Novel method for recycling synthetic rutile mother liquor

An artificial rutile and resource-based technology, applied in the chemical industry, can solve problems such as poor economic benefits, achieve the effects of less consumption, ensure dispersion and weather resistance, and increase market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

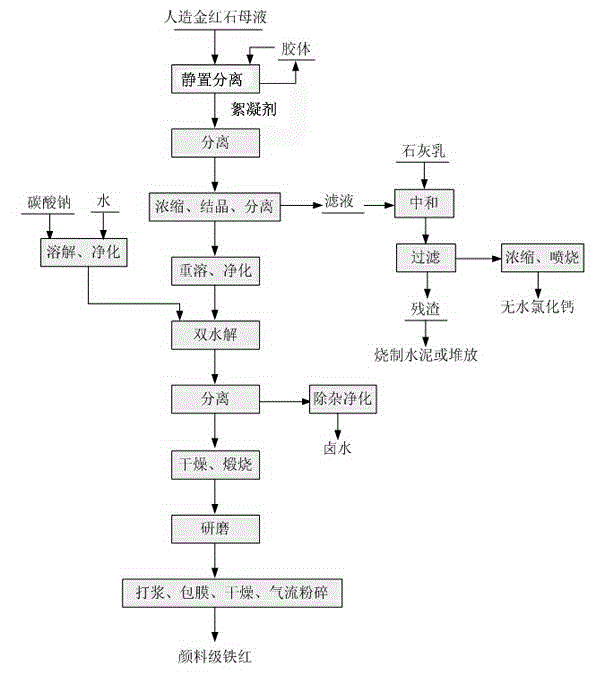

Method used

Image

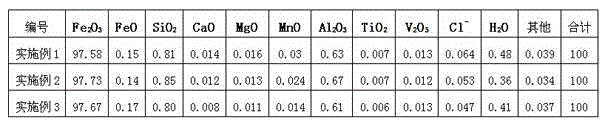

Examples

Embodiment 1

[0049] (1) The mother liquor was allowed to stand for 48h to separate to obtain colloidal precipitate and clear mother liquor, then add 0.1% colloidal precipitate by volume to the clear mother liquor and stir, heat it to boiling within 30min, maintain a slightly boiling state for 30min, and cool to room temperature , add modified polyacrylamide with a volume ratio of 0.5%, stand at room temperature for 48h and then filter;

[0050] (2) Evaporating and concentrating the above-mentioned filtered mother liquor, the quality of the evaporated water accounts for 0.3 of the total mass of the mother liquor, crystallizing under cooling to 5°C, and filtering and separating the crystals;

[0051] (3) The above obtained crystal is configured as a 15% ferrous solution, 0.5% by mass of iron powder is added to carry out the replacement reaction, after the reaction is completed, 3% of modified activated carbon is added for adsorption, the adsorption time is 30min, and the filter is separated; ...

Embodiment 2

[0057] (1) The mother liquor was allowed to stand for 48h to separate to obtain colloidal precipitate and clear mother liquor, then add 0.5% colloidal precipitate by volume to the clear mother liquor and stir, heat it to boiling within 30min, maintain a slightly boiling state for 50min, and cool to room temperature , add modified polyacrylamide with a volume ratio of 0.1%, stand at room temperature for 48h and then filter;

[0058] (2) the above-mentioned filtered mother liquor is evaporated and concentrated, the quality of the evaporated water accounts for 0.6 of the total mass of the mother liquor, crystallized under cooling to 5°C, and the crystals are separated by filtration;

[0059] (3) The obtained crystal is configured as a 25% ferrous solution, 1% by mass of iron powder is added to carry out a replacement reaction, after the reaction is completed, 5% of modified activated carbon is added for adsorption, the adsorption time is 60min, and the filter is separated;

[006...

Embodiment 3

[0065] (1) The mother liquor was allowed to stand for 48 hours to separate to obtain colloidal precipitate and clear mother liquor, then add 0.4% colloidal precipitate by volume to the clear mother liquor and stir, heat it to boiling within 30 minutes, maintain a slightly boiling state for 50 minutes, and cool to room temperature , add modified polyacrylamide with a volume ratio of 1%, stand at room temperature for 48h and then filter;

[0066] (2) Evaporating and concentrating the above-mentioned filtered mother liquor, the quality of evaporating water accounts for 0.9 of the total mass of the mother liquor, crystallizing under cooling to 10 °C, and filtering and separating the crystals;

[0067] (3) The above obtained crystal is configured as a 22% ferrous solution, 1% by mass of iron powder is added to carry out the replacement reaction, after the reaction is completed, 5% of modified activated carbon is added for adsorption, the adsorption time is 120min, and the filter is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com