Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Good welding reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

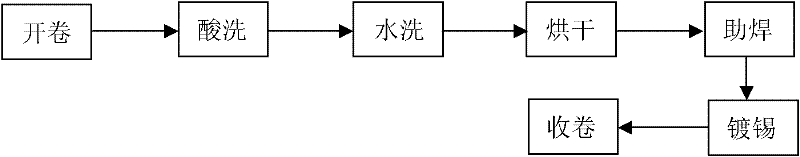

Preparation method for stannum, indium and stibium series lead-free solder tinning copper strip used for solar battery

InactiveCN102174676AHigh hardnessHigh tensile strengthFinal product manufactureSemiconductor devicesTinningDip soldering

The invention relates to a preparation method for a stannum, indium and stibium series lead-free solder tinning copper strip used for a solar battery. The preparation method comprises the following steps: pure stannum, indium and stibium, as well as bismuth, copper and silver are weighted according to the mass ratio of (83-99):(0.5-9):(0.1-8):(0-4):(0-1):(0-1); firstly, stibium, copper and silver are melted along with stannum in a smelting furnace in the proportion of 1:10 and then stirred to enable the stibium, copper and silver to be completely melted in stannum, and a stannum, stibium, silver and copper intermediate alloy is formed; secondly, the residual stannum and the other components are melted to form corresponding intermediate alloys; then two intermediate alloys are melted and stirred to be evenly mixed; and finally, the traditional hot dip-soldering process is used, and lead-free solder is dip-soldered on a copper wire or a copper strip. The Sn-In-Sb series lead-free solder has very low silver content, the solder cost is greatly lowered, the copper strip has better ductility and tensile strength, and the connection interface has high reliability. The high-performance solder alloy is taken as the object of study and is enabled to meet the industrial application requirements, so that the development prospect is good.

Owner:TIANJIN UNIV

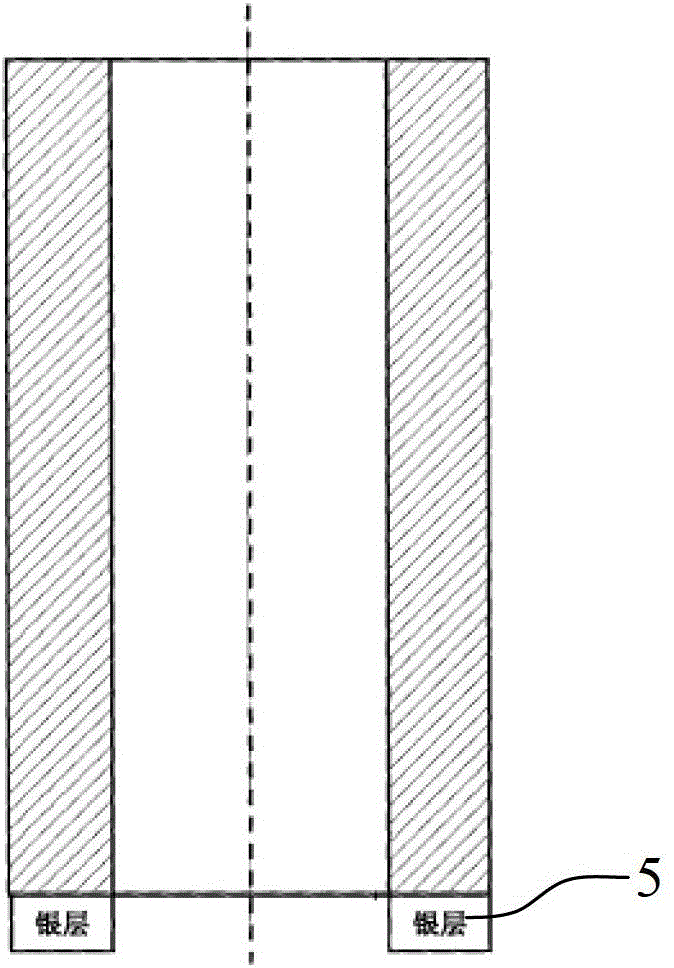

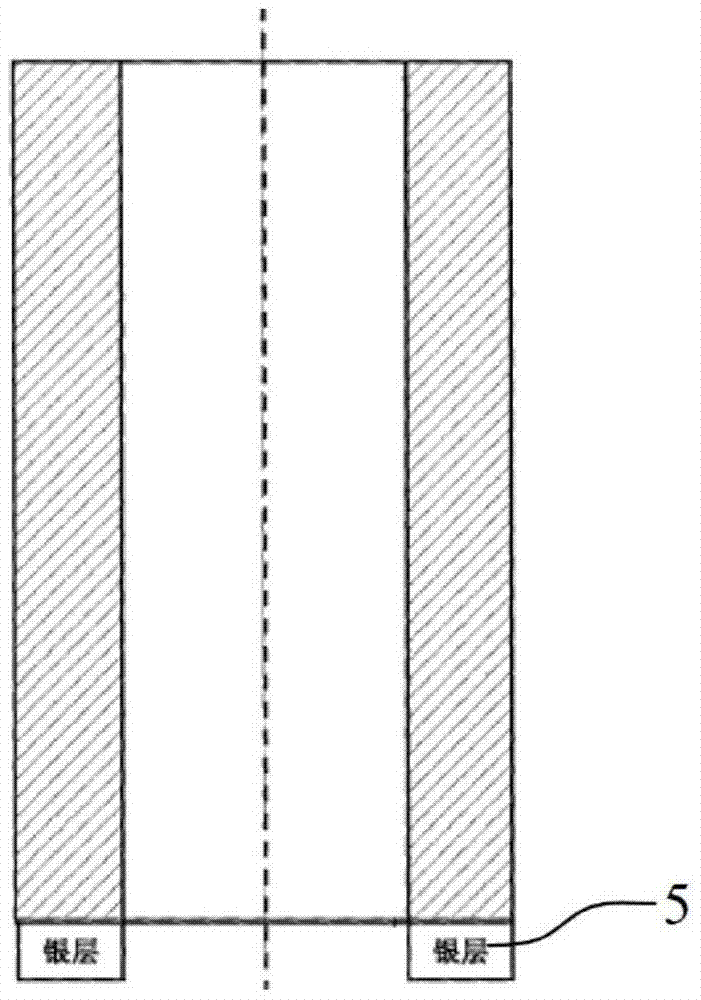

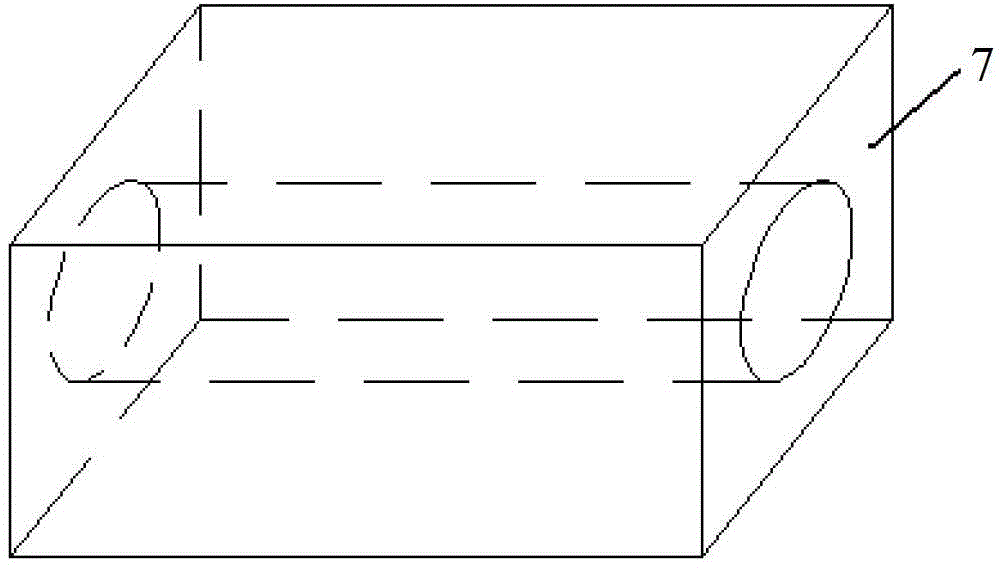

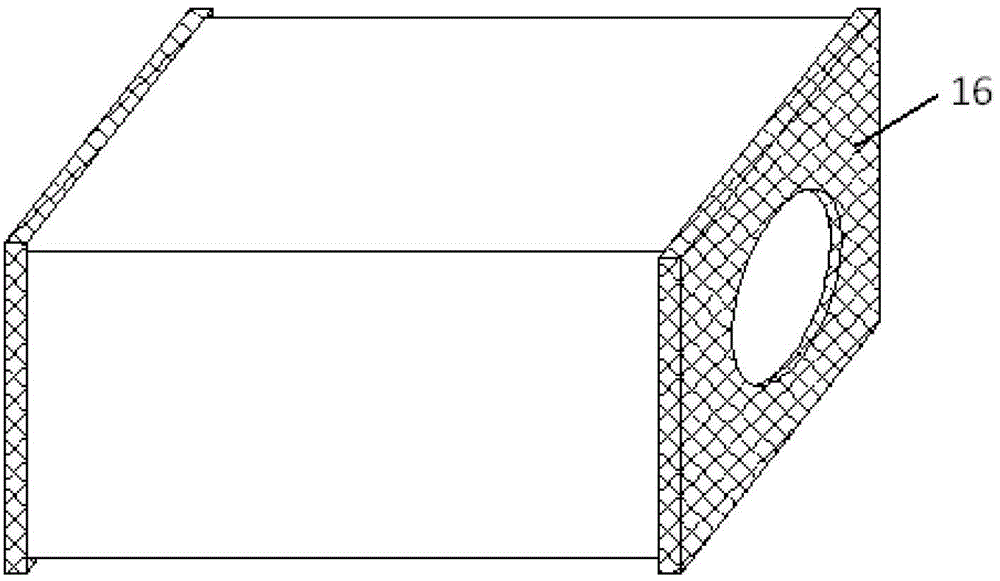

Novel medium cavity filter with cavity

ActiveCN102969549AReduce lossSteep frequency characteristicResonatorsThermal expansionTemperature coefficient

The invention discloses a novel medium cavity filter with a cavity. The novel medium cavity filter comprises the cavity and medium resonators, wherein each medium resonator is a cylinder with a through hole and is prepared from the following components according to mass percent: 29%-32% of calcium carbonate with purity of 97.5%, 9%-11% of aluminum oxide with purity of 97.5%, 21%-25% of neodymium oxide with purity of 99.5%, and 35%-38% of titanium dioxide with purity of 99.6%; a silver layer is coated at one end of each medium resonator, and the other end of the medium resonator is welded inside the cavity; the cavity is prepared from the following components according to mass percent: 95%-96% of aluminum oxide, 2%-3% of calcium carbonate, 0.8%-1.5% of lanthanum oxide, and 0.2%-0.5% of samarium oxide; and the dielectric constant of the cavity is 9.5. The medium cavity filter disclosed by the invention is high in Q value, small in size and adjustable in temperature coefficient, and can ensure high reliability of a product structure and good consistency of thermal expansion coefficients of the cavity and the medium resonators.

Owner:江苏灿勤科技股份有限公司

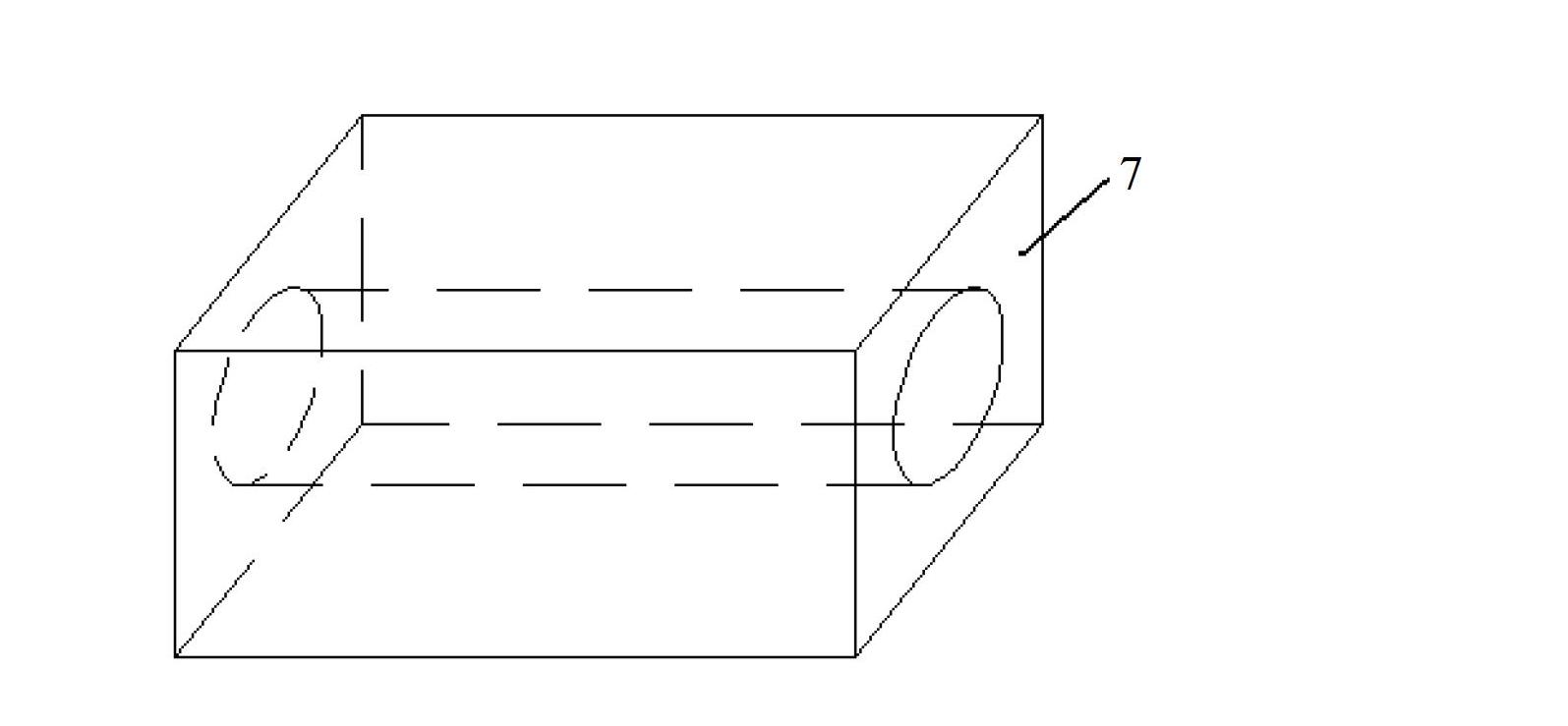

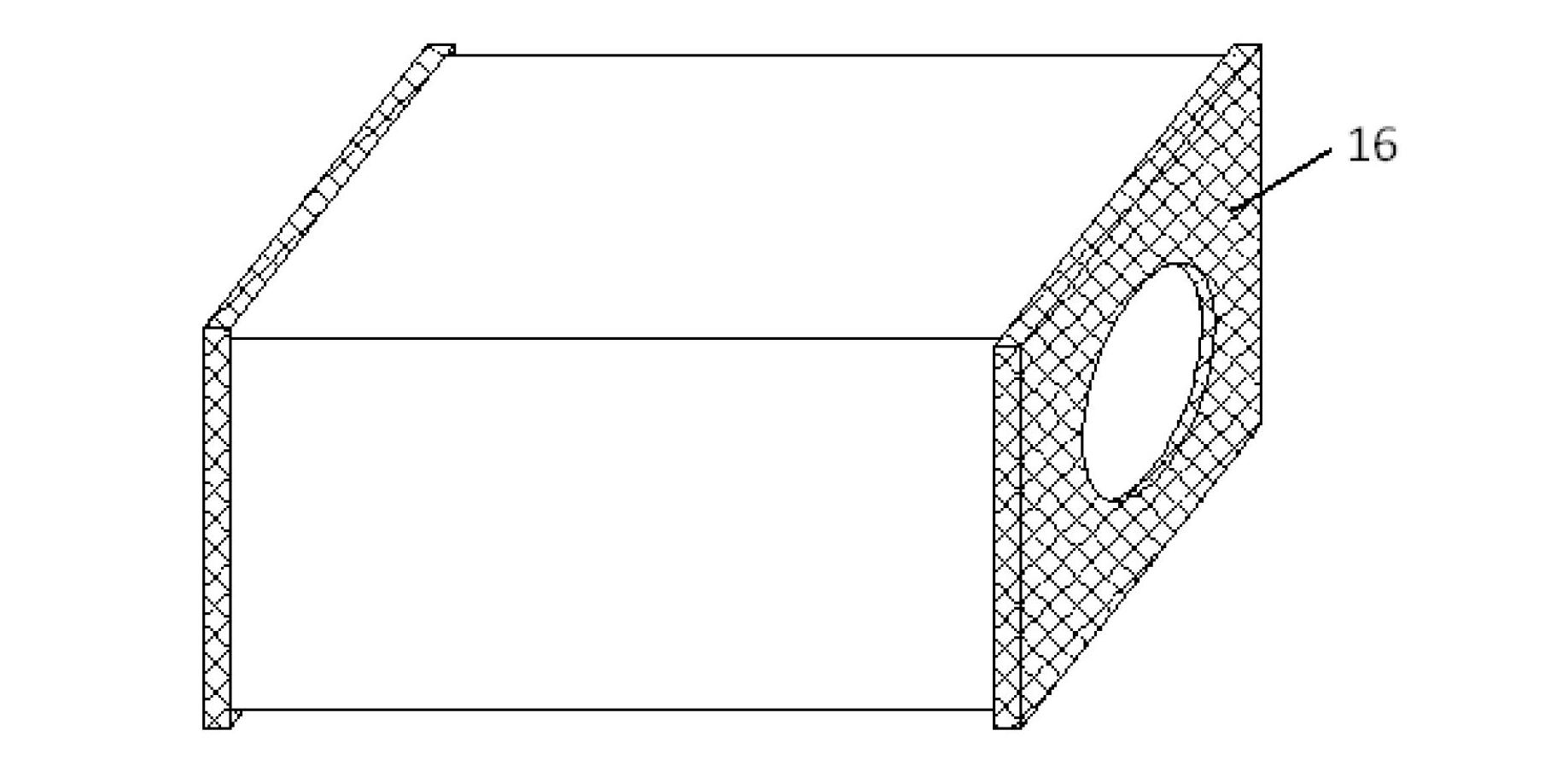

Surface-mounted fuser

ActiveCN102664127ANo consistency issuesImprove breaking capacityContactsEmergency protective devicesHigh volume manufacturingSurface mounting

The invention discloses a surface-mounted fuser, comprising a fusing chip. The fusing chip mainly consists of termination electrodes, a ceramic substrate, a fuse element layer and an arc extinguishing glass layer, wherein the fuse element layer is located on the upper surface of the ceramic substrate; the two termination electrodes are respectively located at the both sides of the fuse element layer and are electrically connected with the fuse element layer; and the arc extinguishing glass layer covers the fuse element layer and the area, which is close to the fuse element layer, of the termination electrodes. The surface-mounted fuser further comprises a fusing main body the middle of which is provided with a round through hole, wherein the fusing chip is located in the round through hole of the fusing main body; two metal covers are respectively located at the both ends of the fusing main body and cover the round through hole so as to form a sealing cavity; and the termination electrodes are electrically connected with the metal covers through welding sheets. The surface-mounted fuser provided by the invention has high temperature resistance and high strength, can coat fusing wires and arc extinguishing glass inside well so as to greatly improve the entire strength, the breaking capability and the thermal shock resistance of the fuser, and is convenient for large-scale production.

Owner:SEMITEL ELECTRONICS

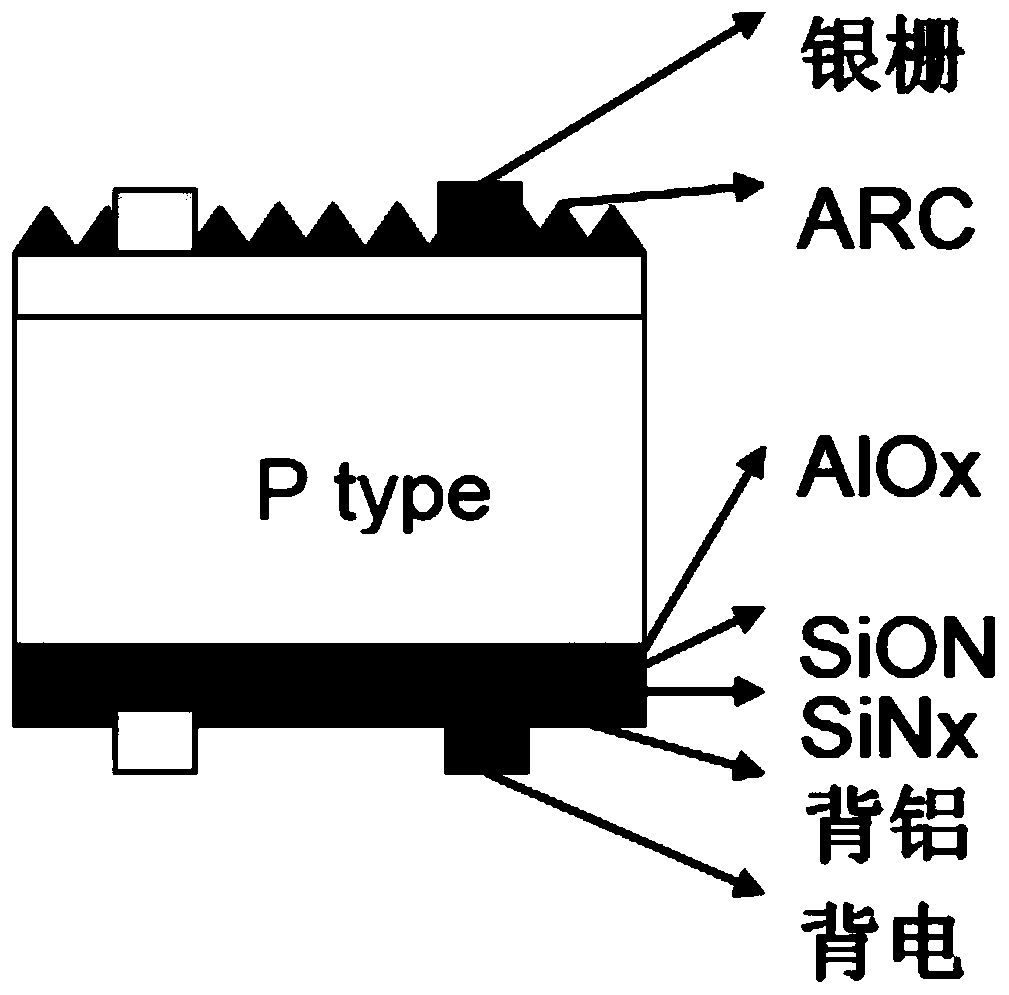

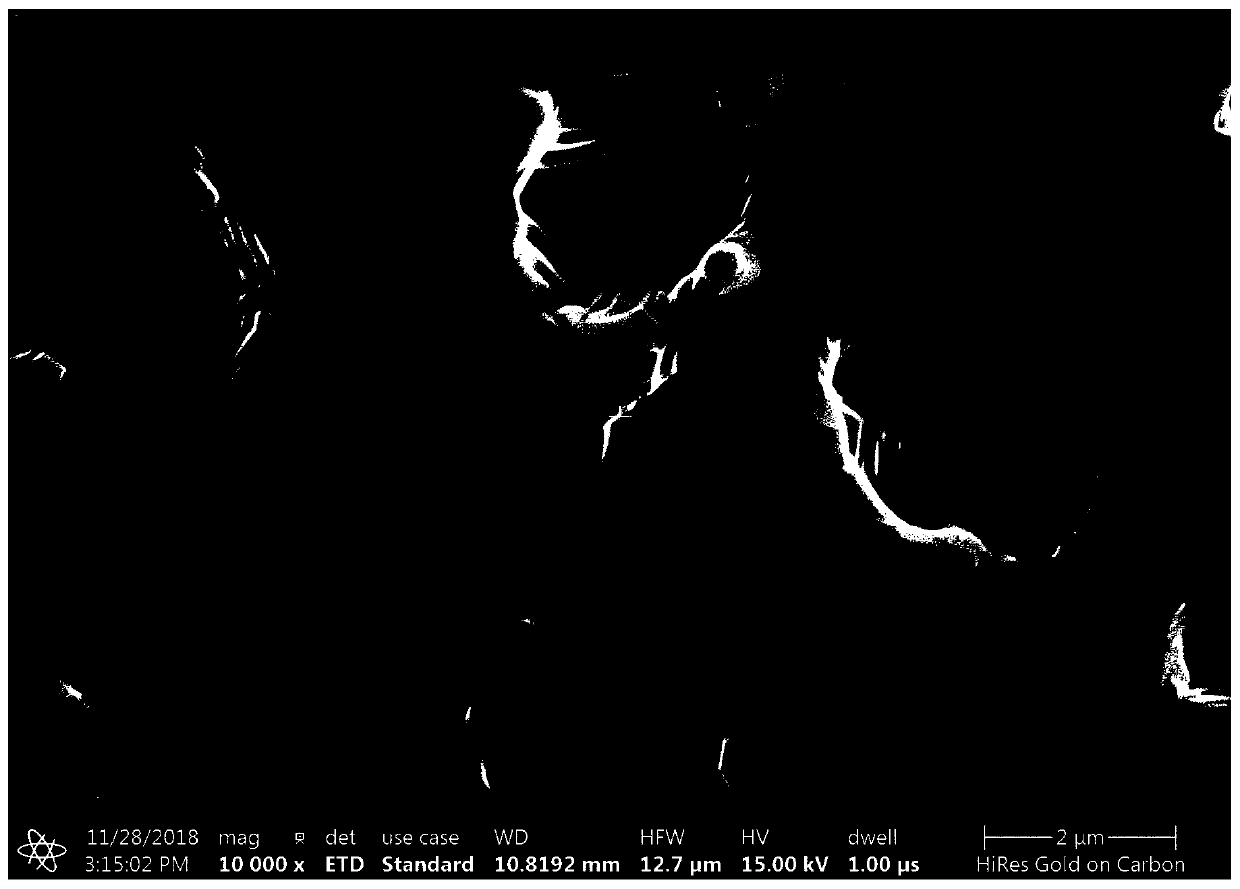

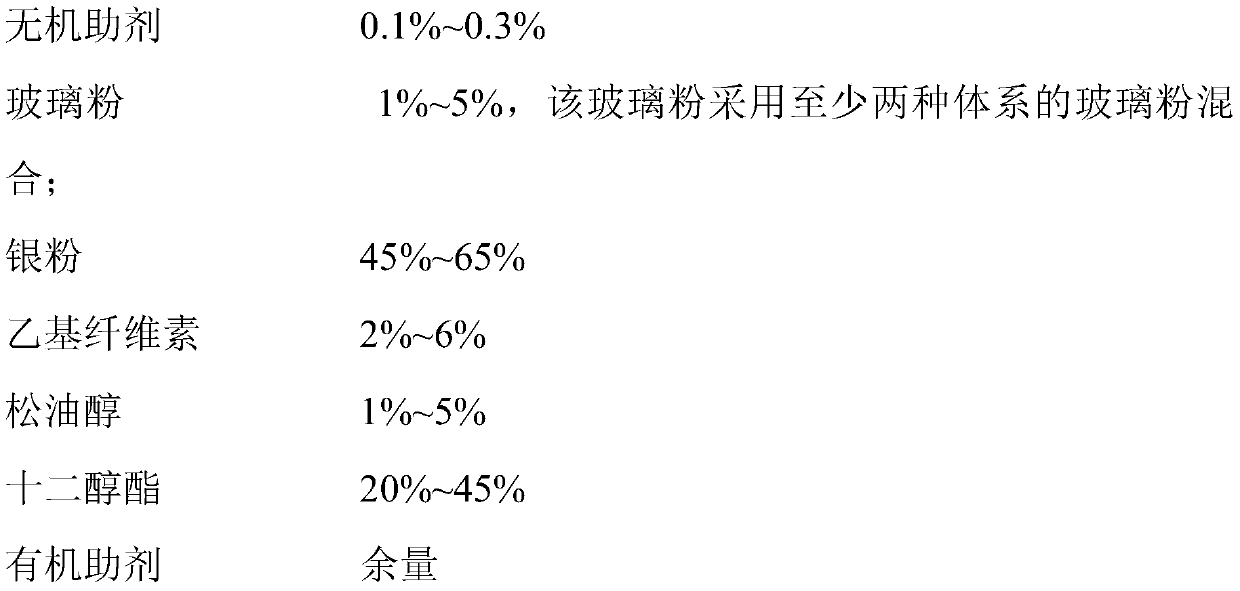

High-reliability PERC back silver conductive paste for crystalline silicon solar cell and preparation process for high-reliability PERC back silver conductive paste

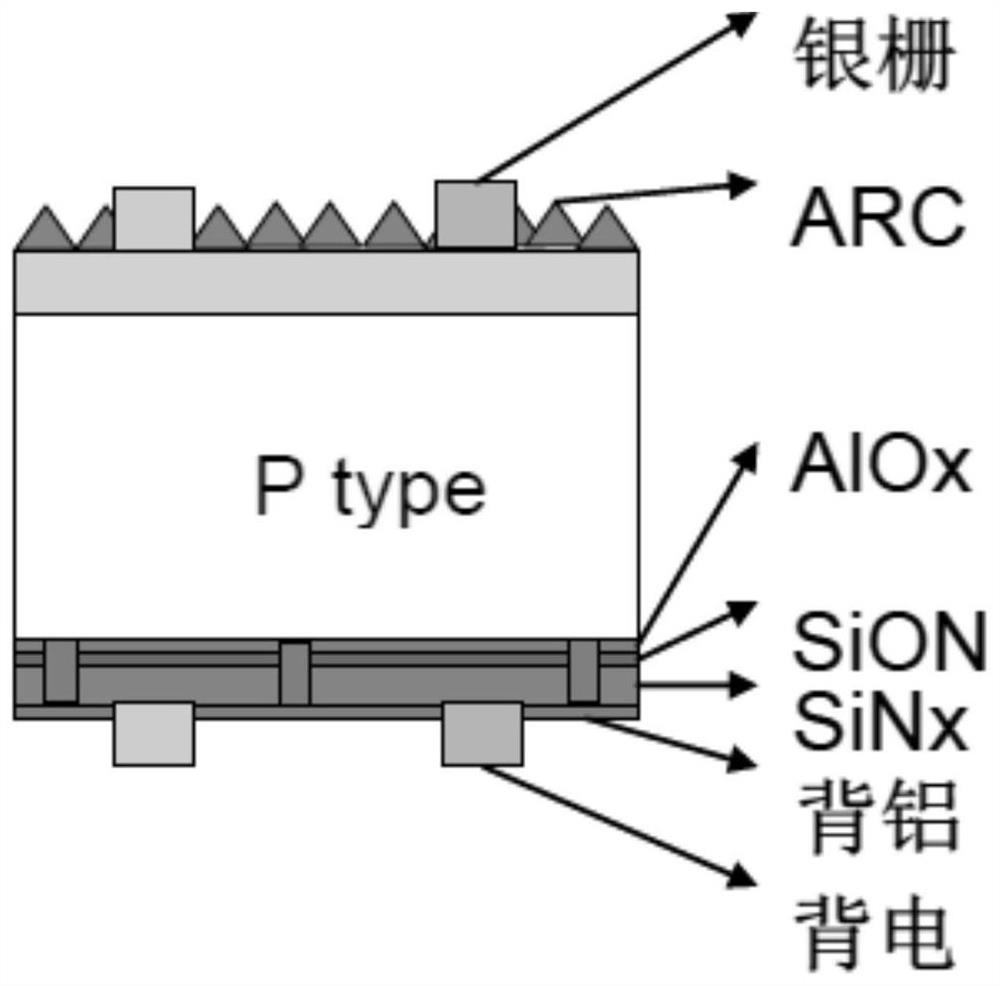

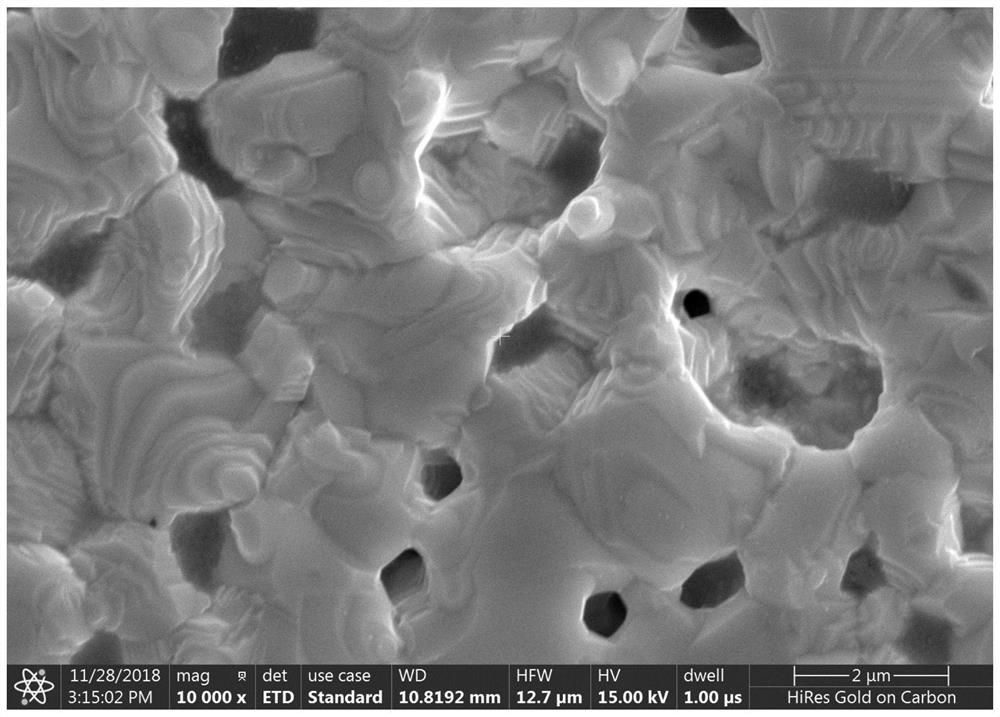

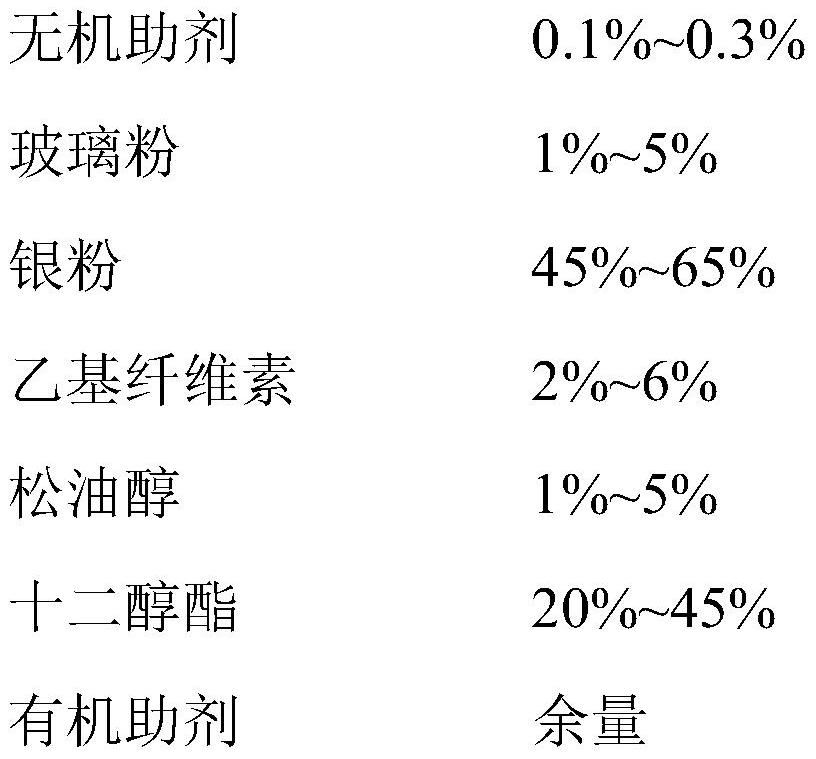

ActiveCN109949966AImprove liquidityHigh mechanical strengthNon-conductive material with dispersed conductive materialCable/conductor manufactureCelluloseElectrical battery

The invention discloses high-reliability PERC back silver conductive paste for a crystalline silicon solar cell and a preparation process for the high-reliability PERC back silver conductive paste. The viscosity of the slurry is 20 to 80 Pa.S, and the paste contains the following components in percentage by mass: 0.1%-0.3% of an inorganic additive, 1%-5% of glass powder, 45%-65% of silver powder,2%-6% of ethyl cellulose, 1%-5% of terpilenol, 20%-35% of texanol ester alcohol and a proper amount of an organic additive, wherein the glass powder is formed by the mixing of glass powder I and glasspowder II. The preparation method comprises the following steps: uniformly mixing the organic additive, ethyl cellulose, terpilenol and texanol ester alcohol under the water bath condition to obtaina carrier; adding the mixed glass system and the inorganic additive into the carrier, and uniformly mixing the mixture; and adding the silver powder system into the system at the step 2, and performing uniform mixing, rolling and filtering to obtain the back conductive silver paste. According to the invention, the PERC back silver paste guarantees the characteristics of the traditional non-contactsilver paste, is fewer in damages to an aluminum oxide passivation layer, is high in welding reliability of a back silver paste sintered electrode due to the fact that a mixed glass system is adopted, and has excellent comprehensive performances under the condition that the actual temperature is 740 DEG C-780 DEG C.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

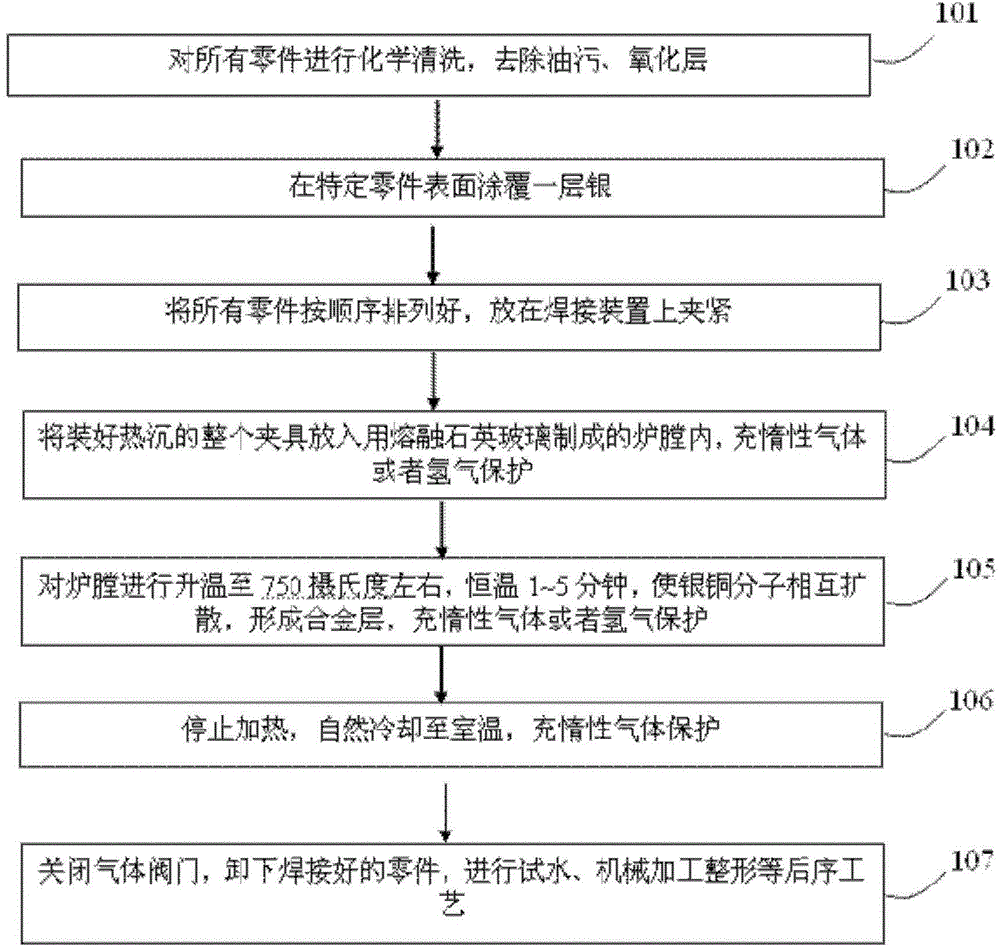

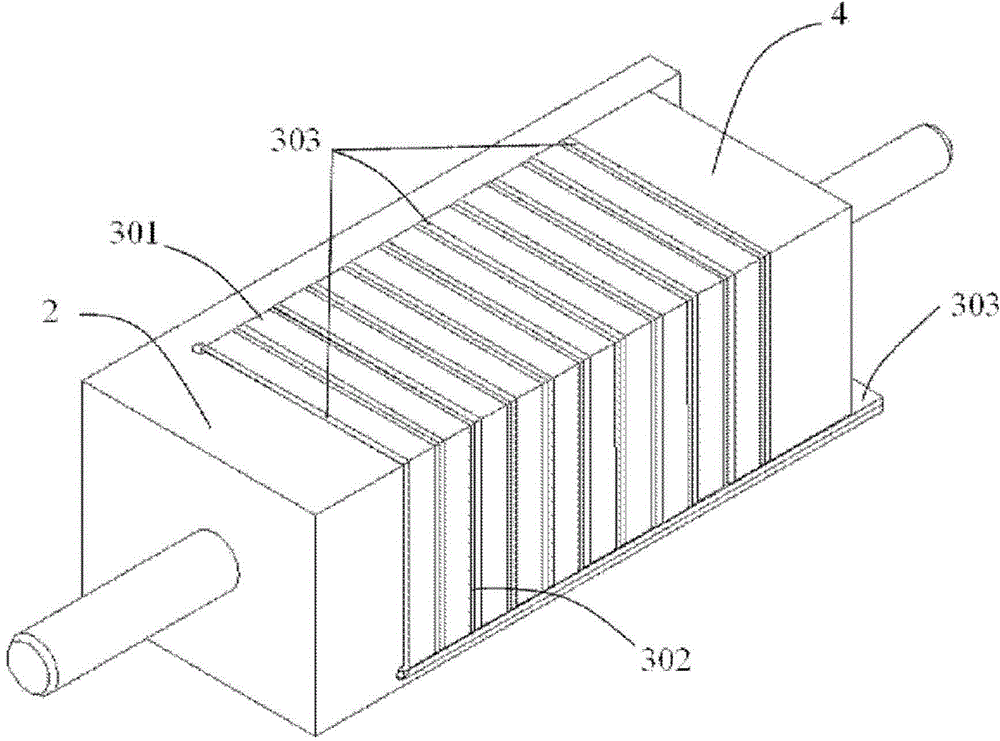

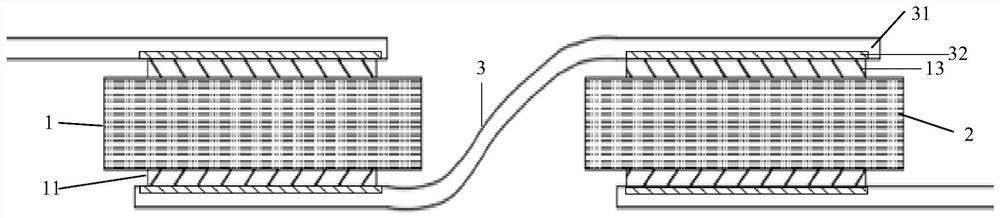

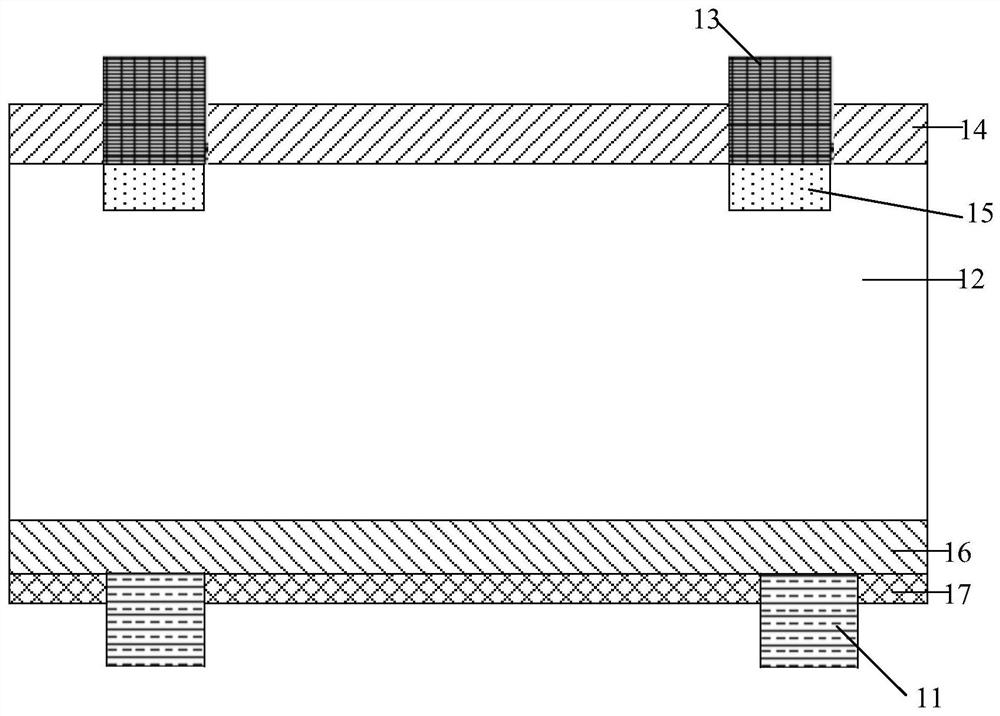

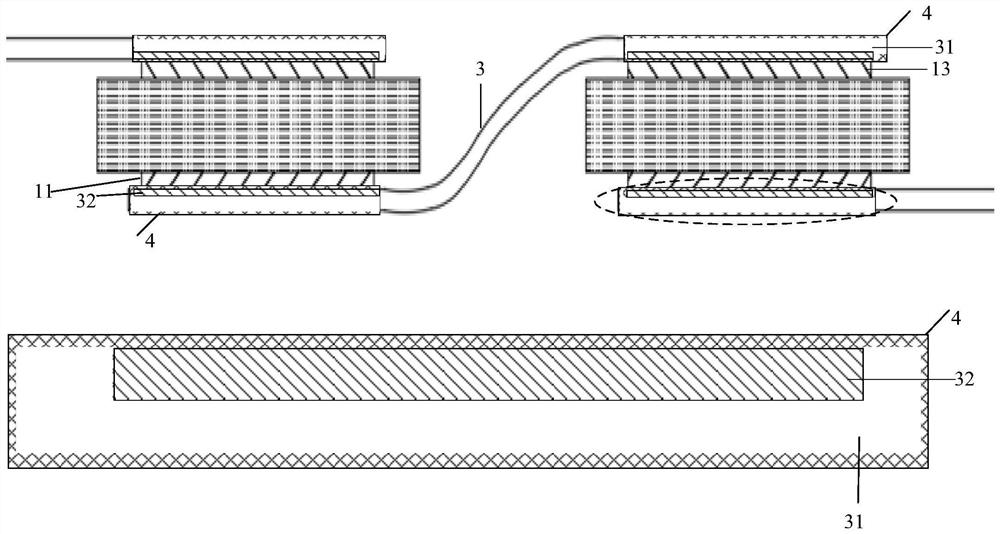

Silver copper diffusion welding method and device

InactiveCN104874932AAvoid heat sinkPrevent oxidationWelding/cutting auxillary devicesAuxillary welding devicesWater basedEngineering

The invention provides a novel silver copper diffusion welding method and a welding device used by same. The method and the welding device can integrally weld a plurality of thin plates or micro radiating graphics by a heat sink manner, have the advantages of being simple in method, high in welding yield, good in welding quality and good in reliability, and are mainly applied to water-based heat sink in refrigerating of a power type electronic element, a laser or an optical gain medium and mass production of bases.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

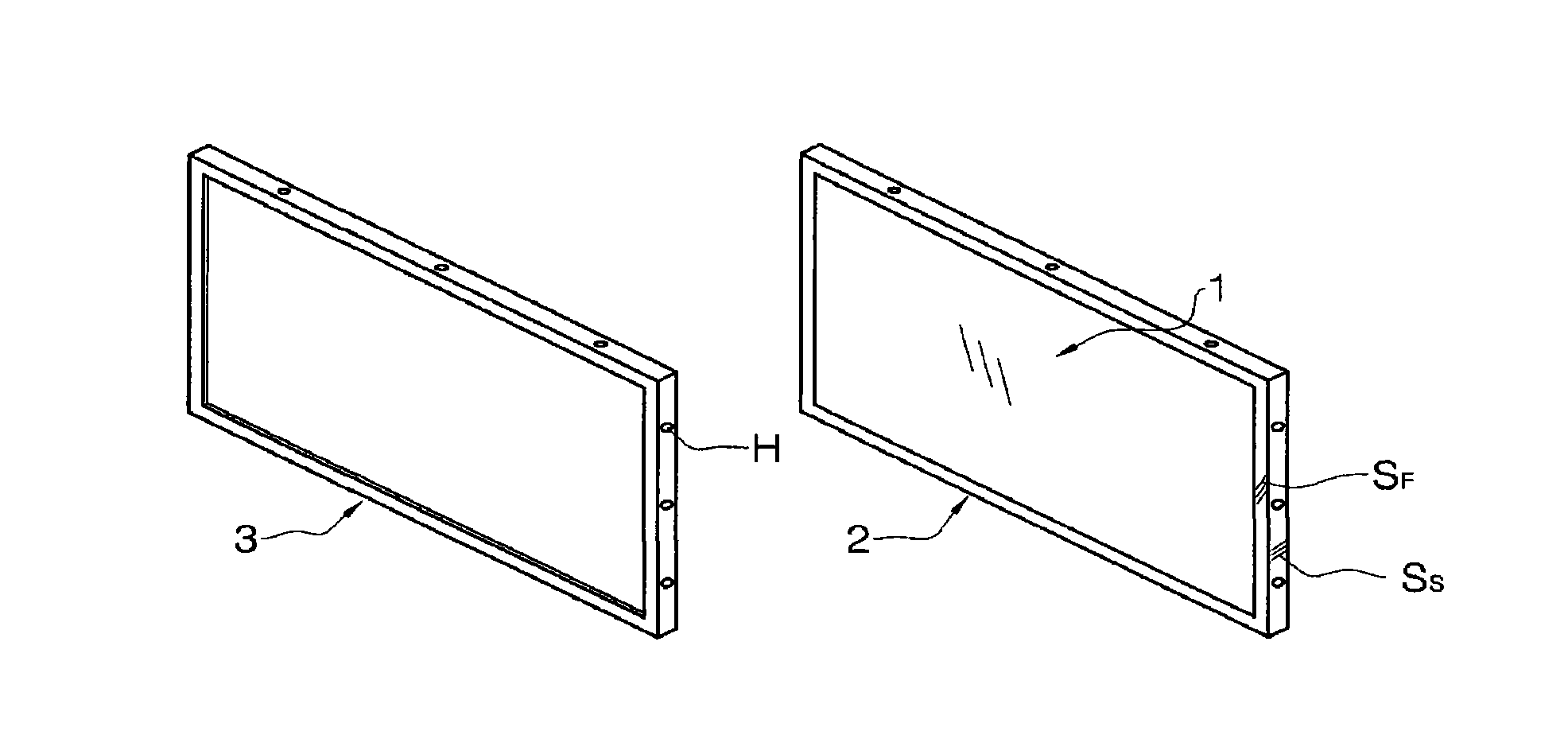

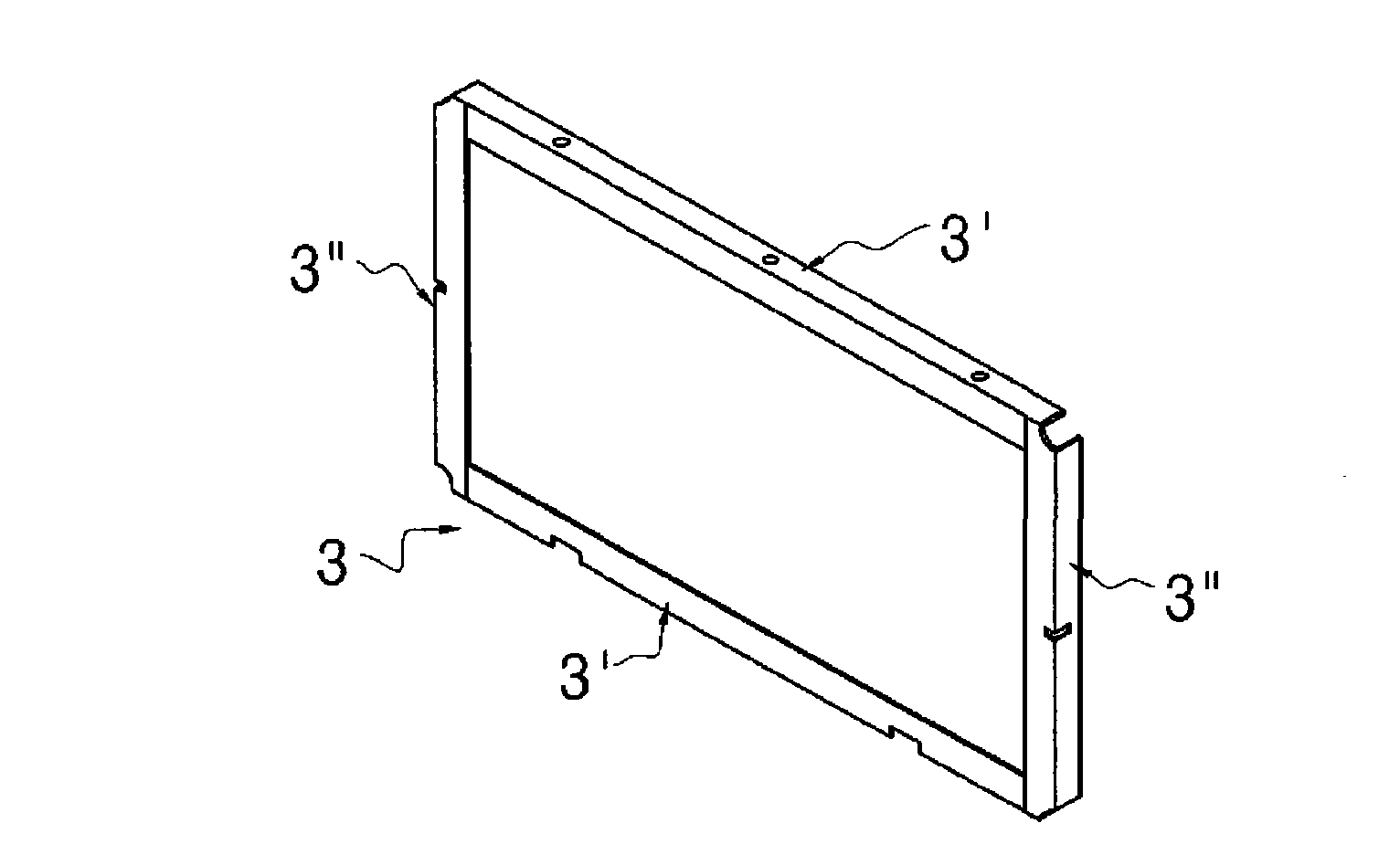

Reinforcement frame for a display panel using extruded aluminum alloy and apparatus and method for manufacturing the same

InactiveCN101528406AStandardized pre-soldering tasksConvenient welding operationEngine componentsNon-linear opticsCalenderingAluminium alloy

The present invention discloses a reinforcement frame for a display panel using aluminum alloy extrusion members and an apparatus and a method for manufacturing the same, wherein, while a number of unitary aluminum alloy extrusion members abut one another, a welding head is used to cause the abutting portions to undergo friction resulting from high-speed rotation so that the members are melted and welded to one another by the resulting frictional heat.

Owner:ALUKO株式会社

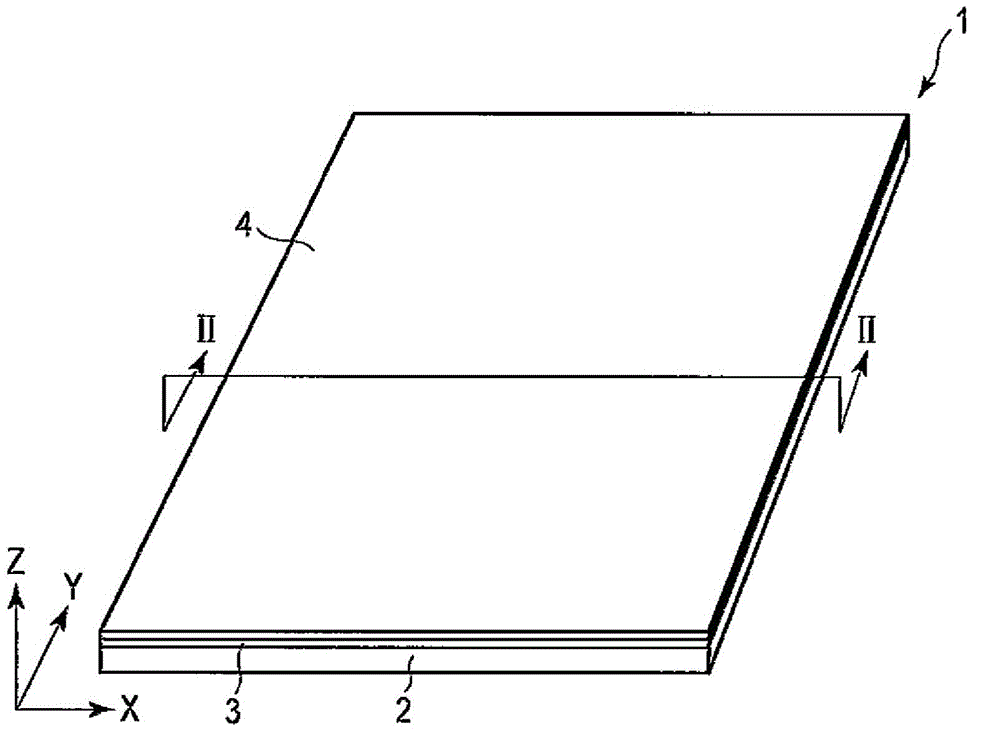

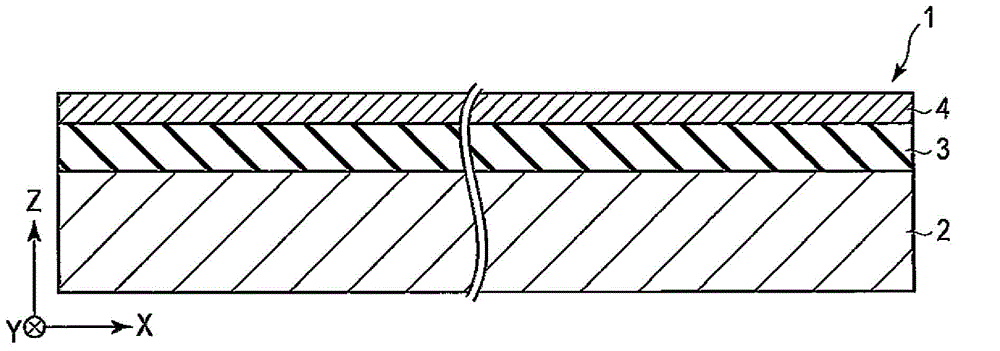

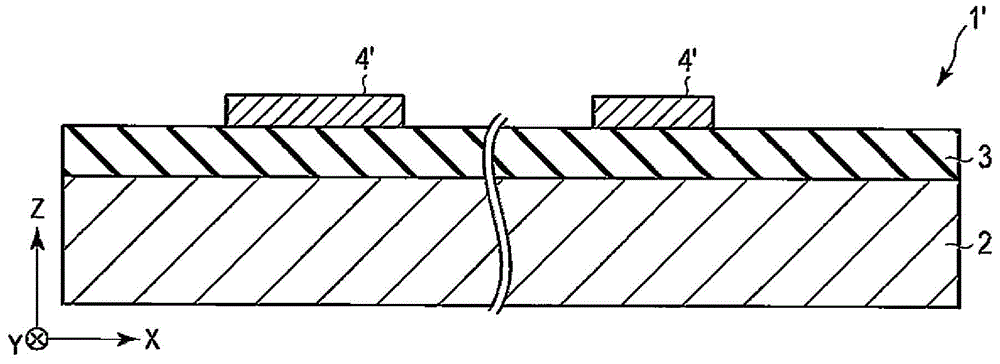

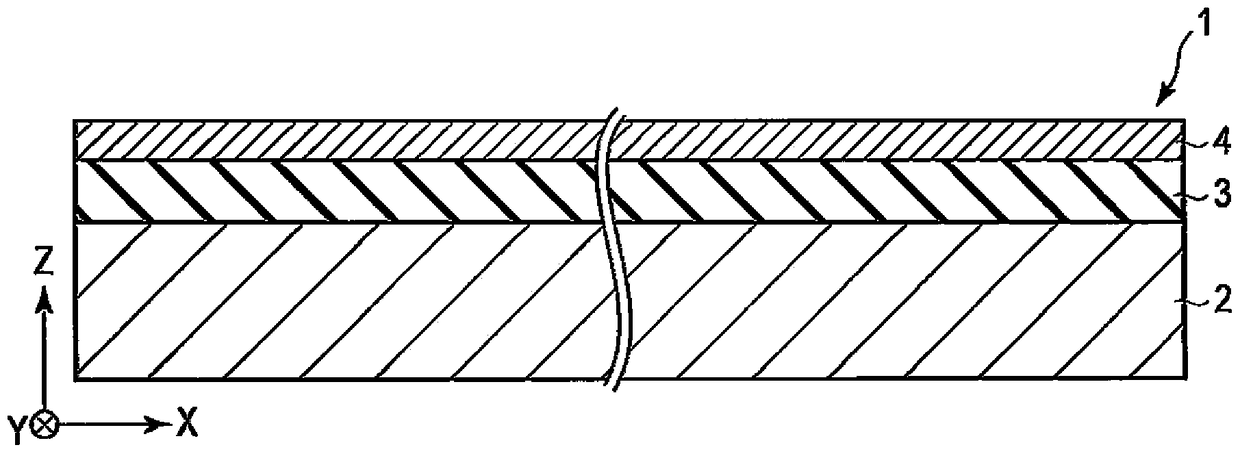

Laminate for circuit boards, metal-based circuit board, and power module

ActiveCN104412721AImprove heat resistanceIncreased durabilitySemiconductor/solid-state device detailsPrinted circuit aspectsMetal foilComputer module

Provided is a laminate for circuit boards, which comprises a metal substrate, an insulating layer that is provided on at least one surface of the metal substrate, and a metal foil that is provided on the insulating layer. This laminate for circuit boards is characterized in that the insulating layer contains an inorganic filler and a crosslinked copolymer of a bisphenol type cyanate resin and a novolac type cyanate resin.

Owner:NHK SPRING CO LTD

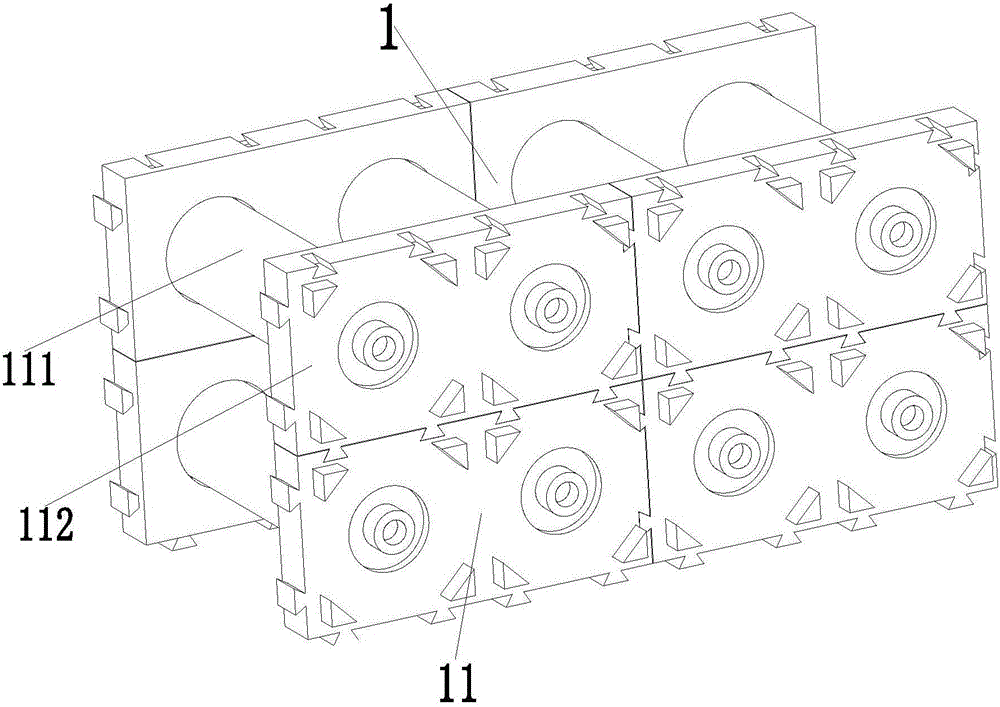

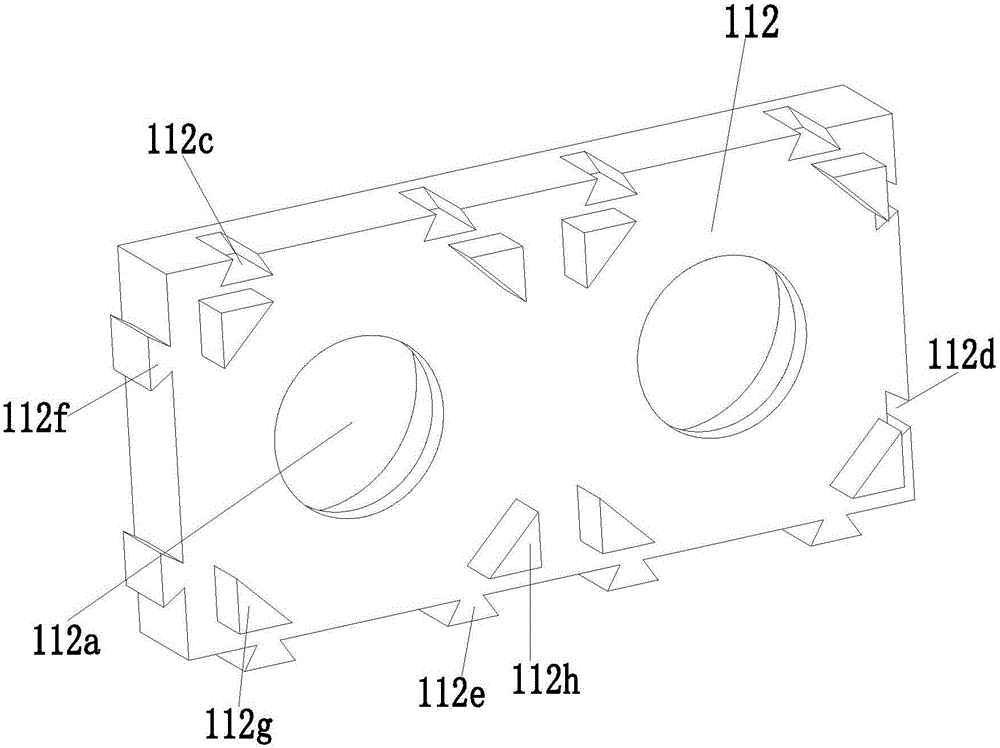

Cylindrical lithium battery assembly tool

InactiveCN105958105AReduce gapIncrease the gapAssembling battery machinesFinal product manufactureLithium-ion batteryLaser

The present invention relates to a cylindrical lithium battery assembly tool. The cylindrical lithium battery assembly tool includes a lithium battery assembly module and two lithium battery connection modules. The two lithium battery connection modules are symmetrically installed at two ends of the lithium battery assembly module by using assembly screws, and each lithium battery connection module and the assembly screw are connected in a laser welding manner. The laser welding manner has high welding quality, and lowers a probability of faults such as short circuit and poor contact that occur after long time use of corresponding lithium battery. The lithium battery assembly module adopts a modular decentralized installation design, so that the lithium batteries can be installed rapidly no matter how many lithium batteries are assembled, and the lithium batteries are simple to assemble and disassemble; and a gap between any two adjacent lithium batteries is large, so that the heat dissipation effect is good. The lithium battery connection modules can be customized and processed according to a quantity of the lithium batteries that are assembled in a modular decentralized manner in the lithium battery assembly module, the lithium batteries can be connected once, and two lithium batteries do not need to be connected separately. Through adoption of the cylindrical lithium battery assembly tool, a modular disassembling function of a lithium battery pack can be realized.

Owner:ZHEJIANG JINKAILAI NEW ENERGY TECH

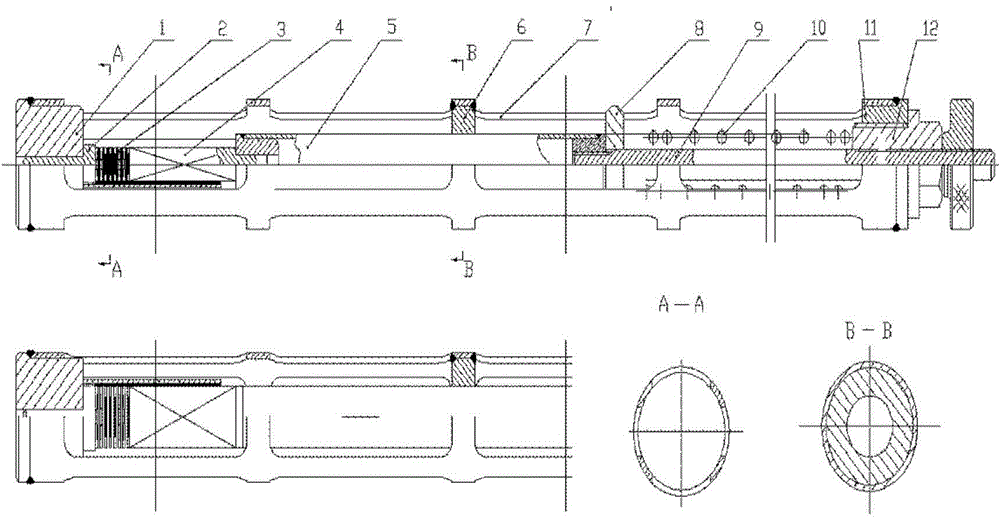

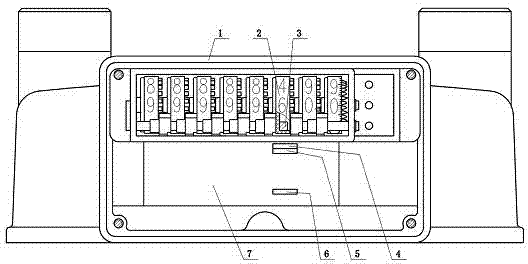

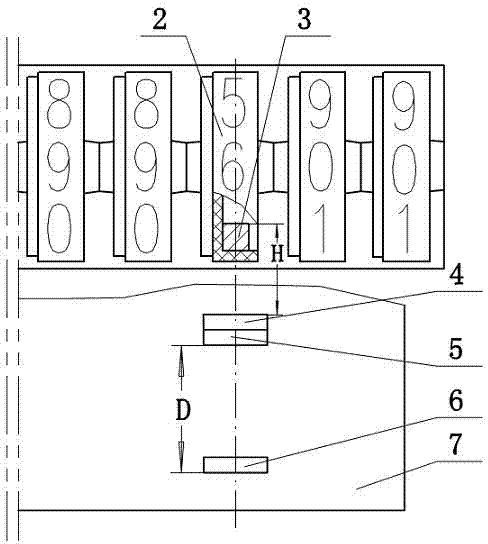

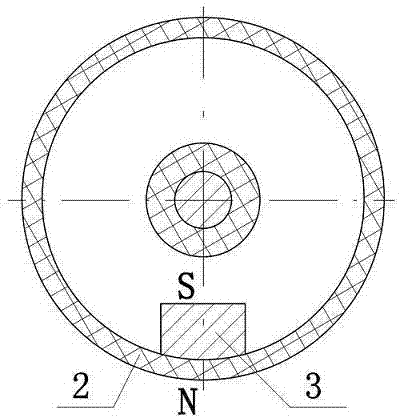

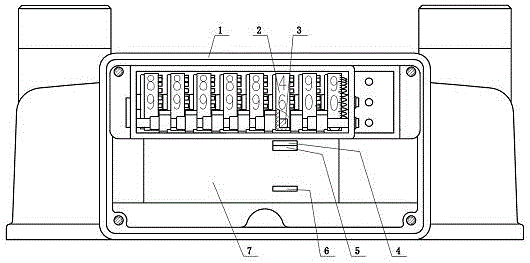

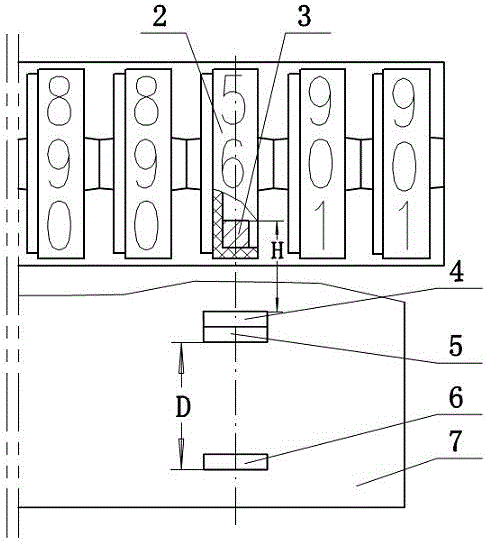

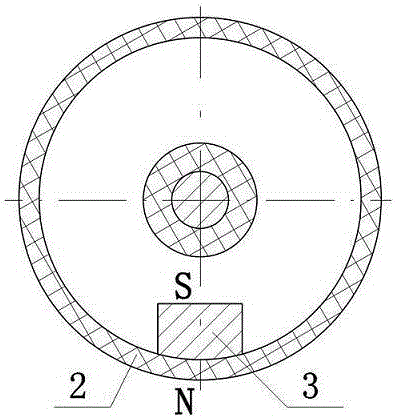

Sampling and counting mechanism for diaphragm gas meter

ActiveCN104296820AReduce intermediate linksSave the process of applying protective glueVolume meteringMagnetic disturbanceGas meter

The invention provides a sampling and counting mechanism for a diaphragm gas meter and relates to the technical field gas meters. The sampling and counting mechanism for the diaphragm gas meter comprises a gas meter upper shell, a number wheel assembly and a control circuit board. Number wheels of the number wheel assembly are provided with multiple pieces of magnetic steel. The control circuit board is provided with a sampling sensor I and a sampling sensor II. The sampling sensor I and the sampling sensor II are close to each other and are located in the diameter direction of the number wheels. According to the sampling and counting mechanism for the diaphragm gas meter, the technical problems that in the prior art, the magnetic disturbance resistance capacity of a sampling and counting device of a gas meter is weak and potential mis-counting dangers exist are solved. The sampling and counting mechanism for the diaphragm gas meter has the advantages that counting signals are collected through the control circuit board directly, an intermediate link is omitted, potential dangers influencing the sampling and counting accuracy are eliminated, the process is simple, production cost is lowered, and production efficiency is improved; the effects for resisting shaking and resisting attacks from external magnetic fields are good, and the accuracy of sampling and counting is guaranteed.

Owner:GOLDCARD HIGH TECH

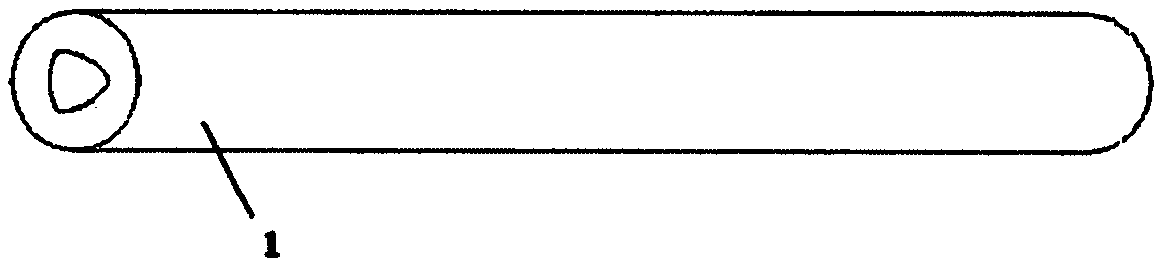

Novel processing technology for root canal file and root canal file

PendingCN111098101AFlexible collocationMeet the surgical requirementsTeeth fillingTeeth cappingProcess engineeringProcessing cost

The invention discloses a novel processing technology for a root canal file and the root canal file and puts forward the root canal file processed with the composite blank body technology so as to overcome the defects of expensive materials, high processing costs and low processing efficiency of root canal files in the prior art. According to a blank of the root canal file, a composite blank bodyis formed through drawing and compositing of two or same materials, and then a handle, a connecting rod and a file body are processed at different parts of the composite blank body. The technology hasthe advantages that inner and outer materials can be matched flexibly, a metal tube and a metal bar of the composite blank body can be made of different materials, the use effect is not affected while materials of a file body meet operation requirements, and the cost is convenient to control. During screwing manufacturing of threads of file bodies, screwing manufacturing is performed on two connected composite blank bodies simultaneously, the two connected composite blank bodies are cut off in the middle finally, two root canal files are processed simultaneously, and thus the processing efficiency is improved.

Owner:江苏盛玛特新材料科技有限公司

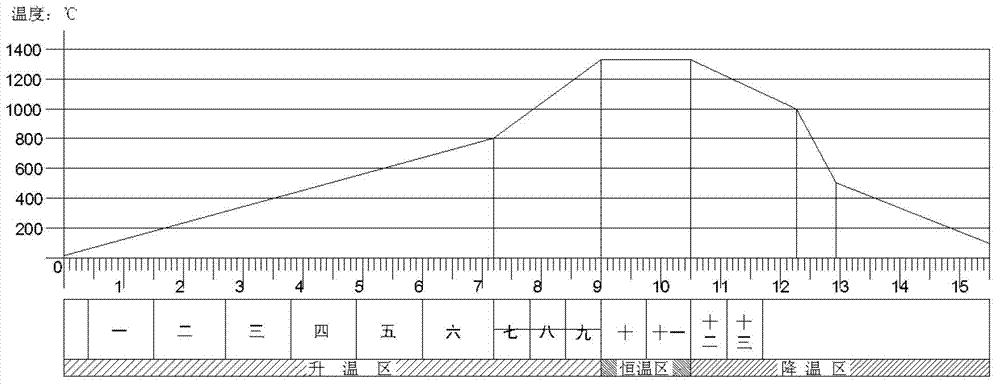

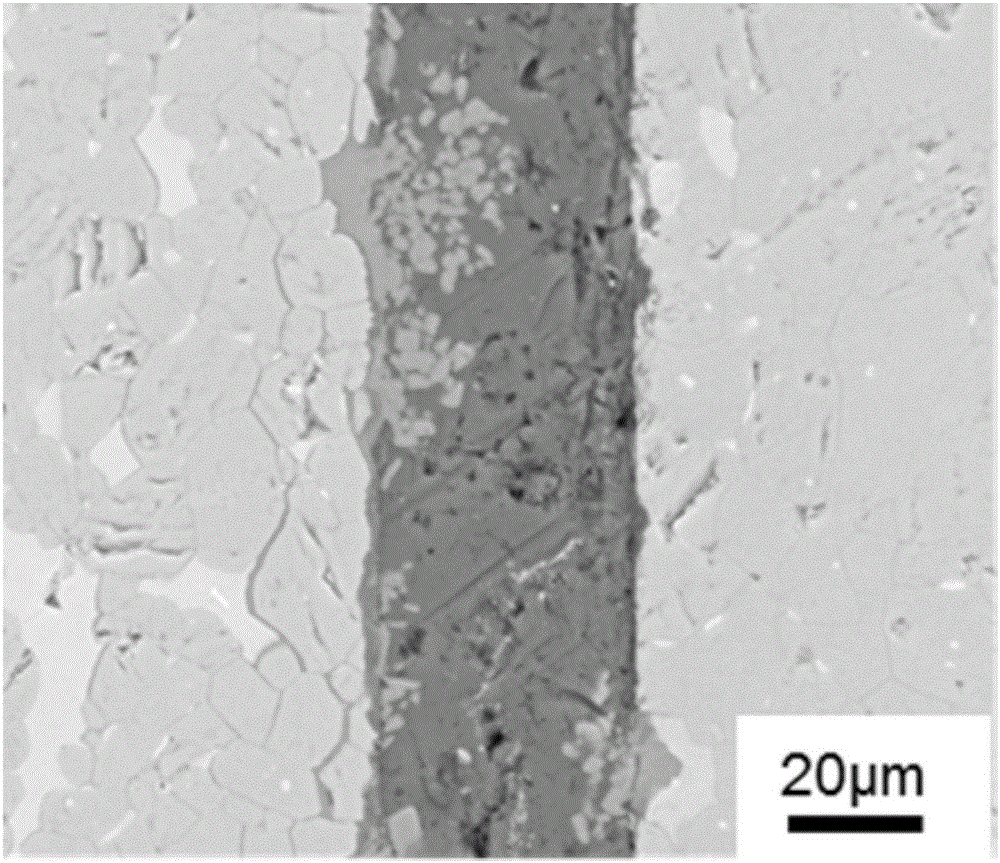

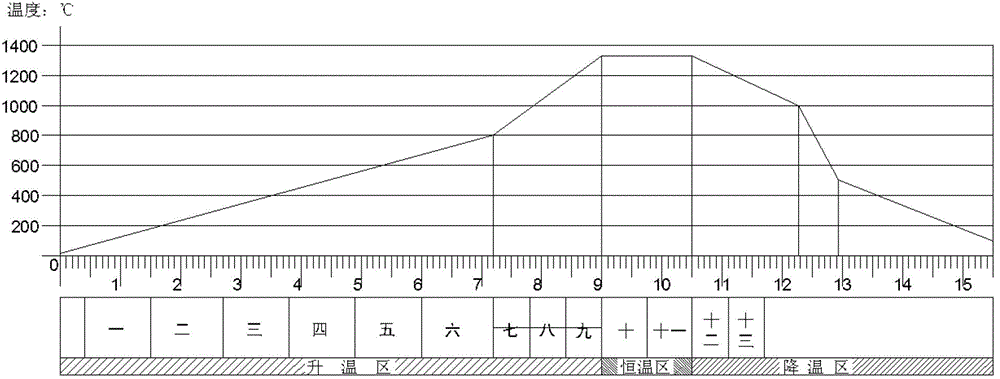

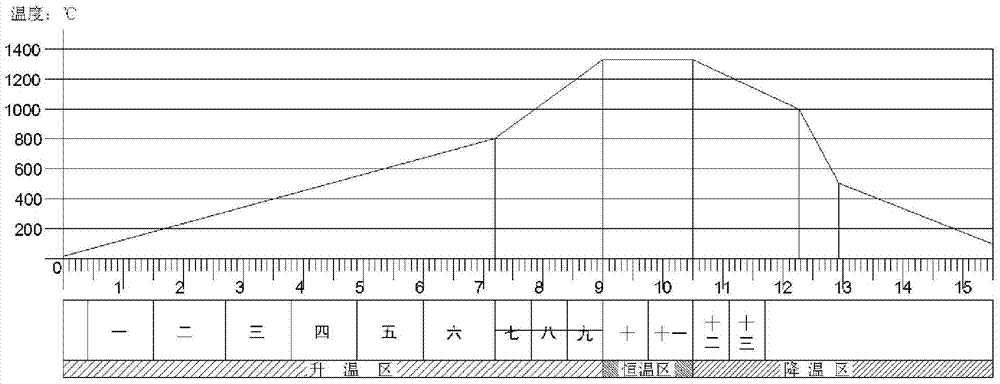

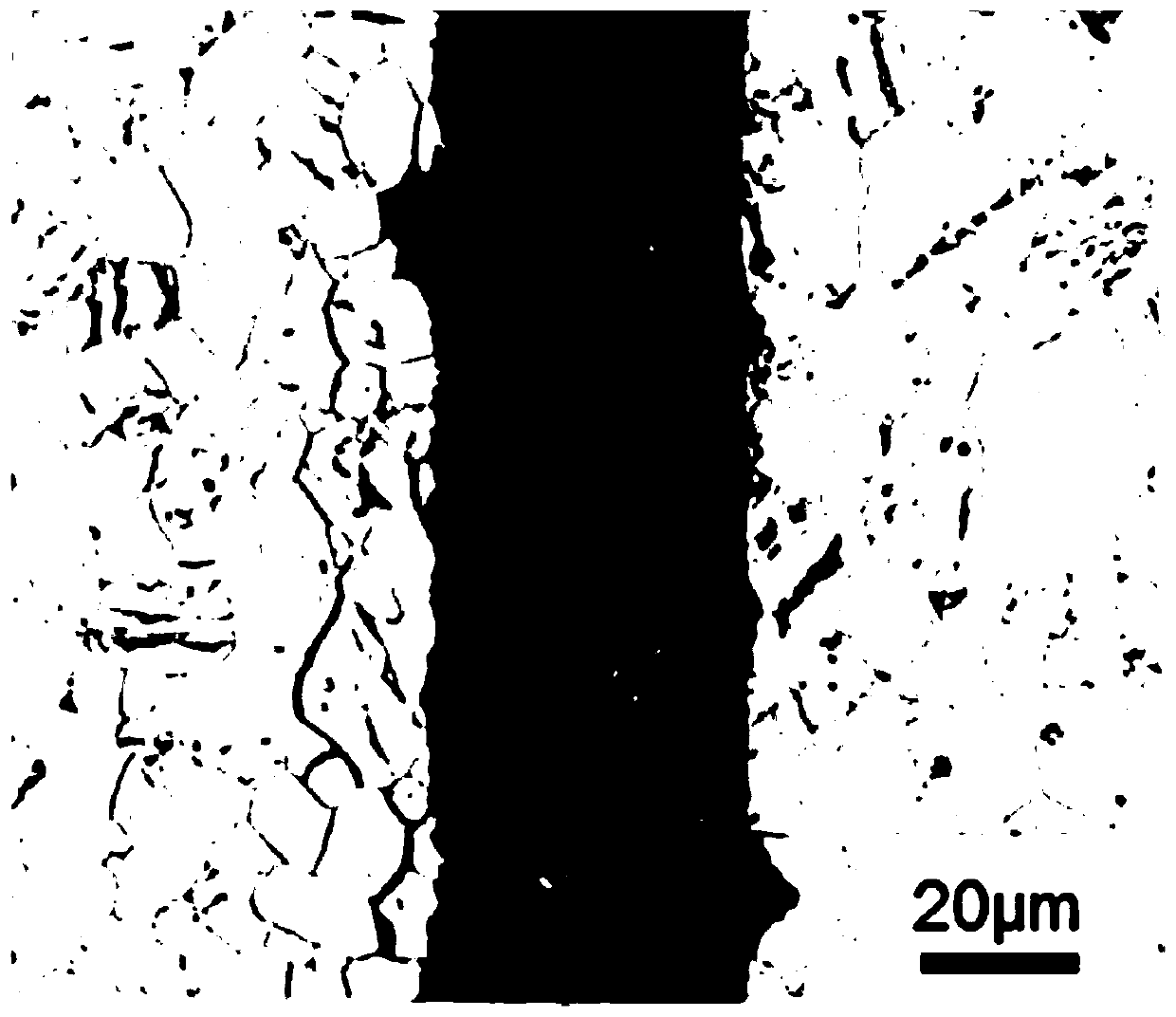

Method for brazing Ti2AlC ceramics by Al base brazing filler metal

InactiveCN107433401ALow melting pointLow costWelding/cutting media/materialsSoldering mediaVacuum pumpingUltimate tensile strength

The invention relates to a method for brazing Ti2AlC ceramics by Al base brazing filler metal, and aims to solve the technical problem of short service life of an existing electric contact component. The method includes the steps: first, preparing the brazing filler metal; second, assembling a Ti2AlC ceramic / brazing filler metal / Ti2AlC ceramic structural part, placing the structural part into a vacuum brazing furnace, performing vacuum pumping to reach 6.0*10<3>Pa, increasing temperature to 300 DEG C at the heating rate of 10 DEG C / min, keeping the temperature for 30min, increasing the temperature to 660-900 DEG C at the heating rate of 10 DEG C / min, keeping the temperature for 5-30min under the pressure of 0.2-1.0MPa, reducing the temperature to 300 DEG C at the cooling rate of 10 DEG C / min, performing furnace cooling and finishing brazing the Ti2AlC ceramics by the Al base brazing filler metal. By the method, a joint with an excellent mechanical property can be obtained, the shear strength of the joint is 70-120MPa, and electrical conductivity is 3.73-4.18*10<6>S / m and reaches 94% or more of the electrical conductivity of the Ti2AlC ceramics.

Owner:HARBIN INST OF TECH

New cavity dielectric cavity filter

ActiveCN102969549BReduce lossSteep frequency characteristicResonatorsThermal expansionTemperature coefficient

The invention discloses a novel medium cavity filter with a cavity. The novel medium cavity filter comprises the cavity and medium resonators, wherein each medium resonator is a cylinder with a through hole and is prepared from the following components according to mass percent: 29%-32% of calcium carbonate with purity of 97.5%, 9%-11% of aluminum oxide with purity of 97.5%, 21%-25% of neodymium oxide with purity of 99.5%, and 35%-38% of titanium dioxide with purity of 99.6%; a silver layer is coated at one end of each medium resonator, and the other end of the medium resonator is welded inside the cavity; the cavity is prepared from the following components according to mass percent: 95%-96% of aluminum oxide, 2%-3% of calcium carbonate, 0.8%-1.5% of lanthanum oxide, and 0.2%-0.5% of samarium oxide; and the dielectric constant of the cavity is 9.5. The medium cavity filter disclosed by the invention is high in Q value, small in size and adjustable in temperature coefficient, and can ensure high reliability of a product structure and good consistency of thermal expansion coefficients of the cavity and the medium resonators.

Owner:江苏灿勤科技股份有限公司

Solar cell module and production method thereof

PendingCN112133780AAvoid damageReduce transmission lossFinal product manufacturePhotovoltaic energy generationMetallic electrodeHot melt

The invention provides a solar cell module and a production method thereof, and relates to the technical field of solar photovoltaics. The solar cell module comprises a plurality of p-type crystallinesilicon solar cells and a plurality of wire groups used for connecting the adjacent p-type crystalline silicon solar cells. Each wire group comprises a preset number of wires which are arranged in parallel; the preset number is 4-30; the wire comprises a baseline; and the wire further comprises a hot melting conducting layer which at least wraps the surface of the base wire. The hot melting conducting layer comprises a first hot-melt conductive layer for hot-pressing connection or viscous connection with a front metal electrode of a p-type crystalline silicon solar cell, and a second hot-meltconductive layer for hot-pressing connection or viscous connection with a back metal electrode of another adjacent p-type crystalline silicon solar cell; and the width of the wire is larger than or equal to 50 micrometers and smaller than or equal to 1000 micrometers. According to the invention, the assembly loss is reduced, the current transmission loss is reduced, and the photoelectric conversion efficiency is high.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

Microwave Dielectric Resonator

The invention discloses a microwave dielectric resonator, comprising a cavity and a dielectric resonator, the dielectric resonator is a cylinder with a through hole; the dielectric resonator is composed of the following components in mass percentage: calcium carbonate, Aluminum oxide, neodymium oxide, titanium dioxide; one end of the dielectric resonator is coated with a silver layer, and the other end of the dielectric resonator is welded in the cavity; the cavity is composed of the following components in mass percentage: alumina 95~ 96%, calcium carbonate 2~3%, lanthanum oxide 0.8~1.5%, samarium oxide 0.2~0.5%; the relative dielectric constant of the cavity is 9.5; the surface roughness of the inner wall of the cavity is about 0.8; the cavity The internal wall is covered with a metal layer through sputtering or electroless plating. The microwave dielectric resonator of the invention has a high Q value, and the tuning range can reach 7%-10% at a specified frequency. The general tuning range of the TE mode resonator is 3%-4%.

Owner:江苏灿勤科技股份有限公司

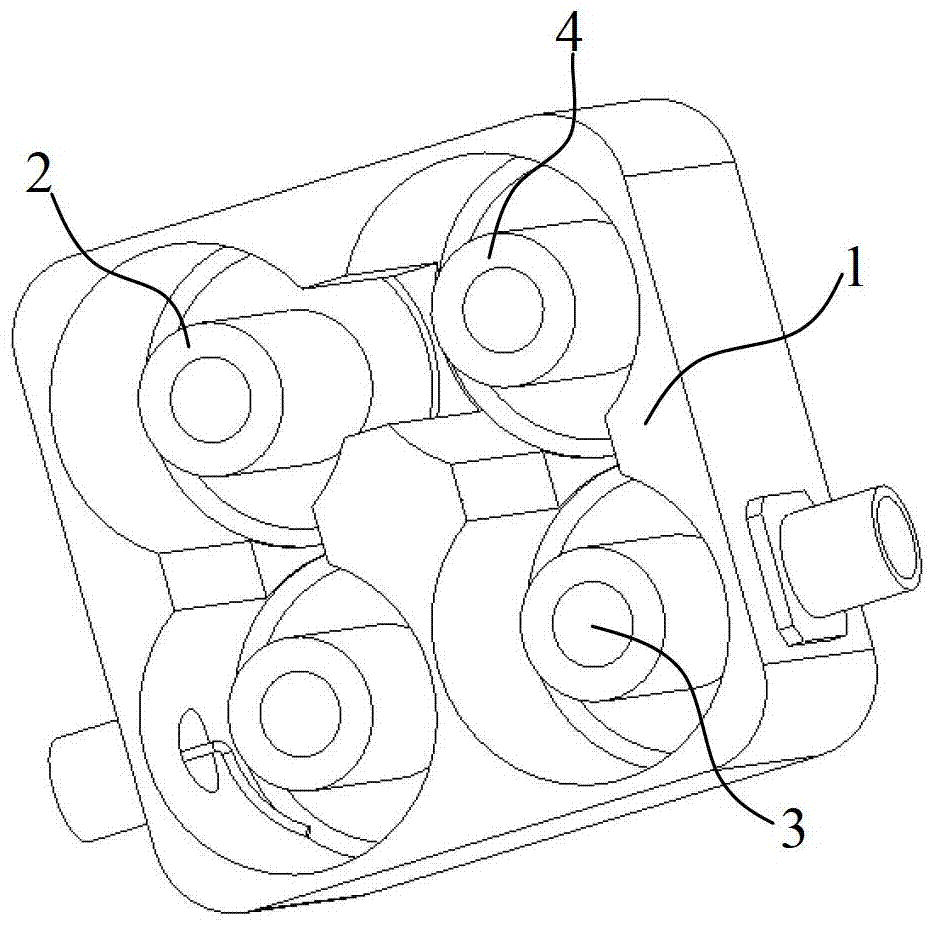

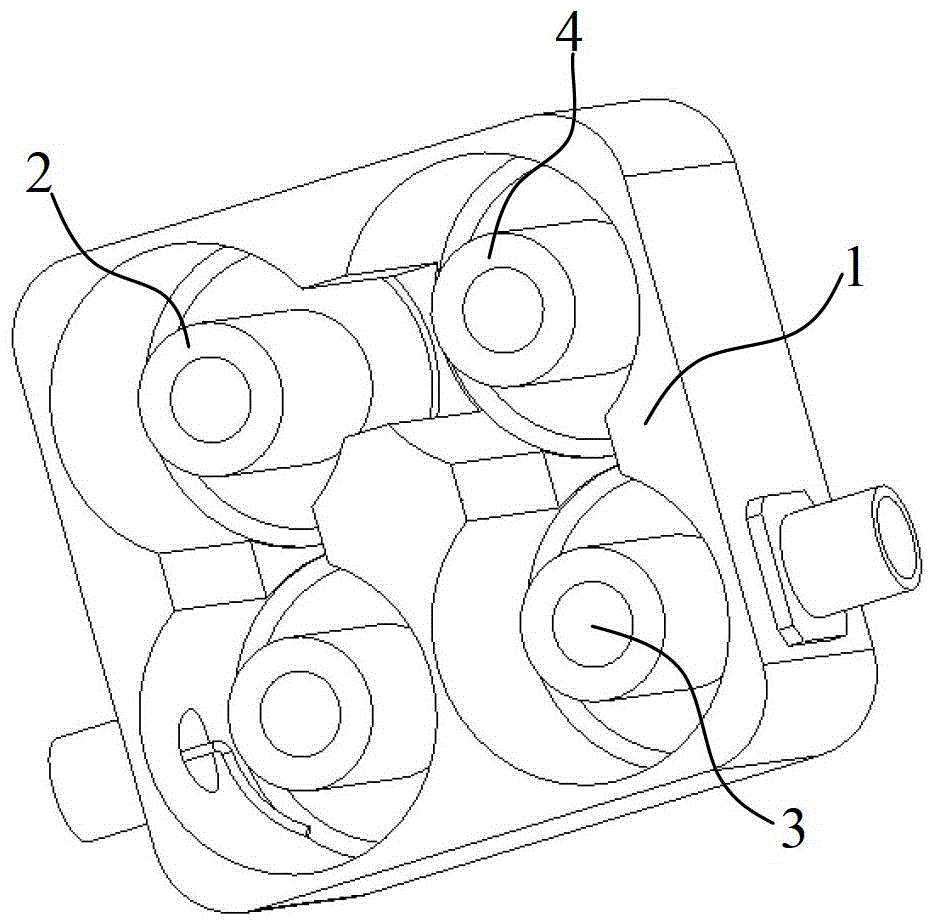

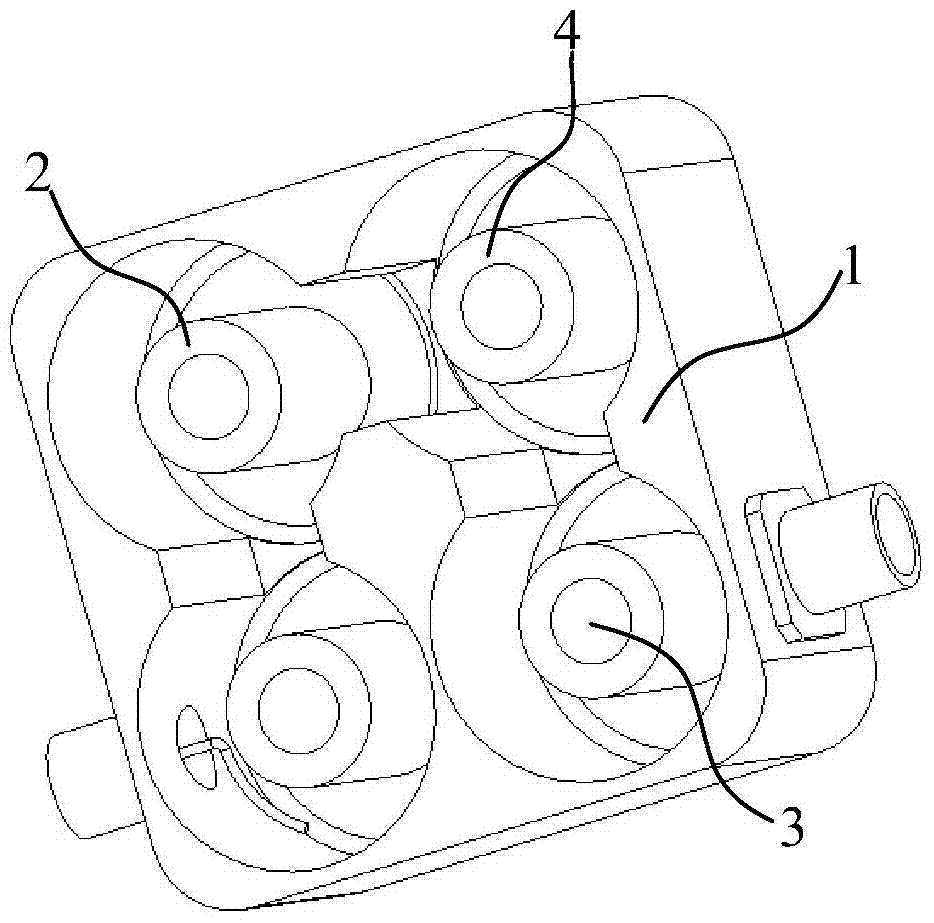

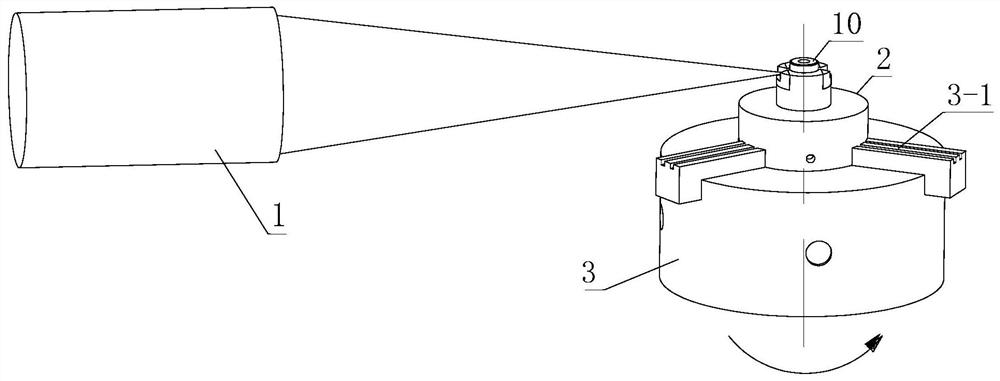

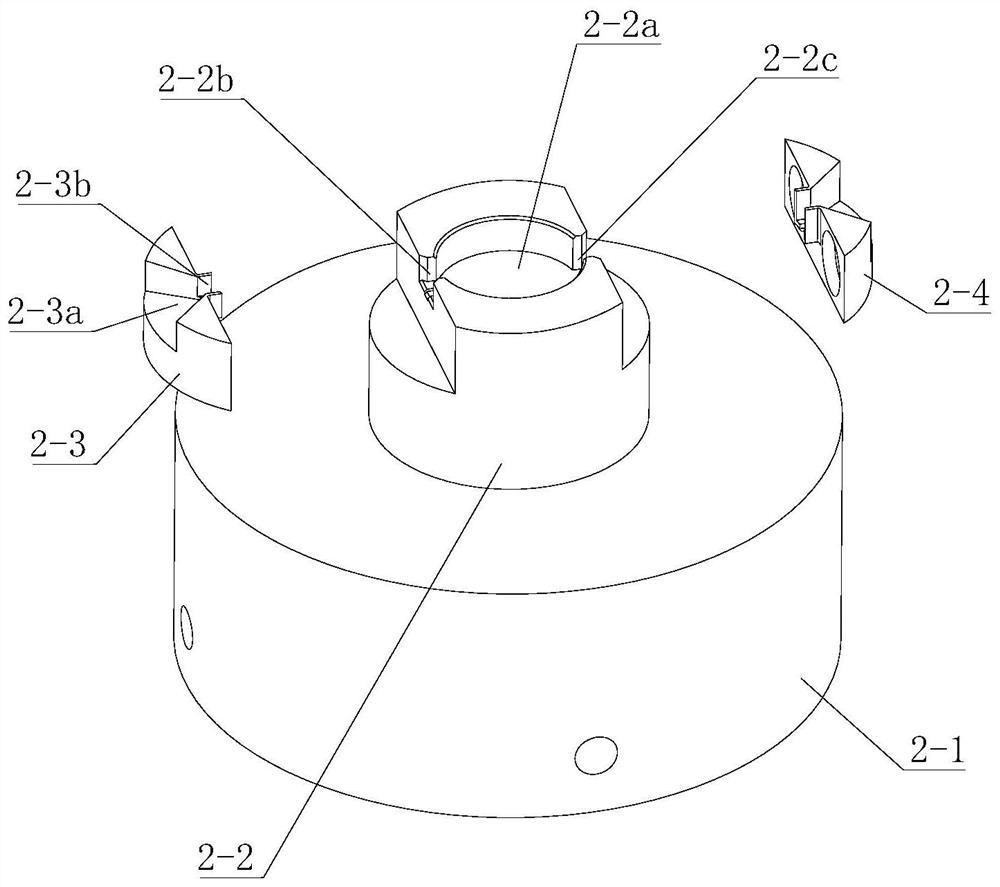

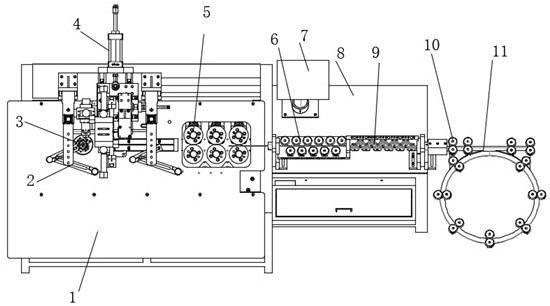

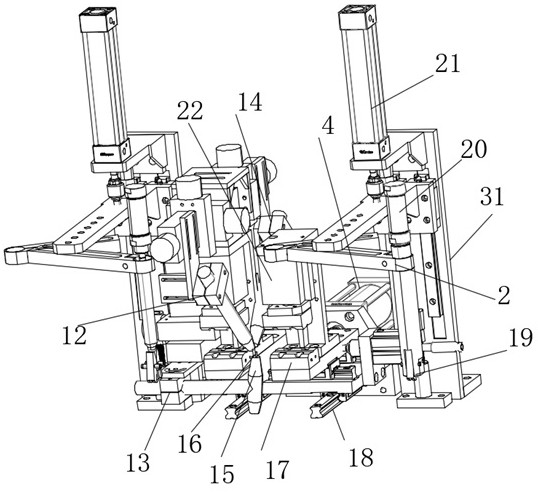

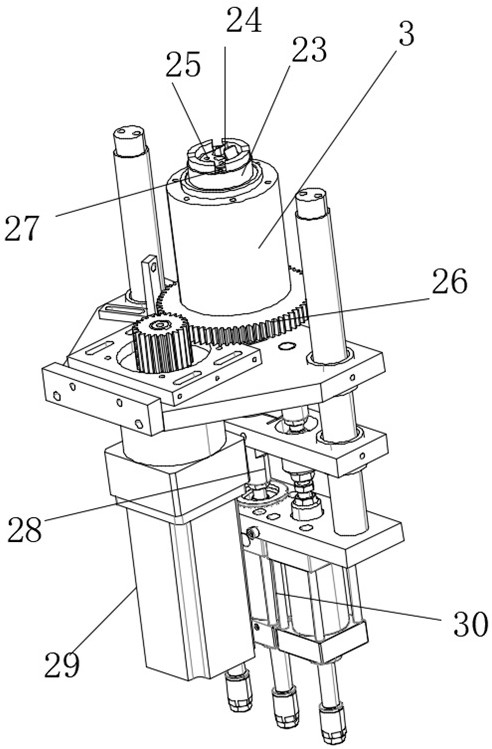

Welding assembly and welding method of battery adapter pieces

ActiveCN113182676ASolve the problem of poor welding qualityGood welding reliabilityWelding/cutting auxillary devicesAuxillary welding devicesContinuous lightElectrical battery

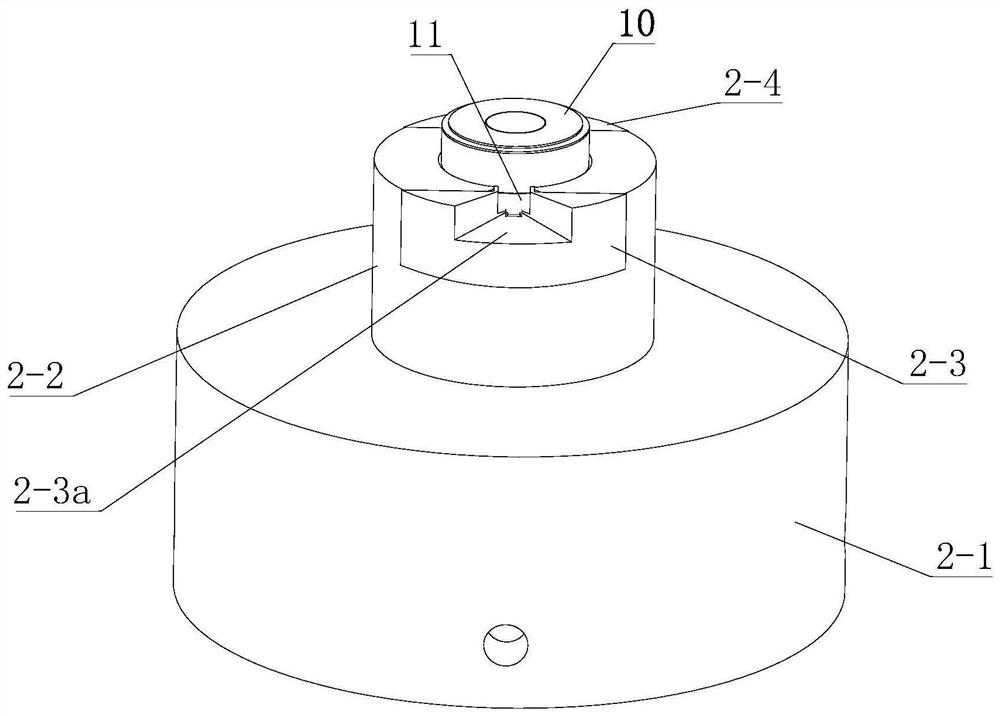

The invention discloses a welding assembly and a welding method of battery adapter pieces. The welding assembly comprises a laser device; a workpiece clamp used for installing a workpiece, wherein the workpiece clamp comprises a base, a workpiece installing part arranged on the base and a welding clamping block arranged on the workpiece installing part, the workpiece installing part is provided with a workpiece installing position for fixing the workpiece and welding piece containing grooves for containing welding pieces, the welding clamping block is provided with a light-transmitting groove allowing laser to penetrate and a clamping part capable of being assembled with the welding piece containing grooves, and the welding pieces are tightly pressed on the surface of the workpiece through the clamping part; and a rotating seat, wherein the workpiece clamp is arranged on the rotating seat, and the rotating seat can drive the workpiece clamp to rotate around the axis of the workpiece. According to the welding assembly, continuous light emitting and rotary welding modes are adopted, and the problems of low welding reliability and a low yield caused by difficult accurate focusing of laser focal length and low welding strength when the adapter pieces are welded in a spot welding mode in the past are solved.

Owner:ZHUHAI COSMX BATTERY CO LTD

A silver conductive paste on the back of a high-reliability perc crystalline silicon solar cell and its preparation process

ActiveCN109949966BImprove liquidityHigh mechanical strengthNon-conductive material with dispersed conductive materialCable/conductor manufactureCelluloseElectrical battery

The invention discloses high-reliability PERC back silver conductive paste for a crystalline silicon solar cell and a preparation process for the high-reliability PERC back silver conductive paste. The viscosity of the slurry is 20 to 80 Pa.S, and the paste contains the following components in percentage by mass: 0.1%-0.3% of an inorganic additive, 1%-5% of glass powder, 45%-65% of silver powder,2%-6% of ethyl cellulose, 1%-5% of terpilenol, 20%-35% of texanol ester alcohol and a proper amount of an organic additive, wherein the glass powder is formed by the mixing of glass powder I and glasspowder II. The preparation method comprises the following steps: uniformly mixing the organic additive, ethyl cellulose, terpilenol and texanol ester alcohol under the water bath condition to obtaina carrier; adding the mixed glass system and the inorganic additive into the carrier, and uniformly mixing the mixture; and adding the silver powder system into the system at the step 2, and performing uniform mixing, rolling and filtering to obtain the back conductive silver paste. According to the invention, the PERC back silver paste guarantees the characteristics of the traditional non-contactsilver paste, is fewer in damages to an aluminum oxide passivation layer, is high in welding reliability of a back silver paste sintered electrode due to the fact that a mixed glass system is adopted, and has excellent comprehensive performances under the condition that the actual temperature is 740 DEG C-780 DEG C.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

Surface-mounted fuser

ActiveCN102664127BNo consistency issuesImprove breaking capacityContactsEmergency protective devicesHigh volume manufacturingSurface mounting

A surface-mounted fuse comprises a fusing chip (1). The fusing chip mainly consists of terminal electrodes (2), a ceramic substrate (3), a fusing body layer (4), and an arc extinction glass layer (5). The fusing body layer is located on an upper surface of the ceramic substrate. The two terminal electrodes are located on two sides of the fusing body layer respectively, and are electrically connected to the fusing body layer. The arc extinction glass layer covers the fusing body layer and the regions, close to the arc extinction glass layer, of the terminal electrodes. The surface-mounted fuse further comprises a fuse body (7) having a round through hole (6) in the middle. The fusing chip is located in the round through hole of the fuse body. Two metal covers (8) are located at two ends of the fuse body respectively, and cover the round through hole to form an enclosed chamber. The terminal electrodes are electrically connected to the metal covers through solder lugs (9). The surface-mounted can endure high temperature, has high strength, and can wrap a fuse wire and the arc extinction glass therein. The overall strength, the breaking capability, and the resistance to cold and hot shocks of the fuse are improved, and mass production is convenient.

Owner:SEMITEL ELECTRONICS

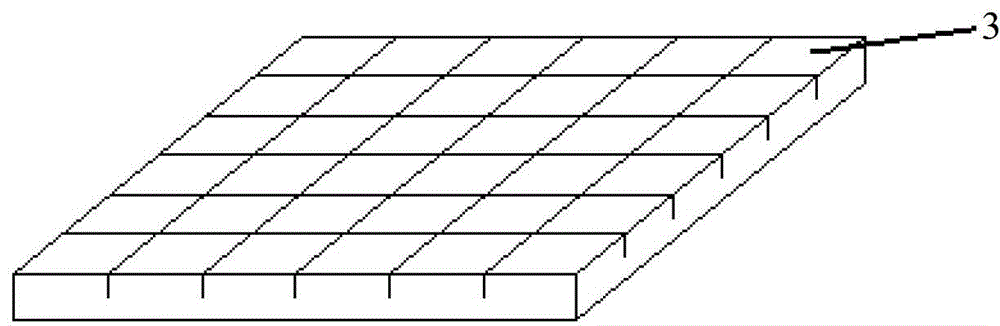

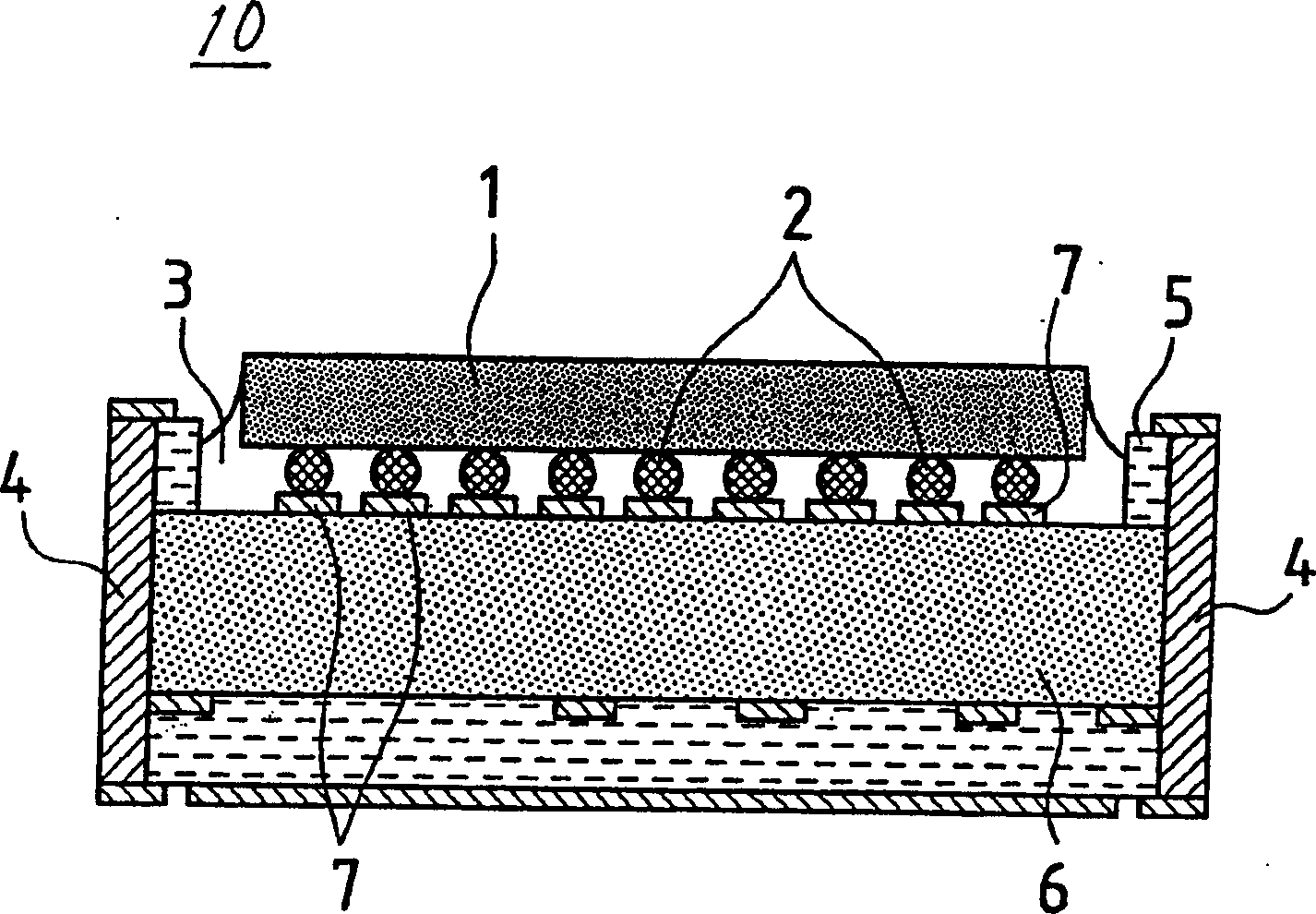

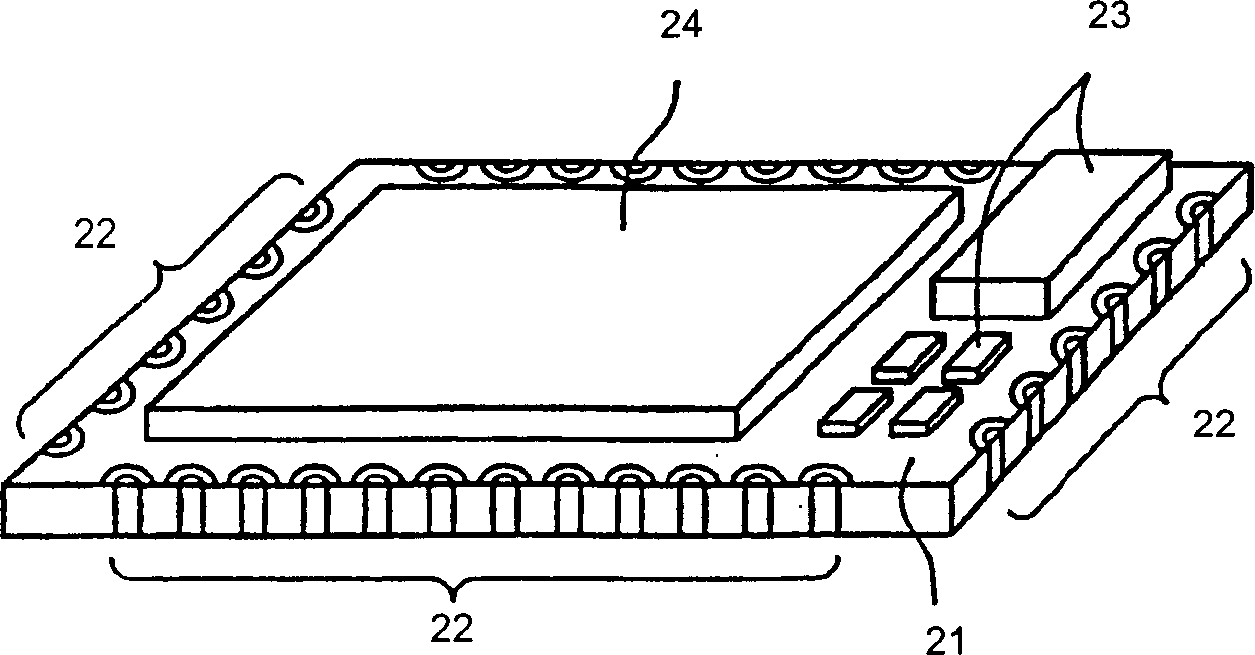

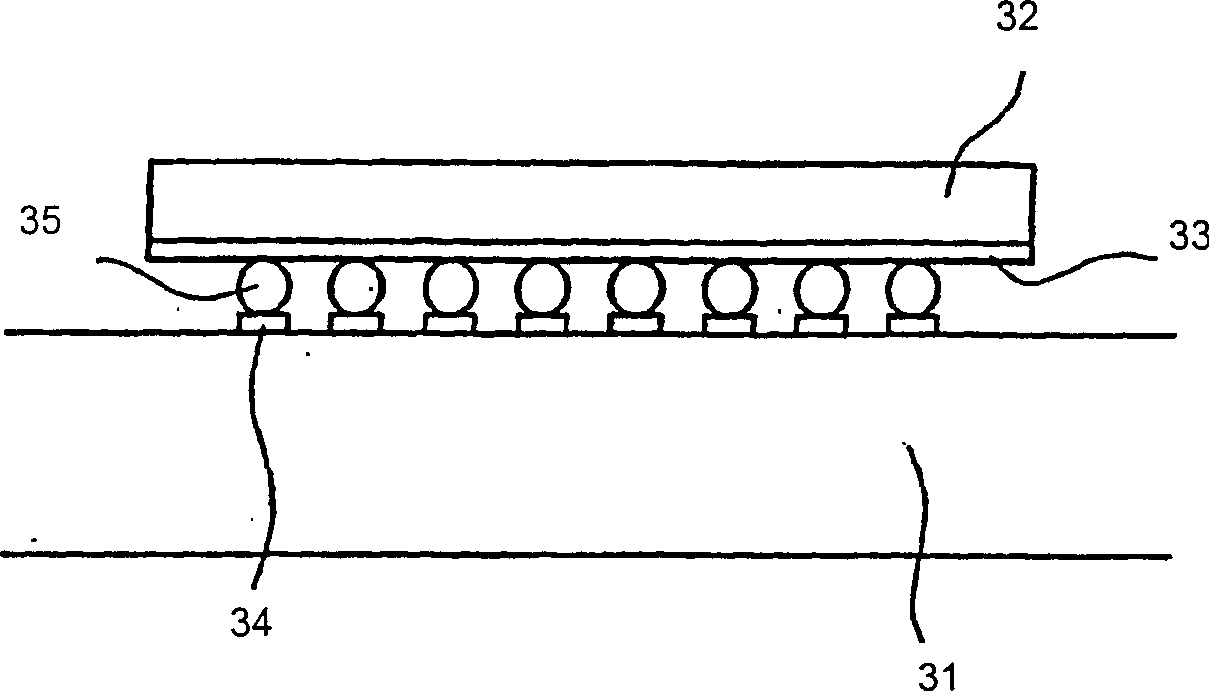

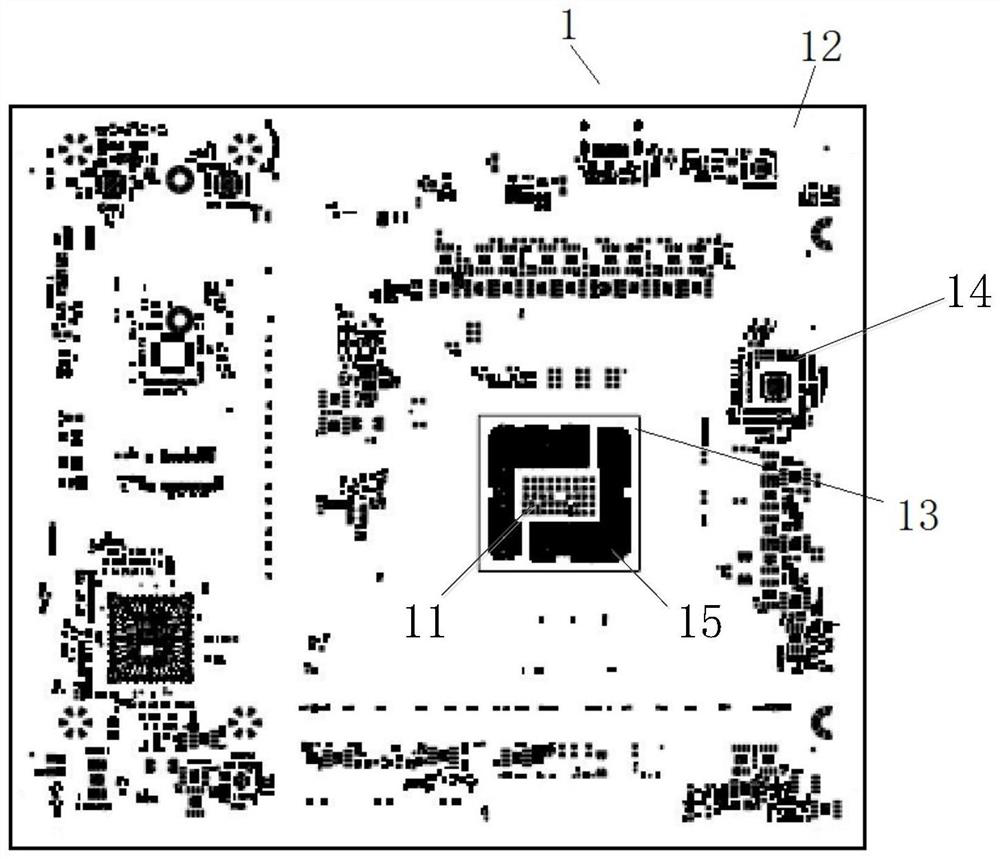

Surface-mounting high frequency modular

InactiveCN1540750APrevent inflowGood welding reliabilityMagnetic/electric field screeningSemiconductor/solid-state device detailsSurface mountingEngineering

A surface-mount-type high-frequency module in accordance with the present invention comprises BGA package IC(s) 1 and printed circuit board(s) carrying such BGA package IC(s) 1; such printed circuit board(s) being multilayer board(s), laminated at which there are inner layer(s) comprising core material(s) 6, and outer layer(s) constituting exterior(s) relative to inner layer(s) and comprising build-up layer(s) 5. Top surface(s) of printed circuit board(s) (core material(s) 6), in region(s) where BGA package IC(s) 1 carried thereby is / are mounted, is / are formed so as to be lower than top surface(s) of outer layer(s) (build-up layer(s) 5). Gap(s) between core material(s) 6 and BGA package IC(s) 1 is / are filled with encapsulant resin(s) 3.

Owner:SHARP KK

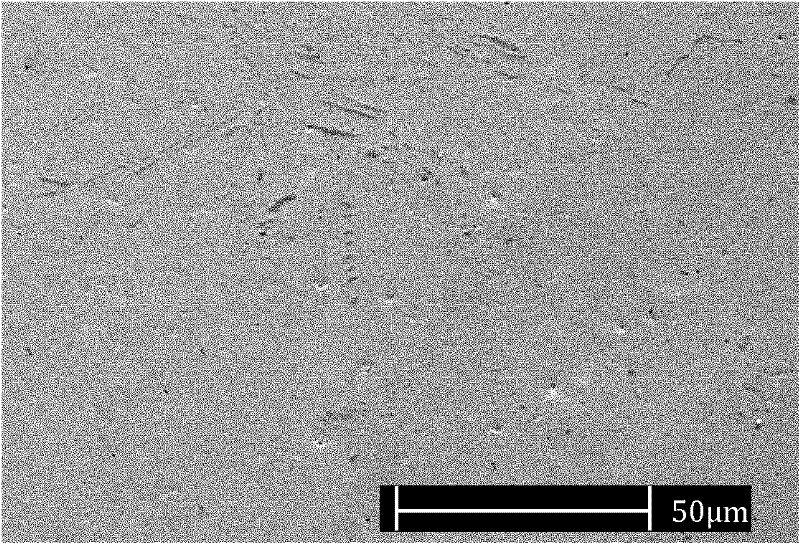

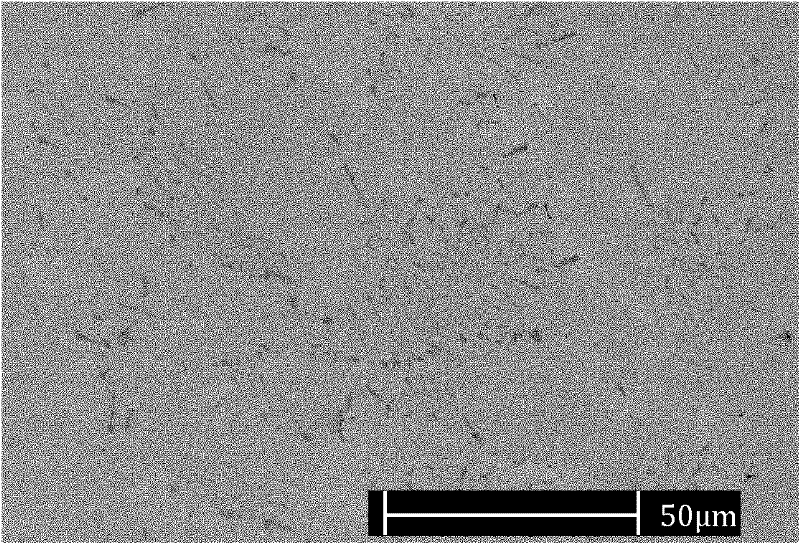

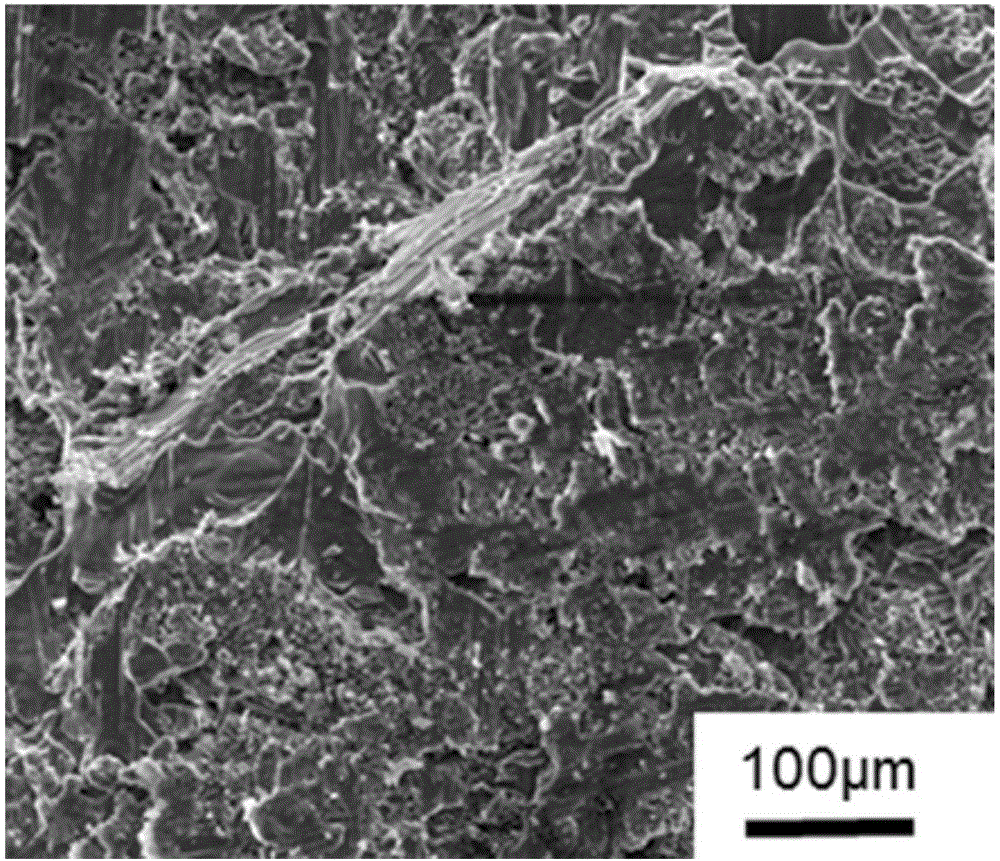

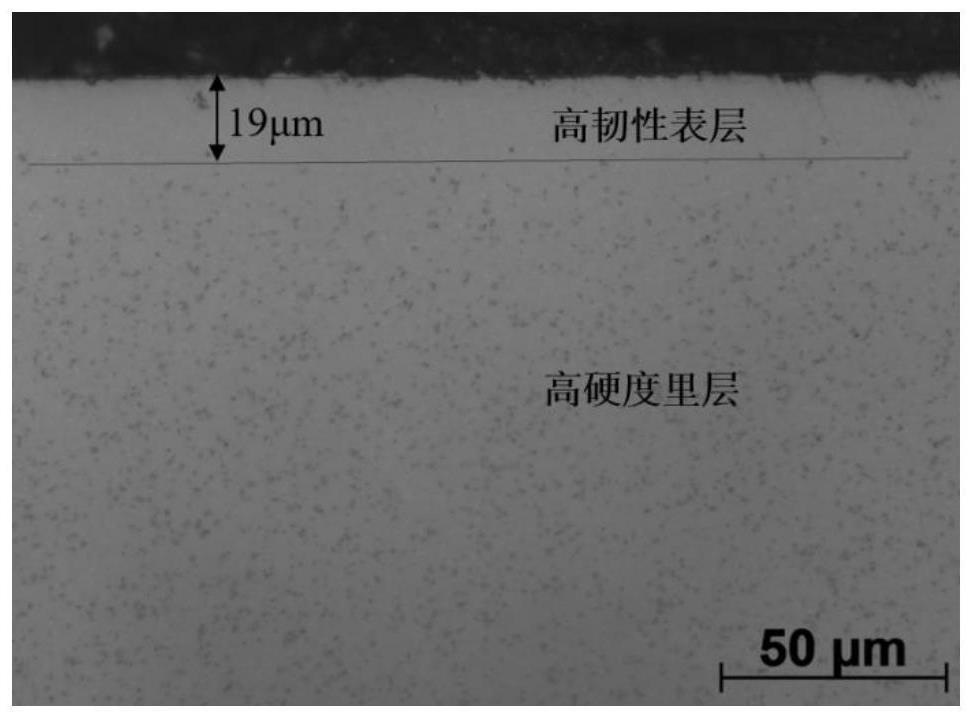

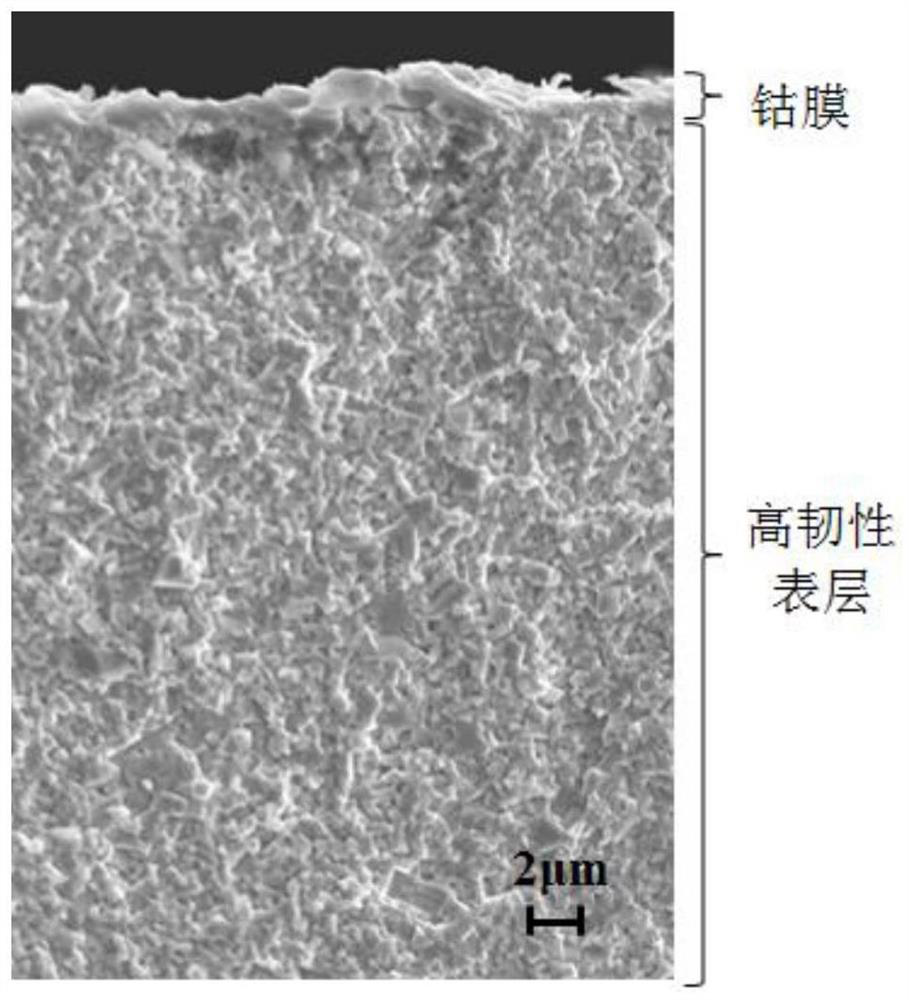

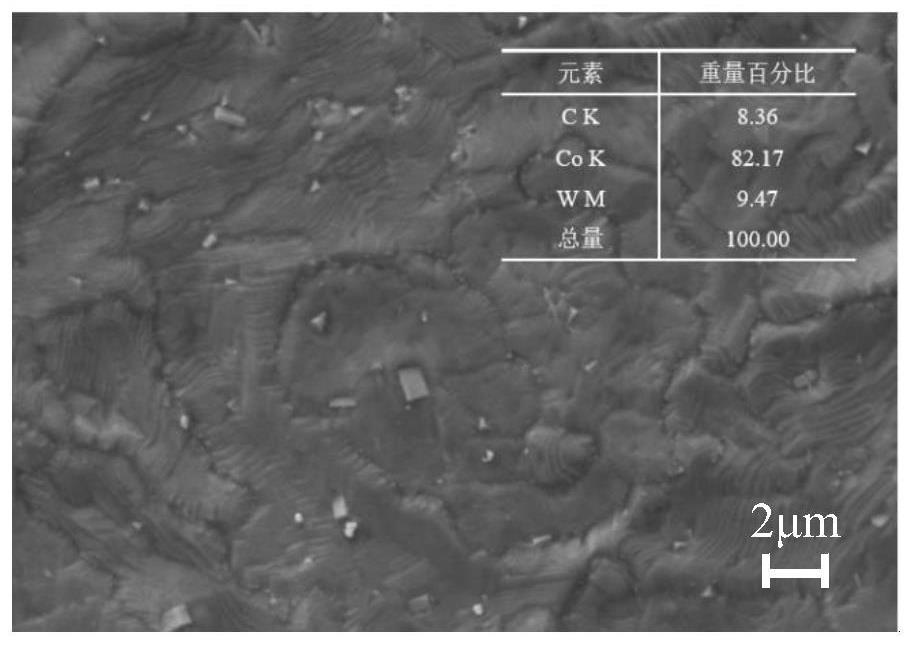

High-hardness hard alloy batten resistant to welding cracking and preparation method of high-hardness hard alloy batten resistant to welding cracking

The invention discloses a high-hardness hard alloy batten resistant to welding cracking and a preparation method thereof.The hard alloy batten is provided with a high-toughness surface layer and a high-hardness inner layer, the binding phase content of the surface layer is 1.2 times or above that of the inner layer, the surface layer is only composed of a WC phase and a binding phase, the thickness of the surface layer is 5-100 microns, and the inner layer is composed of the WC phase, the binding phase and a cubic carbide phase; in addition, the outer surface of the batten is coated with a binding phase, and the thickness of a coating layer is 1-5 microns. The hard alloy batten is prepared from the following components: 80 to 96 weight percent of WC (Wolfram Carbide), 2.0 to 16.5 weight percent of binding phase and 0.5 to 8 weight percent of cubic carbide, wherein the average particle size of the WC is 0.1 to 6 microns. The preparation method comprises the steps of wet grinding, drying, forming, sintering and heat treatment. The batten has excellent welding crack resistance and wear resistance, and has a good application prospect in the field of metal and wood processing.

Owner:九江金鹭硬质合金有限公司

Membrane gas meter sampling and counting mechanism

ActiveCN104296820BReduce intermediate linksSave the process of applying protective glueVolume meteringEngineeringControl circuit

The invention provides a membrane gas meter sampling and counting mechanism, which relates to the technical field of gas meters. It includes the upper casing of the gas meter, the character wheel assembly and the control circuit board. The number wheel of the character wheel assembly is provided with several magnets, and the control circuit board is provided with sampling sensor Ⅰ and sampling sensor Ⅱ. The sampling sensor Ⅰ and sampling sensor Ⅱ are close to each other. , and is located in the diameter direction of the number wheel. The invention solves the technical problems of the gas meter sampling and counting device in the prior art, which have weak anti-magnetic interference capability and hidden dangers of miscounting. The beneficial effect of the present invention is that the counting signal is directly collected by the control circuit board, eliminating intermediate links, eliminating hidden dangers affecting the accuracy of sampling and counting, and saving raw materials. The magnetic sensing element and the control circuit board are directly welded, which is suitable for the SMT chip technology, and the welding reliability is good, the process is simple, the production cost is reduced, and the production efficiency is improved. The anti-shake and anti-external magnetic field attack effects are good, ensuring accurate sampling and counting.

Owner:GOLDCARD HIGH TECH

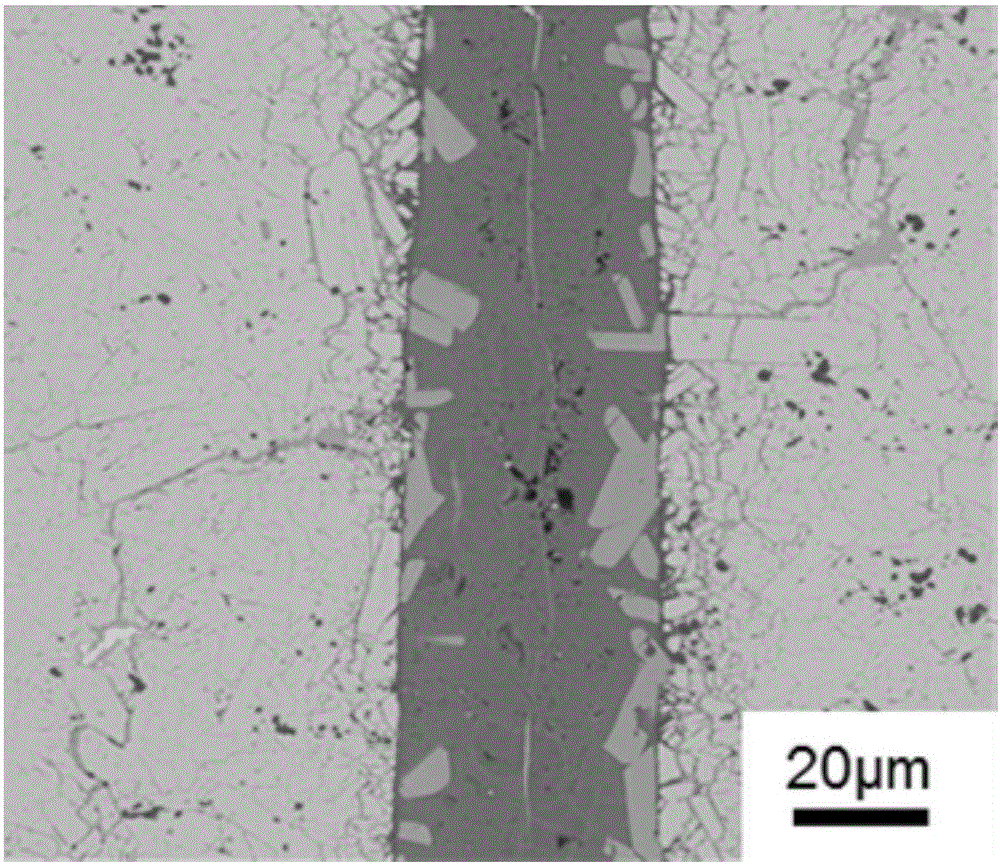

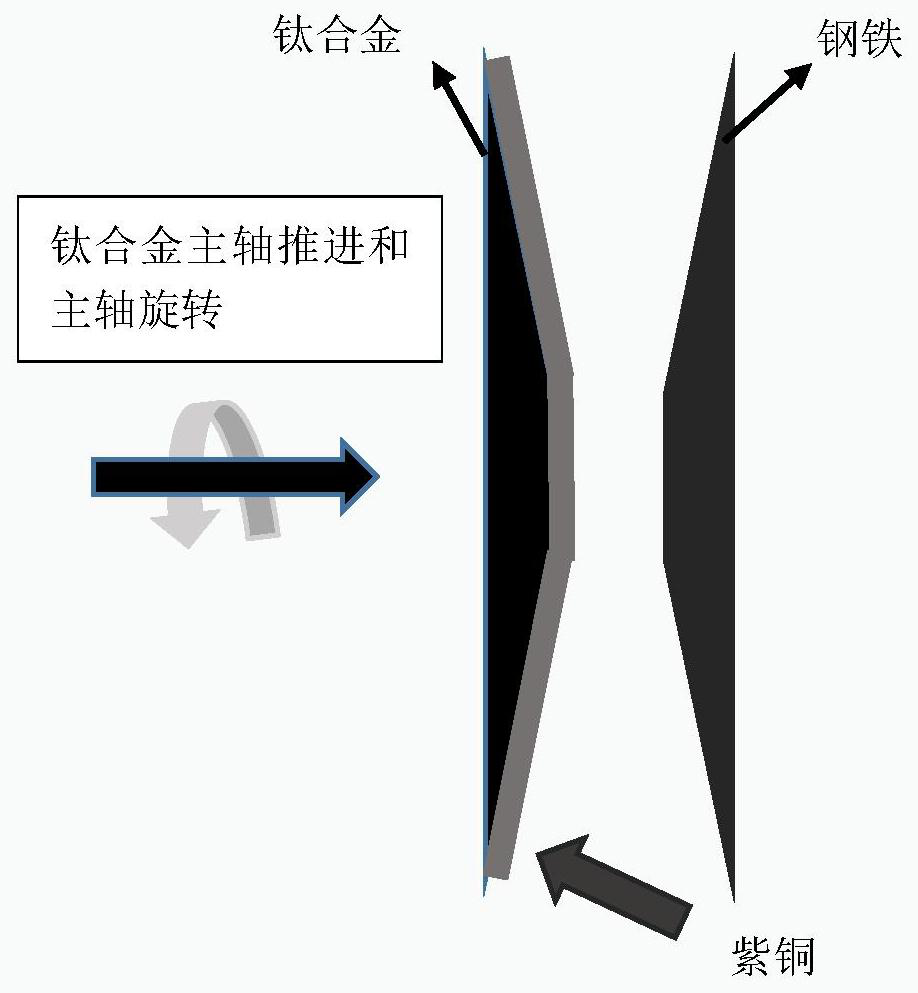

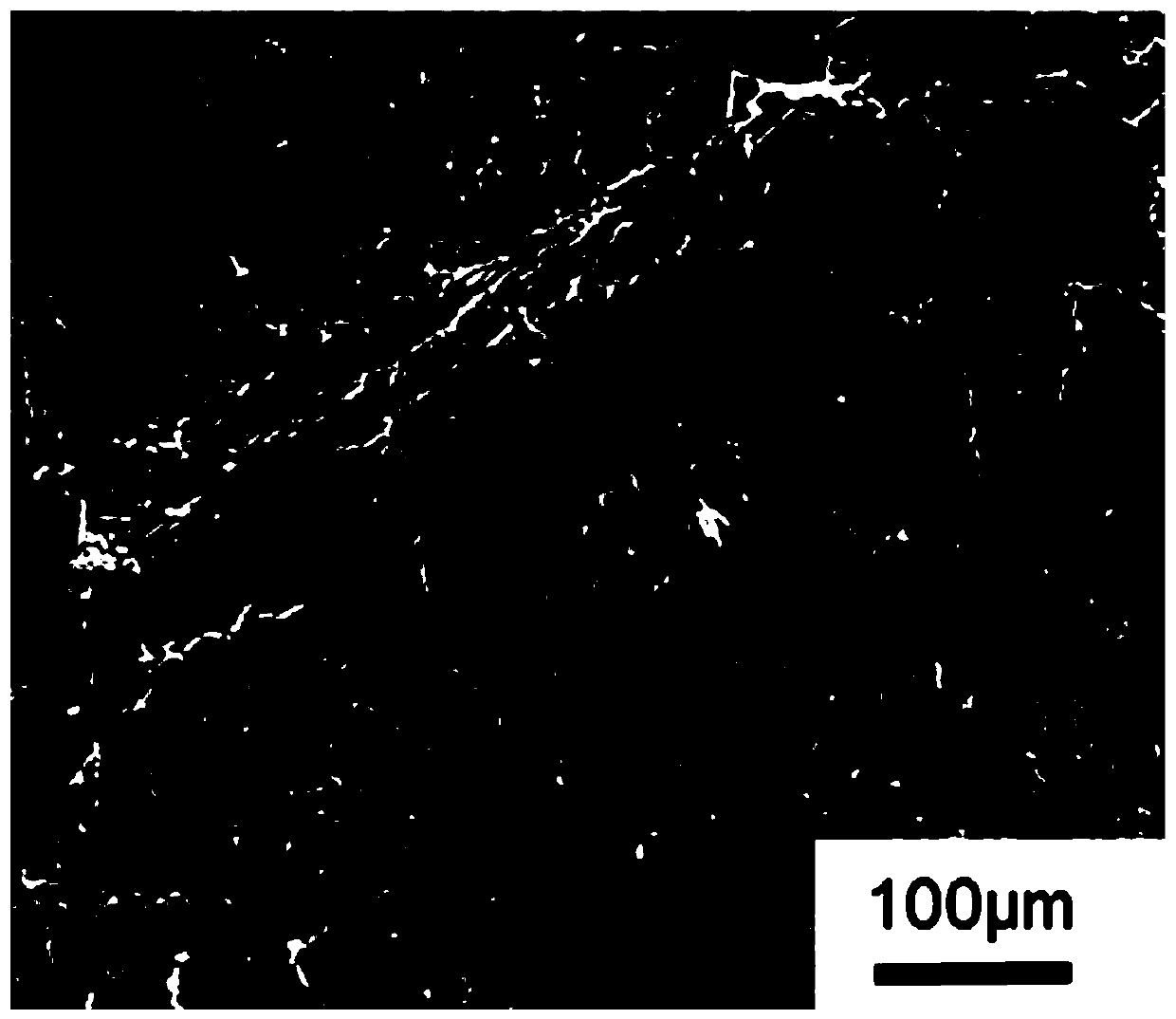

A method of rotational friction welding of titanium alloy and steel heterogeneous

ActiveCN112207420BRealize solid phase connectionGood lookingWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingWeld seam

A method for dissimilar rotary friction welding of titanium alloy and steel belongs to the field of solid-phase connection of dissimilar metals. In order to realize the heterogeneous welding of titanium alloy and steel and avoid the generation of brittle phase in the welding zone, the invention uses copper as the welding transition metal to obtain high-quality friction welding seam by rotating friction welding, and realizes the heterogeneous welding of titanium alloy and steel. Welded parts. The invention uses Cu as the intermediate phase to realize the heterogeneous welding of titanium alloy and steel, which not only effectively prevents the diffusion of elements in Ti and steel, but also eliminates brittle phases such as Ti / Fe intermetallic compounds, improves the strength of the welded joint, and at the same time makes the The welded joint is firm, which effectively improves the quality and performance of the welded joint. The invention has the advantages of simplicity and convenience, high welding efficiency, excellent quality and performance of the obtained welded joint, and greatly reducing labor and processing costs.

Owner:UNIV OF SCI & TECH BEIJING

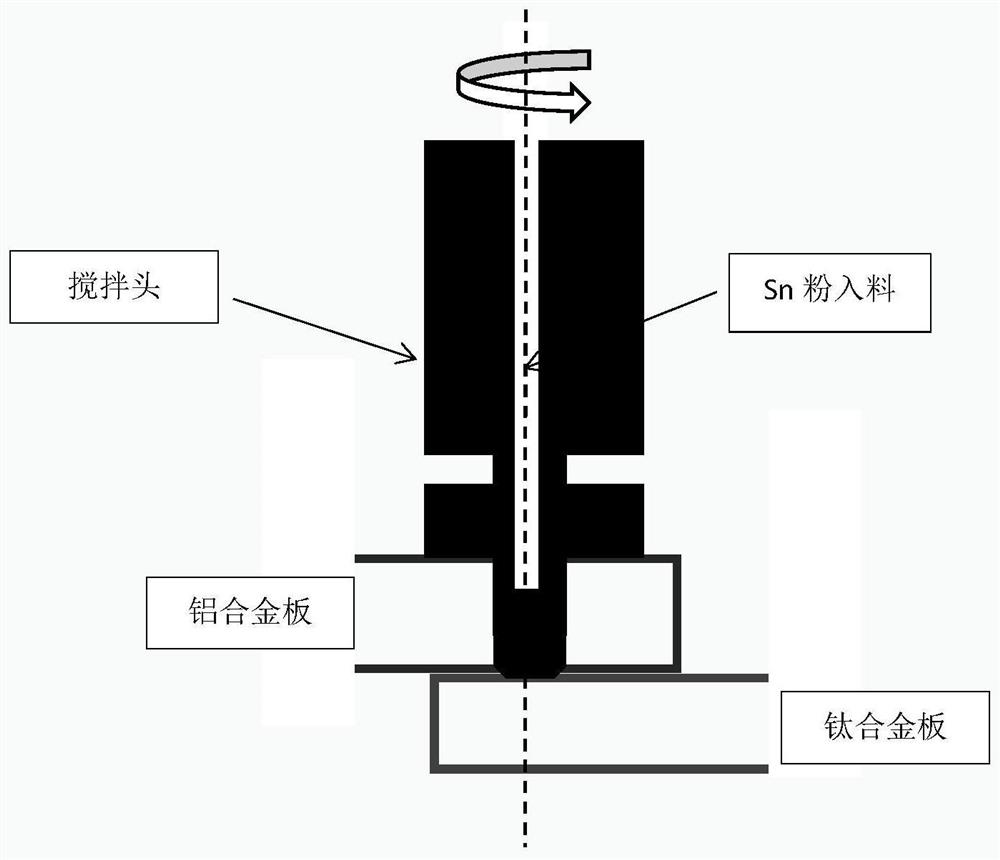

A method for realizing heterogeneous welding of titanium alloy and aluminum alloy

ActiveCN112207419BRealize solid phase connectionGood lookingWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingTitanium alloy

A method for realizing dissimilar welding of titanium alloy and aluminum alloy belongs to the field of solid-phase connection of dissimilar metals. In order to realize the heterogeneous welding of titanium alloy and aluminum alloy and avoid the generation of Ti / Al brittle phase in the welding zone, the invention uses tin as the welding transition metal, and obtains high-quality friction welding seam through friction stir welding, and realizes the realization of titanium alloy and aluminum alloy. Dissimilar welding of aluminum alloys. The invention uses Sn as the intermediate phase, and realizes the heterogeneous welding of the high melting point titanium alloy and the low melting point aluminum alloy through friction stir welding, which not only effectively prevents the formation of brittle phases such as Ti / Al during the welding process, but also prevents the welding temperature from being too high. The resulting large amount of burning loss of the aluminum alloy improves the strength of the welded joint, and at the same time makes the welded joint firm, effectively improving the quality and performance of the welded joint. It has the advantages of simplicity and convenience, high welding efficiency, excellent quality and performance of the obtained welded joint, and greatly reducing labor and processing costs.

Owner:UNIV OF SCI & TECH BEIJING

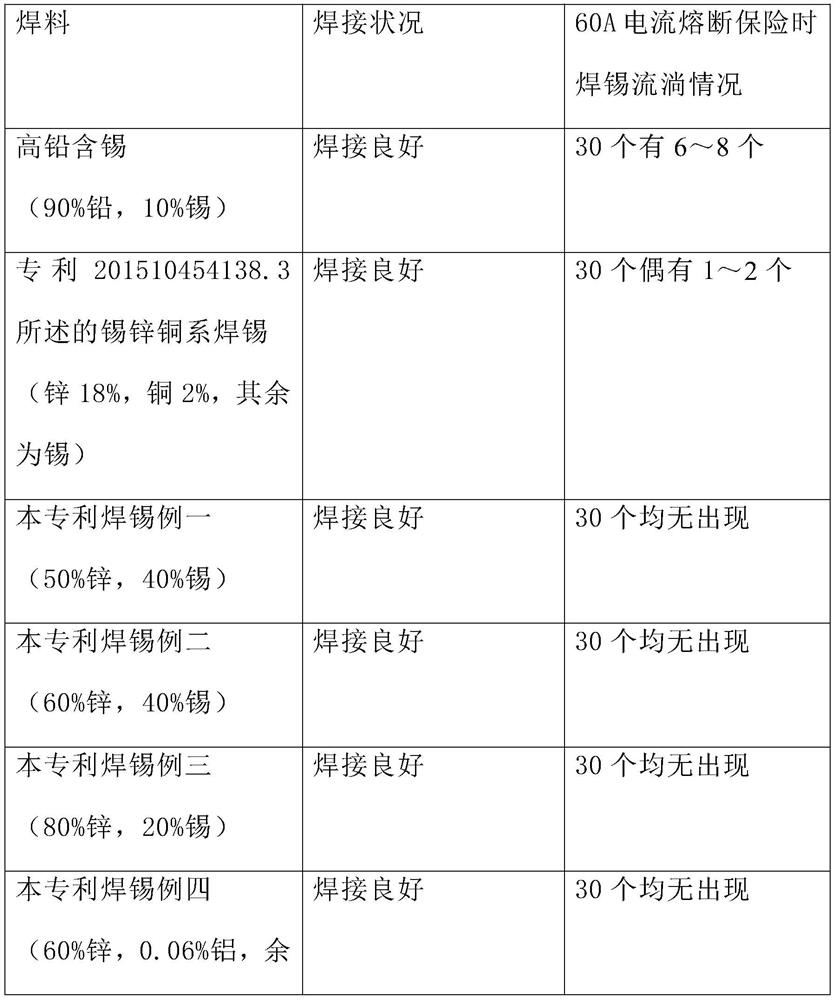

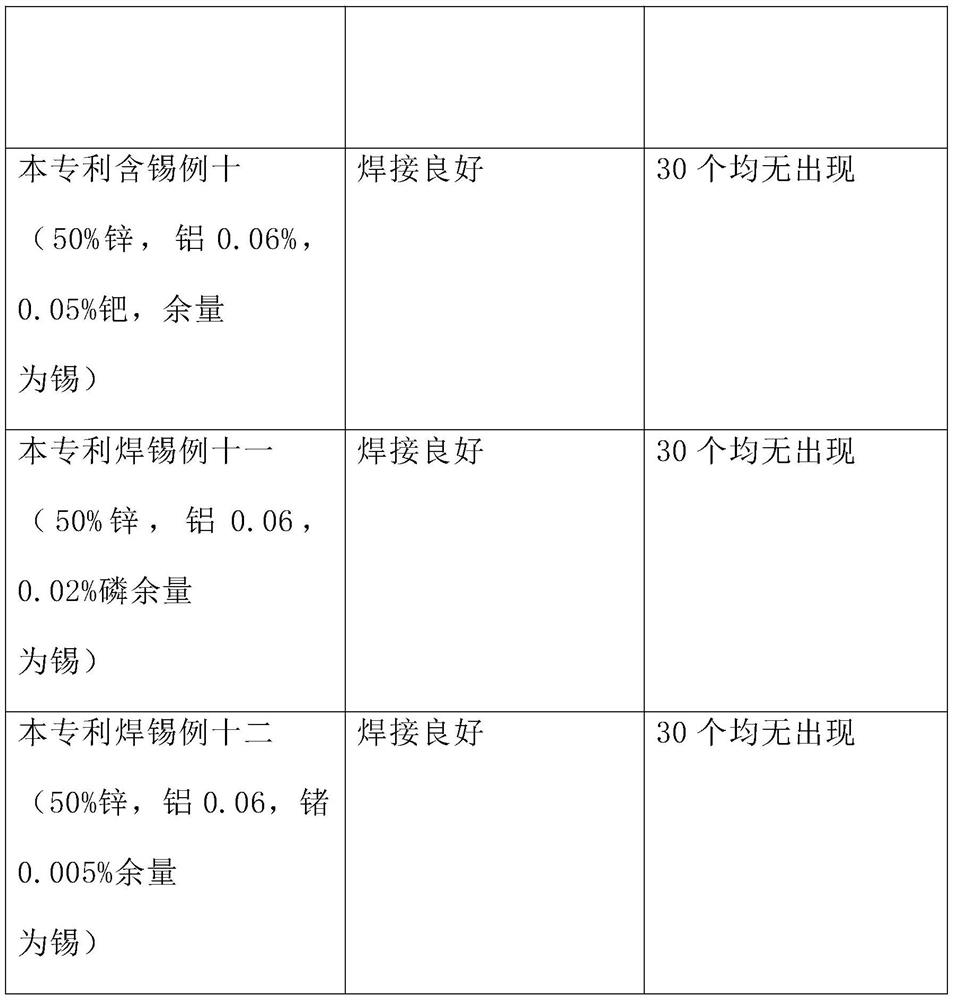

A kind of zinc-based high-temperature lead-free solder and production method thereof

ActiveCN112296550BGuaranteed smooth productionGood welding reliabilityWelding/cutting media/materialsSoldering mediaTrace elementZinc

A zinc-based high-temperature lead-free solder, which contains 50% to 80% by weight of zinc, and also contains any one or two of aluminum, bismuth, palladium, nickel, germanium or phosphorus as additional trace elements, And the weight percentages of the above-mentioned additional trace elements are respectively: aluminum 0-0.09%, bismuth 0-3%, palladium 0-0.08%, nickel 0-0.05%, germanium 0-0.006% or phosphorus 0-0.03%, the balance is tin. The soldering tin of the invention can achieve good welding effect, and when the subsequent protection circuit of the high rated current fuse tube fuses, the solder in the end cap of the fuse tube does not overflow the outside of the tube.

Owner:好利来(厦门)电路保护科技有限公司

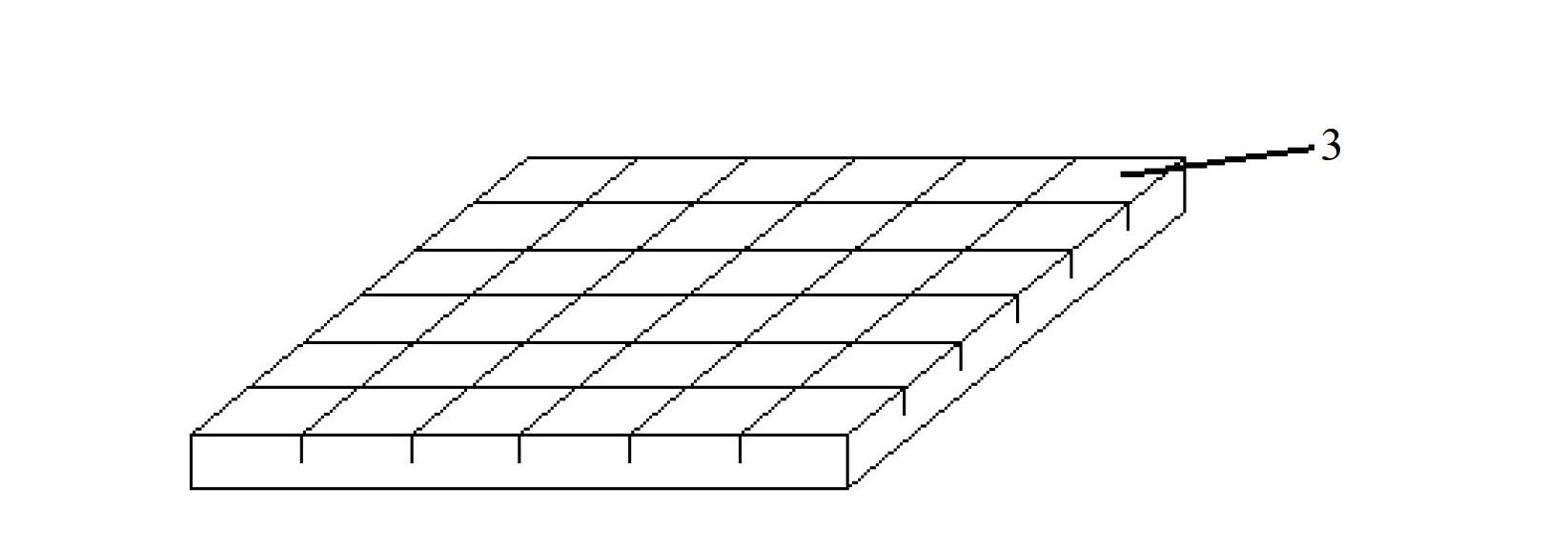

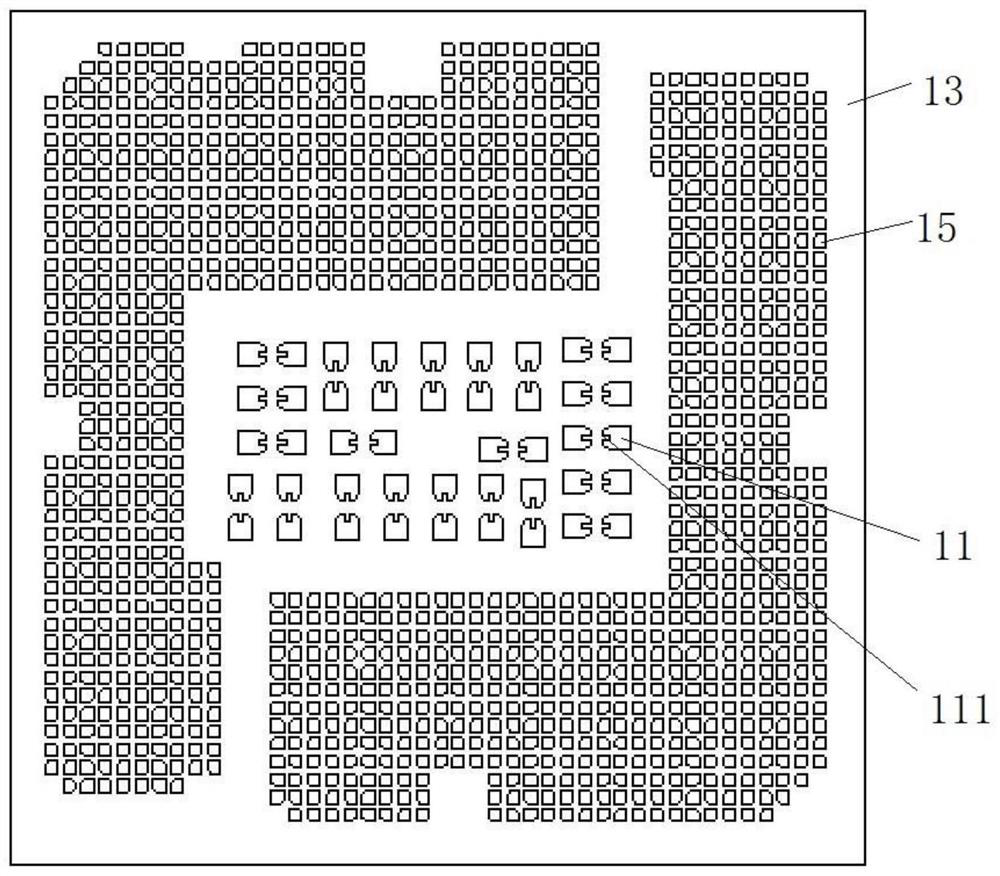

High-reliability solder paste printing screen

PendingCN114103408AIncrease heightAvoid Lian TinScreen printersConductive pattern formationSolder pastePrint-through

The invention provides a high-reliability solder paste printing screen which comprises a printing screen body, the printing screen body comprises a base plate and at least one boss, the boss is arranged on the base plate, a plurality of first printing through holes are formed in the base plate at intervals, a plurality of second printing through holes are formed in the boss at intervals, and the first printing through holes are communicated with the second printing through holes. The distance between any two adjacent second printing through holes is smaller than the distance between any two adjacent first printing through holes, the distance between any two adjacent second printing through holes is smaller than 0.2 mm and larger than 0.1 mm, the thickness of the base plate ranges from 0.1 mm to 0.15 mm, and the thickness of the boss is 20%-25% of the thickness of the base plate.

Owner:SHENZHEN BESTWORK SCI & TECH CO LTD

A kind of brazing ti using al-based solder 2 alc ceramic method

InactiveCN107433401BLow melting pointLow costWelding/cutting media/materialsSoldering mediaVacuum pumpingUltimate tensile strength

The invention relates to a method for brazing Ti2AlC ceramics by Al base brazing filler metal, and aims to solve the technical problem of short service life of an existing electric contact component. The method includes the steps: first, preparing the brazing filler metal; second, assembling a Ti2AlC ceramic / brazing filler metal / Ti2AlC ceramic structural part, placing the structural part into a vacuum brazing furnace, performing vacuum pumping to reach 6.0*10<3>Pa, increasing temperature to 300 DEG C at the heating rate of 10 DEG C / min, keeping the temperature for 30min, increasing the temperature to 660-900 DEG C at the heating rate of 10 DEG C / min, keeping the temperature for 5-30min under the pressure of 0.2-1.0MPa, reducing the temperature to 300 DEG C at the cooling rate of 10 DEG C / min, performing furnace cooling and finishing brazing the Ti2AlC ceramics by the Al base brazing filler metal. By the method, a joint with an excellent mechanical property can be obtained, the shear strength of the joint is 70-120MPa, and electrical conductivity is 3.73-4.18*10<6>S / m and reaches 94% or more of the electrical conductivity of the Ti2AlC ceramics.

Owner:HARBIN INST OF TECH

Laminates for circuit boards, metal base circuit boards, and power modules

ActiveCN104412721BImprove heat resistanceIncreased durabilitySemiconductor/solid-state device detailsPrinted circuit aspectsMetal foilComputer module

Provided is a laminated plate for a circuit substrate, the laminated plate for a circuit substrate comprising: a metal substrate; an insulating layer, the insulating layer is disposed on at least one surface of the metal substrate; a metal foil, the metal foil is disposed on the insulating layer; It is characterized in that the insulating layer contains a cross-linked copolymer of bisphenol cyanate resin and phenolic cyanate resin and an inorganic filler.

Owner:NHK SPRING CO LTD

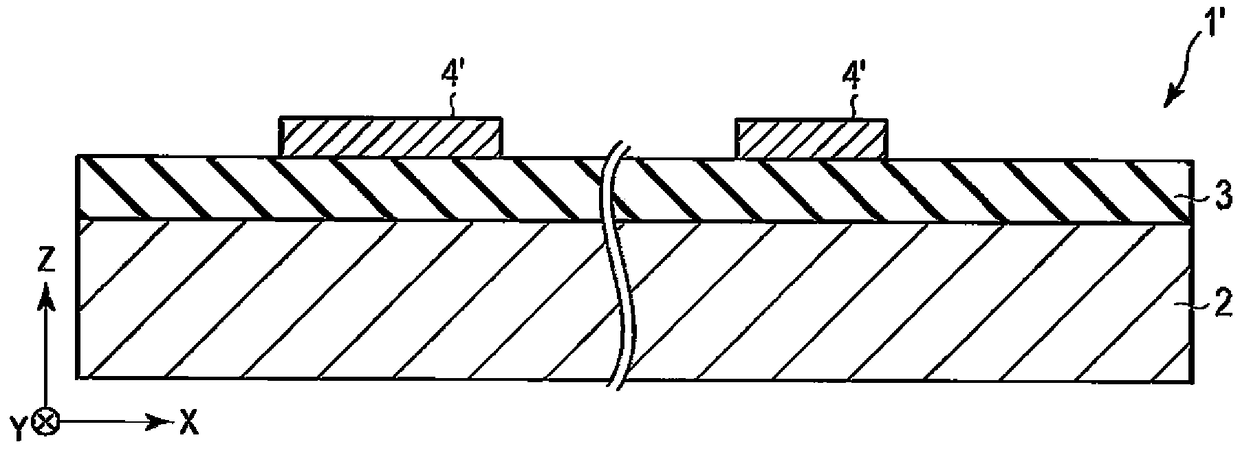

Copper-aluminum mixed welding method and apparatus for chip welding

ActiveCN113257714AExtended service lifeNot easy to fall offSemiconductor/solid-state device manufacturingCopper wireSolder ball

The invention discloses a copper-aluminum mixed welding apparatus for chip welding. The copper-aluminum mixed welding apparatus comprises a conveying mechanism for conveying a chip, an aluminum welding device for welding an aluminum solder ball on the chip and a copper welding device for welding a copper wire on the aluminum solder ball; the aluminum welding device is connected with the input end of the conveying mechanism; and the copper welding device is connected with the output end of the conveying mechanism. The aluminum solder ball is welded on the welding position of the chip, after the aluminum solder ball is welded, the copper wire is welded on the surface of the aluminum solder ball, the copper wire is not in contact with copper on the chip and is directly welded with the aluminum solder ball, and good welding reliability is achieved between the copper and the aluminum, so that the copper wire is not easy to fall off from the chip, and the welding reliability of the copper wire and the chip is improved, and the service life of the chip is prolonged.

Owner:广州飞虹微电子有限公司

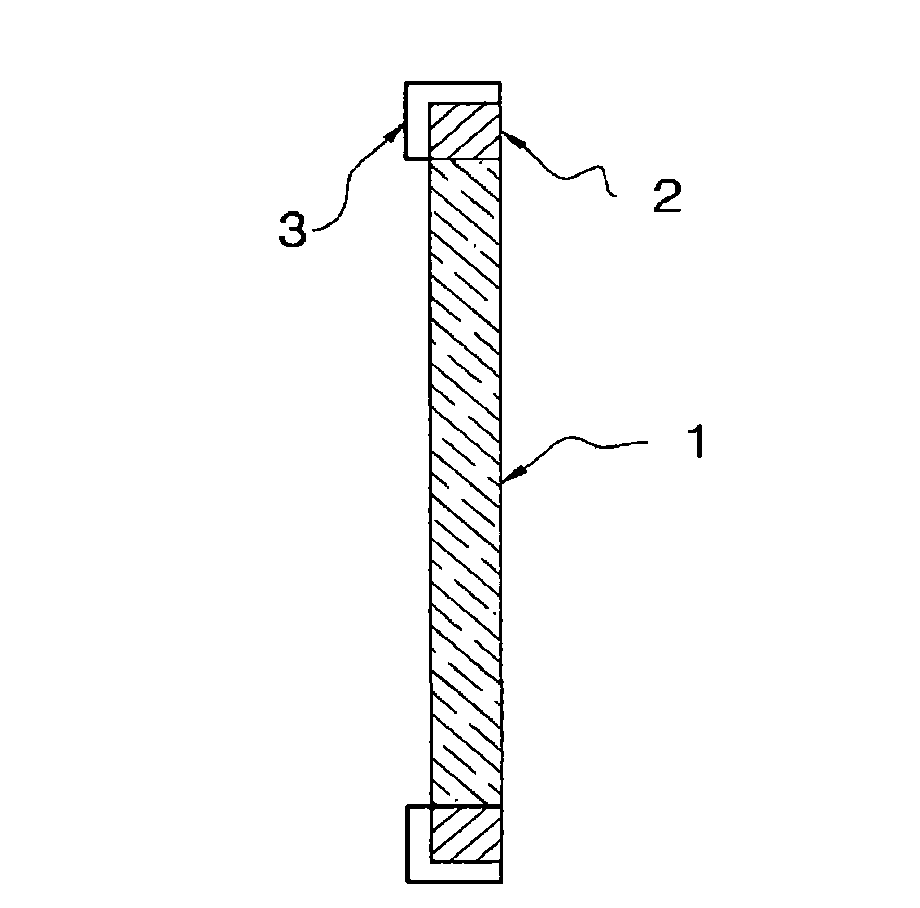

1/2 screwed pipe cable welded type connector and welding method thereof

InactiveCN106450805AReduce gapFirmly connectedSoldered/welded conductive connectionsThreaded pipeTin

The invention discloses a 1 / 2 screwed pipe cable welded type connector and a welding method thereof. The 1 / 2 screwed pipe cable welded type connector is characterized by comprising a screwed pipe connector body (1), a screwed pipe connector welding shell (2), a screwed pipe cable (3), a screwed pipe connector inner wall thread (4) and a screwed pipe cable outer wall thread (5), wherein a screwed pipe connector outer wall hole (6) is formed in the screwed pipe connector welding shell (2) and communicates with the screwed pipe connector inner wall thread (4). During welding, soldering tin after being molten is completely fitted in the threads, the welding reliability is greatly improved, and the intermodulation performance is substantially improved.

Owner:镇江百励电子有限公司

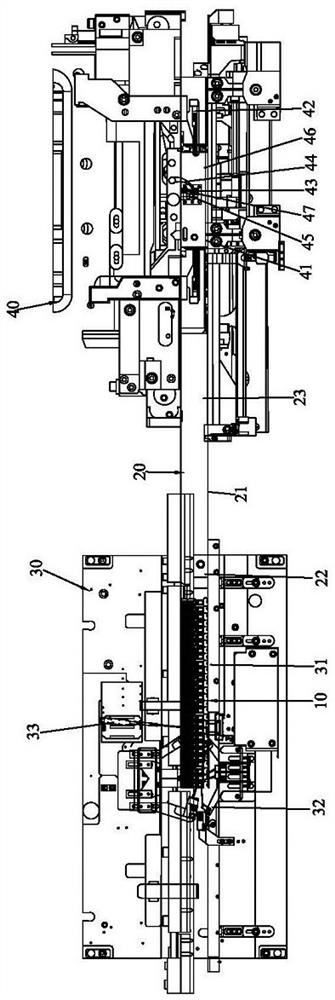

Linear forming and welding integrated machine

PendingCN111975362AImprove processing efficiencyHigh degree of automationOther manufacturing equipments/toolsWire rodIndustrial engineering

The invention relates to the technical field of welding, and particularly relates to a linear forming and welding integrated machine. The linear forming and welding integrated machine comprises a welding workbench, wherein a wire bending mechanism, a wire welding mechanism and a wire conveying roller are fixedly mounted on the upper end face of the welding workbench; a correction workbench is arranged on the right side of the welding workbench; a first correction mechanism, a control box, a correction workbench and a second correction mechanism are mounted on the upper end face of the correction workbench; and a third correction mechanism is mounted on the right side of the correction workbench. The linear forming and welding integrated machine adopts integrated design, a traditional manual wire welding method is changed, the automation degree is high, the wire machining efficiency is effectively improved, and the welding firmness is better.

Owner:佛山市金春工业自动化科技有限公司

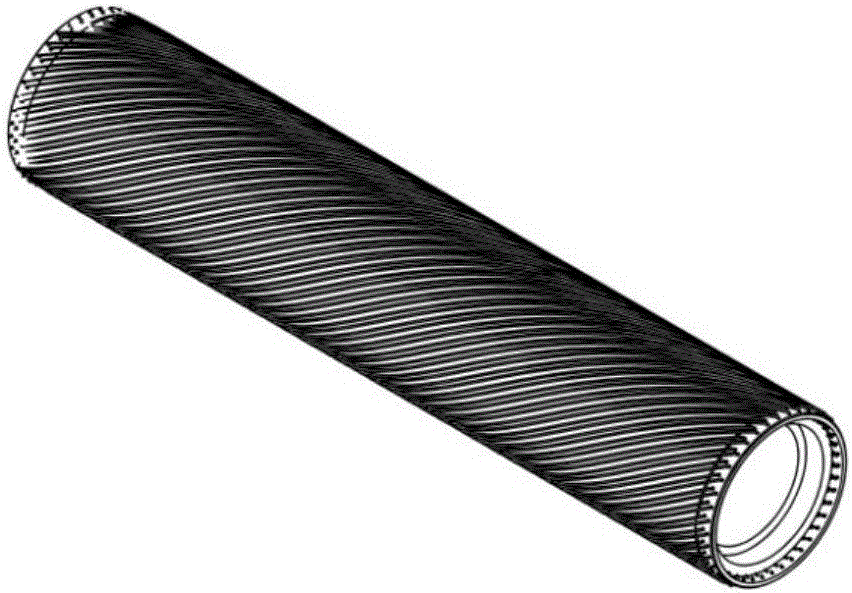

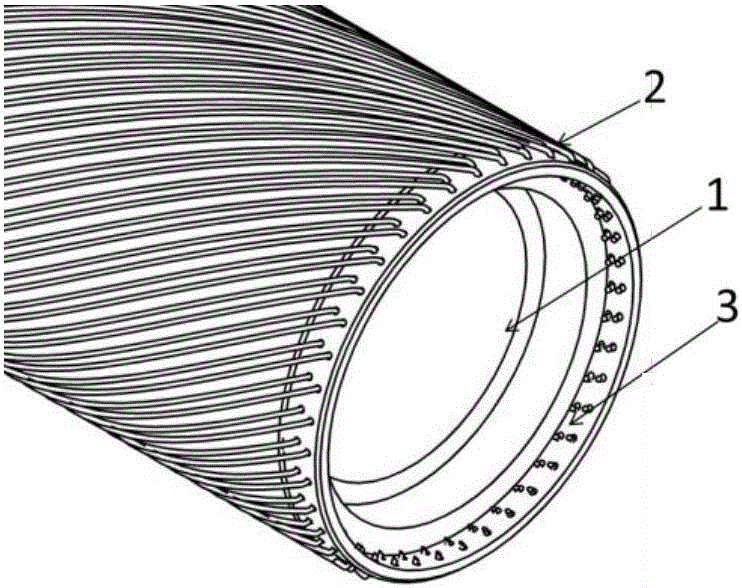

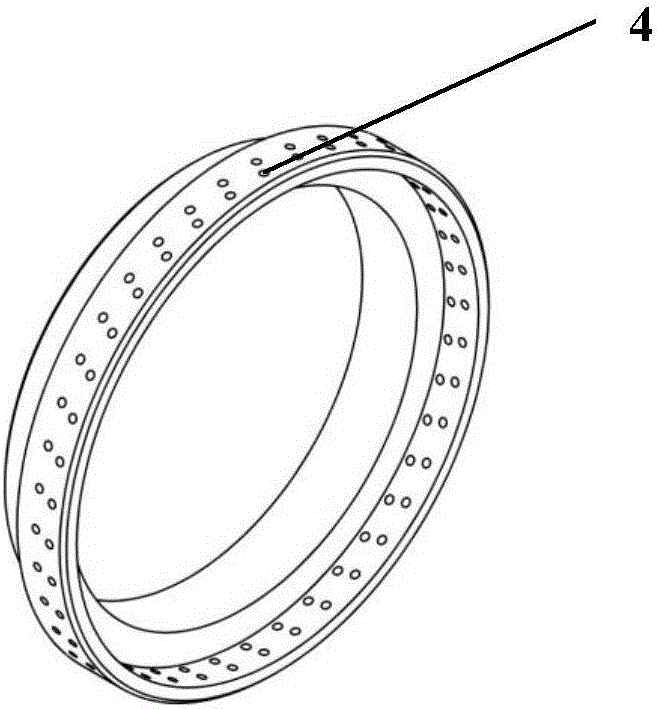

Helix pulse forming line and manufacturing method thereof

PendingCN106788344AUniform transmissionReduce voltagePulse generation by energy-accumulating elementHigh probabilityEngineering

The invention belongs to the technical field of pulse power and relates to a helix pulse forming line and a manufacturing method thereof. The helix pulse forming line comprises an insulating base cylinder and a plurality of helix lines spirally wound on the insulating base cylinder, and is characterized by further comprising helix line harness restraint rings which are two thin-walled metal rings respectively mounted at the two ends of the insulating base cylinder, wherein a plurality of restraint hole sets are formed in each helix line harness restraint ring in the axial direction; each restraint hole set comprises a plurality of restraint holes formed in the circumferential direction; the hole distance between every two adjacent restraint holes is larger than the line diameter of each helix line; the two ends of the helix lines are respectively fixed on the restraint holes of the helix line harness restraint rings at the two ends of the insulating base cylinder in a soldering manner. By adoption of the helix pulse forming line, the problems that a conventional broadband wire has high probability of breakdown between the adjacent turns and is large in wave transmission distortion are solved.

Owner:NORTHWEST INST OF NUCLEAR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com