Helix pulse forming line and manufacturing method thereof

A helical wire and helical technology, which is applied in the field of helical pulse forming wire and its production, can solve the problems of large wave transmission distortion and inter-turn breakdown, and achieve the effects of small wave transmission distortion, low voltage, and improved surface current propagation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

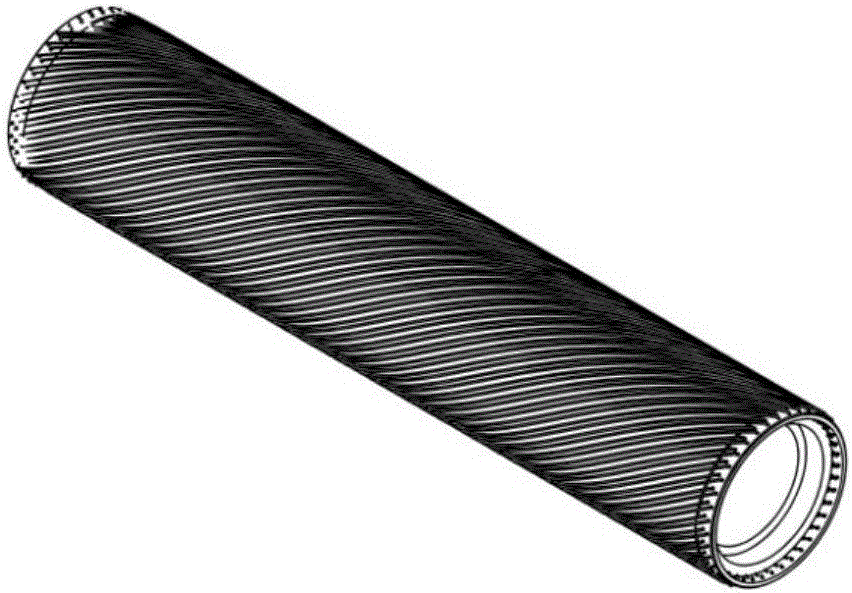

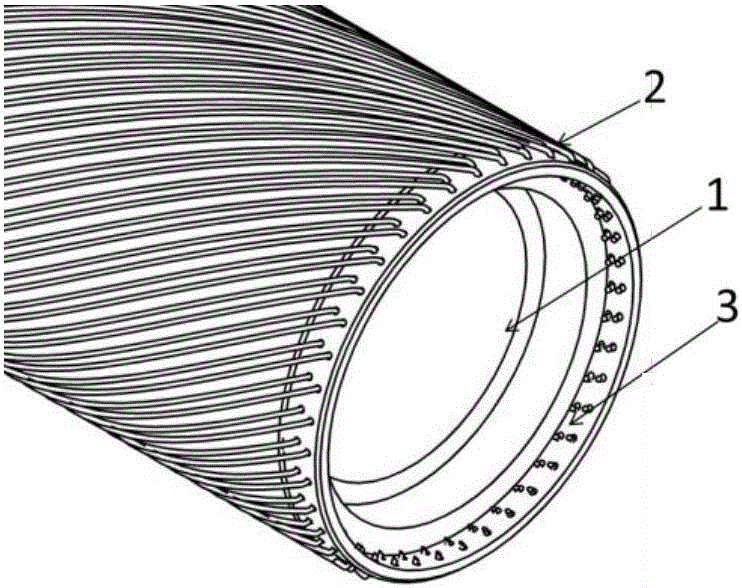

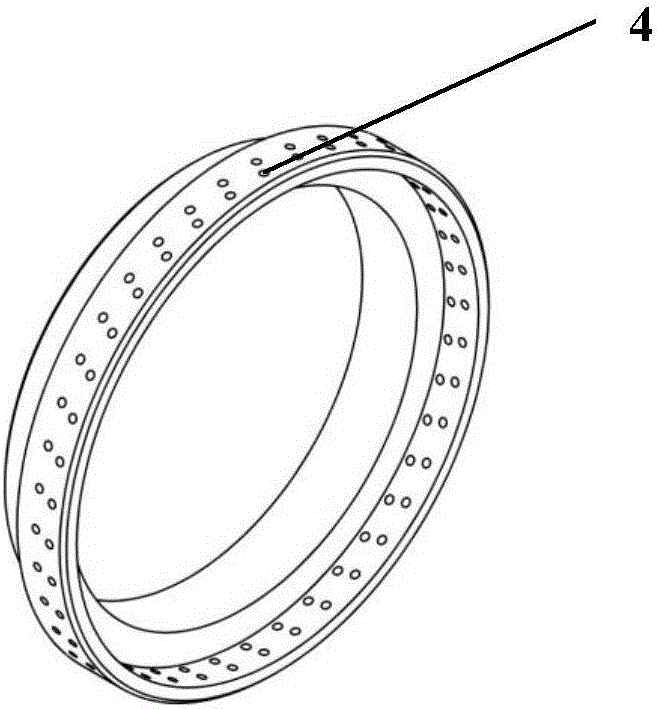

[0030] Such as Figure 1 to Figure 5 As shown, the present invention provides a helical pulse forming wire, which mainly includes three components including an insulating base cylinder 1 , a helical wire 2 and a helical wire harness restraining ring 3 . There are 3 spiral wire harness restraining rings, two of which are respectively installed at both ends of the insulating base cylinder 1; a plurality of restraining hole groups are opened in the axial direction on the spiral wire harness restraining ring 3, and each restraining hole group includes a plurality of restraining holes arranged along the circumferential direction 4. The hole spacing between two adjacent constraining holes 4 is greater than the wire diameter of the helix 2, and the two ends of each helix 2 are respectively fixed on the helical wire harness constraining ring at both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com