Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Extend hardening time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium phosphate cement composition and a method for the preparation thereof

ActiveUS6929692B2Good water solubilityIncreased formationOther chemical processesBone implantChemical synthesisCalcium biphosphate

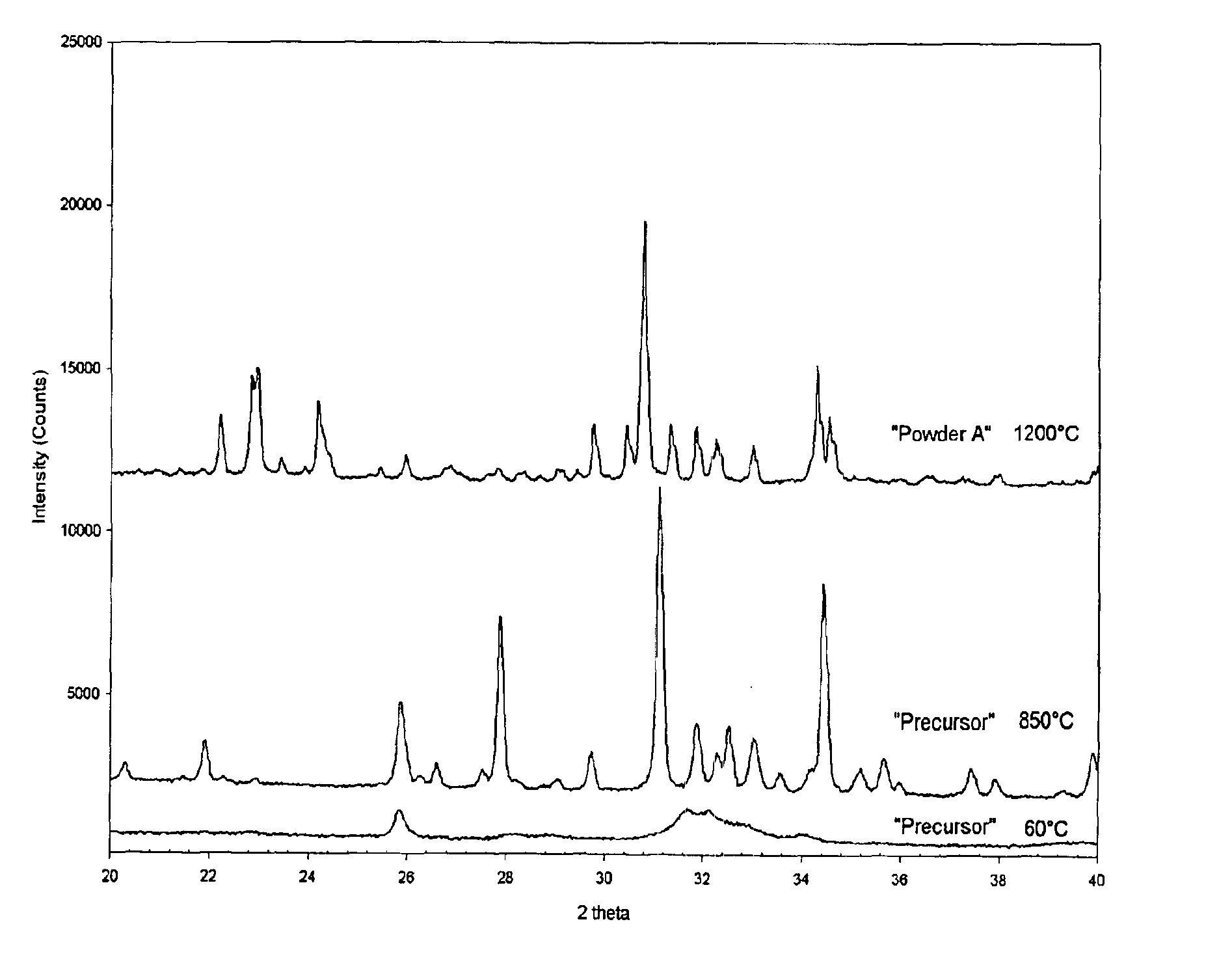

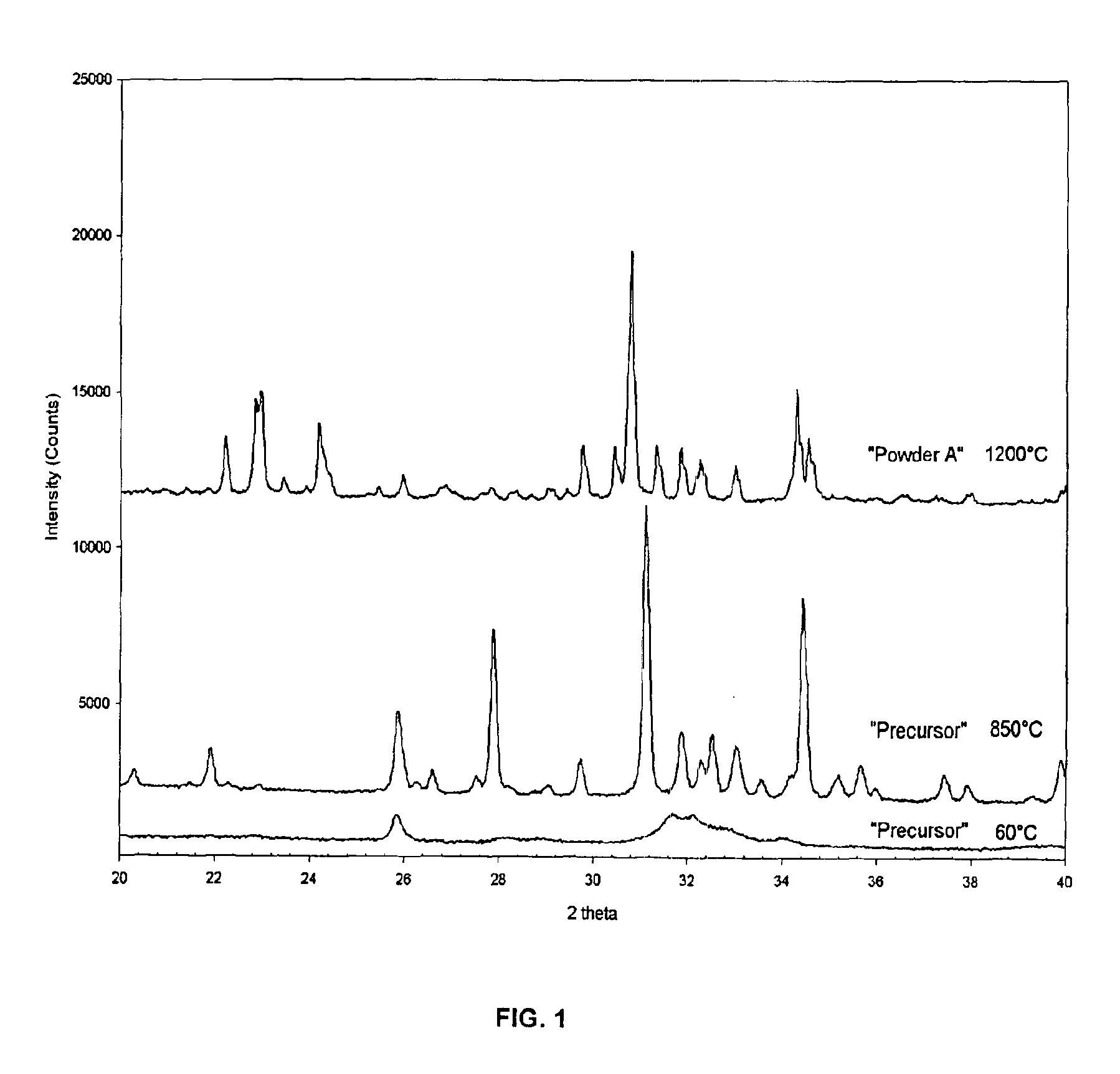

The invention describes a new calcium phosphate cement powder, whose composition can best be described over the Ca / P molar ratio range of 1.35 to 1.40, most preferably 1.39, and whose two components were prepared by wet chemical synthesis procedures. One component is chemically-synthesized, bi-phasic alpha-TCP (Ca3(PO4)2, 95 wt %)+HA (Ca10(PO4)6(OH)2, 5 wt %) powder, while the second component is again a chemically-synthesized, single-phase DCPD (CaHPO4·2H2O) powder. A setting solution (Na2HPO4·2H2O) is used to form a self-setting calcium phosphate cement from the powder mixture. This cement can be used as bone filler or bone substitute in applications, which require higher rates of resorption.

Owner:DR AHMET CUNEYT TAS

Meteorological balloon and preparation method thereof

InactiveCN102352060AIncreased blast diameterImprove permeabilityCoatingsInstrumentsPotassium hydroxideIsoprene

The invention belongs to the technical field of meteorological sounding balloons and particularly discloses a meteorological balloon and a preparation method thereof. The meteorological balloon is prepared from natural centrifuged and concentrated latex, casein, potassium hydroxide, a dispersant NF, sodium tetraborate, nekal BX, peregal O, sulfur, an accelerator zinc ethylphenyl dithiocarbamate (PX), an anti-aging agent, 4010NA, zinc oxide, a cold-resistant agent, and a neoprene latex and polyisoprene polymer by the steps of material mixing, mould impregnation, film attaching, solidification and demoulding, and aerating and setting. The meteorological balloon has the characteristics of high surface smoothness, long sounding life and good product quality, and the blasting diameter is increased.

Owner:衡水华铭橡塑制品厂

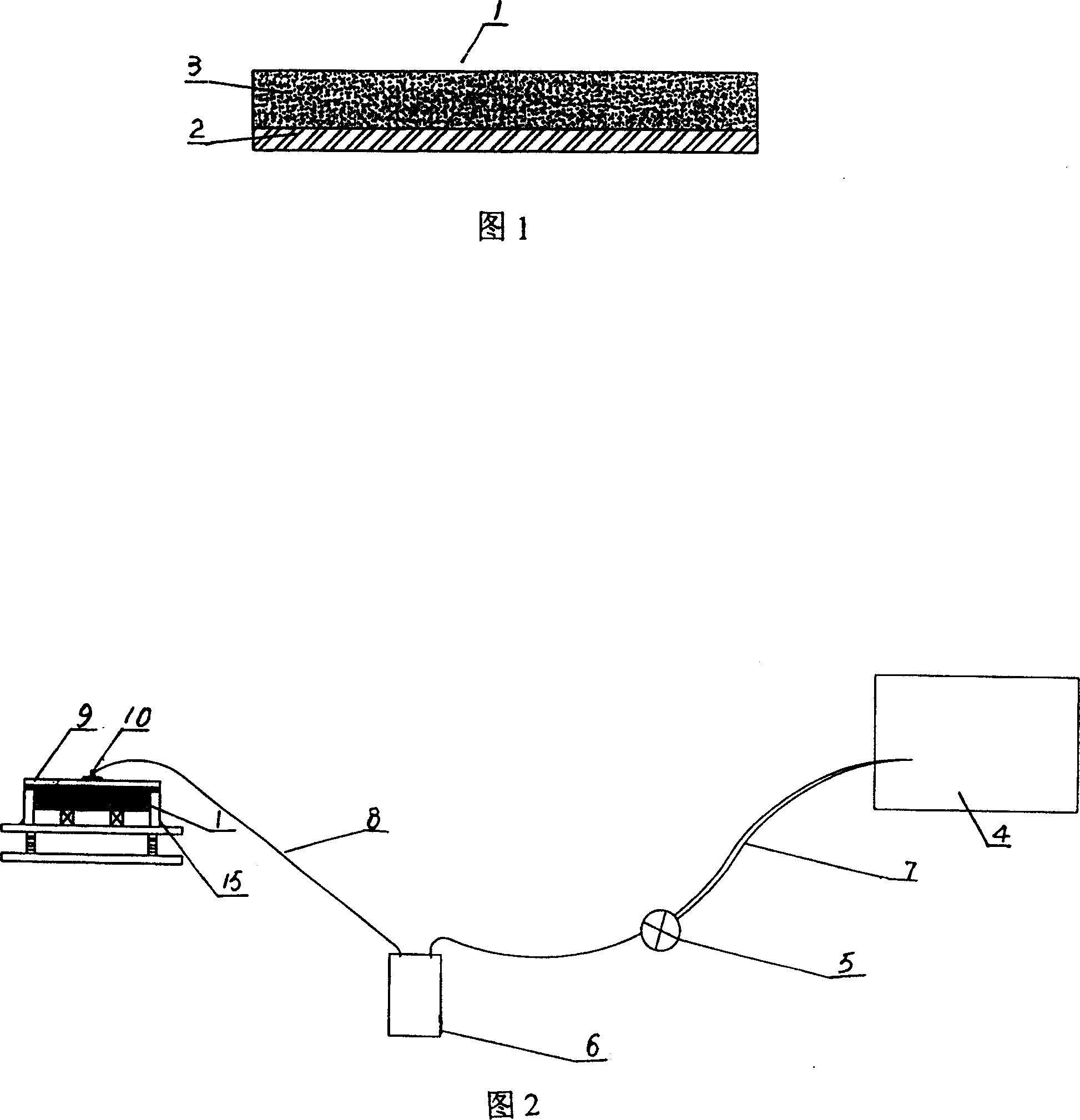

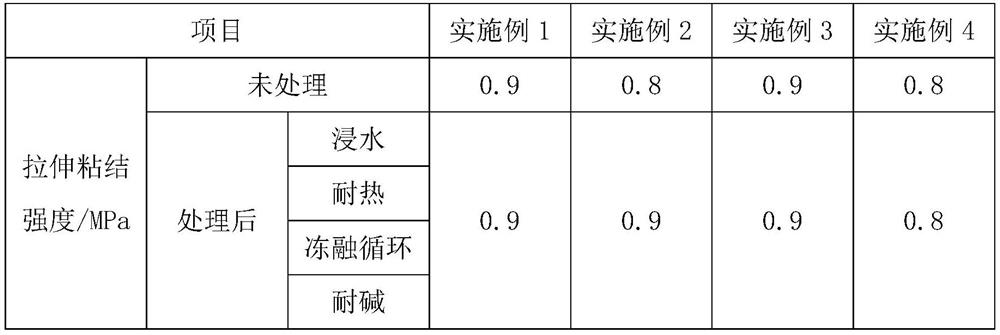

Binder for installation of thermal insulation decorative plate

The invention provides a binder for installation of a thermal insulation decorative plate. The binder comprises, by weight, 25 to 40% of cement, 25 to 45% of silica sand of 20 to 40 meshes, 8 to 15% of silica sand of 40 to 70 meshes, 3 to 8% of silica sand of 70 to 140 meshes, 0 to 5% of talcum powder, 0 to 5% of ground calcium carbonate powder, 2 to 8% of dispersible latex powder, 0 to 1% of cellulose ether, 0 to 0.6% of plant fibers and 0 to 0.5% of a thixotropic agent. The binder for installation of the thermal insulation decorative plate has the characteristics of high adhesion, strong anti-sliding capability, strong initial adhesion, long construction operation time and difficult skinning, effectively solves the problems produced in thermal insulation decorative plate pasting installation, guarantees enough adhesion between a thermal insulation decorative plate and a wall surface, and improves safety of the thermal insulation decorative plate in engineering application.

Owner:ASIA CUANON TECH SHANGHAI

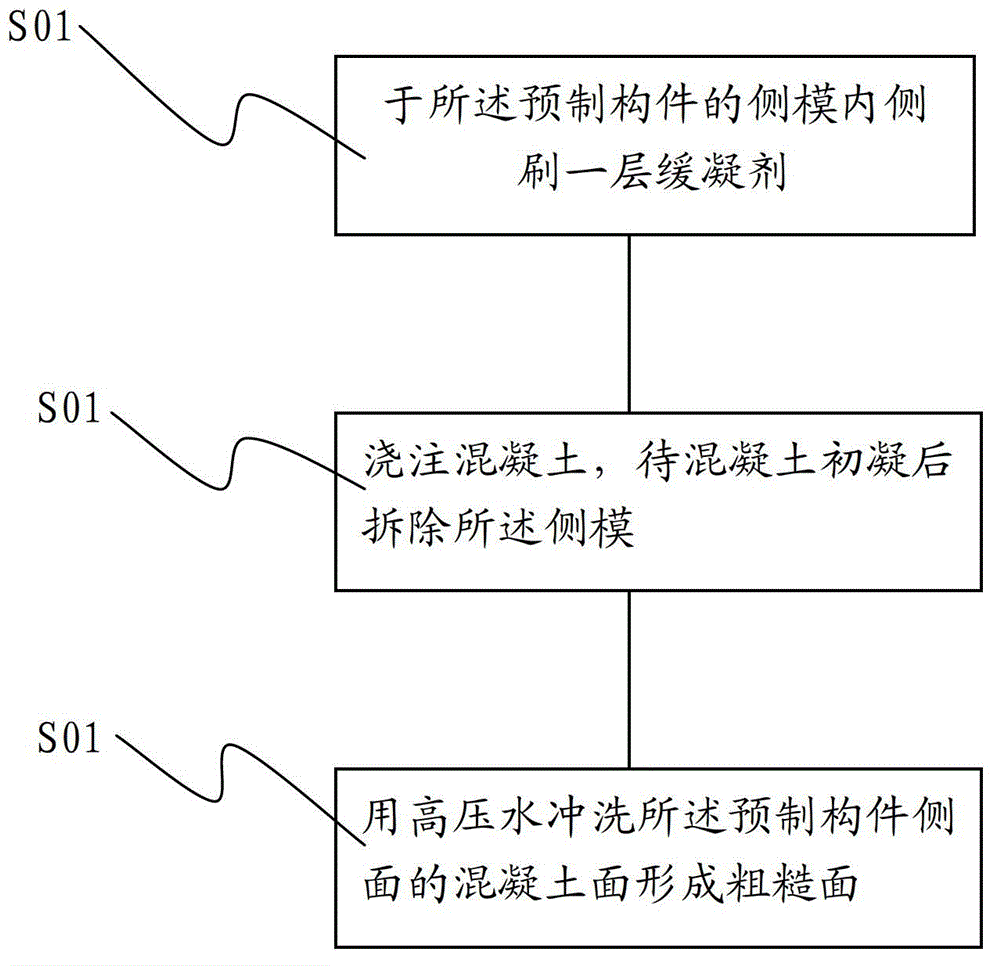

Method for fabricating side rough surfaces of prefabricated part

The invention discloses a method for fabricating side rough surfaces of a prefabricated part, and the method mainly comprises the following steps of: brushing a layer of retarder to the inner side of the side form of the prefabricated part; pouring concrete, and removing the side form after the concrete is pre-hardened; and flushing the concrete surface of the side surfaces of the prefabricated part by using high-pressure water to form rough surfaces. A layer of mortar is applied to the surface of the side form in advance before brushing the retarder to the surface of the side form, and then the retarder is brushed on the mortar. The method for fabricating side rough surfaces of the prefabricated part provided by the invention can be used for prolonging the hardening time of the concrete and enabling the concrete to keep plasticity in long time by brushing a layer of retarder at the inner side of the side form of the prefabricated part; and the high-pressure water is applied to flushing the concrete surfaces of the side surfaces of the prefabricated part to form rough surfaces; and the method is simple to operate and capable of forming the rough surfaces on the side surfaces of the concrete of the prefabricated part.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Big cake formula and production process thereof

The invention discloses a big cake formula, wherein a sesame oil big cake formula includes the following raw materials in parts by weight: 62% of glutinous rice flour, 25% of white granulated sugar, 8% of maltose, 2-2.5% of vegetable oil, 5% of drinking water, 1.5% of refined sesame oil, 0.03% of sodium dehydroacetate, and 0.5% of glycerol monostearate. According to the big cake formula and a production process thereof, the refined sesame oil in the sesame oil big cake preparation formula is 1.5%; pumpkin flour in a pumpkin big cake preparation formula is 3-3.5%; black sesame in a sesame big cake preparation formula is 2%; moreover, a certain proportion of jam prepared by apple is added in the big cake preparation process, the apple jam, pectin and syrup are fused together into glutinous rice, and the pectin has a condensation effect, can prolong the time keeping good mouthfeel in shelf life to 15 days, and greatly prolongs the hardening time of the big cake.

Owner:JIANGXI NORMAL UNIV

Processing method of preserved rock candy and loquat fruits

Owner:FUJIAN AGRI & FORESTRY UNIV

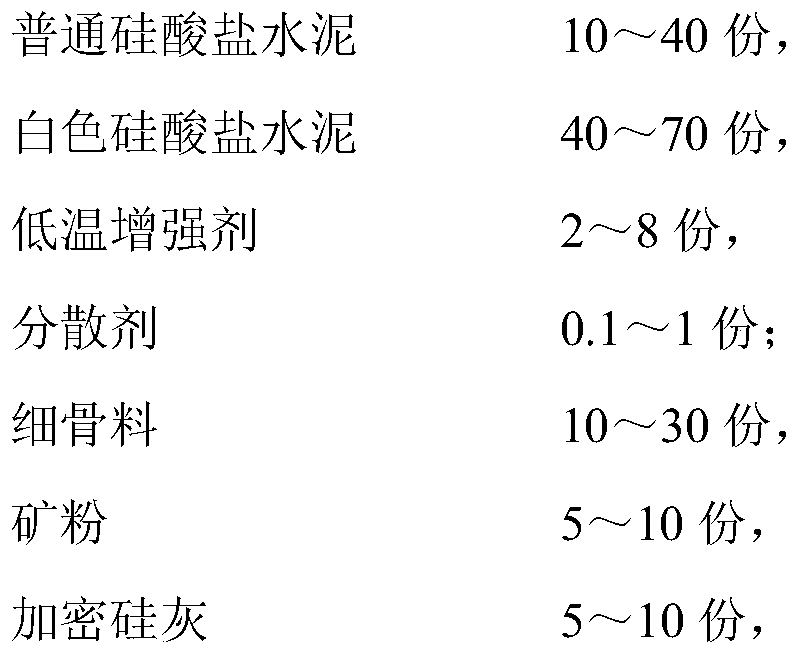

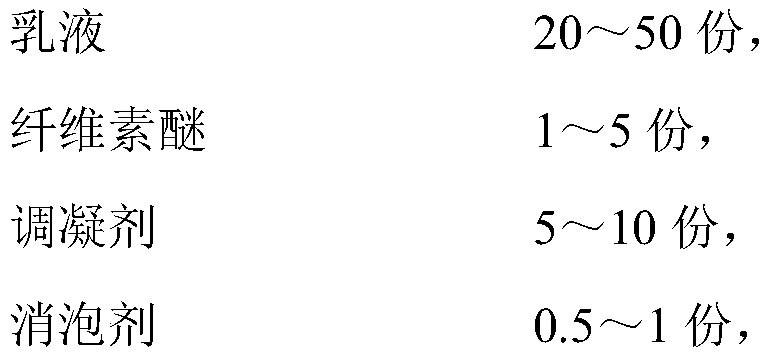

Interface agent and preparation method thereof and application of interface agent in fabricated building structure

The invention provides an interface agent, a preparation method thereof and an application of the interface agent in a fabricated building structure. The interface agent uses an ultrafine composition,and the low-temperature construction performance and the bonding strength of the interface agent are improved. The interface agent is prepared from a component A and a component B, wherein the component A is prepared from ordinary Portland cement, white Portland cement, a low-temperature reinforcing agent, a dispersing agent, fine aggregate, mineral powder and dense silica fume, and the componentB is prepared from emulsion, cellulose ether, a thickening time control agent, a defoaming agent and water. The interface agent has the excellent characteristics of high bonding strength, long hardening time, low temperature resistance and the like. The interface agent is applied to a fabricated building structure, and has remarkable economic and social benefits for improving the construction efficiency and engineering quality of the fabricated building structure.

Owner:JIANGSU SOBUTE NEW MATERIALS

Waterproof closed-cell expanded perlite

InactiveCN101781098AHighlight the effect of closed poresImprove thermal insulationHeat proofingCompressive strengthUltimate tensile strength

The invention provides a waterproof closed-cell expanded perlite which is prepared by the following steps of: matching silica sol, water glass, a waterproof agent, cement powder, a curing agent and water in parts by weight, and uniformly mixing to prepare a waterproof closed-cell sizing agent; then uniformly spraying the waterproof closed-cell sizing agent to the surface of an expanded perlite, and then drying or airing the expanded perlite to obtain the waterproof closed-cell expanded perlite, wherein 215.1-262.9 kilograms of the waterproof closed-cell sizing agent is sprayed to the expanded perlite per cubic metre. The waterproof closed-cell expanded perlite has the outstanding advantages of light capacity, good heat insulation property, waterproofness, good affinity, high compression strength, extensive usage temperature, high chemical stability, innocuity, odourless, incorruption and non-inflammation, acid-alkali resistance, simple preparation process and low cost, thereby being an ideal building heat insulation material.

Owner:韩志同

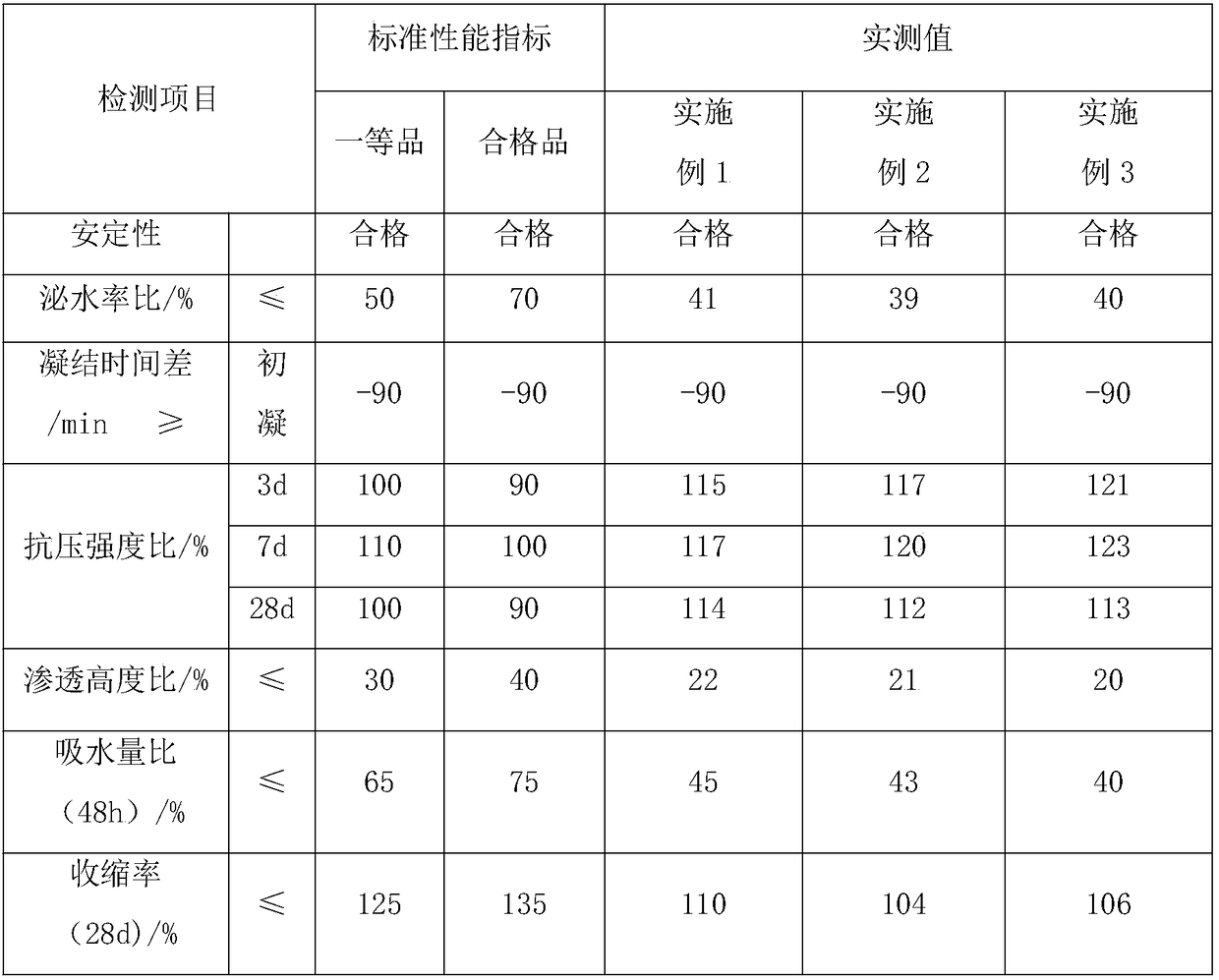

Preparation method of cement-based waterproof material

InactiveCN108359292AAntisepticImprove adsorption capacityFireproof paintsCement coatingsSodium bicarbonateSodium Bentonite

The invention relates to the field of waterproof materials, and specifically discloses a preparation method of a cement-based waterproof material. The preparation method comprises the following steps:mixing water, ethanol and a silane coupling agent, and carrying out ultrasonic oscillation, thus obtaining an oscillation solution; grinding sodium bentonite, adding and mixing the sodium bentonite powder in a sodium hydroxide solution, carrying out ultrasonic oscillation, taking a suspension solution, preheating and stirring, dropwise adding the oscillation solution, stirring, refluxing, cooling, filtering, and washing, thus obtaining a washing product; mixing butyl acrylate, methacrylic acid and methyl methacrylate, thus obtaining a mixed solution; mixing water, sodium hydrogen carbonate and a composite emulsifying agent, dropwise adding the mixed solution, heating, adding organosilicone and an initiator, heating, cooling and filtering, thus obtaining emulsion; mixing the washing product with deionzed water, dropwise adding an ammonium persulfate-phosphoric acid water solution, stirring, adding the emulsion and a composite flame retardant, and uniformly stirring, thus obtaining a stirring solution; mixing the stirring solution, methyl hydroxyethyl cellulose ether and defoaming agent, stirring, adding cement under a stirring state, and uniformly stirring, thus obtaining the cement-based waterproof material.

Owner:王景硕

Hardening-time-controllable magnesium oxysulfate cement and preparation method of hardening-time-controllable magnesium oxysulfate cement plate

The invention relates to hardening-time-controllable magnesium oxysulfate cement and a preparation method of a hardening-time-controllable magnesium oxysulfate cement plate. The cement is prepared from the following raw materials in parts by weight: 30 to 60 parts of active magnesia, 30 to 70 parts of magnesium sulfate, 0.5 to 2 parts of modifying agents, 5 to 10 parts of light perlite, 10 to 20 parts of hemihydrate gypsum and 5 to 10 parts of citric acid. A transfer film is laid on a glass plate; cement and water are weighed; the magnesium sulfate is firstly dissolved into water; then, the magnesium sulfate is uniformly mixed with other raw materials to form material slurry; the material slurry is poured onto the transfer film; flat spreading is performed; the maintenance is performed for 15 to 30 hours at the normal temperature; demoulding is performed; the transfer film is removed; a finished product is obtained. The prepared decoration plate does not deform, does not crack and does not generate halogenide; the initial setting time can be controlled to be longer than 30 minutes; the final setting time is controlled to be within 1 hour.

Owner:SHANDONG JIANZHU UNIV

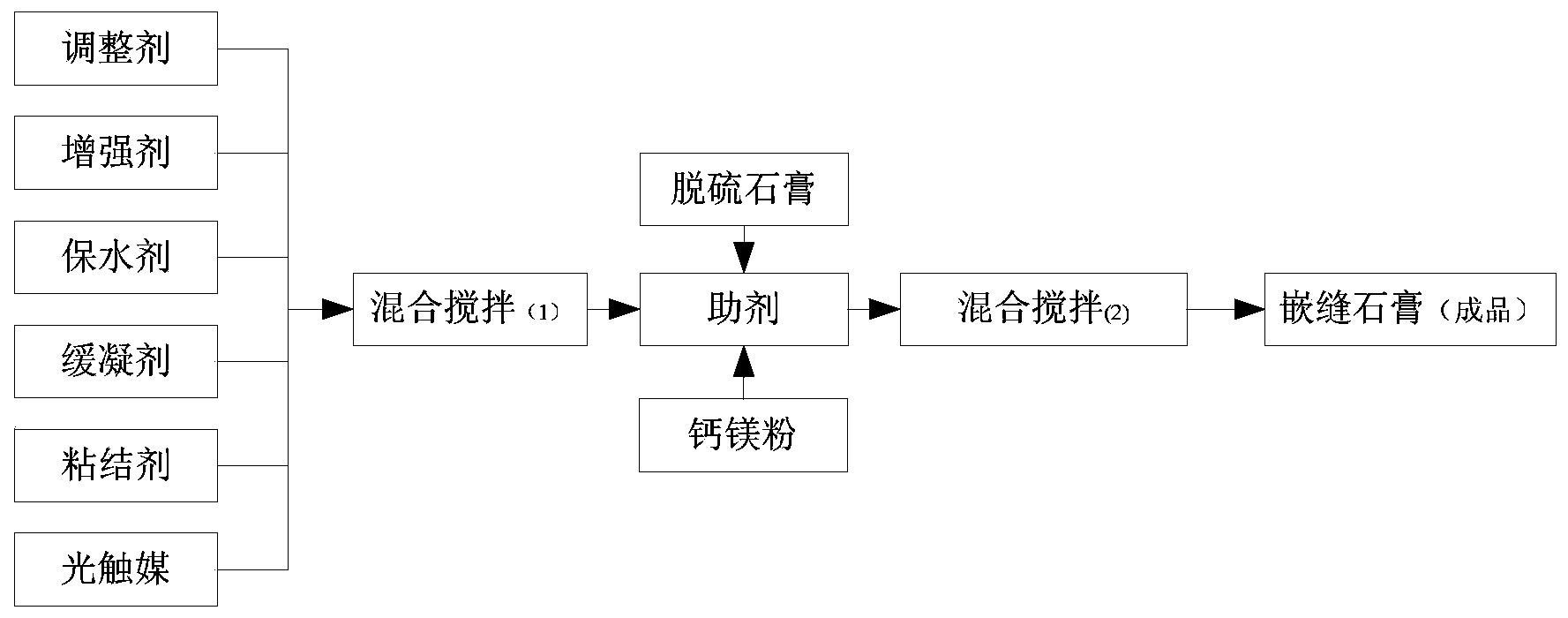

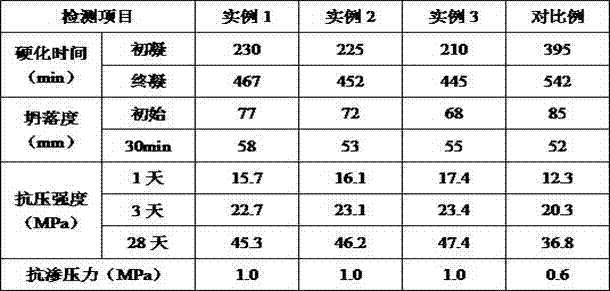

Method for preparing caulking gypsum putty powder from flue gas desulfurization gypsum

The invention discloses a method for preparing caulking gypsum putty powder from flue gas desulfurization gypsum. The method comprises the following steps: crushing the waste desulfurization gypsum till the particles with granularity of 25-35um are over 80 percent, and performing high-temperature calcining, so that CaSO4.2H2O loses crystal water to form CaSO4.1 / 2H2O or CaSO4; uniformly stirring and mixing the following components at one time in percentage by weight: 0.5-3 percent of regulator, 0.5-1.5 percent of enhancer, 0.1-0.6 percent of water-retaining agent, 0.3-0.5 percent of retarder, 0.2-0.5 percent of photocatalyst and 0.2-0.25 percent of adhesive; adding 80-87wt% of desulfurization gypsum powder and 10-20wt% of calcium magnesium powder into the obtained mixture, and performing secondary stirring and mixing, thus obtaining the caulking gypsum putty powder. The prepared product has the advantages of environment friendliness, cracking resistance, availability and low cost, and more importantly has the characteristic of degrading formaldehyde and other volatile organic compounds.

Owner:浙江固德优科技有限公司

Basalt fiber composite novel wall material and preparation method thereof

The invention discloses a basalt fiber composite novel wall material and a preparation method thereof, wherein the basalt fiber composite novel wall material is prepared from the following raw materials by weight: 0.6-0.8% of basalt fiber yarns, 0.3-0.7% of basalt fiber grid cloth, 24-25% of fast hardening sulphoaluminate cement, 40-45% of river sand, 1-3% of screw thread steel, 5-7% of reinforcing steel bars, 2-5% of channel steel, 0.3-0.4% of flame-retardant foam, 13-15% of water, 0.24-0.3% of expanded perlite, 2.9-3.2% of an adhesive, 0.12-0.15% of an early strength agent or a retarder, 0.6-0.8% of a styrene-acrylic emulsion, 0.24-0.26% of ferrous sulfate, 0.49-0.51% of calcium and magnesium powder, and 0.98-1% of a concrete surface reinforcing agent. According to the invention, the wall material prepared from the components according to the specific ratio according to the architectural conventional method has characteristics of uniform thermal expansion and cold contraction, goodtoughness and breakage resistance, has weak alkality so as not to easily corrode iron, aluminum and other metal materials, further has advantages of light weight, environmental protection, high strength, good toughness and low energy consumption, can be freely modeled according to molds, and is suitable for popularization in the building material field.

Owner:乐山一拉得电网自动化有限公司

Preparation method for early-strength agent for concrete

The invention belongs to the technical field of concrete additive preparation, and particularly relates to a preparation method for an early-strength agent for concrete. According to the preparation method, cellulose, acetamide and water are first uniformly mixed, sodium hydroxide solution is used for regulating pH, temperature is then kept for reaction, bromooctadecane is then added, mixing and filtration are carried out, filter residue is collected, washed and air-dried, afterwards the air-dried matter is collected to react with tetrahydrofuran, n-butyllithium and dimethylformamide, discharge is carried out, the collected discharged matter and Gamma-aminopropyltriethoxysilane are then uniformly mixed and distilled, finally distilled residue, nano-titanium dioxide and aluminium silicate are mixed, the stirred mixture is collected, and thereby the early-strength agent for concrete is obtained. The early-strength agent obtained by the invention can effectively increase the strength of concrete at each age, and can also effectively shorten concrete hardening time, and in addition, the plasticity-maintaining property is good as well.

Owner:攀枝花市润泽建材有限公司

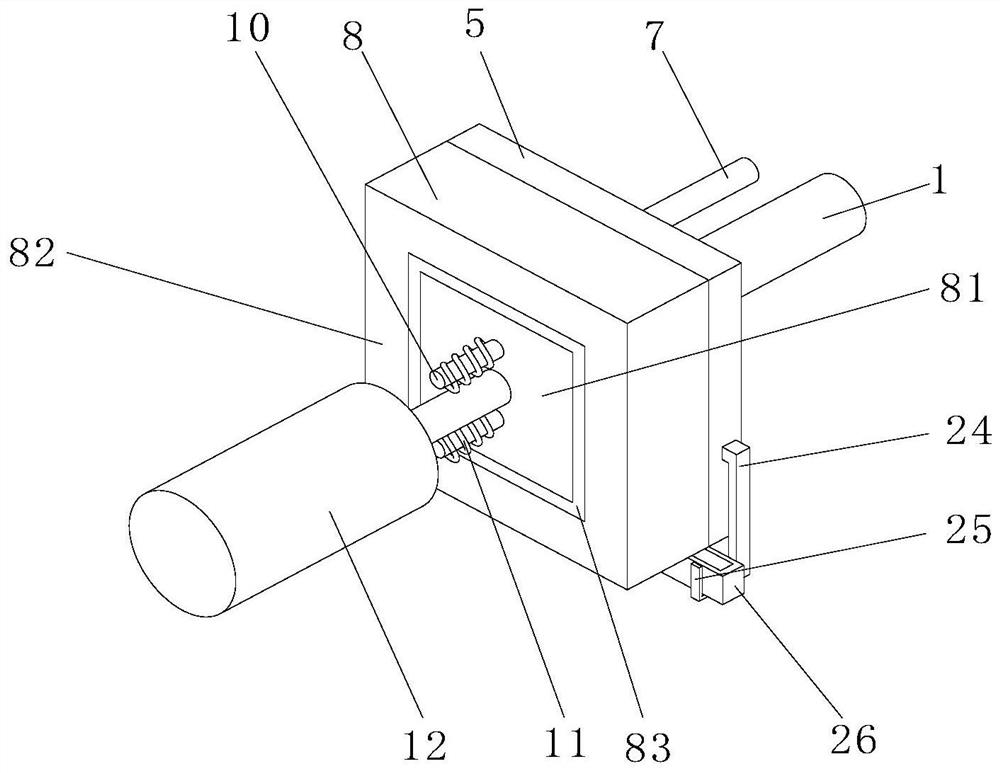

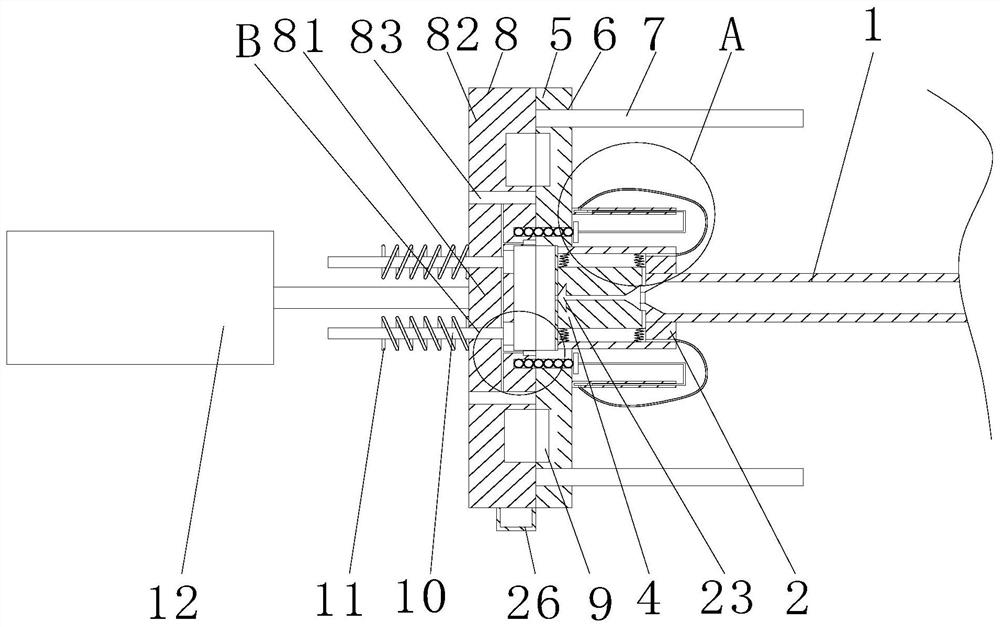

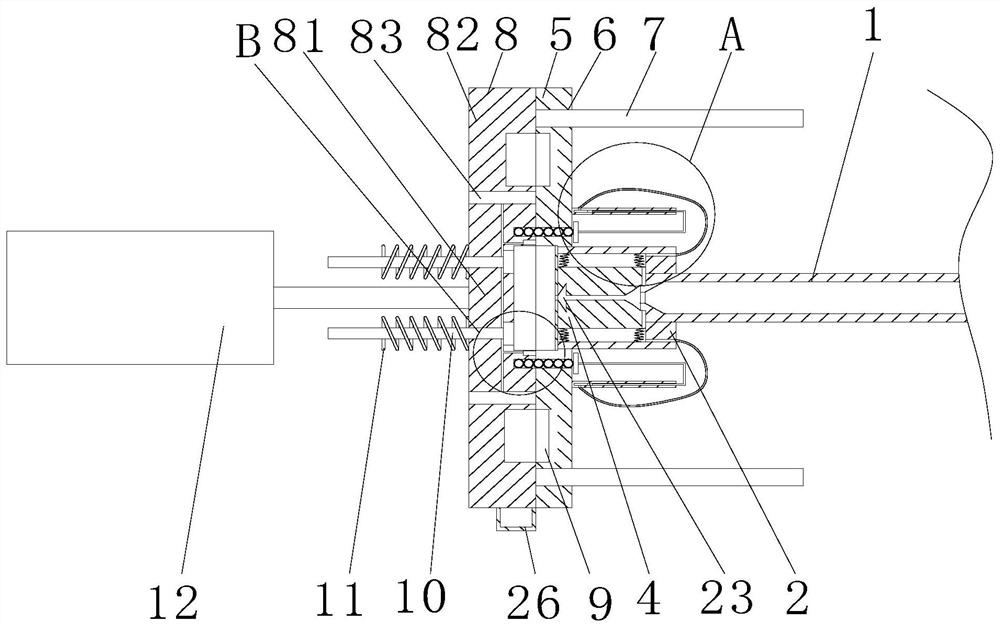

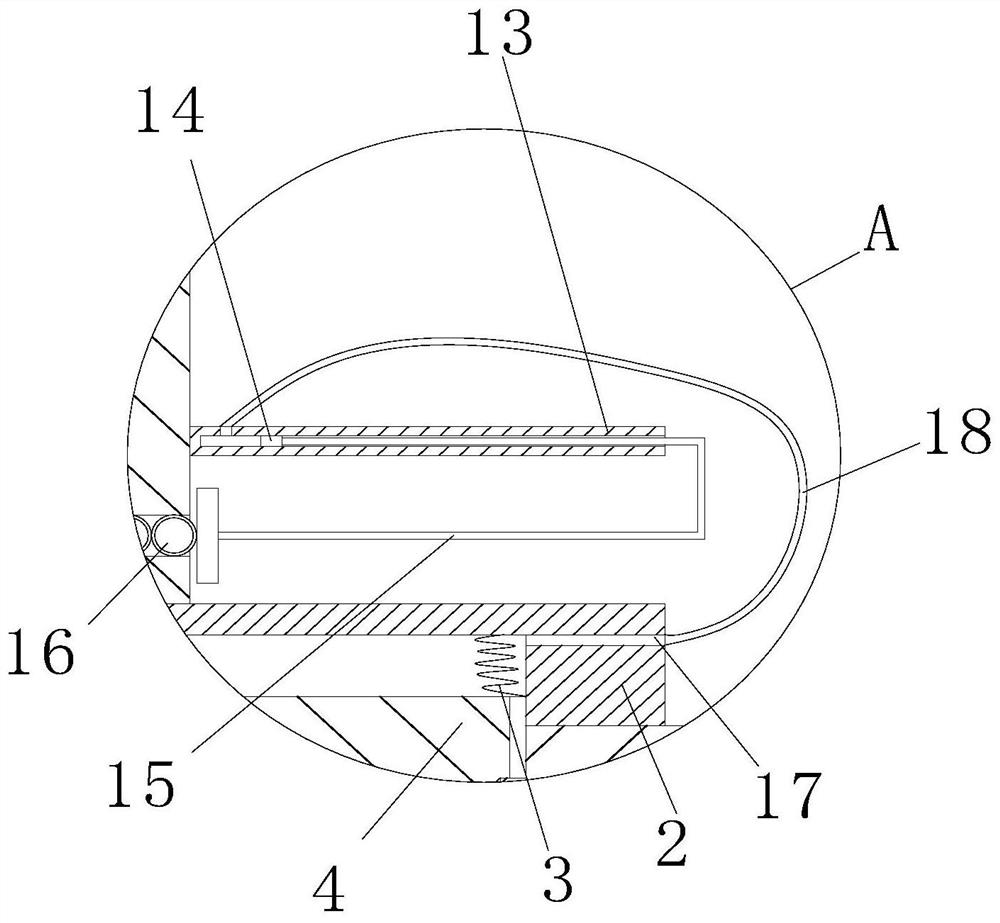

Injection mold device

ActiveCN111941751AAvoid the problem of increased resistance or even cloggingGuaranteed cooling moldingHydraulic cylinderEngineering

The invention relates to the technical field of injection molding, and discloses an injection mold device. The injection mold device comprises an injection molding gun head, a fixed mold, a movable mold and a hydraulic cylinder; the outer wall of the right end of the injection molding gun head is fixedly connected with a plastic guide barrel, and the inner walls of the top face and the bottom faceof the plastic guide barrel are each fixedly connected with a spring A; clamping blocks are fixedly connected with the ends, away from the inner wall of the plastic guide barrel, of the two springs A; the face, away from the injection molding gun head, of the plastic guide barrel is fixedly connected with the fixed mold; insertion holes A are formed in the upper end and the lower end of the sideface of the fixed mold correspondingly; each inserting hole is provided with an inserting rod in a sleeved mode, and the left ends of the two inserting rods are fixedly connected with the movable mold; and mold cavities are formed in the faces, corresponding to the movable mold, of the inserting rods. A circulating cooling pipe is separated from the fixed mold and the movable mold through injection molding pressure, the problem that resistance is increased and even blockage is caused due to raw material cooling in the injection molding process is avoided, and the circulating cooling pipe is automatically connected with the fixed mold and the movable mold after injection molding is completed, so that cooling molding of the raw materials is ensured.

Owner:福捷(武汉)电子配件有限公司

Can for magnetically coupled pumps and production process

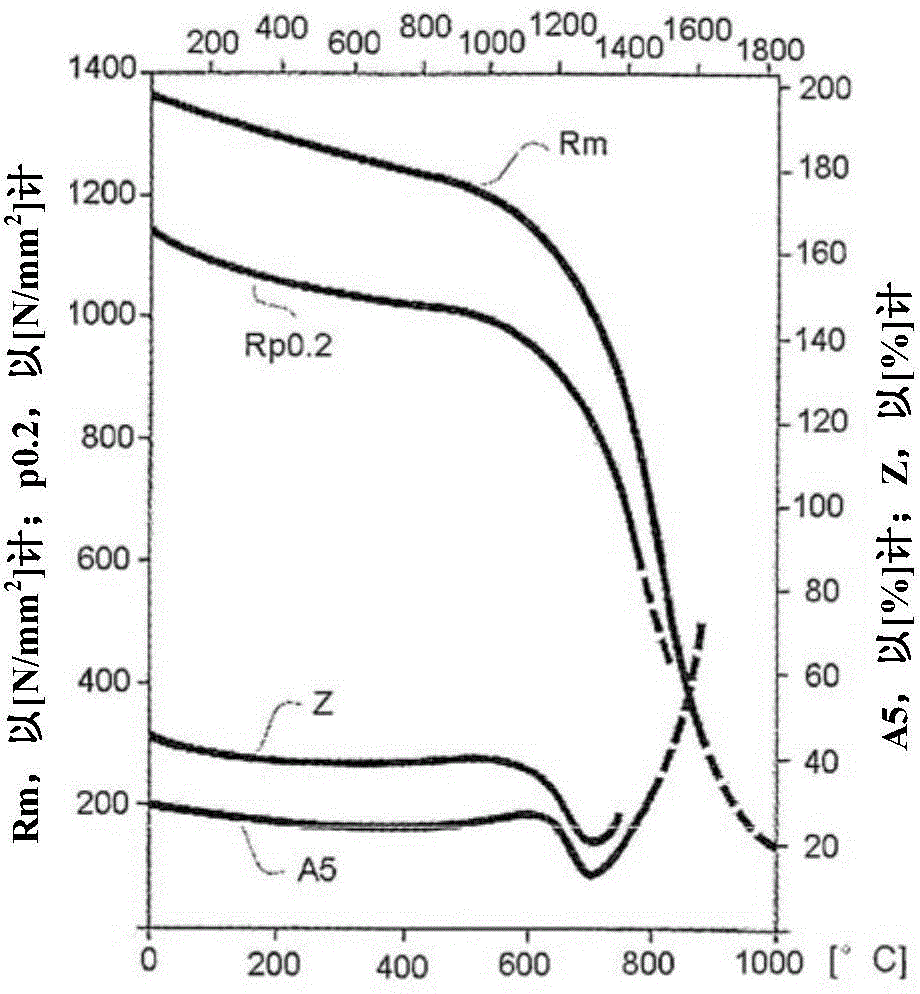

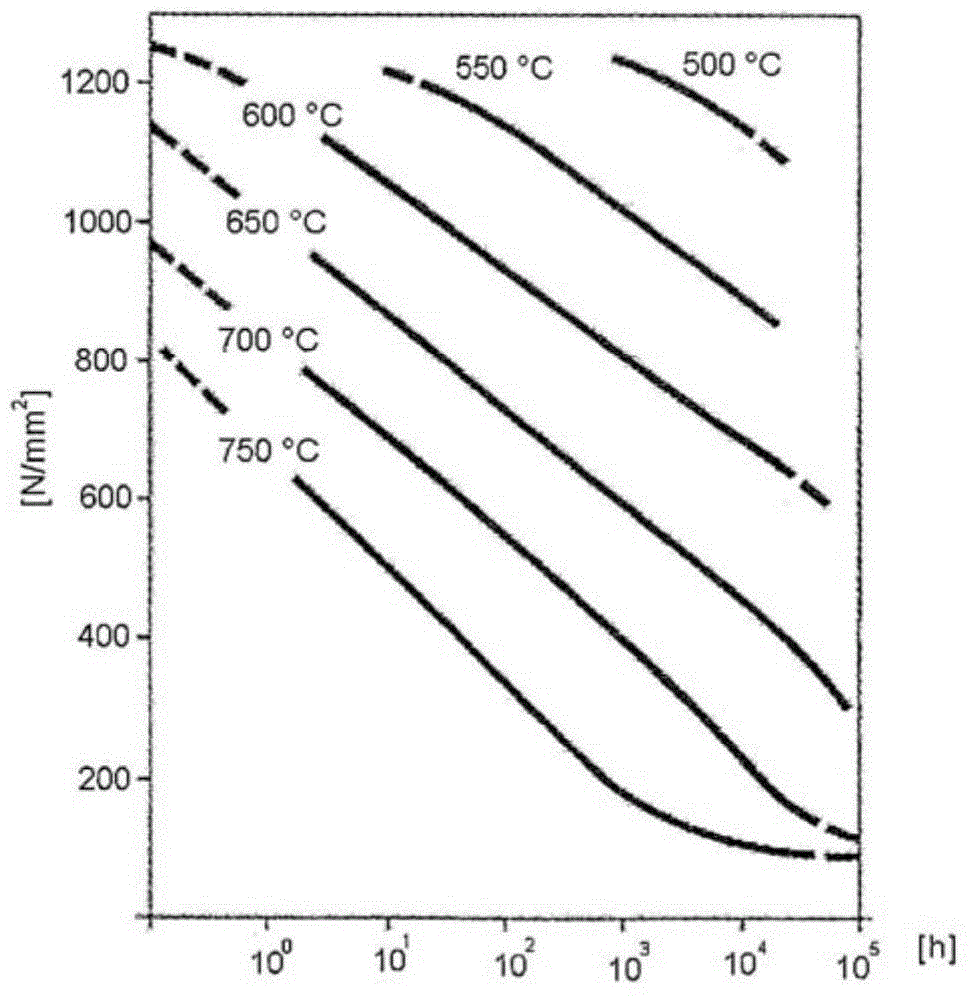

ActiveCN104937277AHigh hardnessImprove heat resistancePump componentsPump installationsNickel chromium alloyNichrome

Magnetically coupled pumps use cans which have a side wall arranged in a gap between a driver and a rotor of the pump. With a view to good efficiency of the pump, the gap should be as narrow as possible, which can only be achieved with a side wall of a thin wall thickness. In this case, the can must be of a sufficiently great strength, in particular to withstand the differences in pressure in the pump. At the same time, it must be possible for the can to be shaped into a desired geometry in a simple way and to have a high degree of dimensional stability, even under high pump pressures. It is proposed to make a can (1) with a side wall (3) that consists at least partially of a material with a nickel component, wherein the material is a nickel-chromium alloy comprising at least 50 percent by weight of nickel and 17 to 21 percent by weight of chromium, and to harden the side wall (3) by a heat treatment. This allows a can (1) that is very resistant to corrosion and / or high temperatures to be provided in a simple way.

Owner:KLAUS UNION

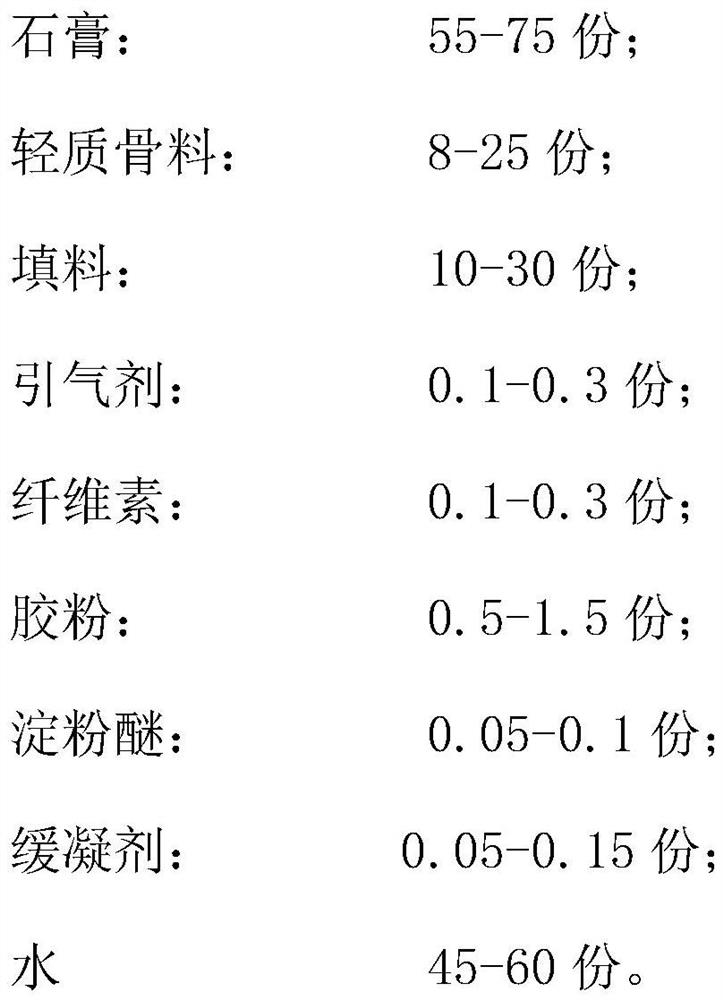

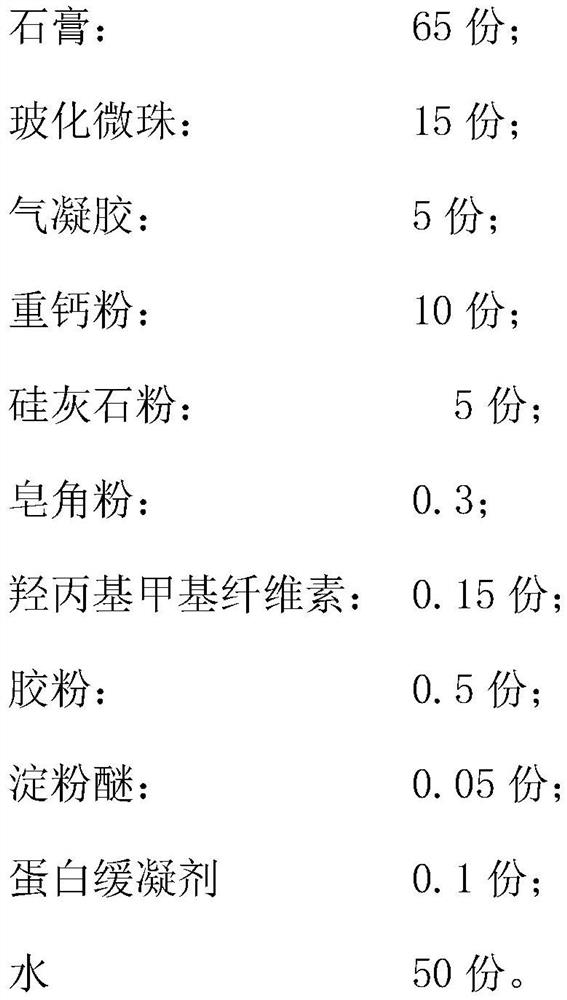

Heat-preservation and heat-insulation plaster for interior wall

The invention discloses an interior wall thermal insulation plaster, which comprises the following components by mass: 55 to 75 parts of gypsum; 8 to 25 parts of lightweight aggregate; 10 to 30 parts of filler; 0.1 to 0.3 part of an air entraining agent; 0.1 to 0.3 part of cellulose; 0.5 to 1.5 parts of rubber powder; 0.05 to 0.1 part of starch ether; and 0.05 to 0.15 part of a retarder. The internal wall heat insulation plastering method is convenient and simple in manufacturing, the material has the advantages of being high in strength, low in heat conductivity coefficient, good in heat insulation effect and the like, construction operation is easy and convenient, and good market prospects are achieved.

Owner:漆仙姑新材料技术重庆有限公司

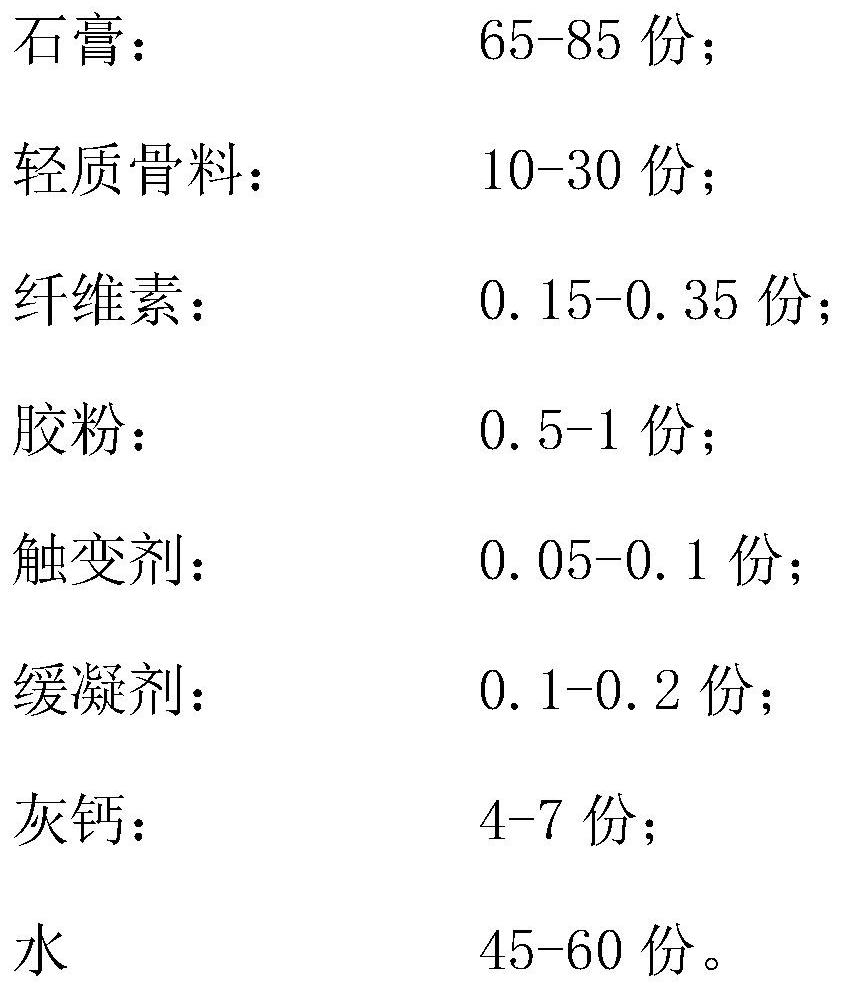

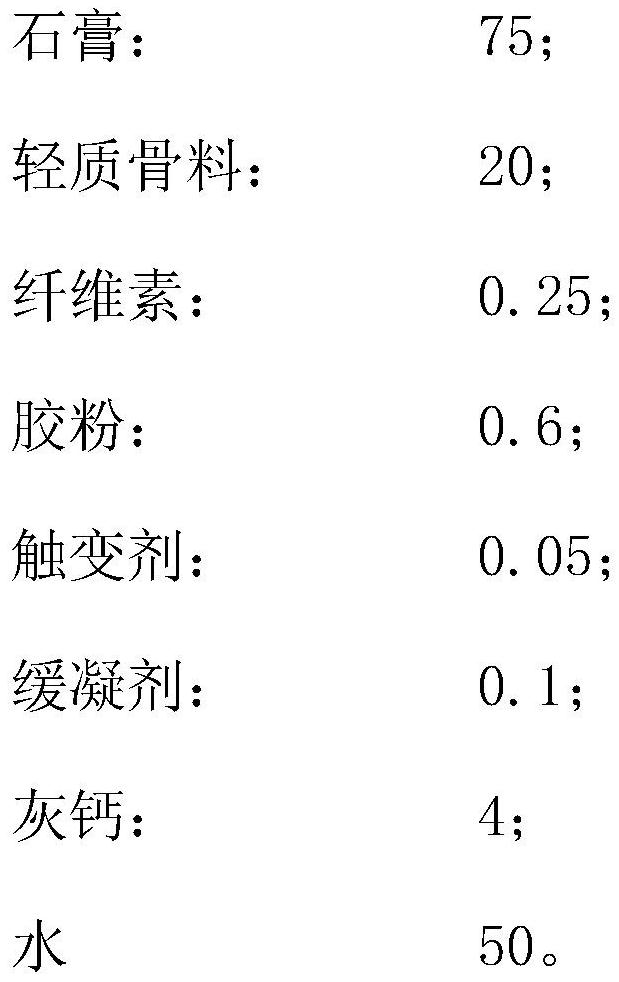

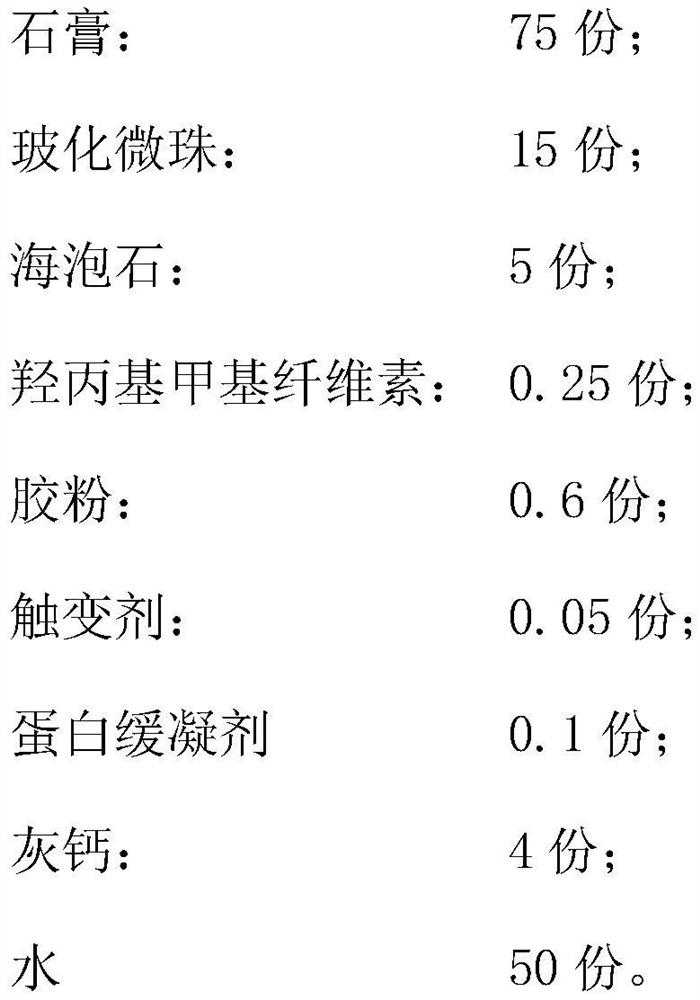

Multi-functional thermal insulation material

The invention discloses a multi-functional thermal insulation material which comprises the following components in parts by mass: 65-85 parts of gypsum; 10-30 parts of a lightweight aggregate; 0.15-0.35 parts of cellulose; 0.5-1 part of rubber powder; 0.05-0.1 parts of a thixotropic agent; 0.1-0.2 parts of a retarder; and 4-7 parts of ash calcium. The lightweight aggregate is one or more of vitrified microbeads, expanded perlite, polyphenyl granules, ceramic microbeads, sepiolite or closed-cell perlite. The cellulose is one or more of hydroxypropyl methyl cellulose, ethyl cellulose or carboxymethyl cellulose. The rubber powder is one or more of dispersible latex powder, VAE rubber powder or resin rubber powder. The thixotropic agent is one or two of fumed silica, organic bentonite, asbestos, magnesium aluminum silicate or kaolin. The material has the advantages that the method for preparing the multi-functional thermal insulation material is simple and easy to implement, the thermal insulation material has the characteristics of low density, high strength and low heat conductivity coefficient, subsequent construction operation is simple and convenient, and manpower can be greatly saved.

Owner:漆仙姑新材料技术重庆有限公司

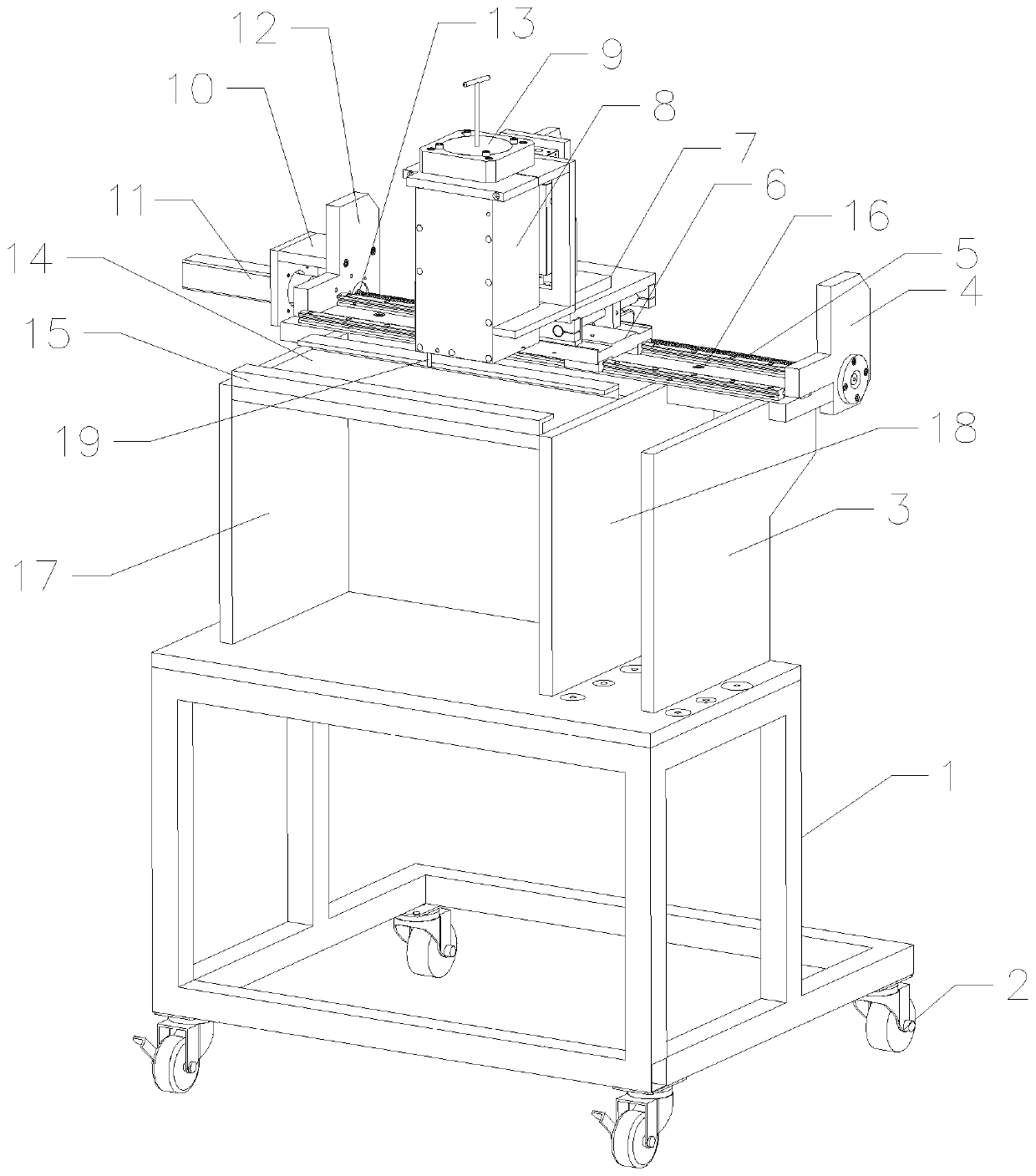

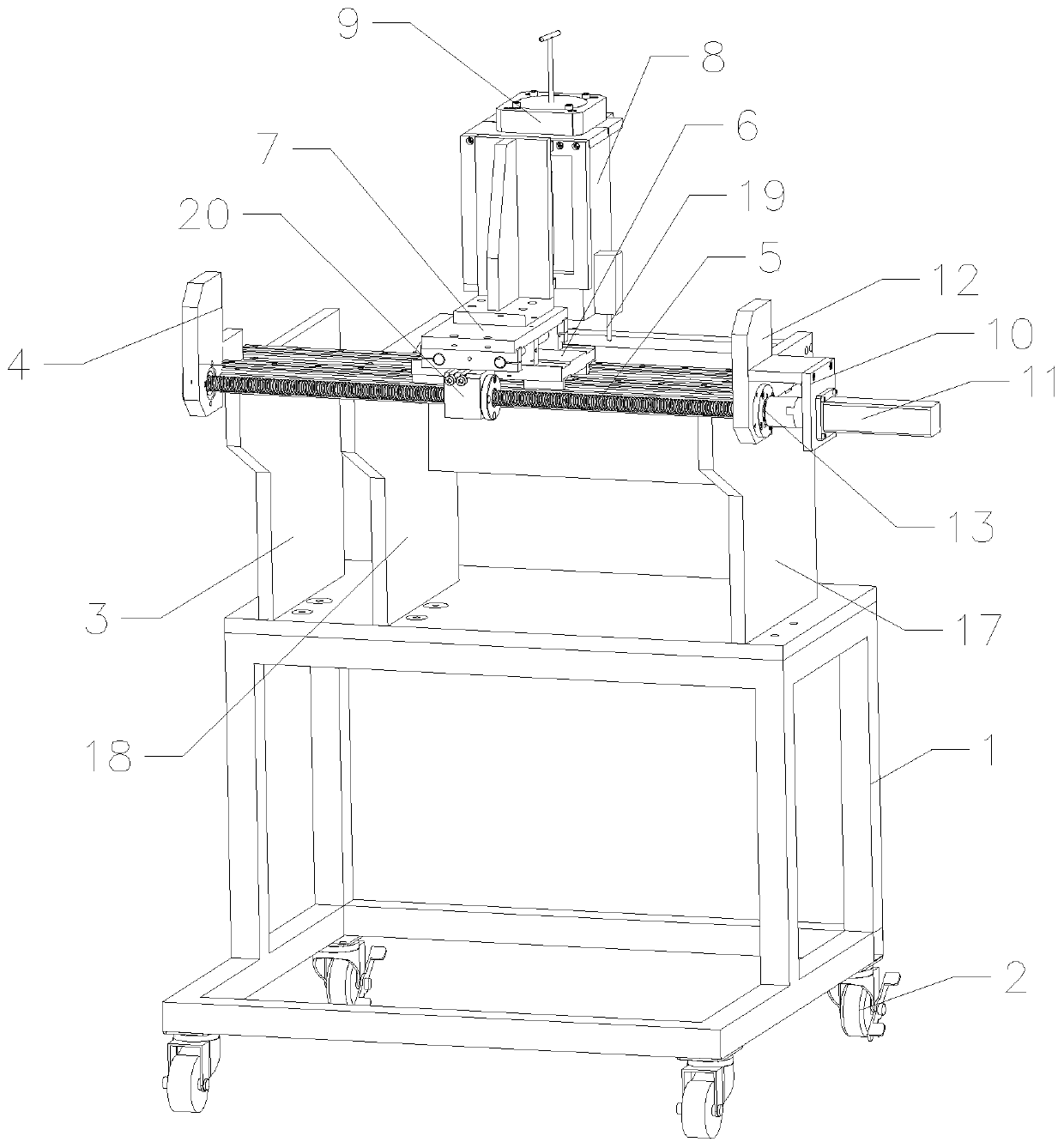

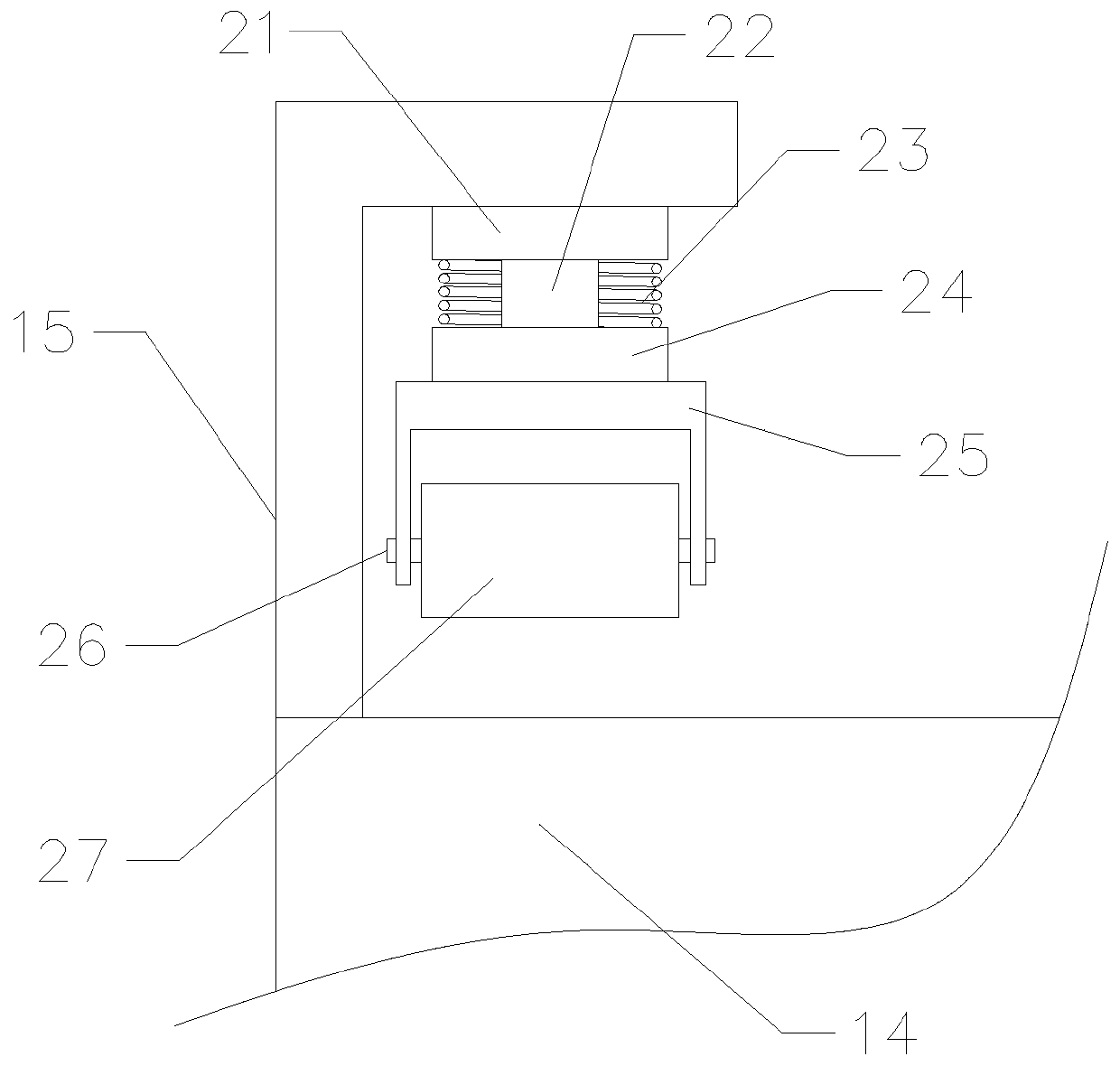

Gluing device for luggage production

ActiveCN110841843AQuality assuranceAchieve ejectionSpraying apparatusPretreated surfacesElectric machineryEngineering

The invention discloses a gluing device for luggage production, and relates to the technical field of dental comprehensive treatment machines. The gluing device for luggage production aims to solve the problem that the gluing efficiency of luggage production is low. The gluing device for luggage production specifically comprises a support, wherein a guide rail is arranged between a fourth mountingplate and a fifth mounting plate; a bearing plate is connected between a third mounting plate and a second mounting plate; the bearing plate is parallel to the guide rail; a sliding block capable ofsliding along the guide rail is arranged on the guide rail; a material box is arranged on the sliding block; a spray head is arranged on the material box; a booster pump for extruding glue from the spray head is arranged at the upper end of the material box; a linear motor mounting frame is arranged on one side of the fifth mounting plate; a linear motor is arranged on the linear motor mounting frame; a through hole is formed in the fifth mounting plate; a screw rod penetrating through the through hole is arranged on the linear motor; the screw rod penetrates through the fourth mounting plate;and a threaded sleeve connected to the screw rod in a sleeving mode is arranged on the sliding block. According to the gluing device for luggage production, the gluing quality and the gluing efficiency in the luggage production process can be improved.

Owner:耒阳市康意电子箱包科技有限公司

A kind of injection mold device

ActiveCN111941751BAvoid the problem of increased resistance or even cloggingGuaranteed cooling moldingHydraulic cylinderEngineering

The invention relates to the technical field of injection molding, and discloses an injection mold device, which includes an injection gun head, a fixed mold, a movable mold and a hydraulic cylinder. The inner wall of the bottom surface is fixedly connected with a set of springs A, and the ends of the two sets of springs A away from the inner wall of the plastic guide tube are fixedly connected with a clamp block. The side of the plastic guide tube away from the injection gun head is fixedly connected with the fixed mold, and the upper and lower ends of the fixed mold side Both sockets A are provided, and inserting rods are sleeved in the two sockets A. The left ends of the two inserting rods are fixedly connected to the movable mold. The corresponding sides of the inserting rod and the movable mold are provided with mold cavities. The pressure makes the circulating cooling pipe separate from the fixed mold and the movable mold, avoiding the cooling of the raw material during the injection molding process, resulting in increased resistance or even blockage, and the circulating cooling pipe is automatically connected to the fixed mold and the movable mold after the injection molding is completed, so as to ensure the cooling of the raw material forming.

Owner:福捷(武汉)电子配件有限公司

Manufacturing method for elastic composite material

Owner:TAIWAN CARBON NANO TECHNOLOGY CORPORATION

Production equipment and method for stone flake composite board

The present invention is the process and apparatus for producing composite thin stone slab with two glass reinforced cement (GRC) sides. The production process includes setting thin stone slab inside mold with frame on a vibration stage; dressing GRC slurry and vibrating to densify the GRC slurry; mounting vacuum sucker to the mold and starting the vacuum dewatering machine to dewater GRC slurry for densifying and hardening; letting stand for curing; turning to the other side; dressing GRC slurry, vibrating, vacuum dewatering, curing and demolding; wet curing in curing box; splitting into two thinner stone slabs; trimming and decorating. The production apparatus includes vacuum dewatering machine set and vacuum dewatering stage.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

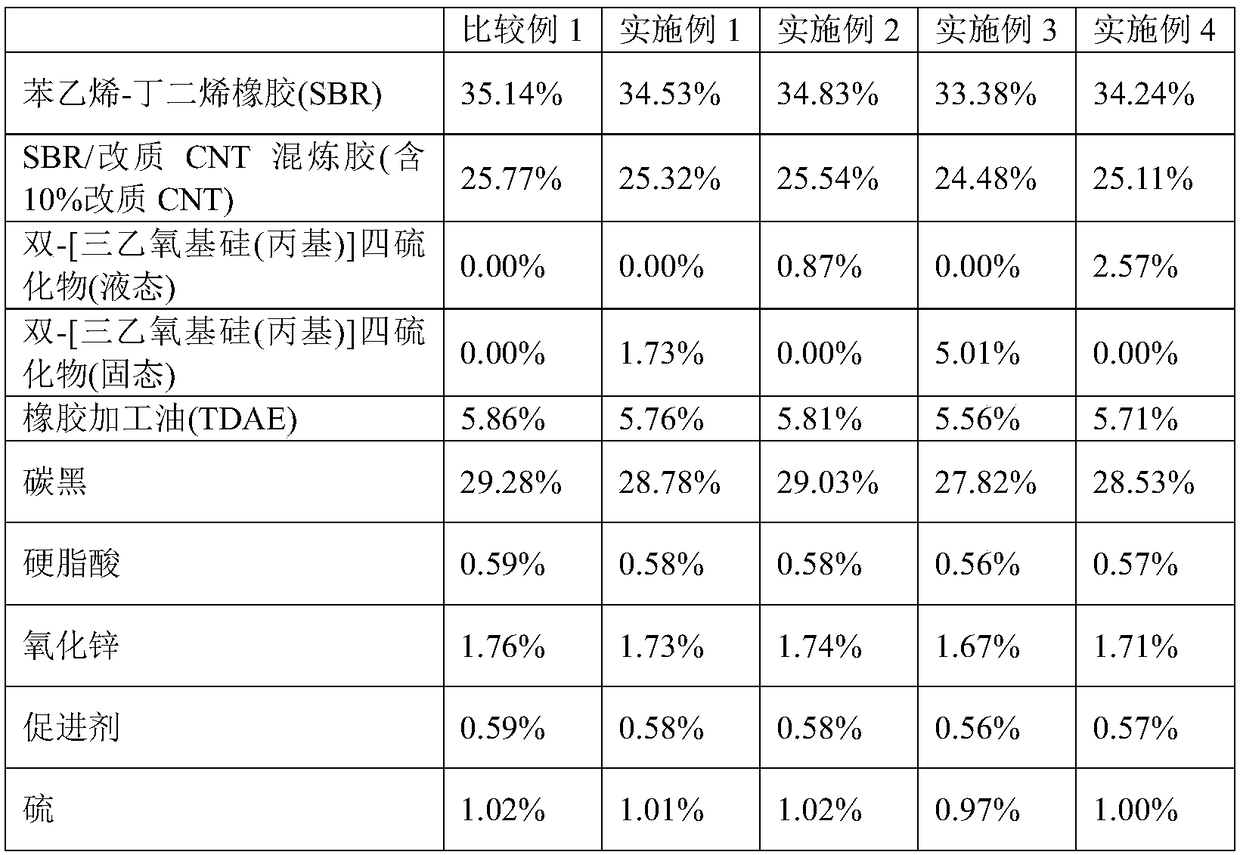

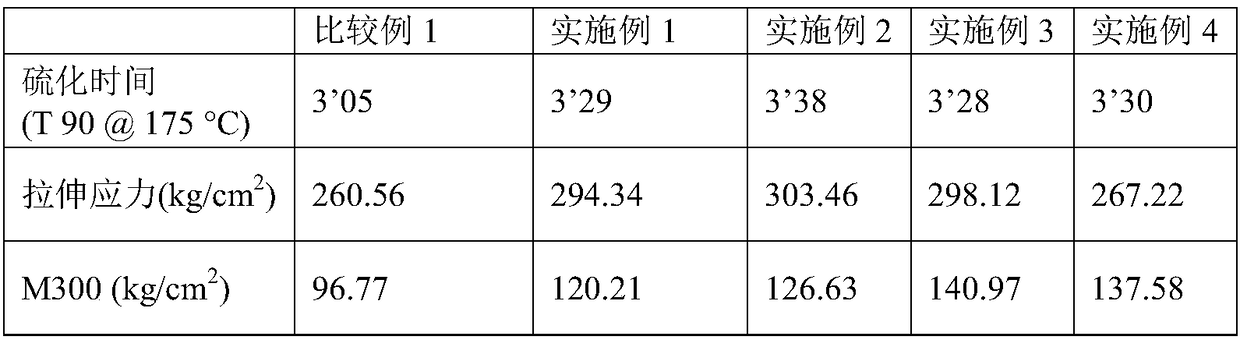

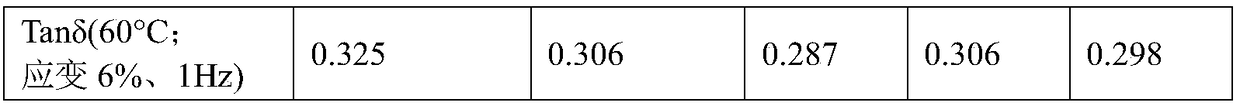

Manufacturing method for elastic composite material

InactiveUS20180362725A1High tensile strengthIncreased durabilitySpecial tyresCross-linkHybrid compound

The invention provides a manufacturing method for an elastic composite material, which comprises the following steps of: mixing a carbon material with a silicon rubber material, and uniformly dispersing the carbon material in the silicon rubber material to form a mixed compound; mixing the mixed compound with a (Bis(triethoxysilylpropyl)tetrasulfide) and a cross-linking agent to form a mixture; and heating the mixture to harden it to obtain the elastic composite material. The elastic composite material produced by the above method has improved durability.

Owner:TAIWAN CARBON NANO TECHNOLOGY CORPORATION

Concrete

The invention discloses concrete, which is prepared from the following ingredients in parts by weight: 150 to 180 parts of cement, 30 to 40 parts of copper slag, 30 to 40 parts of coal gangue, 230 to 265 parts of gravel, 280 to 320 parts of machine-made sand, 20 to 25 parts of early strength agents, 10 to 15 parts of synergists and 70 to 85 parts of water. Wherein the early strength agent comprises the following components in parts by weight: 20-30 parts of calcium chloride, 10-15 parts of calcium nitrite, 8-10 parts of calcium nitrate, 5-8 parts of triethanolamine, 3-5 parts of hydroxymethyl cellulose, 5-6 parts of a polycarboxylate superplasticizer, 5-8 parts of nano silicon dioxide, 5-6 parts of diatomite and 3-5 parts of methacrylic acid. According to the concrete provided by the invention, the hardening time of the concrete can be shortened, and the strength and durability of the concrete can be enhanced.

Owner:湖南余阗建材有限公司

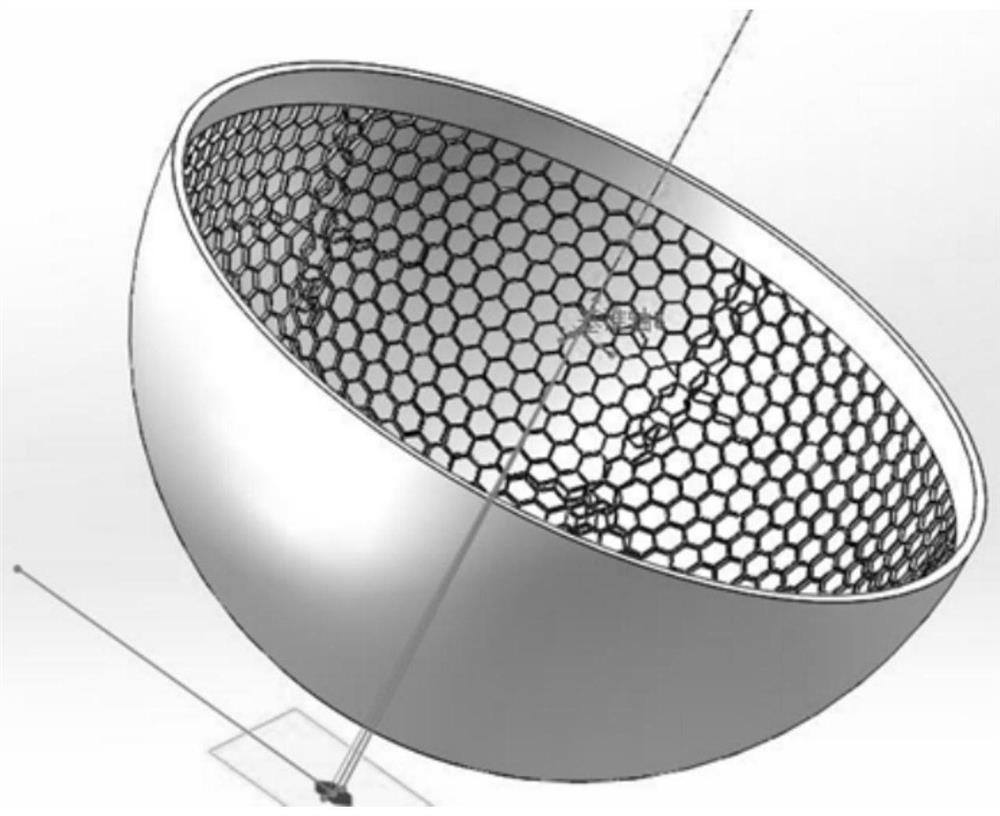

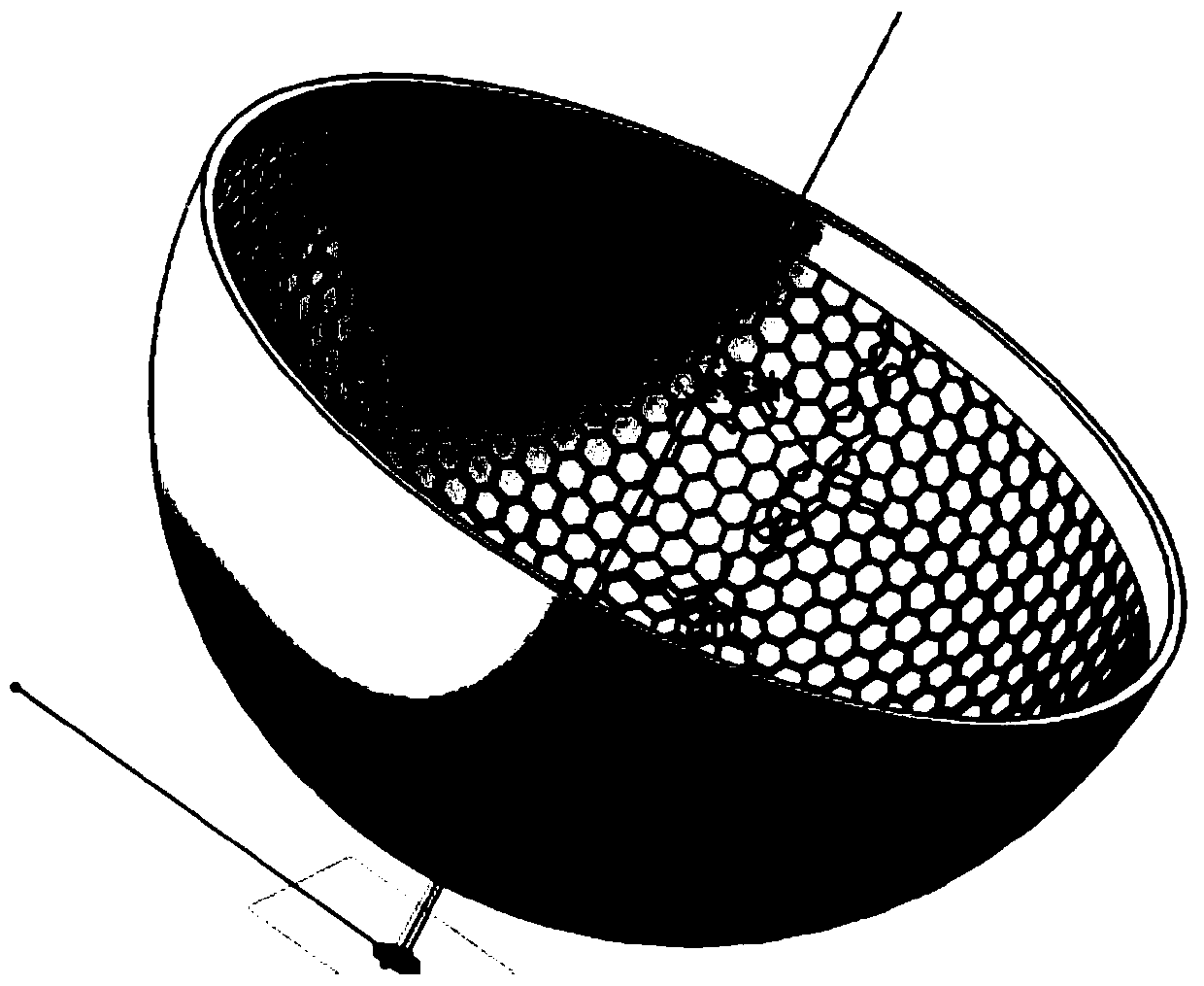

A composite spherical shell for omnidirectional motion spherical robot and preparation method thereof

ActiveCN109880299BStrong acid and alkali corrosion resistanceGood damping functionPolyurea/polyurethane coatingsElastomerResin matrix

The patent of the present invention provides a composite spherical shell of a spherical robot. The spherical shell composite structure includes a rigid matrix shell and a flexible coating layer. The rigid matrix shell is a structural fiber-reinforced composite material, which is composed of reinforcing fibers and a thermosetting resin matrix. Honeycomb stiffeners are arranged on the inner surface of the rigid matrix shell. The stiffener material is thermosetting resin, which can be combined with the rigid matrix shell. Integrated thermoforming; flexible coating layer adopts copolymer elastomer material. The lightweight composite spherical shell has high specific strength, specific stiffness, rolling friction coefficient, impact energy dissipation coefficient and quick repair function. The spherical shell and the corresponding spherical robot are used as an open automatic control platform, and a variety of functional spherical robots can be developed on the basis of the spherical robot composite spherical shell.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Interface agent for fabricated wallboard as well as preparation method and application of interface agent

PendingCN112390566ASolve crackingLow water absorptionConstruction materialUltimate tensile strengthPowder talc

The invention discloses an interface agent for a fabricated wallboard. The interface agent is prepared from the following components in parts by mass:30-60 parts of permeable acrylic emulsion, 10-15 parts of an active material, 10-20 parts of a retarder, 10-20 parts of barium sulfate, 150-180 parts of talcum powder, 10-20 parts of titanium dioxide, 120-170 parts of water and a proper amount of anauxiliary agent. After the process of the interface agent is adopted, the formula cost of the bonding mortar can be greatly reduced, and only the bonding mortar is required to have good bonding strength and self-strength slightly higher than that of a light wallboard. And in combination with the interface agent, the cost can be reduced by half or more than half of the original cost.

Owner:GUANGZHOU CITY LUBAN CONSTR

Pumping agent suitable for lightweight aggregate concrete

The invention discloses a pumping agent suitable for a lightweight aggregate concrete, and relates to the technical field of building material manufacturing. The pumping agent suitable for the lightweight aggregate concrete comprises the following raw materials in percent in terms of the total weight of the raw materials: 50%-75% of silica fume, 15%-25% of lignin fibers, 1%-5% of a retarder, 5%-10% of cellulose ether, 1%-5% of a dispersant, 0.3%-0.9% of an air entraining agent, 1%-5% of sodium glucoheptonate, and 0.5%-3% of zinc stearate. According to the pumping agent, the moisture absorbed by a lightweight aggregate in a pumping process can be compensated, and the pumping loss of the lightweight aggregate concrete can be reduced. In addition, the homogeneity of the lightweight aggregateconcrete can be improved by using the silica fume as a carrier material. Moreover, the lignin fibers can be dispersed and lapped into a fiber network in the lightweight aggregate concrete, thereby thefloating of the lightweight aggregate is restrained, the homogeneity of the concrete is further improved, and the pumping performance is improved.

Owner:贵州凯襄新材料有限公司

Compound spherical shell oriented to omnidirectional movement spherical robot, and preparation method thereof

ActiveCN109880299AHigh strengthStrong enoughPolyurea/polyurethane coatingsElastomerAutomatic control

The invention provides a compound spherical shell of a spherical robot. The compound structure of the spherical shell comprises a rigid substrate shell and a flexible coating layer, wherein the rigidsubstrate shell is made of structural type fiber reinforced compound material and is compounded by reinforced fibers and a thermosetting resin substrate; a honeycomb-shaped stiffening rib is arrangedon the inner surface of the rigid substrate shell, is made of thermosetting resin and can be subjected to integral hot press molding with the rigid substrate shell; the flexible coating layer is madeof copolymer elastomer materials. The light compound spherical shell has high specific strength, specific stiffness, rolling friction coefficients and impact energy dissipation factors and also has aquick repairing function. The spherical shell and the corresponding spherical robot serve as an open type automatic control platform, and various functional spherical robots can be developed and derived on the basis of the compound spherical shell of the spherical robot.

Owner:BEIJING UNIV OF POSTS & TELECOMM

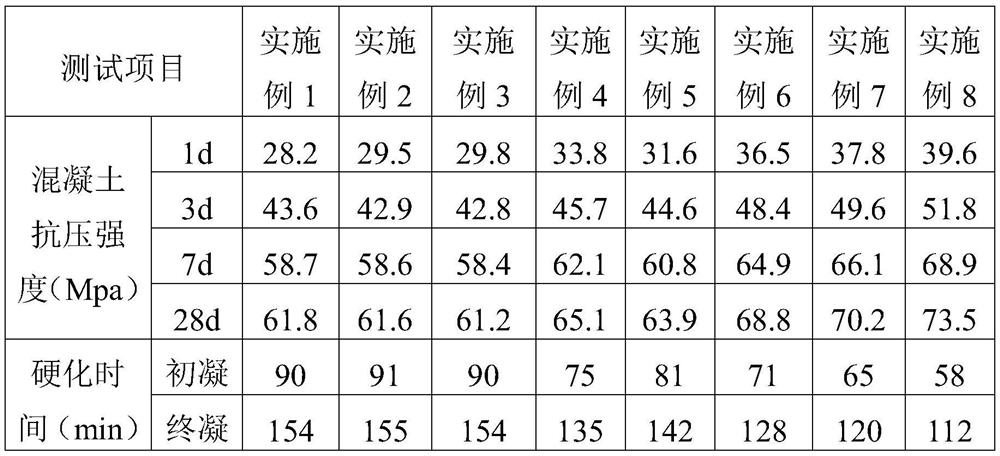

A kind of early strength agent and its application in concrete material

The invention discloses an early strength agent and its application in concrete materials. The early strength agent comprises the following components in parts by weight: 30-50 parts of magnesium fluorosilicate, 14-20 parts of lithium sulfate, sulfuric acid 15-25 parts of sodium, 15-25 parts of sodium nitrite, 55-75 parts of pre-hydrated cement particles. The preparation method of the prehydrated cement granules is as follows: in parts by weight, mix 80-120 parts of cement and 20-40 parts of water evenly, perform maintenance for 28-30 days after granulation, then ball mill, and sieve through 200-300 mesh , to obtain prehydrated cement particles. The present invention can significantly improve the performance of the early strength agent by self-made prehydration cement particles and combination with other components, accelerate the hardening time, and have a significant effect on the strength enhancement of the cement base material in the later stage, without shrinkage, and meet the service strength of concrete and durability requirements.

Owner:绵阳市安州区荣盛建材有限公司

A kind of glue for 3D printer and preparation method thereof

The invention discloses glue for a 3D (Three-Dimensional) printer and a preparation method thereof. The glue comprises the following components in parts by weight: 55-75 parts of deionized water, 12-18 parts of ethylene glycol, 15-20 parts of isopropanol, 10-13 parts of triethanolamine, 3-6 parts of nonyl phenol polyoxyethylene ether, 3-6 parts of polyvinyl alcohol and 0-5 parts of industrial dye. The preparation method comprises the following steps: stirring; standing; deoxidizing; filtering and the like. The glue disclosed by the invention shortens the curing time of a printed object, and isopropanol enhances dissolution of polyvinyl alcohol, so that the viscidity among layers is enhanced, the tensile strength and hardness of the printed object are enhanced, the hot wind curing and hardening time is shortened, the efficiency is improved and the energy consumption is reduced. The method provided by the invention is simple and strong in operability.

Owner:GUANGZHOU VIVID PRINT MATERIAL

Siliceous plastic refractory and preparation method thereof

The invention relates to a siliceous plastic refractory and a preparation method thereof. According to the technical scheme, the method comprises the steps that under the water bath condition, urea resin, polyacrylamide, carboxymethylcellulose, polyethylene glycol 200 and water are stirred to obtain a binding agent; quartzite, silica powder, silicon carbide and dolomite are mixed and ground till the granularity is not larger than 80 micrometers, under the condition that the pressure is 20-30 MPa, compression molding is performed, thermal treatment is performed at the air atmosphere under the temperature of 1,300-1,450 DEG C, materials obtained after thermal treatment are crushed and screened to obtain a material A with the granularity being 3-4 mm, a material B with the granularity being 1-2 mm, a material C with the granularity being 0.088-0.5 mm and a material D with the granularity being not larger than 80 micrometers; the four materials with the different granularities and silicon nitride powder are mixed to obtain a mixed homogenous material; the binding agent is added into the mixed homogenous material to be mixed to be uniform, and the siliceous plastic refractory is obtained. The siliceous plastic refractory has the advantages of being low in cost and simple in technology, and the obtained siliceous plastic refractory is long in hardening time and large in volume density and strength.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com