Light source module group

A technology of light source module and light guide plate, applied in the direction of light source, electric light source, point light source, etc., can solve the problem of inability to transmit large-area illumination, achieve uniform transmission, and improve the effect of light coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

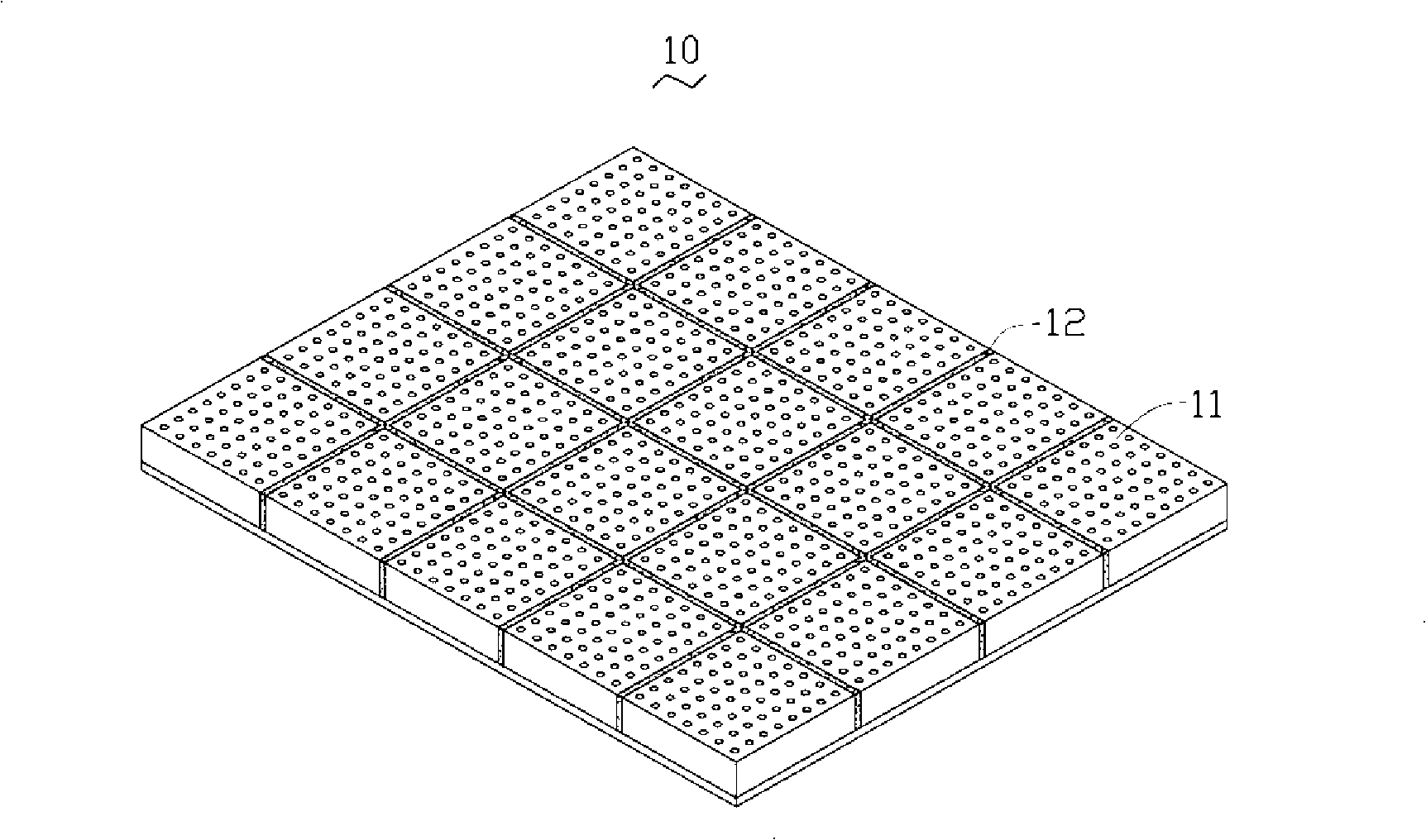

[0014] see figure 1 The light source module 10 provided by the first embodiment of the present invention includes a plurality of light emitting units 11 , and two adjacent light emitting units 11 in the plurality of light emitting units 11 are connected by a transparent adhesive 12 .

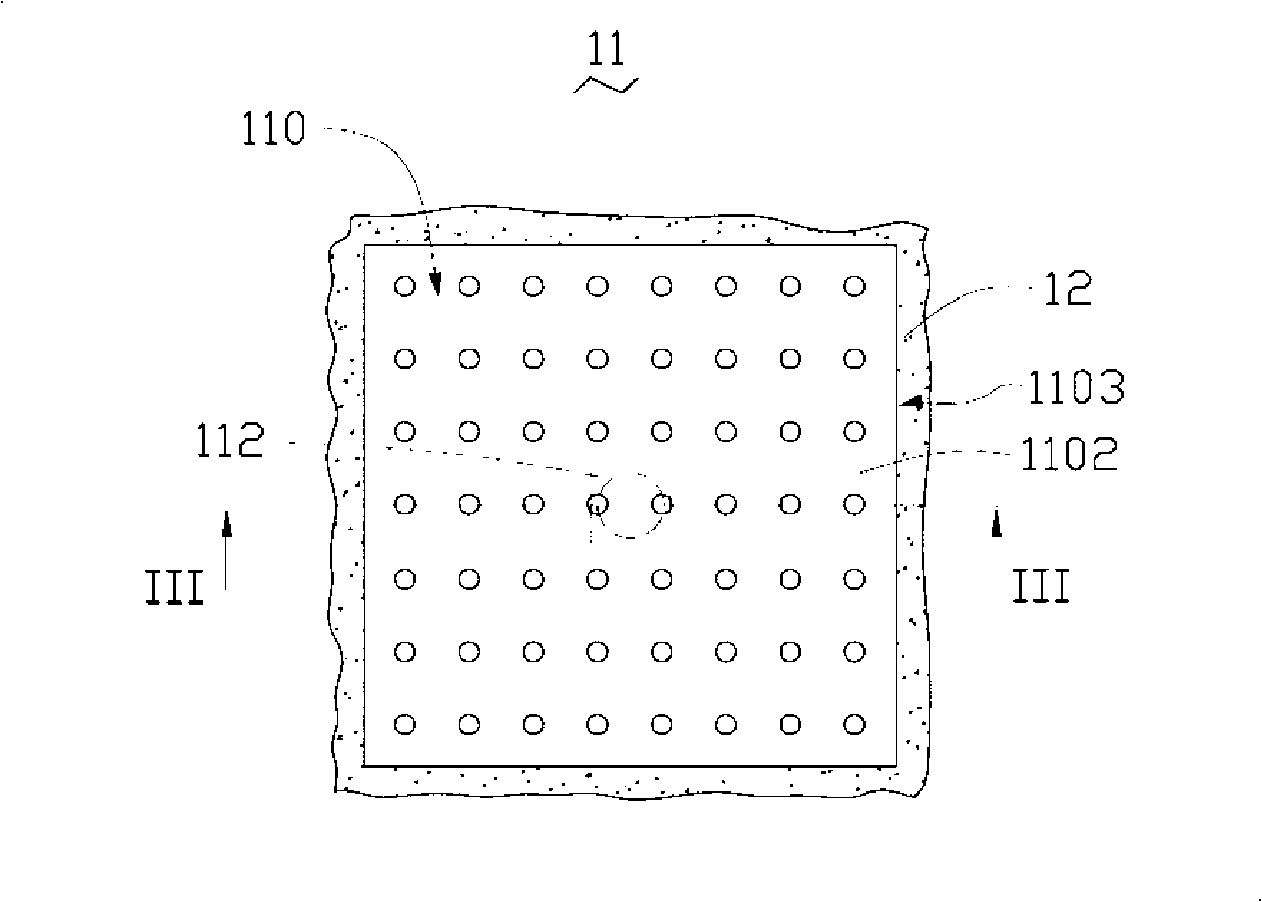

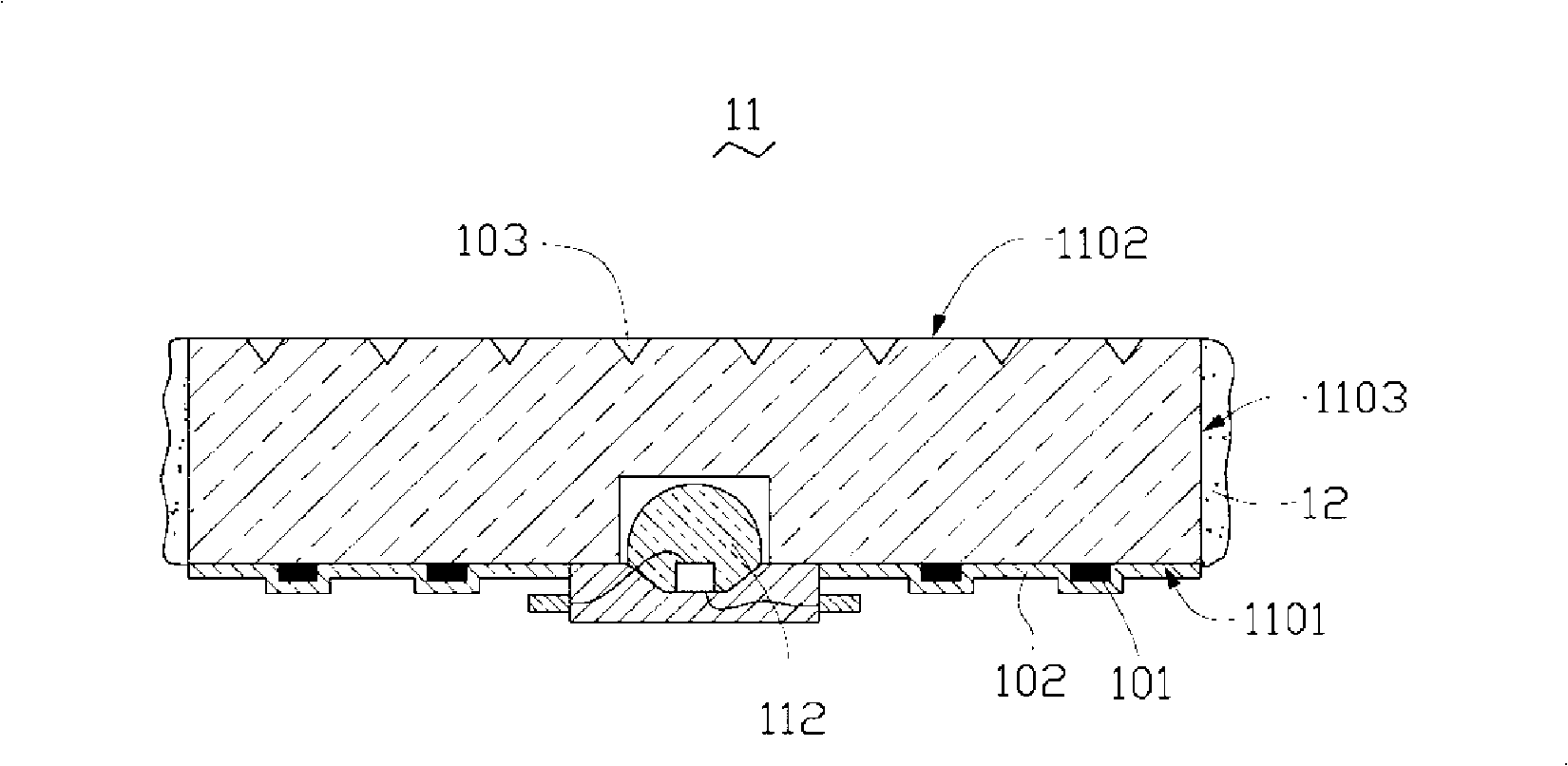

[0015] see figure 2 and image 3 , the light emitting unit 11 includes a light guide plate 110 and a light emitting element 112 optically coupled with the light guide plate 110 .

[0016] The light guide plate 110 includes a bottom surface 1101 , a light emitting surface 1102 opposite to the bottom surface 1101 , and a side surface 1103 disposed between the bottom surface 1101 and the light emitting surface 1102 . The shape of the light guide plate 110 can be square, triangular, regular hexagonal deformation and other shapes that are convenient for splici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com