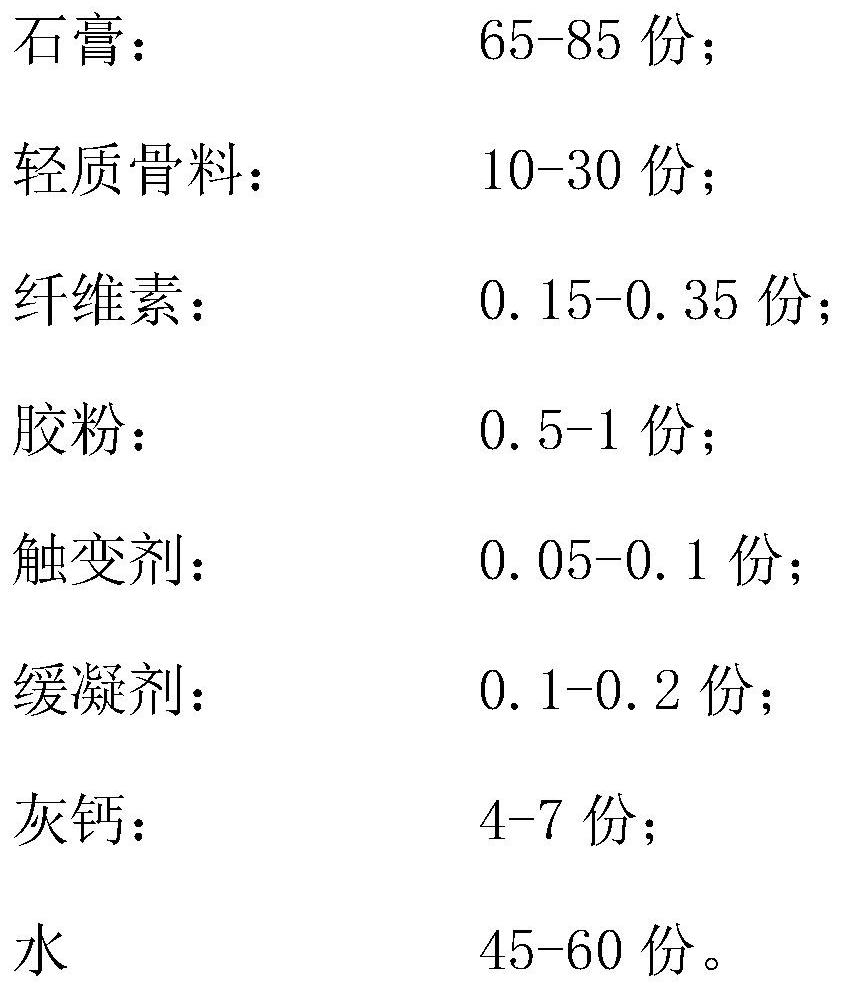

Multi-functional thermal insulation material

A thermal insulation and multi-functional technology, applied in the field of thermal insulation materials, can solve the problems of poor water insulation, poor thermal insulation, high thermal conductivity, etc., to save manpower, improve sag resistance, and low thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

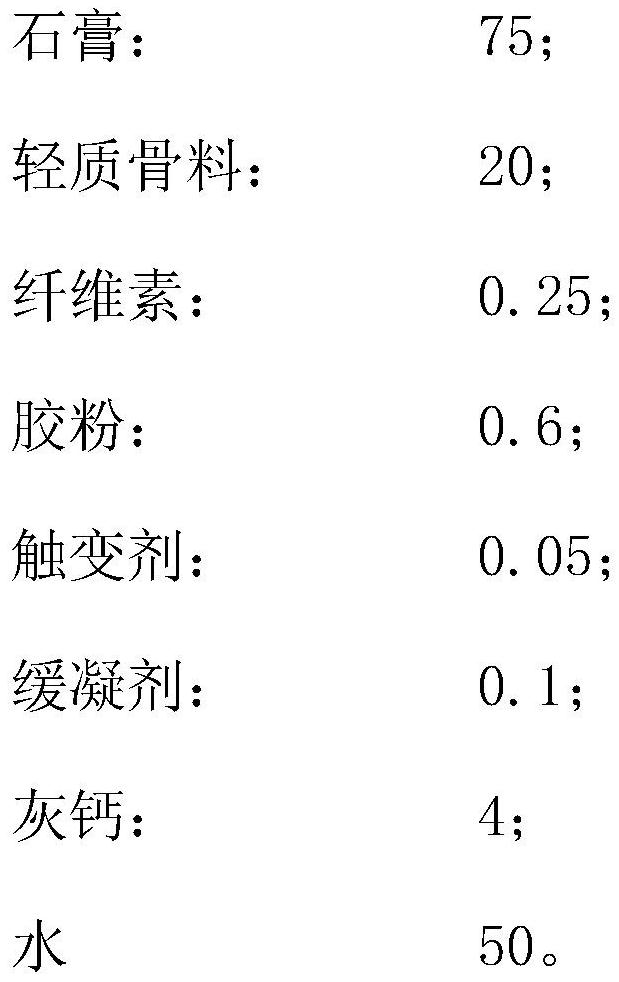

[0037] A method for preparing a multifunctional thermal insulation material, comprising the following steps:

[0038] S1. Weigh gypsum, lightweight aggregate, cellulose, rubber powder, thixotropic agent, retarder, and ash calcium respectively, and add them to the powder material mixer in order according to the formula amount and stir evenly.

[0039] S2. according to the preparation method of claim 7 thermal insulation material, weighing water is 50% of powder total amount, the mixed powder that step S1 is made is joined in the water of formula quantity;

[0040] S3. After stirring evenly according to the obtained product in step S2, stir evenly, that is, the multi-functional thermal insulation material.

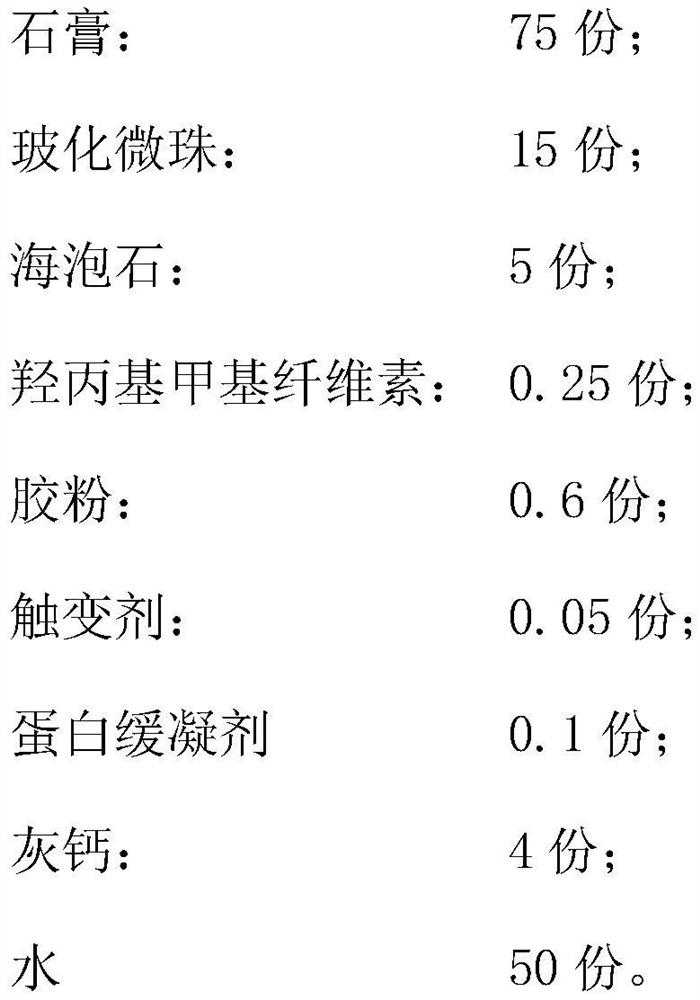

Embodiment 1

[0042] In step S1, the lightweight aggregate is vitrified microbeads, airgel and sepiolite, the cellulose is hydroxypropyl methylcellulose, the rubber powder is VAE rubber powder, the thixotropic agent is magnesium aluminum silicate, and the retarded The agent is a protein retarder, and each component is added in sequence according to the following mass ratio:

[0043]

Embodiment 2

[0045] In step S1, the lightweight aggregate is vitrified microbeads and expanded perlite, the cellulose is ethyl cellulose and carboxymethyl cellulose, the rubber powder is resin rubber powder, the thixotropic agent is silicon dioxide and kaolin, and the retarded The agent is sodium citrate, and each component is added in sequence according to the following mass ratio:

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com