High-hardness hard alloy batten resistant to welding cracking and preparation method of high-hardness hard alloy batten resistant to welding cracking

A cemented carbide and high hardness technology, applied in the field of powder metallurgy, can solve problems such as cemented carbide cracking, achieve the effects of reducing the probability of cracks, improving welding reliability, and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

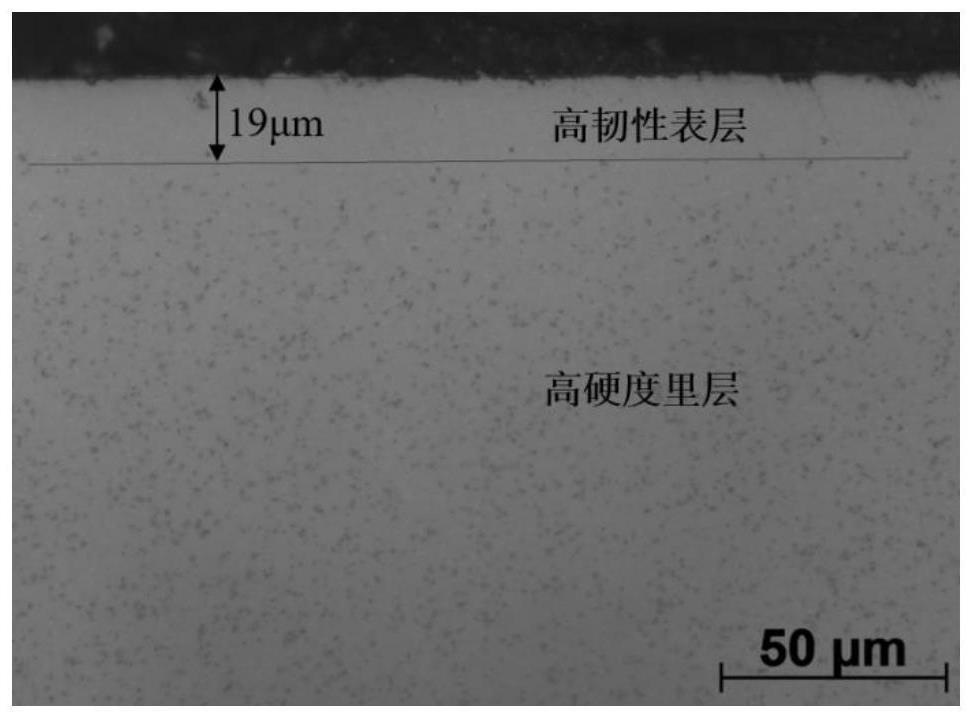

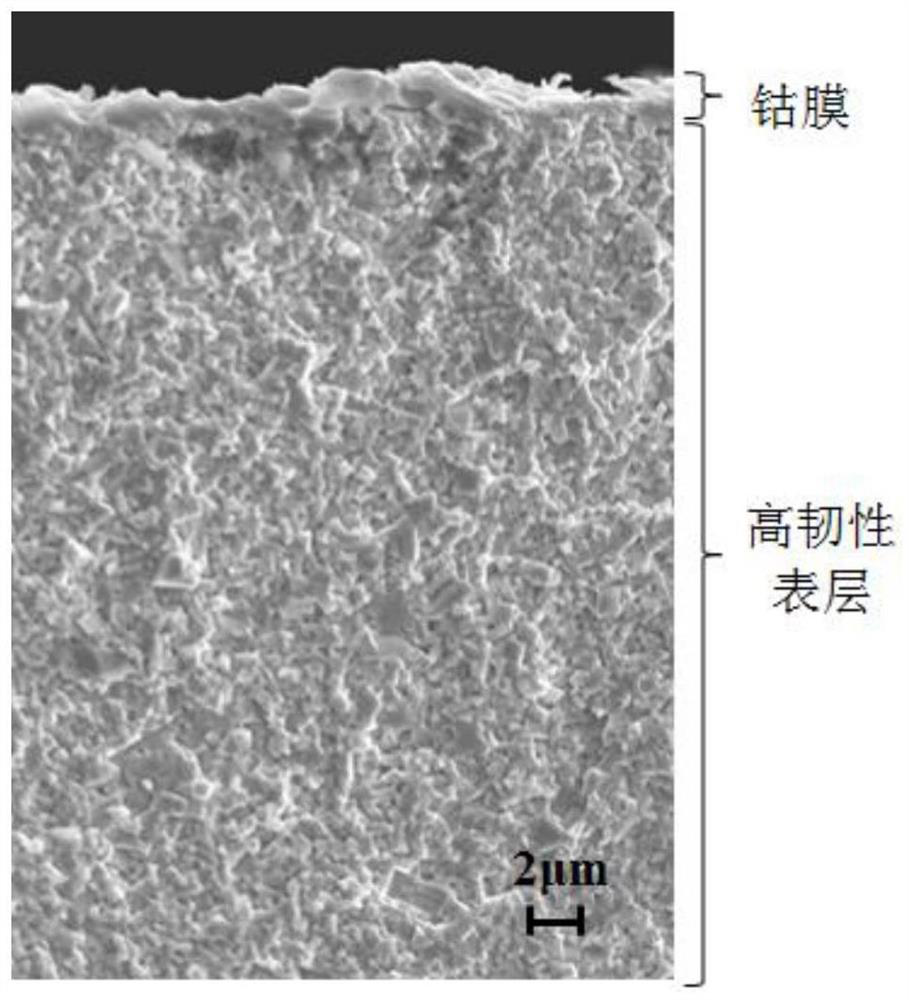

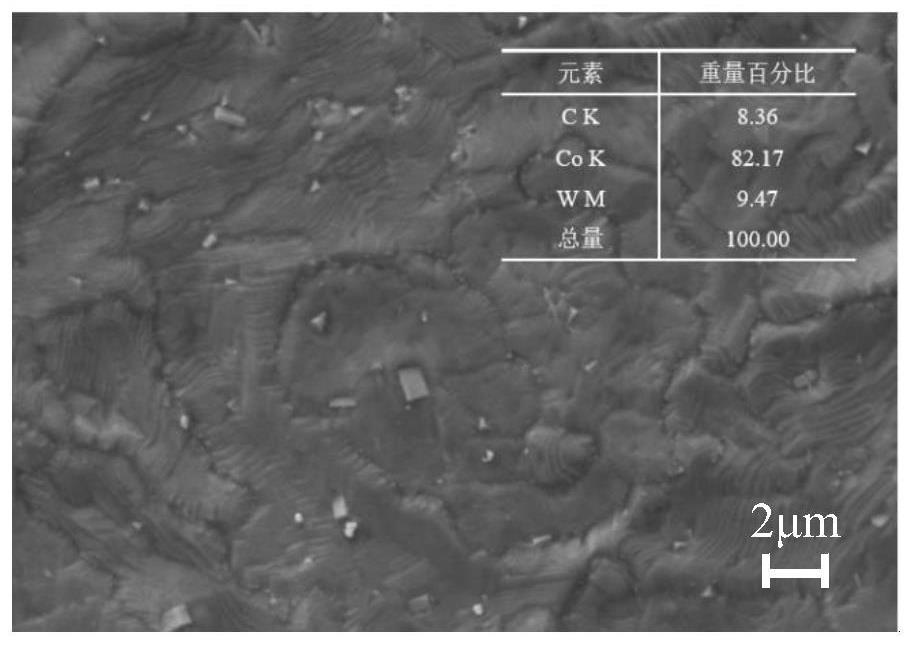

[0037] A high-hardness cemented carbide strip resistant to welding cracking of the present invention is composed of the following composition, WC content 90.5wt.%, TaC content 1.5wt.%, Co content 7wt.%, TiC 0.5 N 0.5 The content is 1.0 wt.%, and the WC particle size is 1.0 μm. The thickness of the high toughness surface layer of the cemented carbide strip is 19 μm, such as figure 1 shown.

[0038] The preparation method of the high-hardness cemented carbide strip resistant to welding cracking includes the steps of batching, wet grinding, drying, forming, sintering, and heat treatment, and is characterized in that the specific steps are as follows:

[0039] (1) Ingredients and wet grinding: WC powder, Co powder, TaC powder, TiC 0.5 N 0.5 After weighing the powder according to the specified ratio, weigh 2.0wt.% PEG4000, put it into the horizontal ball mill together, add cemented carbide balls 5 times the weight of the material and industrial anhydrous alcohol with 18% of the...

Embodiment 2

[0046] A high-hardness cemented carbide strip resistant to welding cracking of the present invention is composed of the following composition: WC content 86.0wt.%, NbC content 0.5wt.%, TiC content 0.7wt.%, Co content 12wt.%, TiC 0.7 N 0.3 The content is 0.8 wt.%, and the WC particle size is 0.4 μm.

[0047] The preparation method of the high-hardness cemented carbide strip resistant to welding cracking includes the steps of batching, wet grinding, drying, forming, sintering, and heat treatment, and is characterized in that the specific steps are as follows:

[0048] (1) Ingredients and wet grinding: WC powder, Co powder, NbC powder, TiC powder, TiC powder 0.7 N 0.3 After weighing the powder according to the specified ratio, weigh 2.5wt.% PEG1500, put it into the horizontal ball mill together, add cemented carbide balls 6 times the weight of the material and industrial anhydrous alcohol with 22% of the weight of the material, and mix the wet Grind for 60 hours;

[0049] (2)...

Embodiment 3

[0055] A high-hardness cemented carbide strip that resists welding cracking according to the present invention is composed of the following composition: the WC content is 87.0wt.%, the TaNbC solid solution content is 1.5wt.%, the TiC content is 2.0wt.%, and the binder phase content is 8wt.%. %, TiC 0.3 N 0.7 The content is 1.5 wt.%, and the WC particle size is 1.5 μm.

[0056] The preparation method of the high-hardness cemented carbide strip resistant to welding cracking includes the steps of batching, wet grinding, drying, forming, sintering, and heat treatment, and is characterized in that the specific steps are as follows:

[0057] (1) Ingredients and wet grinding: WC powder, Co powder, Ni powder, TaNbC powder, TiC powder, TiC powder 0.3 N 0.7 After the powder is weighed according to the specified ratio, then weigh 2.0wt.% of paraffin, put it into the horizontal ball mill together, add cemented carbide balls 4 times the weight of the material and industrial absolute alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com