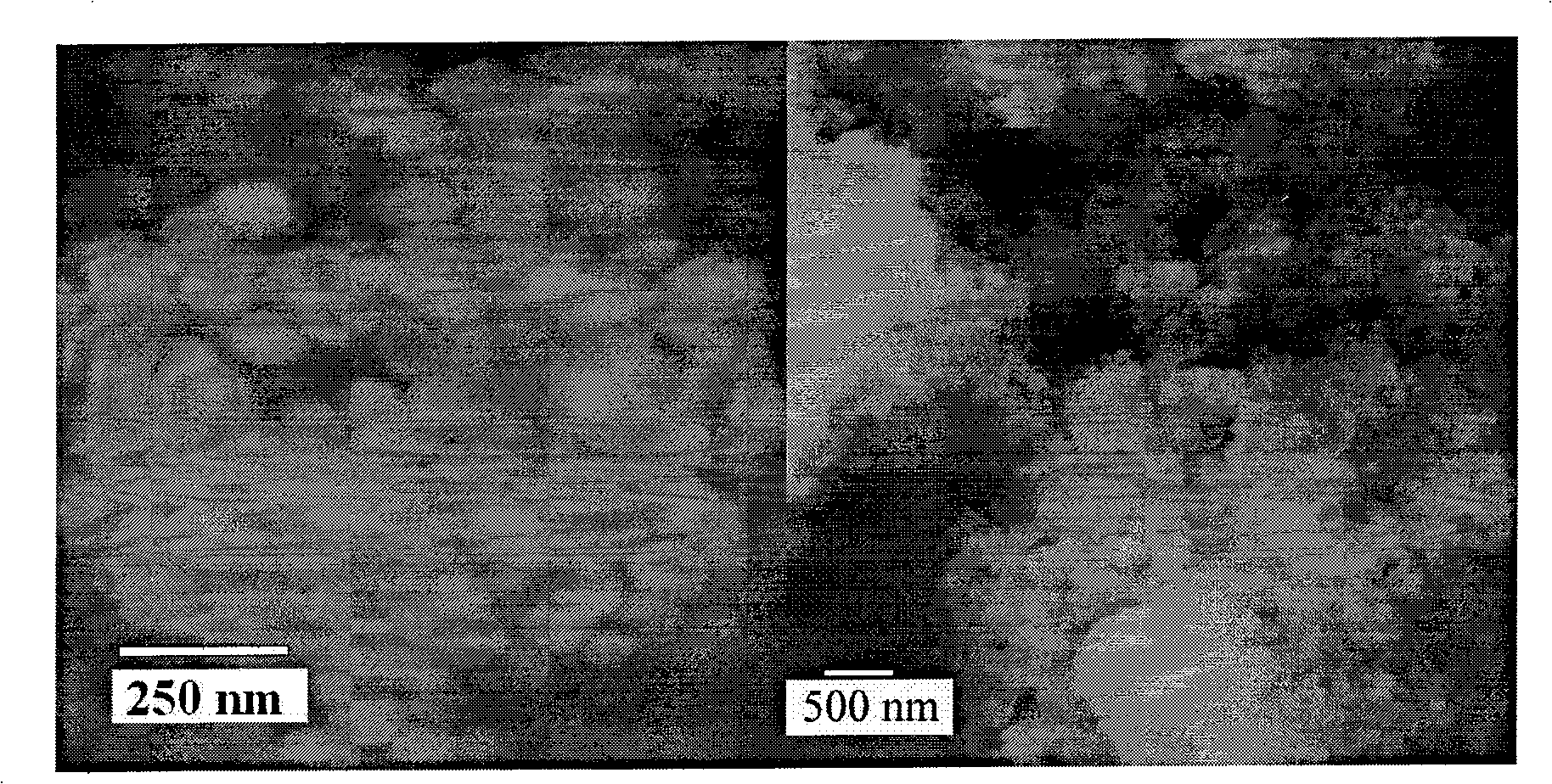

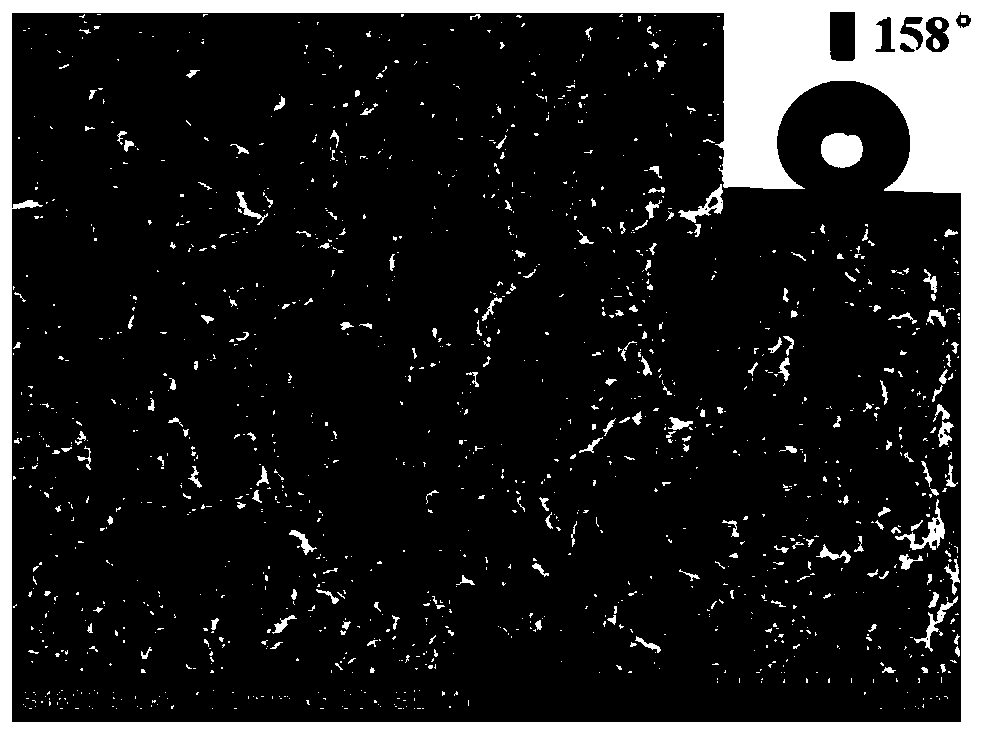

Super-hydrophobic self-cleaning radiation cooling film and preparation method thereof

ActiveCN110483924AMild conditionsLow surface energy propertiesFlat articlesCoatingsNon solventMicro nano

The invention discloses a super-hydrophobic self-cleaning radiation cooling film and a preparation method thereof. The preparation method comprises the following steps: dissolving P (VDFx-Co-HFPy) andPDMS in a composite polar solvent to form a P (VDFx-Co-HFPy) / PDMS polymer composite semitransparent solution; dropwise adding a non-solvent into the solution to enable P (VDFx-Co-HFPy) / PDMS to be subjected to phase separation to form sol; and casting and drying the sol to obtain the film with the micro-nano dual porous structure. The preparation process is simple, the method is easy to implement,and large-area production can be achieved.

Owner:SHAANXI UNIV OF SCI & TECH

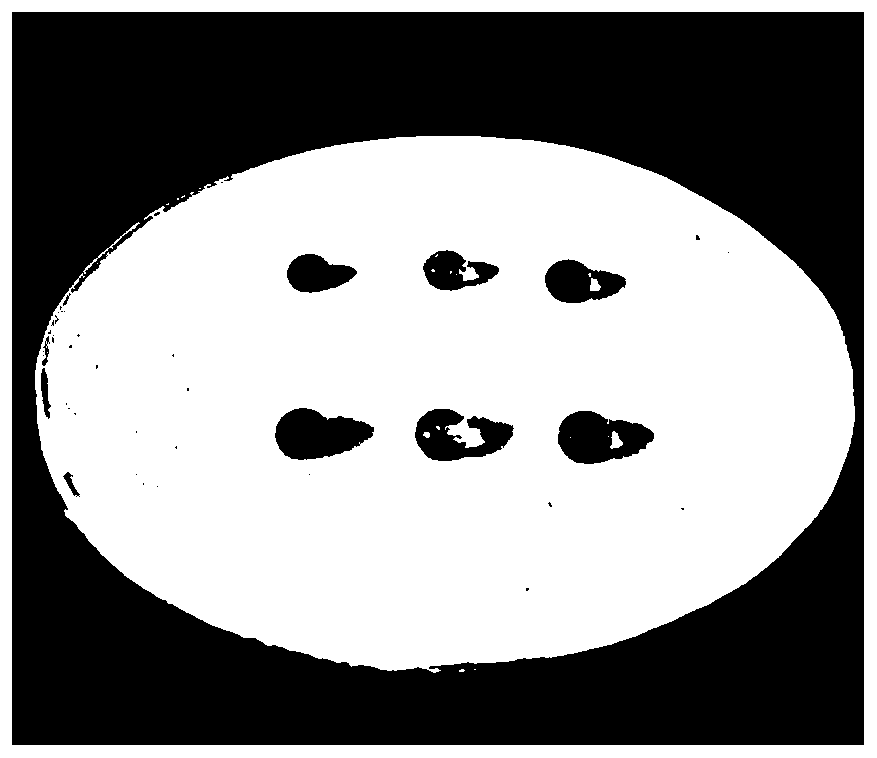

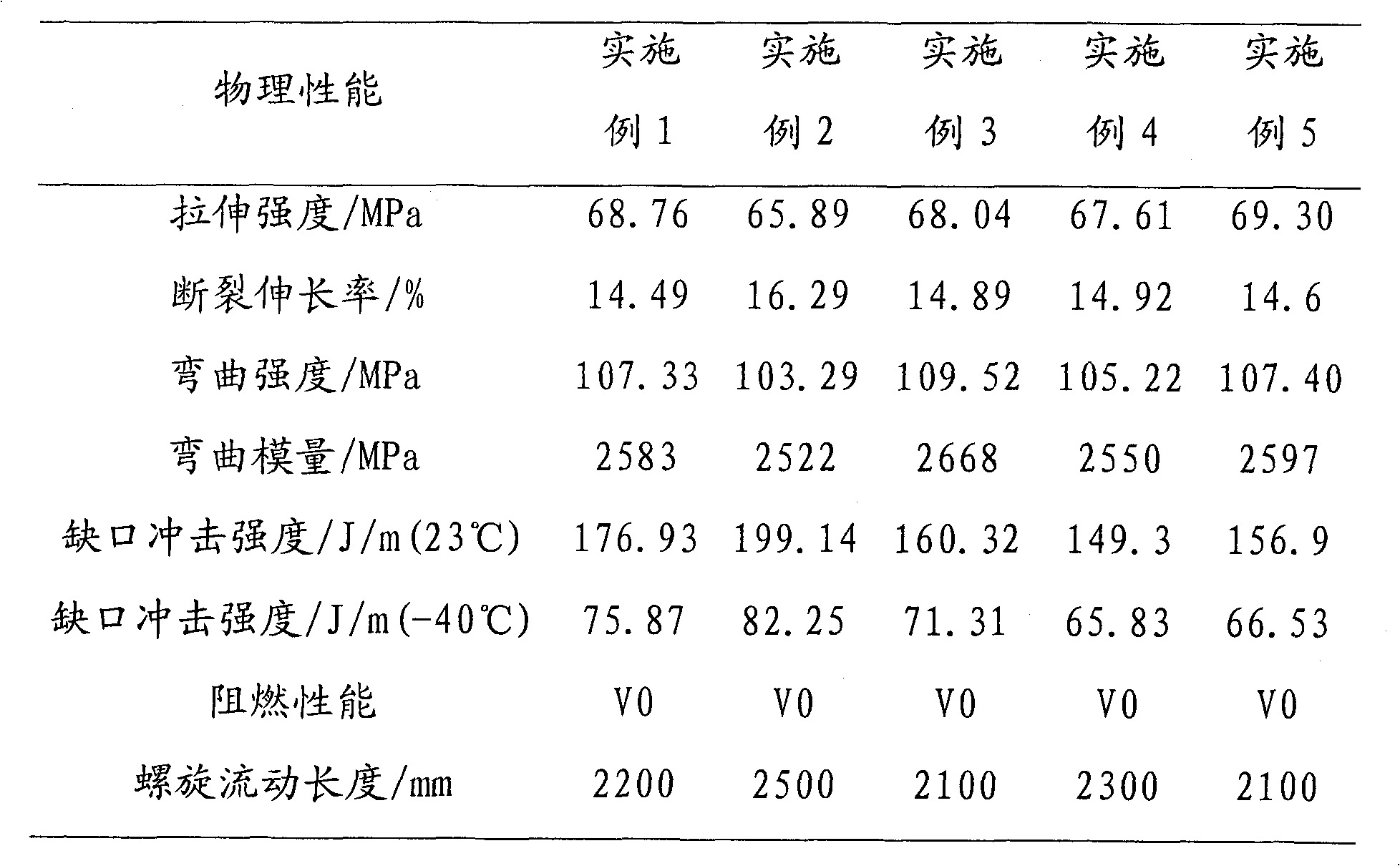

Polyphenyl ether compound used for solar battery connecting box

The invention discloses a polyphenyl ether compound used for a solar battery connecting box, comprising the following components in parts by weight: 60-80 parts of polyphenyl ether resin, 20-40 parts of high impact polystyrene resin, 1-5 parts of polyolefine resin, 5-12 parts of phosphorus flame retardant, 0.5-1 part of antioxygen and 0.1-0.5 part of anti-ultraviolet agent. The polyphenyl ether compound has the advantages of better rigidity, good low-temperature toughness, good flame retardant property, good insulating property, good weather resistance, easy processing shaping and the like. Products meet the requirements of the ROHS standard. The invention is suitable for producing the components of electronic and electrical products, such as the solar battery connecting box and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

Concrete-curing agent applicable to strong-wind arid area and preparation method thereof

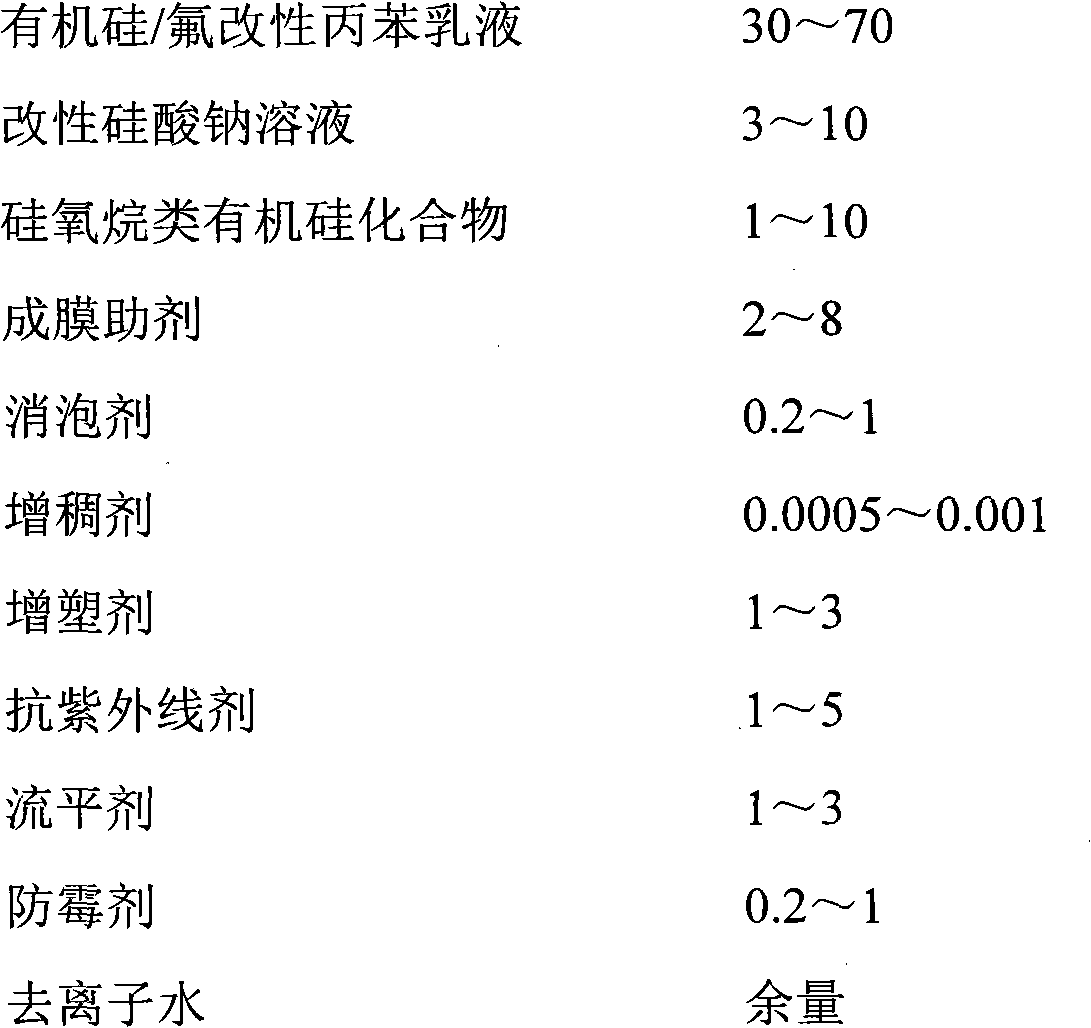

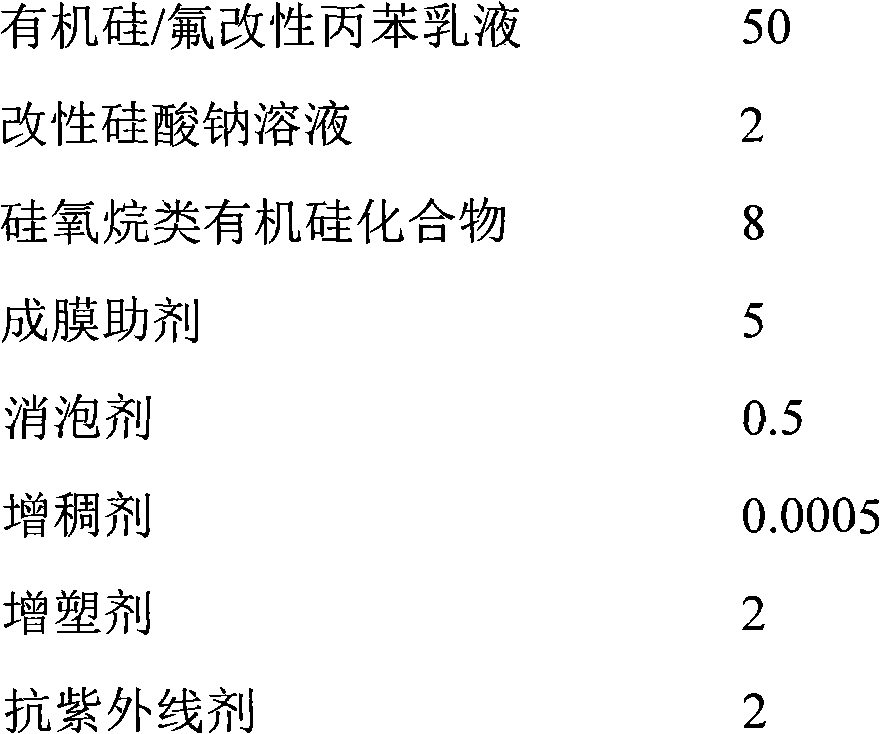

The invention relates to a concrete-curing agent applicable to a strong-wind arid area and a preparation method thereof. The curing agent is prepared through the following steps of: by using an organic / inorganic composite system with an organic-silicon / fluorine modified propyl-benzene emulsion and active aluminum-silicate modified sodium-silicate solution as a main fluid and adopting a siloxane organic-silicon compound with a certain reactive group as a cross-linked component, compounding with a film-forming aid, a defoaming agent, a thickening agent, a wetting and dispersing agent, a mildew-proof agent, a flatting agent, an ultraviolet-resisting agent and deionized water under the condition at a normal temperature. The production process of the concrete-curing agent is simple, and reaction conditions are easy to control. The water-resisting property, the scrubbing-resisting property, the durability and the flexibility of a film after the film of the curing agent is formed are improved by introducing the propyl-benzene emulsion of organic silicon / fluorine onto a high-molecular chain; and the compactness of the film is enhanced by introducing the modified sodium-silicate solution, thereby the water evaporation of a concrete surface is greatly reduced. The curing agent has the technical characteristics that the curing agent can be sprayed after concrete is finished, the film-forming speed is high, the water retention rate is high, ultraviolet rays are resisted, and the like, and is applicable to the concrete curing of western strong-wind arid areas.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Method of using poplar or poplar and paulownia to manufacture imitated precious wood

InactiveCN103895070AWide variety of sourcesGuaranteed uniformityWood treatment detailsWood veneer joiningPaulownia coreanaPaulownia

The invention discloses a method of using a poplar or the poplar and paulownia to manufacture imitated precious wood. The method comprises the steps of force drying, dyeing, vacuum pressing and dipping, thermo-compression forming and the like. In the method, a paulownia single plate and a poplar bundle are dyed into a required color and then are assorted and combined, and alternatively different polar bundles dyed into different colors are assorted and combined according to the different colors; a traditional scientific method that when the wood is manufactured, large-warp wood is rotationally cut into specification single plates, then drying, dyeing, gluing and thermo-compression sizing are conducted, so that the imitated precious wood is manufactured is changed. The method makes good use of waste materials, and the use rate of the wood can reach more than 90%.

Owner:CHINA PAULOWNIA RES CENT

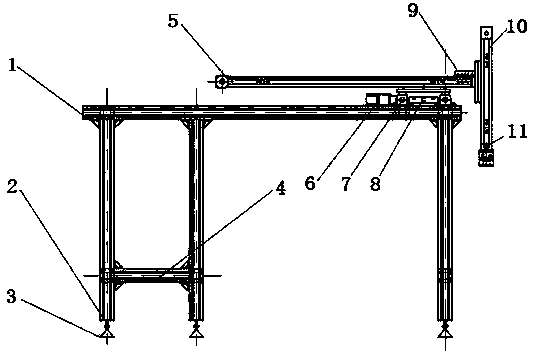

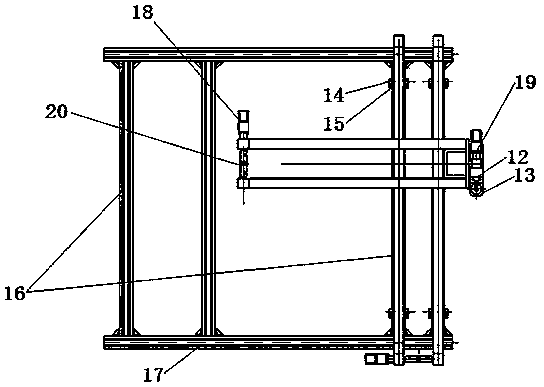

Automatic online mark spraying machine for steel plates

The invention discloses an automatic online mark spraying machine for steel plates. The automatic online mark spraying machine for steel plates comprises an equipment foundation rack, a three-dimensional coordinate positioning mechanism is installed on the equipment foundation rack and provided with an alternating current servo device connected with a computer, the computer controls the alternating current servo device to achieve three-dimensional movement positioning of the three-dimensional coordinate positioning mechanism, and the three-dimensional coordinate positioning mechanism is provided with a flow restraining device. Compared with the prior art, the automatic online mark spraying machine for steel plates can solve the problems that existing mark spraying equipment is huge and large in occupied space, specific temperature requirements are provided when the surfaces of steel plates are marked, the spray printing quality is poor, the existing mark spraying equipment is incompatible with existing enterprise equipment, the cost is high as the whole set of equipment needs to be imported, a spraying mechanism is not provided with a flow restraining device, and the environment of working sites is poor.

Owner:LIUZHOU IRON & STEEL

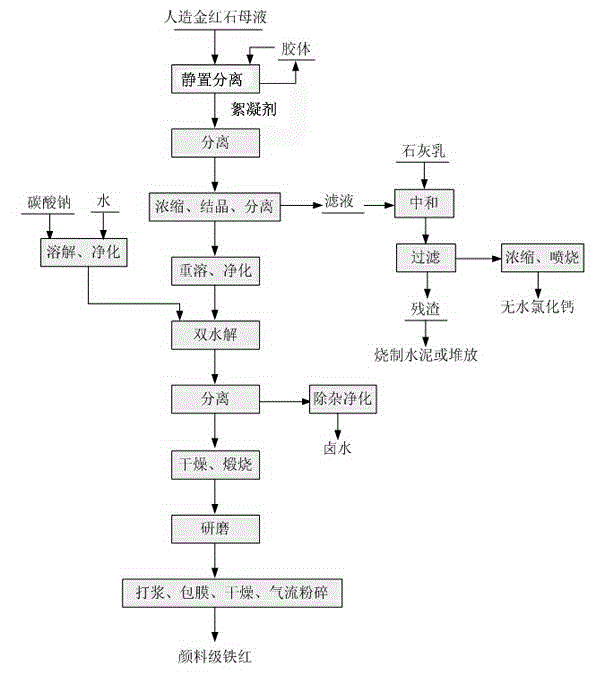

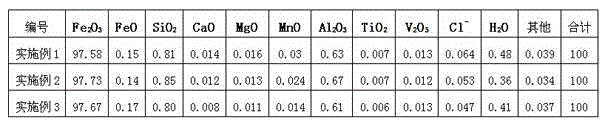

Novel method for recycling synthetic rutile mother liquor

ActiveCN104528834AQuality assuranceAvoid technical difficulties of separationInorganic pigment treatmentFerric oxidesRutileImpurity

The invention discloses a novel method for recycling synthetic rutile mother liquor. The method comprises the following steps: treating TiO2 colloid, mechanical impurities and a part of residual metal ions in the mother liquor, concentrating and crystallizing the pretreated mother liquor to obtain a ferrous crystal, re-dissolving the ferrous crystal in deionized water, adding iron powder to reduce, and adsorbing with modified activated carbon to obtain the purified solution of ferrous oxide; preparing the solution of sodium carbonate, adding a certain amount of a heavy-metal precipitating agent, and adding activated charcoal to purify; carrying out coprecipitation reaction on the purified solution of ferrous oxide and the purified solution of sodium carbonate under a certain condition, and introducing air to oxidize at the same time; filtering the product of reaction after reaction, and separating to obtain a filter cake; calcining the filter cake at a certain temperature, cooling, and grinding to obtain primary iron oxide red; and coating the primary iron oxide red, and pulverizing by gas flow to finally obtain the finished iron oxide red. By adopting the method provided by the invention, high-quality rutile mother liquor can be obtained, and the problem of poor economic benefit of the existing technology for treating synthetic rutile mother liquor can be solved.

Owner:YIBIN TIANYUAN GRP CO LTD +1

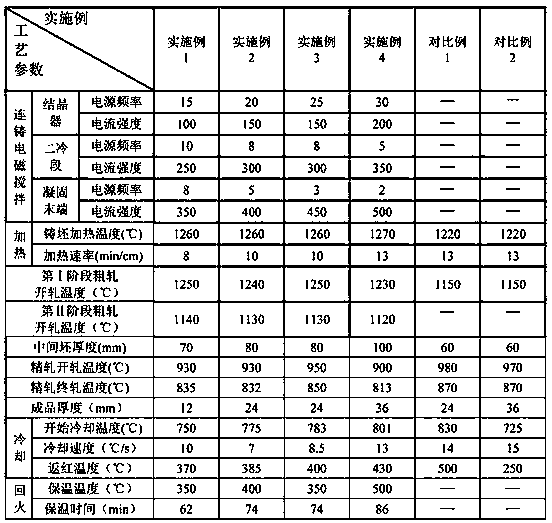

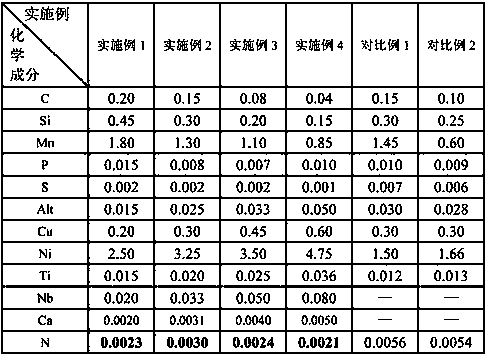

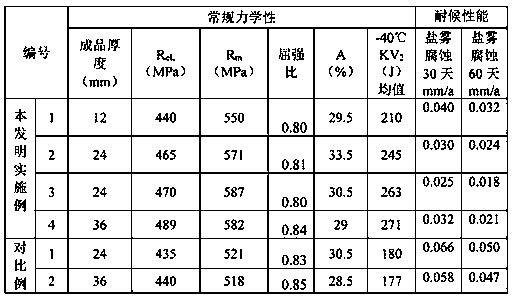

420 MPa grade low yield strength ratio resistance to marine atmospheric corrosion bridge steel and production method thereof

ActiveCN109136752AImprove low temperature impact toughnessImprove corrosion resistanceFurnace typesHeat treatment furnacesChemical compositionImpurity

The invention discloses a steel 420MPa grade low yield ratio marine atmospheric corrosion resistant bridge and a production method thereof, the steel comprises the following chemical components in percentage by mass: 0.04-0.20% of C, 0.15-0.45% of Si, 0.85-1.80% of Mn, 0.015-0.050% of Alt, 2.50-4.75% of Ni, 0.20-0.60% of Cu, 0.020-0.080% of Nb, 0.015 to 0.036 percent of Ti, 0.0020 to 0.0050 percent of Ca, less than or equal to 0.020%of P, less than or equal to 0.002%of S, less than or equal to 0.004%of N and the balance of Fe and other inevitable impurities; after the steel of passes the composition design, the inclusion control, the controlled rolling , the controlled cooling and heat treatment, the steel has the advantages of high strength, low yield strength, and can be used for manufacturing various bridges under the ocean atmospheric environment, and the safety of use is greatly improved.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

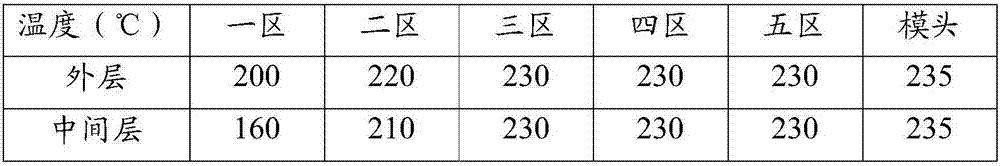

Polyvinylidene fluoride composite membrane and method for preparing same

InactiveCN107199752AImprove adhesionImprove aging resistanceSynthetic resin layered productsElectrical equipmentElastomerPolyolefin

The invention relates to a polyvinylidene fluoride composite film and a preparation method thereof, wherein the polyvinylidene fluoride composite film comprises: an outer PVDF layer, a middle layer and an inner polyolefin layer, wherein the middle layer is acrylic acid Copolymer layer or olefinic copolymer layer, wherein said acrylic acid copolymer comprises ethylene-acrylate EMA, ethylene-acrylic acid EAA, ethylene-ethyl acrylate EEA, ethylene-methacrylic acid copolymer EMAA and ethylene-methyl acrylate One or more of the copolymer EMAC; the olefinic copolymer layer is one or more of the graft-modified ethylene-vinyl acetate EVA and the graft-modified polyolefin elastomer POE. The polyvinylidene fluoride composite film and its preparation method in this invention are adopted, and the solar battery back plate prepared adopts the modified PVDF composite film, which has good bonding performance and good aging resistance effect, greatly reduces the production cost of the fluorine film, and The preparation method is simple and practical, and reduces the difficulty of compounding it with other substrates.

Owner:SHANGHAI HIUV NEW MATERIALS

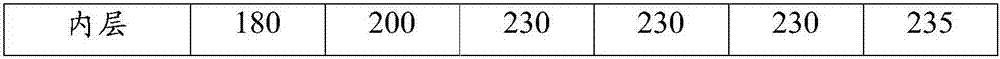

High-strength and high-weather-resistance cold-rolled dual-phase weather-resistant steel and manufacturing method thereof

ActiveCN112301276AHigh Yield StrengthGuaranteed weather resistanceFurnace typesHeat treatment furnacesWeather resistanceContinuous annealing

The invention discloses high-strength and high-weather-resistance cold-rolled dual-phase weather-resistant steel and a manufacturing method thereof, and relates to the technical field of metal plate manufacturing. The high-strength and high-weather-resistance cold-rolled dual-phase weather-resistant steel comprises the following chemical components in percentage by weight: 0.008-0.04% of C, 0.15-0.30% of Si, 0.20-0.50% of Mn, less than or equal to 0.020% of P, less than or equal to 0.01% of S, 0.35-0.45% of Cu, 0.25-0.40% of Ni, 3.5-5.0% of Cr, 0.025-0.050% of Als, 0.010-0.025% of Ti, equal toor less than 0.0080% of N, 0.0015-0.0035% of Ca and the balance of Fe and unavoidable impurities. According to the high-strength and high-weather-resistance cold-rolled dual-phase weather-resistant steel and the manufacturing method thereof, a 1.0 mm to 3.0 mm cold-rolled high-weather-resistance steel plate is obtained through reasonable chemical component design, hot rolling process control, acid rolling and continuous annealing processes, the material yield strength is higher than 350 MPa, the tensile strength is 500-700 MPa, the welding performance is excellent, and the relative corrosionrate is smaller than or equal to 30% (contrast sample Q345B), and the1.0 mm to 3.0 mm cold-rolled high-weather-resistance steel plate is used for the shell of a railway car, therefore, the steel platecan well adapt to high-speed development of high-speed trains, and the weather resistance of bullet train carriages is well guaranteed.

Owner:MAANSHAN IRON & STEEL CO LTD

Weather-proof gas protection welding wire for coating-free weather-proof steel bridge

ActiveCN105798481AGuaranteed StrengthGuaranteed weather resistanceWelding/cutting media/materialsSoldering mediaCorrosionGas protection

The invention provides a weather-proof gas protection welding wire for a coating-free weather-proof steel bridge, and belongs to the field of welding materials. According to the technical scheme, in the weather-proof gas protection welding wire for the coating-free weather-proof steel bridge, chemical components comprise the basic component Fe, and the welding wire is further prepared from, by mass percent, 0.03%-0.10% of C, 0.30%-0.50% of Si, 1.20%-1.60% of Mn, not larger than 0.012% of P, not larger than 0.005% of S, 0.30%-0.60% of Cr, 0.20%-0.50% of Ni, 0.20%-0.50% of Cu, 0.005%-0.025% of Ca and 0.005%-0.05% of Re. The welding wire is used for welding of weather-proof bridge steel, the strength of extension of deposited metal is high, the yield strength is high, the elongation is larger than or equal to 24%, and the low temperature impact resisting performance and the atmosphere corrosion resisting performance are excellent; and the welding wire is easy to manufacture and suitable for being popularized on a large scale.

Owner:YANSHAN UNIV

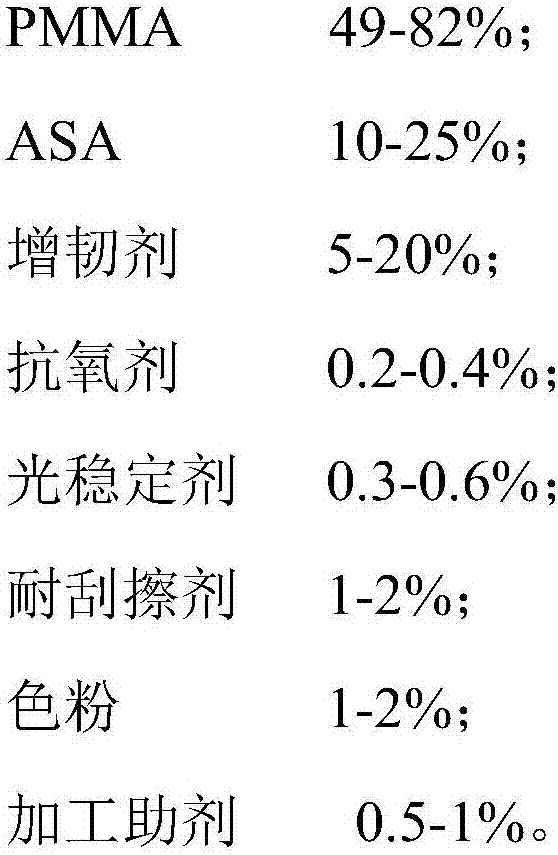

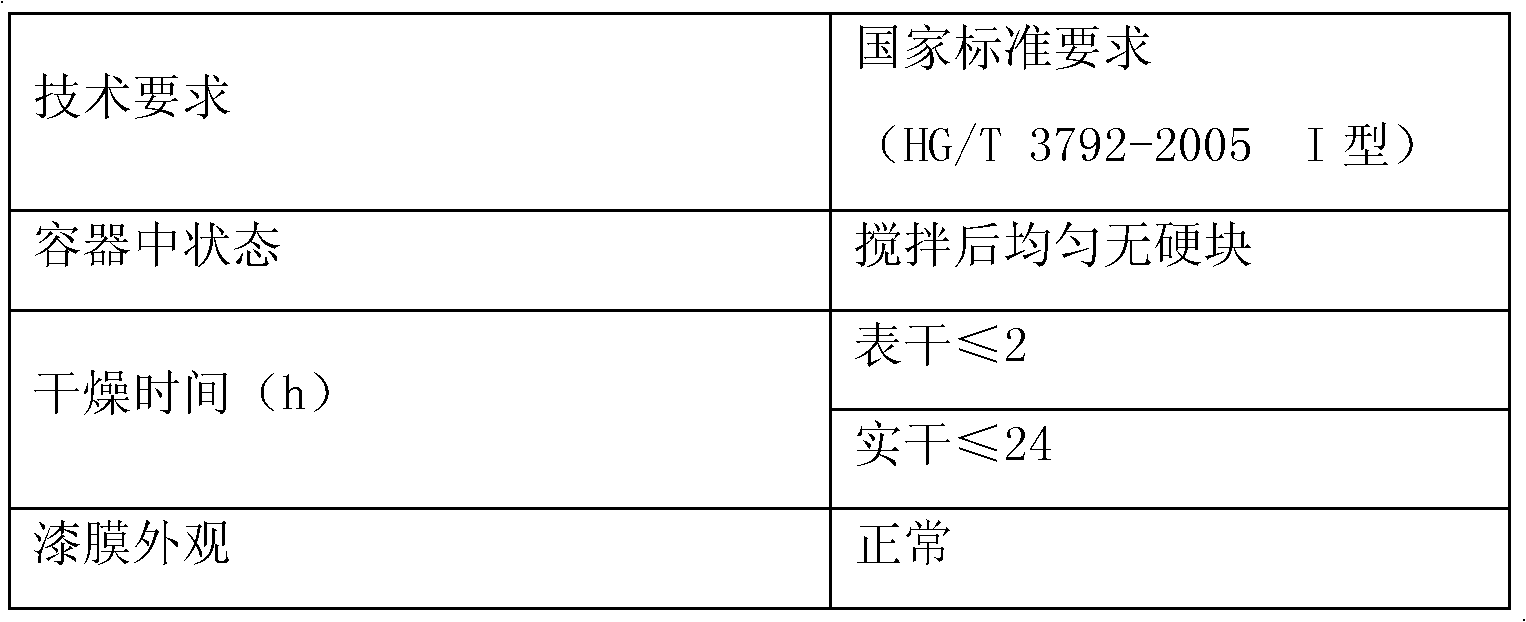

PMMA/ASA composite material and preparation method thereof

The invention belongs to the technical field of high polymer materials and particularly relates to a PMMA / ASA composite material and a preparation method thereof. The PMMA / ASA composite material comprises the following components in percentage by mass: 49-82 percent of PMMA, 10-25 percent of ASA, 5-20 percent of a toughening agent, 0.2-0.4 percent of an antioxidant, 0.3-0.6 percent of a light stabilizer, 1-2 percent of a scratch resistant agent, 1-2 percent of a toner and 0.5-1 percent of a processing aid. The preparation method comprises the following steps: respectively weighing the raw materials according to the components and the contents thereof and performing mixed treatment to obtain a mixed material; and putting the mixed material into a twin-screw extruder, fusing, extruding and granulating. The composite material is rigid and balanced in overall performance, high in strength, resistant to scratch, ductile, attractive in appearance and very suitable for being used in the fields of automobiles, electronic appliances, other outdoor products and the like.

Owner:ANHUI KEJU NEW MATERIALS

High-resilience wear-resistant EVA composite foam material, preparation method and composition for preparing material

PendingCN110698750ANarrow relative molecular mass distributionUniform distribution of short chain branchesPolyesterPolymer science

The invention discloses a high-resilience wear-resistant EVA composite foam material, a preparation method and a composition for preparing the material. The composition comprises the ingredients in parts by mass: 30-50 parts of ethylene-vinyl acetate copolymer, 10-20 parts of polyolefin thermoplastic elastomer, 10-20 parts of polyolefin block copolymer, 4-10 parts of thermoplastic polyurethane, 5-10 parts of thermoplastic polyester elastomer, 5-10 parts of anti-wear agent, 0.5-1 part of zinc oxide, 0.5-1.5 parts of zinc stearate, 0.5-1.2 parts of cross-linker, 0.1-0.3 part of crosslinking assistant and 1.5-3.5 parts of foamer. The preparation method comprises the steps of feed weighing, reblending, granulating and foaming. The obtained high-resilience wear-resistant EVA composite foam material is high in resilience and excellent in wear resistance and is applied to production of shoe soles of sports shoes.

Owner:ANTA CHINA

Composite membrane, preparation method thereof and solar cell assembly

InactiveCN104992995AGuaranteed weather resistanceLight weight unitFinal product manufactureSynthetic resin layered productsBlock layerBlocking layer

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Rosin modified road guide line resin process flow and production formula

InactiveCN101033372ATo achieve the purpose of protectionSolve pollutionRosin coatingsTraffic signalsWeather resistanceRosin

The invention relates to a kind of road marking resin, which particularly relates to the road marking resin lipid-modified by the high-quality rosin to replace petroleum resin, acrylic or chlorinated rubber for solving the pollution problem. The material has excellent mobility of construction as well as anti-shed, light resistance, wear resistance, oxidation resistance, water-resistance, pressure resistance, filthy resistance, weather resistance and chemical resistance.

Owner:广西梧州金原树脂有限公司

Elastic metal shining coating and its preparation method

InactiveCN102443347AGood metallic glitterIncrease elasticityPolyurea/polyurethane coatingsPolymerFluorocarbon Resins

The invention discloses an elastic metal shining coating and its preparation method, and belongs to the field of building materials. The coating is composed of a component 1 and a component 2 at the weight ratio of 6-10:1. The component 1 contains the following raw materials of: by weight, xylene, hexone, butyl acetate, propylene glycol methyl ether acetate, a fluorocarbon resin, aluminum paste, a dispersant, a leveling agent, an antifoaming agent, a scratch-resistance auxiliary agent and a polyester polyol resin. The component 2 is a curing agent. The combination of a fluorine-containing polymer and the elastic polyester resin in the coating endows the paint film with good elasticity, resistance to chemicals, non-adhesiveness, low friction and the like. Therefore, the coating provided by the invention is an elastic and persistant coating with excellent comprehensive properties. The raw materials of the coating are easily available. The coating requires a simple production method and convenient manual operation, accords with application requirements, has an extensive application prospect, and can be used for resisting fine cracks on exterior walls of buildings.

Owner:FIRST NEW MATERIAL TECH DEV

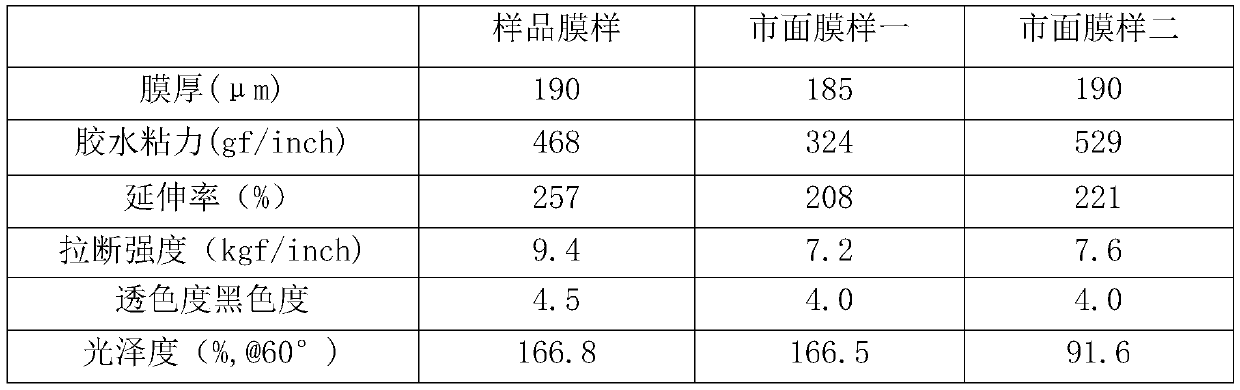

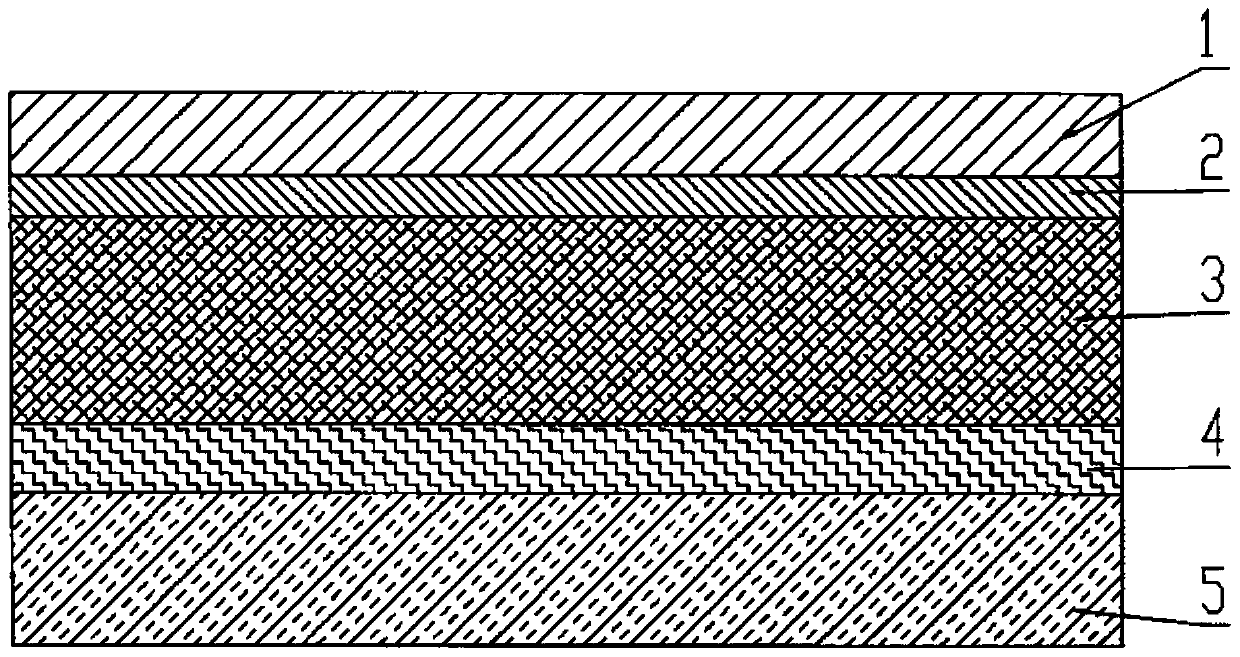

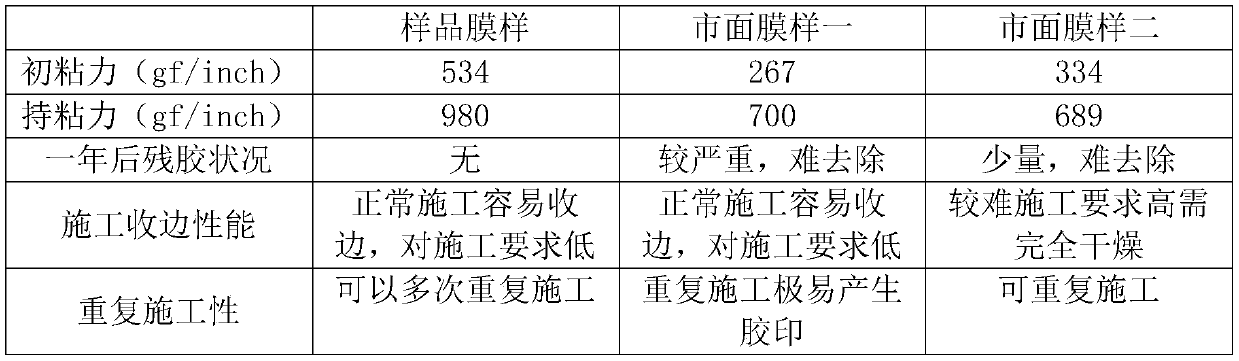

Invisible car cover protective film with TPU substrate and preparation process

InactiveCN110218525AImprove bindingIncrease profitPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolyesterTectorial membrane

The invention discloses an invisible car cover protective film with a TPU substrate. The invisible car cover protective film comprises a protective layer, a substrate layer and a release layer, wherein the protective layer is prepared from PET, the substrate layer is prepared from a polyester / polyether copolymer system, and the release layer is prepared from PET; a lower adhesive layer and an upper adhesive layer are separately adhered to main surfaces on both sides of the substrate layer, an aliphatic pressure-sensitive adhesive is coated on the surface of the release layer, and then the lower adhesive layer is adhered to one main surface of the substrate layer in a film transfer mode; and the upper adhesive layer is directly coated on the other main surface of the substrate layer. The invention also provides a preparation process of the invisible car cover protective film with the TPU substrate, and the preparation process comprises the steps: (1) preparing the TPU substrate layer, (2) pretreating the substrate layer, (3) preparing the lower adhesive layer, (4) performing film transfer, (5) preparing the upper adhesive layer, and (6) preparing the protective layer. The bonding force between the adhesive layers and the substrate layer is good, a high product strength and a high utilization rate of raw materials are achieved, and automatic repair of scratches can be achieved through polyurethane microcapsule particles in the adhesive layers.

Owner:NINGBO JIAHUA NEW MATERIAL TECH CO LTD

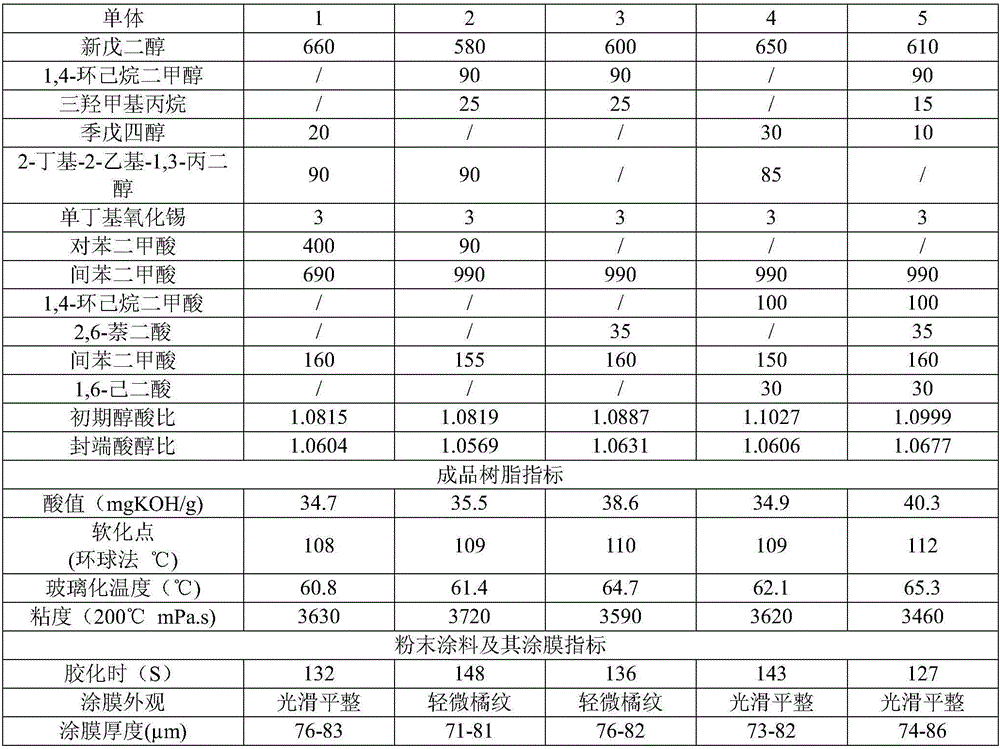

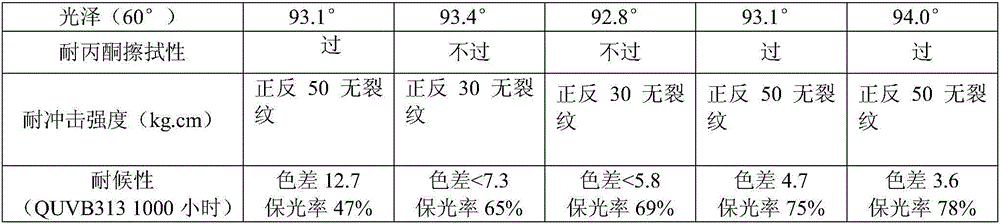

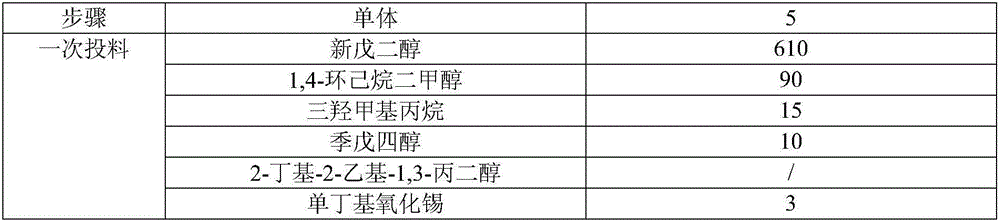

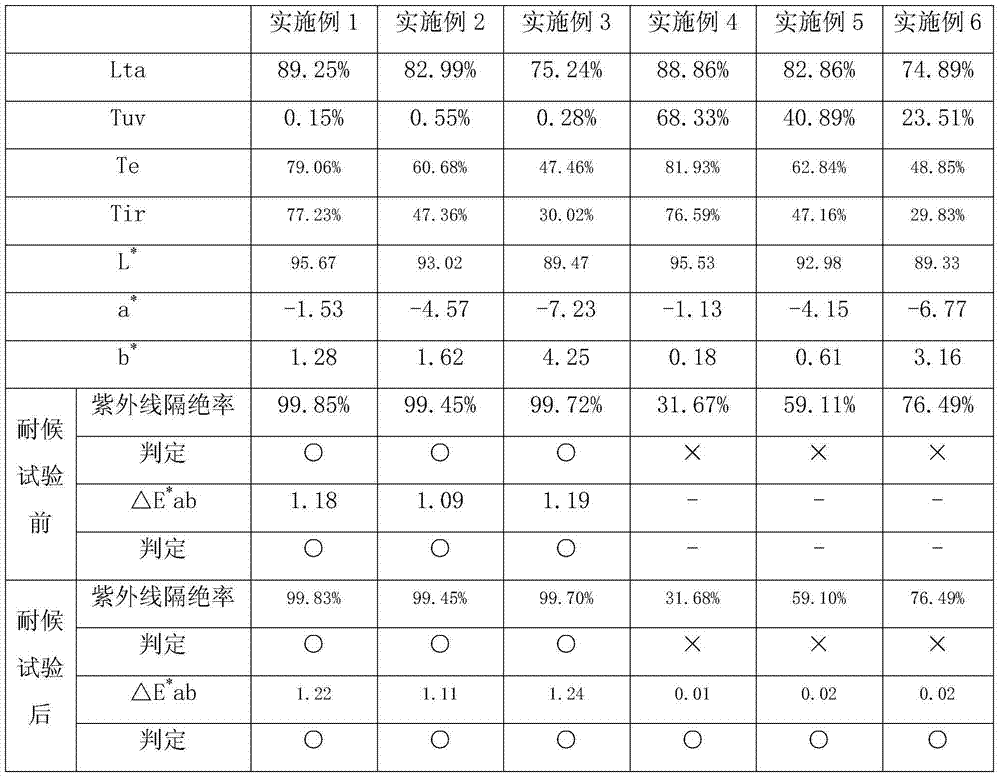

Weather-resisting type single-coating powder paint with metal pattern effect

ActiveCN106280914AHas super weather resistanceStrong three-dimensional sensePowdery paintsPolyester coatingsCyclohexanedimethanolPlasticizer

The invention relates to weather-resisting type single-coating powder paint with metal pattern effect. The weather-resisting type single-coating powder paint comprises bottom powder A and metal powder B; the bottom powder A is prepared from the following components in percentage by weight: 55 percent to 80 percent of weather-resisting type polyester resin, 4.0 percent to 6.2 percent of a curing agent, 0 to 40 percent of modified barium sulfate, 0.3 percent to 1.5 percent of a plasticizer, 0.02 percent to 2 percent of a curing accelerator, 1 percent to 5 percent of an auxiliary agent, 0 to 25 percent of pigment and 0.05 percent to 0.5 percent of a texturizing agent; the weather-resisting type polyester resin is synthesized from the following raw materials: neopentyl glycol, butylene glycol, 2-methyl-1,3-propylene glycol, cyclohexanedimethanol, 2-butyl-2-ethyl-propylene glycol, terephthalic acid and the like. By adopting modified polyester, the weather-resisting type single-coating powder paint with metal pattern effect has excellent weather resistance and also has a three-dimensional pattern effect; the weather-resisting type single-coating powder paint with metal pattern effect can be thickly applied and a thickly coated film with the thickness of 60UM to 120UM is formed by coating in one step; the coated film only needs to be cured for one time; the weather-resisting type single-coating powder paint with metal pattern effect has the characteristics of 10-year weather resistance, high metal stereoscopic impression, clear pattern effect, good coverage, good mechanical property, low cost, no pollution to the environment and the like.

Owner:ZHEJIANG CHAOLANG ADVANCED MATERIALS

Flame-retardant sealing ring for motors of range hoods

The invention discloses a flame-retardant sealing ring for motors of range hoods. The flame-retardant sealing ring is made from raw materials including nitrile rubber, zinc oxide, stearic acid, carbon black, white carbon black, sulphur powder, an accelerant CZ, an accelerant M, an accelerant TMTD, ETU-80, light magnesium oxide, pottery clay, chloroprene rubber adhesive, aluminum hydroxide, a silane coupling agent, zinc borate, antimonous oxide, modified flame retardant, dioctyl phthalate, carnauba wax, antiager 2246, antiager BZ and a processing agent WB-16. The flame-retardant sealing ring is good in high-temperature resistance and flame retardant performance, and meanwhile has the advantages of oil resistance, no halogen, low toxicity and environment friendliness.

Owner:NINGGUO ZOYE PLASTIC & RUBBER CO LTD

Production technology of TPU-substrate invisible car cover protection film

InactiveCN110183985AImprove bindingIncrease profitFilm/foil adhesive primer layersPressure sensitive film/foil adhesivesPolyesterTectorial membrane

The invention discloses a production technology of a TPU-substrate invisible car cover protection film. The TPU-substrate invisible car cover protection film is produced according to the following steps: (1), forming a TPU substrate layer; (2), pretreating the substrate layer; (3), forming a lower adhesive layer; (4), performing film transfer; (5), forming an upper adhesive layer; (6), forming a protective layer. In the TPU-substrate invisible car cover protection film, the protective layer is made of PET, the substrate layer is made of a polyester-polyether copolymer system, and a release layer is made of PET; the lower adhesive layer is an aliphatic pressure-sensitive adhesive, and the upper adhesive layer is aliphatic polyurethane or carbamate-acrylic based surface coating. A TPU substrate of the of TPU-substrate invisible car cover protection film has relatively high modulus and strength, so that good weather resistance, gloss, transparency, crystal flow pattern and other requirements are guaranteed; the adhesive layers have strong adhesion to the substrate layer and have high raw material utilization rate, and during using, the adhesive layers provide suitable initial adhesionand permanent adhesion for the surface of car paint, so that the advantage that glue does not remain on the paint surface is achieved.

Owner:NINGBO JIAHUA NEW MATERIAL TECH CO LTD

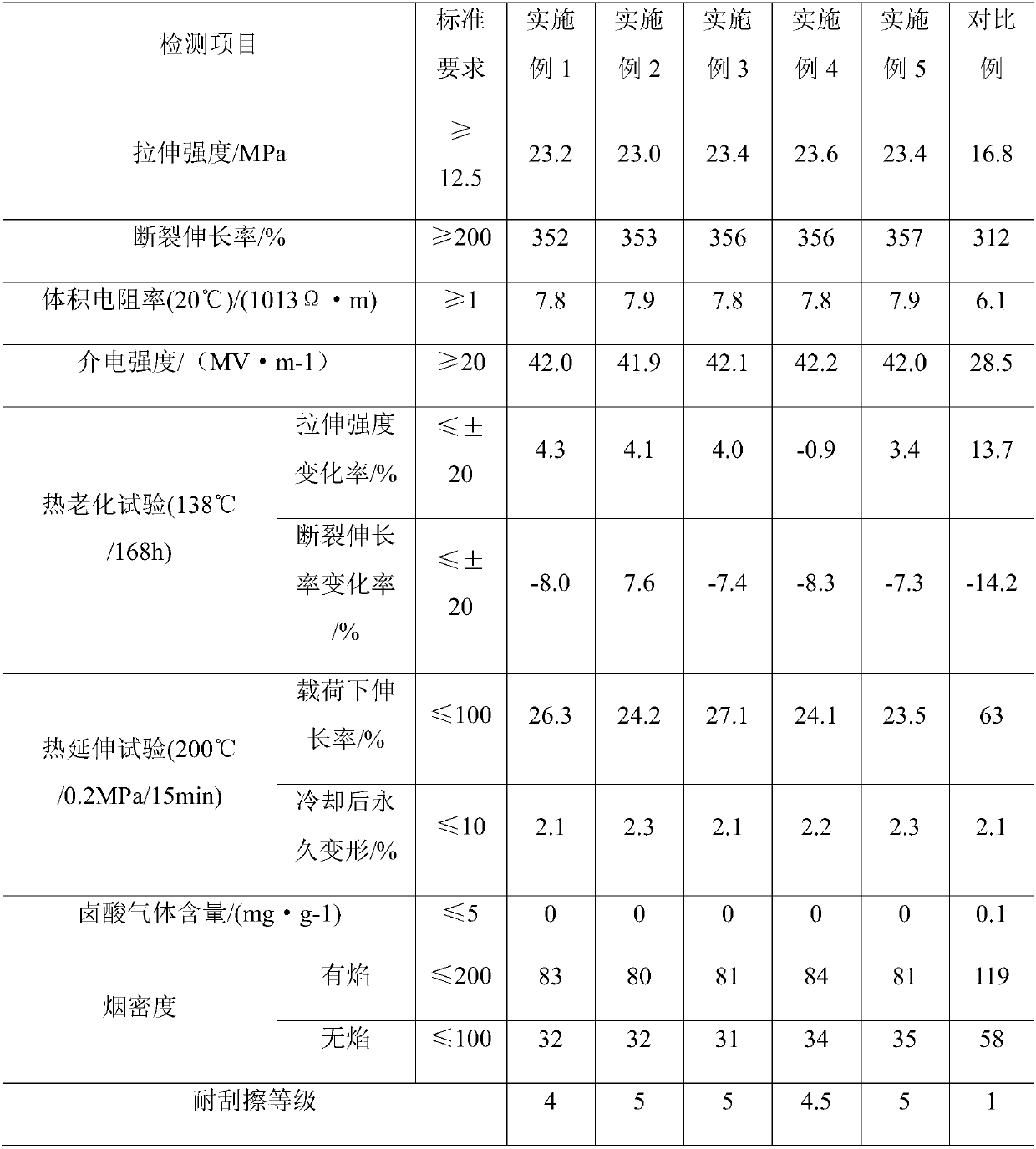

Environment-friendly cable insulation layer, and preparation method thereof

InactiveCN107722439AHas flame retardant propertiesImprove scratch resistancePlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethylenePolyolefin

The invention discloses an environment-friendly cable insulation layer, and belongs to the field of wire cable. The environment-friendly cable insulation layer comprises an internal insulation layer and an external insulation layer; a double layer co-extrusion insulation layer is composed of the internal insulation layer and the external insulation layer; the internal insulation layer is preparedfrom an irradiation crosslinked polyethylene insulation material; the external insulation layer is prepared from a low-smoke halogen-free flame-resistant irradiation crosslinked polyolefin insulationlayer; the external insulation layer comprises, by weight, 43 to 65 parts of an ethylene-vinyl acetate copolymer, 40 to 60 parts of linear low density polyethylene, 35 to 47 parts of ethylene propylene diene monomer, 54 to 75 parts of a scratch-resistant agent, 25 to 30 parts of a sensitizing agent, 48 to 60 parts of a silicon nitrogen flame retardant, 25 to 35 parts of a composite anti-aging agent, 12 to 20 parts of a reinforcing filler, and 25 to 35 parts of a composite compatilizer. The environment-friendly cable insulation layer, is friendly to the environment, and is capable of improvingthe scratch resistance of cables greatly.

Owner:南京创贝高速传动机械有限公司

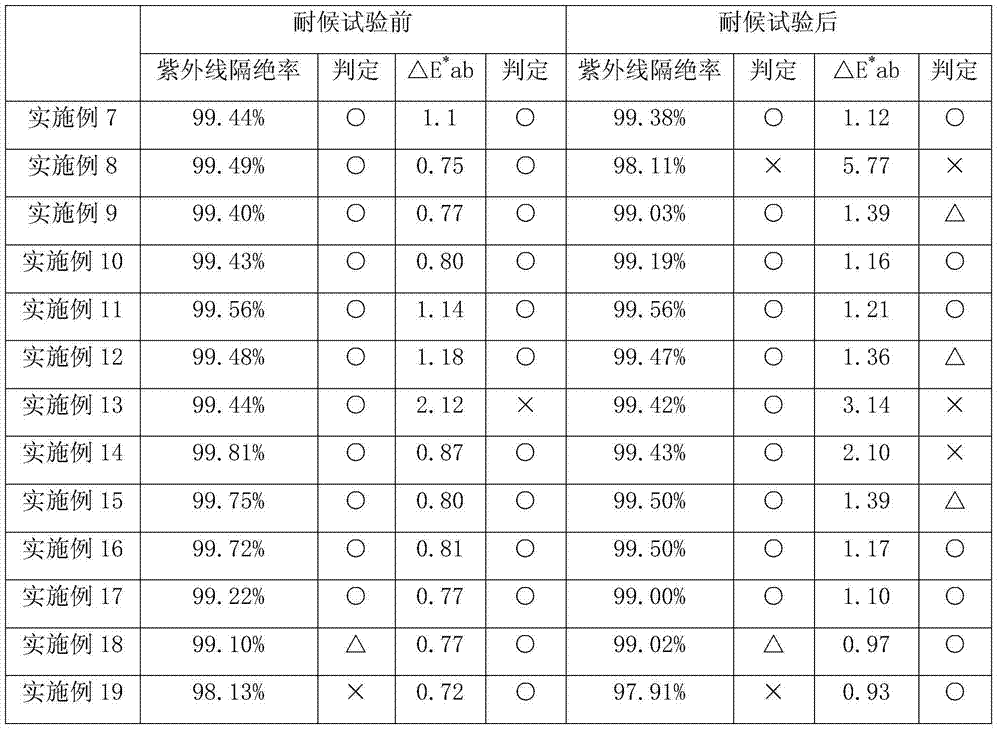

Coating liquid for forming ultraviolet absorbing coatings and ultraviolet absorbing glass

ActiveCN103613280APrevent discolorationInhibit devitrificationSynthetic resin layered productsRadiation-absorbing paintsDevitrificationWeather resistance

The invention relates to the technical field of ultraviolet absorbing coatings, particularly provides coating liquid for forming ultraviolet absorbing coatings on the surfaces of objects, such as glass and the like, and ultraviolet absorbing glass with the ultraviolet absorbing coatings formed by the coating liquid and further provides a method for preparing the ultraviolet absorbing glass. According to the coating liquid for forming the ultraviolet absorbing coating, the ultraviolet absorbing glass and the method for forming the ultraviolet absorbing glass, through storing and releasing ultraviolet excited electrons in an ultraviolet absorbent, the gradually accumulated excited electrons of the ultraviolet absorbent during ultraviolet ray absorption are reduced, then, the ultraviolet absorbent and a silica matrix are protected, the ultraviolet absorbing glass is prevented from discoloration or devitrification, the weather resistance of the ultraviolet absorbing coatings is guaranteed, and the color consistency of the ultraviolet absorbing glass is guaranteed.

Owner:FUYAO GLASS IND GROUP CO LTD

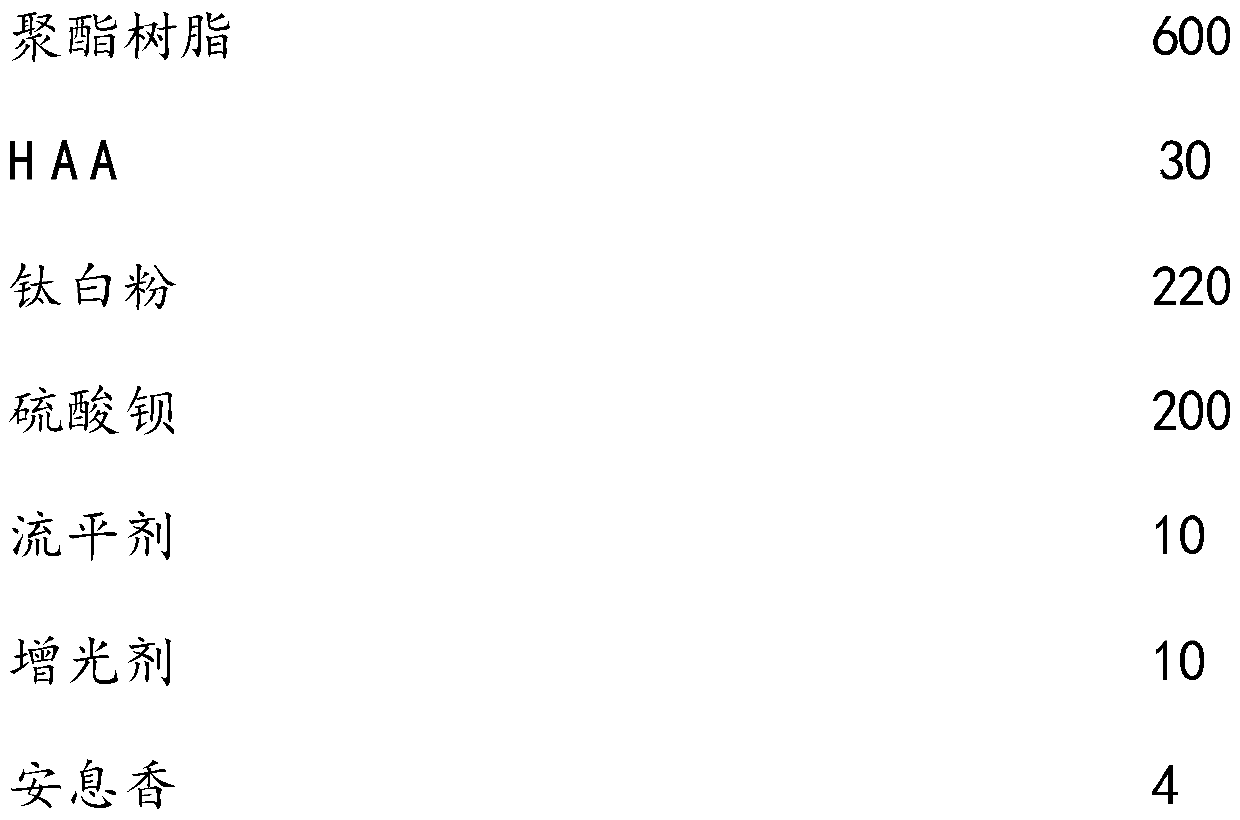

HAA-cured high-leveling and anti-thick-coating pinhole polyester resin, preparation method and application thereof

ActiveCN111333826AGuaranteed flexibilityGuaranteed liquidityPowdery paintsPolyester coatingsPolymer sciencePropanediol

The invention, which belongs to the technical field of preparation of polyester resin, particularly relates to polyester resin for a high-leveling and anti-thick pinhole type HAA system as well as a preparation method and application of the polyester resin. The HAA-cured high-leveling and anti-thick pinhole coating polyester resin provided by the invention is characterized in that the polyester resin is mainly prepared by carrying out polymerization reaction on terephthalic acid, flexible long-chain dicarboxylic acid, neopentyl glycol, pentaerythritol dioleate, polypropylene glycol 400, 1, 2-octanediol and hexamethylene diisocyanate. According to the polyester resin and the preparation method thereof, when polyester resin is prepared, no small molecular substance escapes in the curing process; the thick pinhole resistance is ensured, the finally obtained polyester resin and the curing agent HAA can be cured at a low temperature (140 DEG C / 15 min) by combining proper synthesis process conditions, the finally cured film has good leveling property and strong thick pinhole resistance; and the basic performance also completely meets the conventional requirements of the powder coating.

Owner:黄山市向荣新材料有限公司

EVA large hole composite foam material and preparation method

The invention discloses an EVA large hole composite foam material and a preparation method thereof. The composite foam material is prepared by mixing, granulation and foaming of materials, and the materials include: 40-60 mass parts of an ethylene-vinyl acetate copolymer, 10-20 mass parts of graphene modified isotactic polybutene, 10-15 mass parts of a polyolefin thermoplastic elastomer, 10-20 mass parts of a polyester elastomer, 0.4-0.8 mass part of an active agent, 0.7-1.5 mass parts of a cross-linking agent, 2.5-3.5 mass parts of a foaming agent and 0.1-0.3 mass part of an assistant. The mass content of vinyl acetate in the ethylene-vinyl acetate copolymer is 26%-40%. The preparation method of the EVA large hole composite foam material includes: weighing a certain amount of isotactic polybutene-1 for melting, adding 0.05%-0.2% by mass of graphene when the melting temperature of the isotactic polybutene-1 is 140-170DEG C, and mixing the two substances to obtain graphene modified isotactic polybutene. The large holes in the EVA large hole composite foam material has good foaming effect, the compression resistance and resilience are enhanced, and also the softness and wear resistance are also improved. The preparation method is simple and easy to operate.

Owner:ANTA CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com