Can for magnetically coupled pumps and production process

A container and ferroalloy technology, which is applied to parts, pumps, and pump devices of elastic fluid pumping devices, can solve the problems of reducing the service life of the container, reducing the safety factor, and achieving high heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

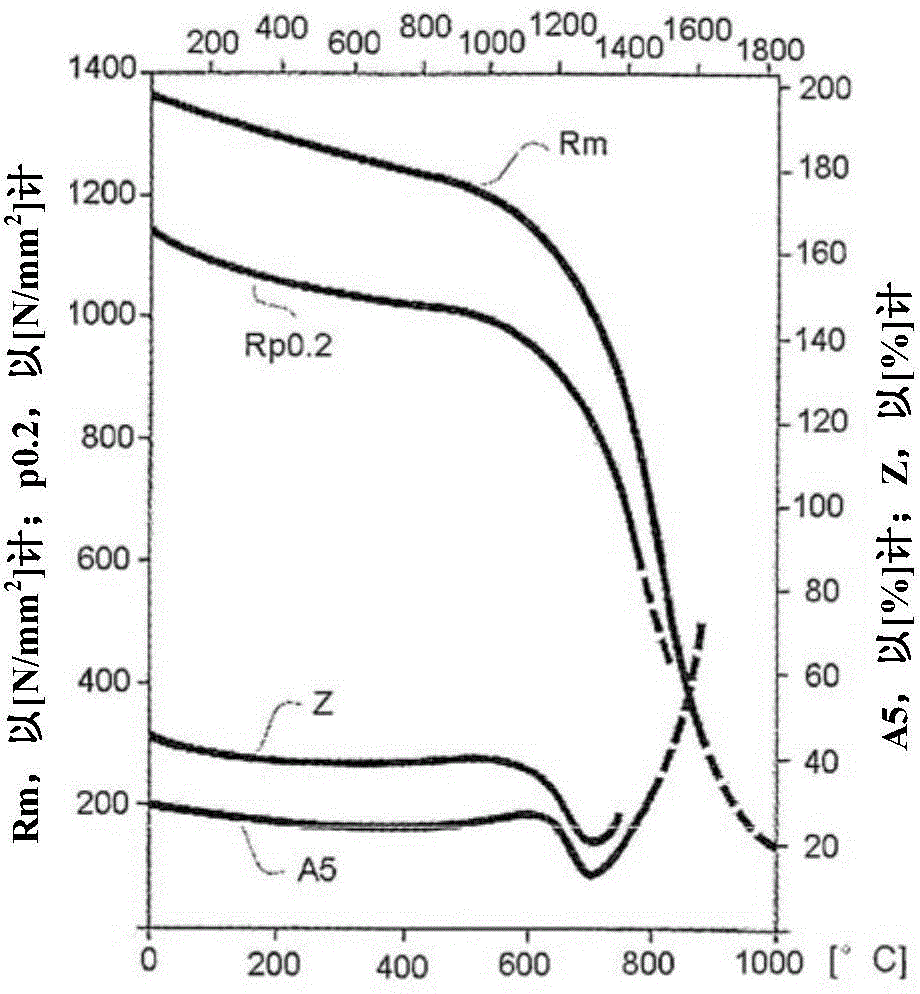

[0106] figure 1 Typical short-term properties of Inconel in solution annealed and hardened conditions are shown as a function of temperature in °C. It can be seen from the graph that fairly constant mechanical properties prevail in the temperature range from room temperature up to 600°C, this applies especially to the elongation at break (A5) and shrinkage (Z), resulting in a good dimensional Advantages are provided in terms of stability.

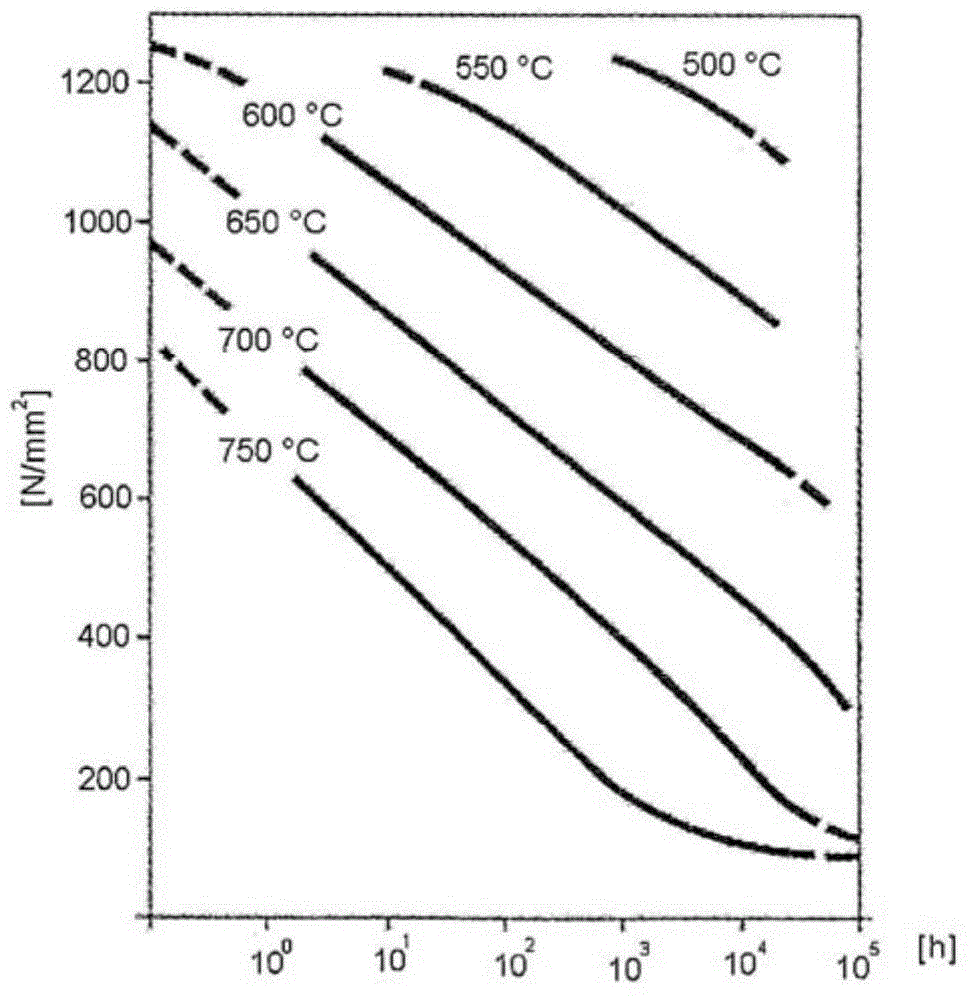

[0107] figure 2 Shows typical creep strength of Inconel in solution annealed and hardened condition as a function of time in hours, where time is logarithmically divided and creep strength is plotted on the y-axis in N / mm 2 marked. It can be seen from the chart that even more than 10 5 Hours of time (equivalent to well over 11 years), at temperatures below 500°C there is little perceptible loss of mechanical properties.

[0108] image 3 A container 1 is shown which is configured symmetrically with respect to an axis of symmetry S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com