Production technology of TPU-substrate invisible car cover protection film

A production process and technology of protective film, applied in the direction of pressure-sensitive film/sheet, film/sheet release coating, film/sheet adhesive, etc., can solve the problem of high cost, glue residue, poor durability of protective film, etc. problem, to achieve the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

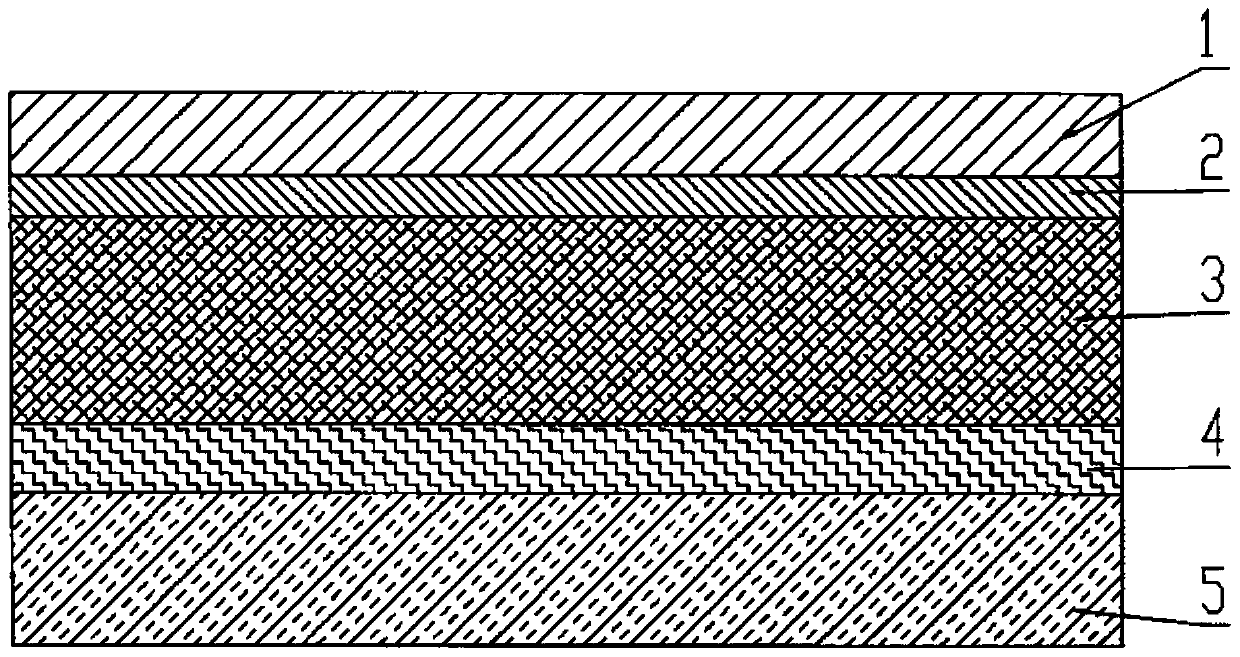

Image

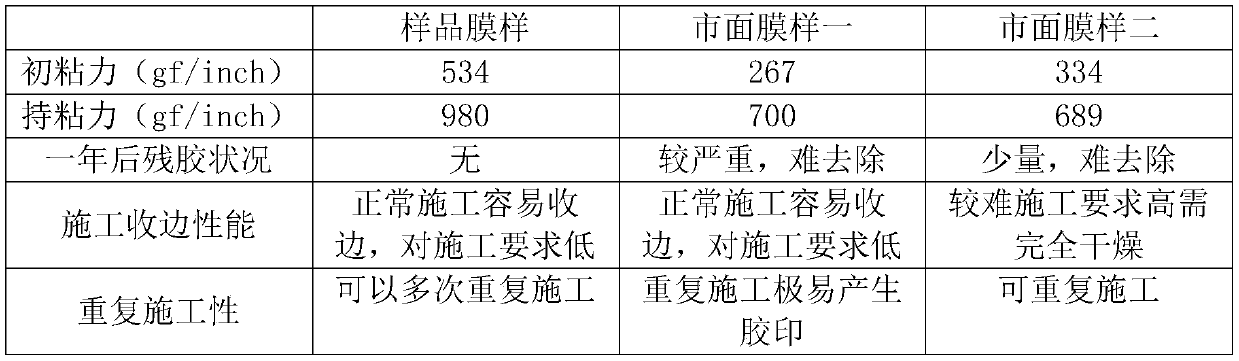

Examples

Embodiment 1

[0059] The present embodiment provides a kind of manufacturing process of the invisible car clothing protection film of TPU base material, specifically as follows:

[0060] First form the TPU substrate layer, and the raw material formula is: 86 parts of polyester-polyether copolymer; 1-6 parts of slip agent 1753; 6 parts of anti-UV agent #531, and 1 part of transparent masterbatch. Dry in a blast drying oven at 80°C for 4 hours, wait until the barrel of the single-screw extruder rises to 180°C in zone 1, 210°C in zone 2, 210°C in zone 3, 220°C in zone 4, 220°C at the adapter, and the temperature of the die at the head rises to 220°C: Add the above granules for melting and plasticization, extrude and cast through a casting die with a gap of 0.15mm, and continuously pass through a horizontal three-roll calender with a preset roll distance to calender and cool with circulating water to form the required film . The thickness of the original TPU film produced by this method is 0.1...

Embodiment 2

[0068] The substrate layer formula of TPU in this embodiment: 91 parts of polyester-polyether copolymer; 1-5 parts of slip agent 1753; 3 parts of anti-UV agent #531, and 1 part of transparent masterbatch. Dry in a blast drying oven at 80°C for 4 hours, wait until the barrel of the single-screw extruder rises to 180°C in zone 1, 210°C in zone 2, 210°C in zone 3, 220°C in zone 4, 220°C at the adapter, and the temperature of the die at the head rises to 220°C: Add the above granules for melting and plasticization, extrude and cast through a casting die with a gap of 0.15mm, and continuously pass through a horizontal three-roll calender with a preset roll distance to calender and cool with circulating water to form the required film .

[0069] The produced TPU original film, because TPU is a non-polar material, has low surface activity and needs to be pretreated with aliphatic polyurethane. Polyurethane oligomers are selected as the pretreatment agent and diluted to a certain conc...

Embodiment 3

[0072] The substrate layer formula of TPU in this embodiment: 91 parts of polyester-polyether copolymer; 1-5 parts of slip agent 1753; 3 parts of anti-UV agent #531, and 1 part of transparent masterbatch. Dry in a blast drying oven at 80°C for 4 hours, wait until the barrel of the single-screw extruder rises to 180°C in zone 1, 210°C in zone 2, 210°C in zone 3, 220°C in zone 4, 220°C at the adapter, and the temperature of the die at the head rises to 220°C: Add the above granules for melting and plasticization, extrude and cast through a casting die with a gap of 0.15mm, and continuously pass through a horizontal three-roll calender with a preset roll distance to calender and cool with circulating water to form the required film .

[0073] One side of the TPU substrate is directly coated. The pretreatment layer is formed by mixing butanone and ethyl acetate, wherein the mixing ratio of butanone and ethyl acetate is 1:8. The anti-scratch coating is composed of 3,7-dimethyloct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| 100% modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com