Interface agent for fabricated wallboard as well as preparation method and application of interface agent

An interface agent and prefabricated technology, applied in building components, building materials, construction, etc., can solve the problems of difficult technology promotion, high cost, cracking of lightweight cement-based wallboards, etc., to reduce water absorption, reduce formulation costs, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

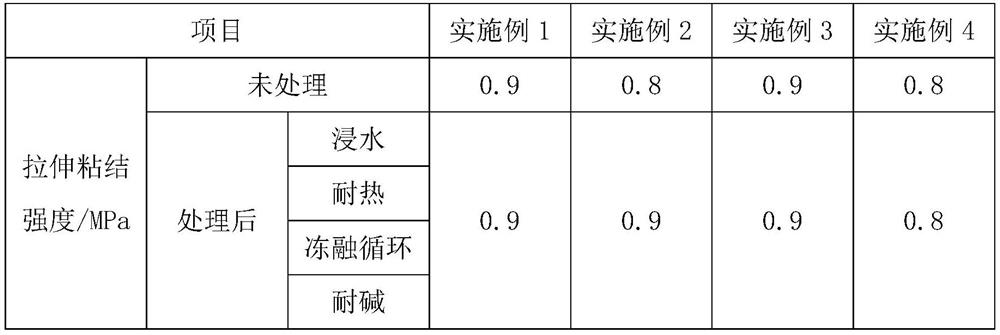

Examples

preparation example Construction

[0040] In a second aspect, the present invention also provides a method for preparing the above-mentioned interface agent for a prefabricated wallboard, the preparation method comprising the following steps:

[0041] (1) Put water, dispersant, defoamer, wetting agent and pH regulator into the mixing tank according to the metering, the stirring speed is 300-500r / min, slowly add the thickener during the stirring process, until the stirring is uniform;

[0042] (2) Put metered titanium dioxide, barium sulfate, talcum powder and active materials into the mixing tank in order, the stirring speed is 900~1100r / min, and stir for at least 20 minutes;

[0043] (3) Put the permeable acrylic emulsion, retarder and pigment into the mixing tank according to the metering, the stirring speed is 400-600r / min, and stir for at least 20 minutes;

[0044] (4) Put the bactericidal and antifungal agent into the mixing tank according to the measurement, and stir until uniform; after stirring, dischar...

Embodiment 1

[0048] Interface agent, including the following components in parts by mass: 30-60 parts of permeable acrylic emulsion, 10-15 parts of active material, 10-20 parts of retarder, 10-20 parts of barium sulfate, 150-180 parts of talcum powder, 10-20 parts of titanium dioxide, 120-170 parts of water, 1-5 parts of dispersant, 1-5 parts of defoamer, 1-5 parts of wetting agent, 2-5 parts of pigment, 2-5 parts of bactericidal and antifungal agent, 1-5 parts of pH regulator and 4-8 parts of thickener.

[0049] Wherein, the active material is volcanic ash; the dispersant is a polyacrylic acid sodium salt dispersant; the defoamer is a polyether water-based defoamer; the wetting agent is polyethylene glycol; Alkali-swellable thickener.

[0050] The preparation method of interface agent described in the present embodiment comprises the following steps:

[0051] (1) Put water, dispersant, defoamer, wetting agent and PH regulator into the mixing tank according to the metering, the stirring ...

Embodiment 2

[0056] Interface agent, including the following components in parts by mass: 30-60 parts of permeable acrylic emulsion, 10-15 parts of active material, 10-20 parts of retarder, 10-20 parts of barium sulfate, 150-180 parts of talcum powder, 10-20 parts of titanium dioxide, 120-170 parts of water, 1-5 parts of dispersant, 1-5 parts of defoamer, 1-5 parts of wetting agent, 2-5 parts of pigment, 2-5 parts of bactericidal and antifungal agent, 1-5 parts of pH regulator and 4-8 parts of thickener.

[0057] Wherein, the active material is volcanic ash; the dispersant is a polyacrylic acid sodium salt dispersant; the defoamer is a polyether water-based defoamer; the wetting agent is polyethylene glycol; Alkali-swellable thickener.

[0058] The preparation method of interface agent described in the present embodiment comprises the following steps:

[0059] (1) Put water, dispersant, defoamer, wetting agent and PH regulator into the mixing tank according to the metering, the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com