Interface agent and preparation method thereof and application of interface agent in fabricated building structure

A technology of interface agent and coagulation agent, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of long hardening time and high bonding strength of interface agent, achieve long hardening time and improve the interface Excellent bonding performance and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

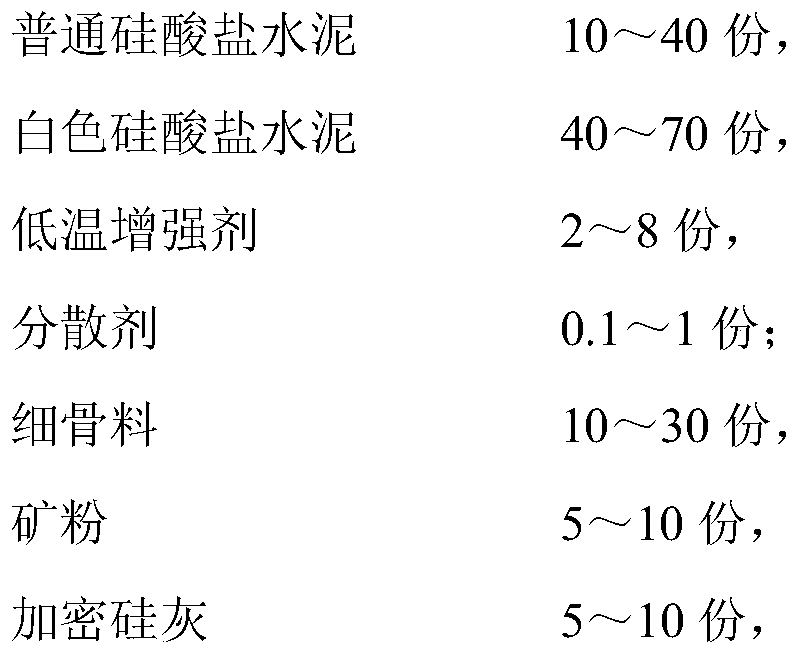

[0045] An interface agent for a prefabricated building structure, consisting of the following component A and component B in parts by weight:

[0046] The composition of the A component calculated in parts by weight is:

[0047]

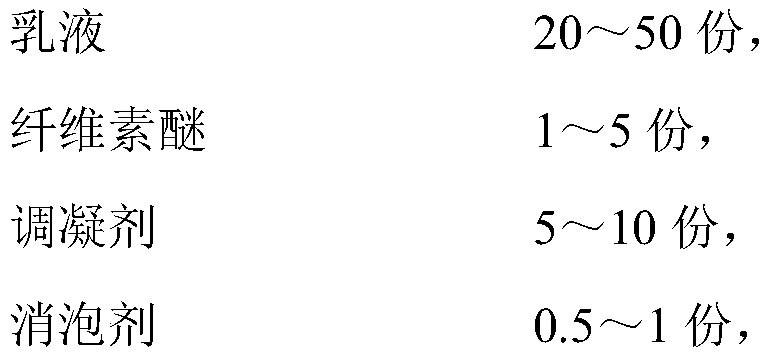

[0048] The composition of the B component calculated in parts by weight is:

[0049]

[0050] Among them, ordinary portland cement is P.O 42.5 type cement; white portland is 42.5 type cement; fine aggregate is 40 mesh quartz sand; mineral powder is ultrafine mineral powder, and its specific surface area is 1400m2 / kg; The bulk density is 500kg / m3; the low-temperature reinforcing agent is a mixture of sodium silicate and calcium nitrate with a mass ratio of 1:1; the dispersant is polycarboxylate early-strength powder superplasticizer; the emulsion is vinyl acetate-ethylene copolymer emulsion; The cellulose ether is hydroxypropyl cellulose ether with a molecular weight of 50,000; the coagulant regulator is hydroxyethylidene diphosphonic acid coag...

Embodiment 2

[0052] An interface agent for a prefabricated building structure, consisting of the following component A and component B in parts by weight:

[0053] The composition of the A component calculated in parts by weight is:

[0054]

[0055] The composition of the B component calculated in parts by weight is:

[0056]

[0057] Among them, ordinary portland cement is P.O 42.5 type cement; white portland is 42.5 type cement; fine aggregate is 40 mesh quartz sand; mineral powder is ultrafine mineral powder, and its specific surface area is 1400m2 / kg; The bulk density is 500kg / m3; the low-temperature reinforcing agent is a mixture of sodium silicate and calcium nitrate with a mass ratio of 1:2; the dispersant is polycarboxylate early-strength powder superplasticizer; the emulsion is vinyl acetate-ethylene copolymer emulsion; The cellulose ether is hydroxypropyl cellulose ether with a molecular weight of 80,000; the coagulant regulator is hydroxyethylidene diphosphonic acid coag...

Embodiment 3

[0059] An interface agent for a prefabricated building structure, consisting of the following component A and component B in parts by weight:

[0060] The composition of the A component calculated in parts by weight is:

[0061]

[0062] The composition of the B component calculated in parts by weight is:

[0063]

[0064] Among them, ordinary portland cement is P.O 42.5 type cement; white portland is 42.5 type cement; fine aggregate is 40 mesh quartz sand; mineral powder is ultrafine mineral powder, and its specific surface area is 1400m2 / kg; The bulk density is 500kg / m3; the low-temperature reinforcing agent is a mixture of sodium silicate and calcium nitrate with a mass ratio of 1:1; the dispersant is polycarboxylate early-strength powder superplasticizer; the emulsion is vinyl acetate-ethylene copolymer emulsion; The cellulose ether is hydroxypropyl cellulose ether with a molecular weight of 80,000; the coagulant regulator is hydroxyethylidene diphosphonic acid coagul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com