Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Good low temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

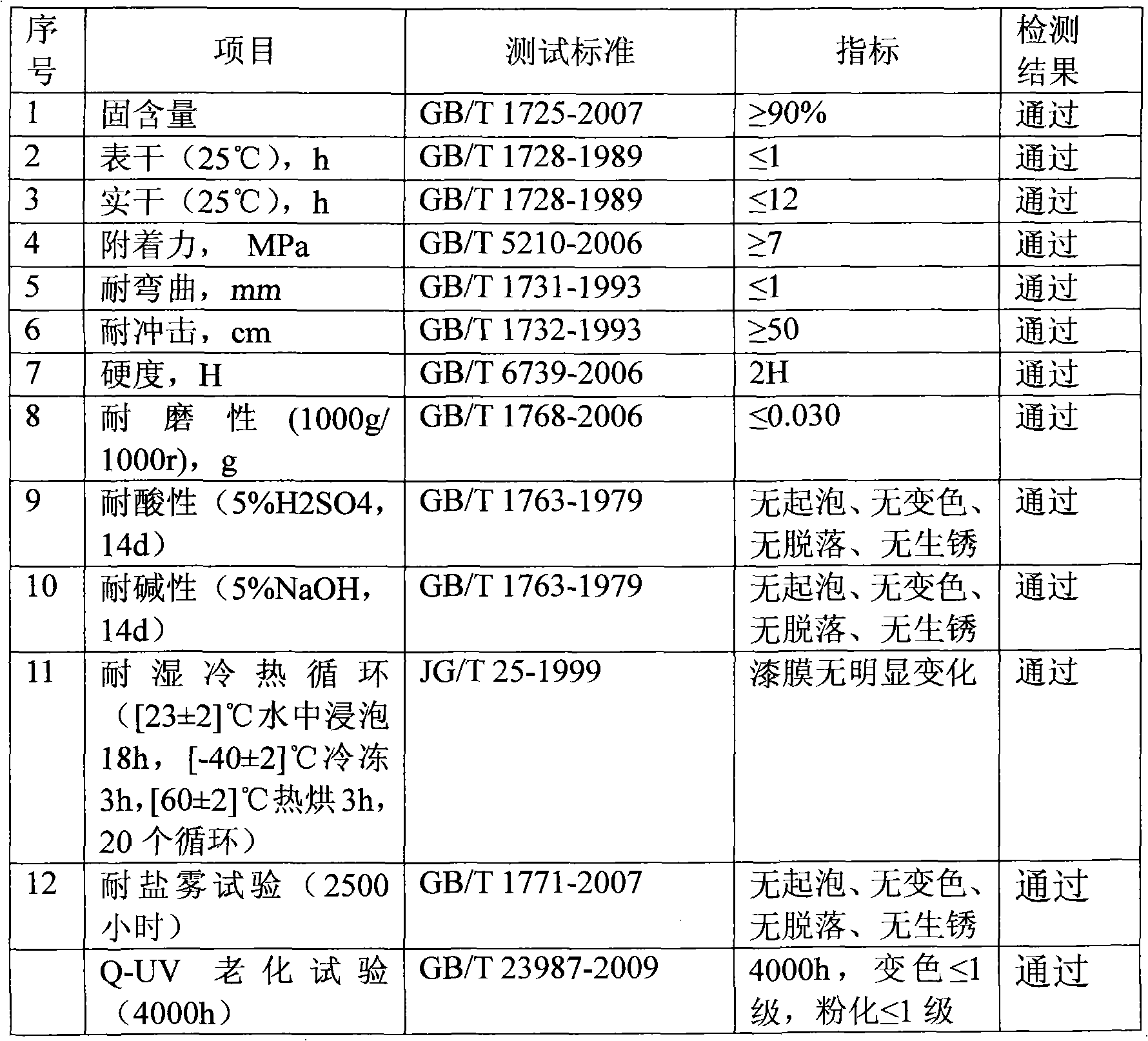

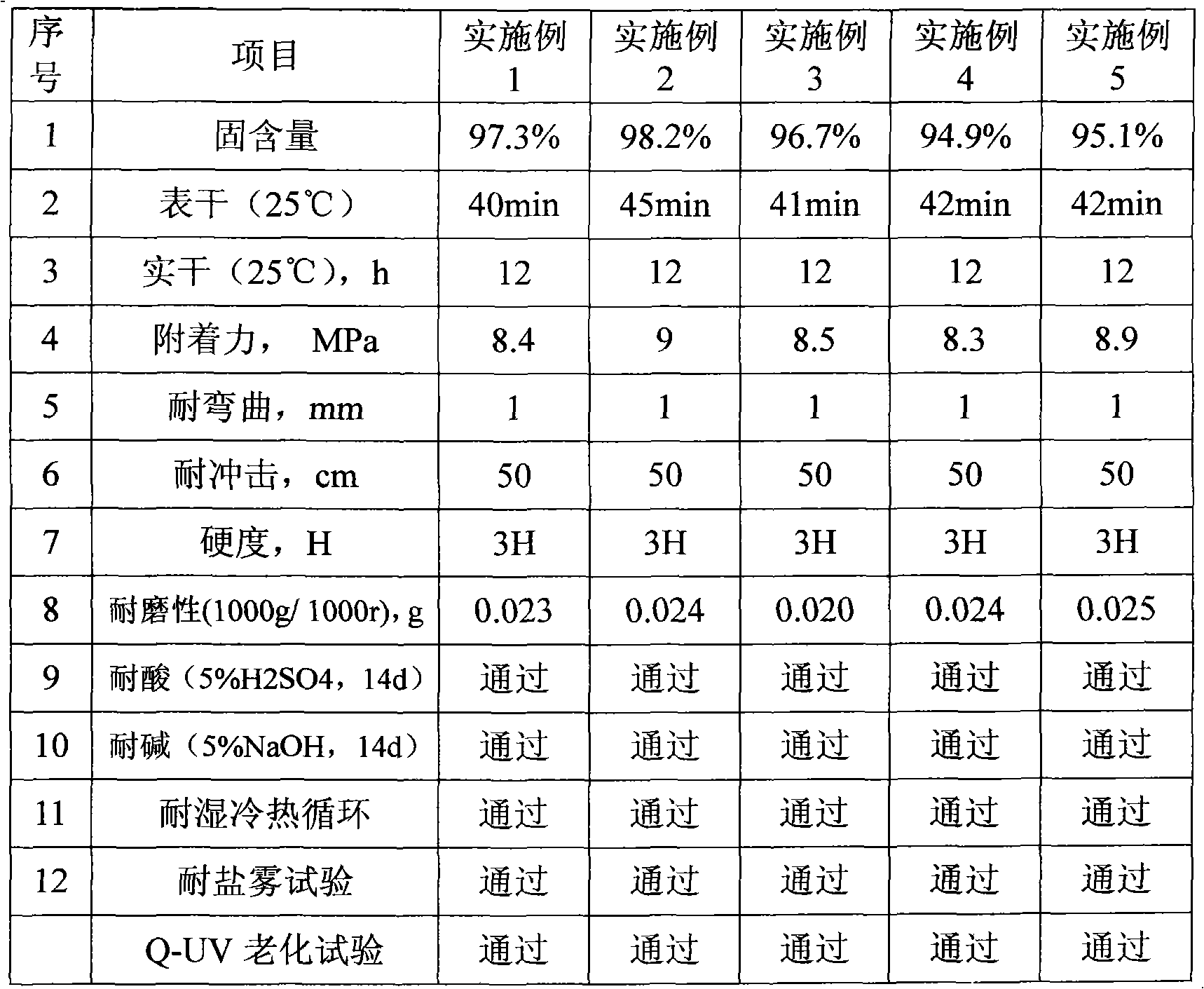

Polysiloxane topcoat for wind power generation equipment

ActiveCN101955729AGood weather resistanceGood low temperature resistanceAnti-corrosive paintsSurface energyWeather resistance

The invention discloses a polysiloxane topcoat for wind power generation equipment. A component A of the topcoat comprises the following compositions in percentage by mass: 50 to 70 percent of acrylic modified polysiloxane resin, 0.1 to 1 percent of wetting and dispersing agent, 1 to 3 percent of thixotropic agent, 10 to 20 percent of lightfast pigment and filler, 5 to 15 percent of wear-resistant filler, 5 to 15 percent of impact-resistant filler, 0.5 to 2 percent of ultraviolet absorber, 0.1 to 2 percent of leveling agent and 1 to 5 percent of low-toxicity organic solvent; the component B is amino alkoxy silane; and the polysiloxane topcoat is prepared in a mass ratio of the acrylic resin to the amino alkoxy silane of 8-12:1. The topcoat has the advantages of outstanding weather resistance, excellent scratch, impact, wear, low temperature and corrosion resistance, hydrophobicity and low surface energy, has the comprehensive performance not lower than that of the conventional fluorocarbon topcoat for the wind power generation equipment, can form a film with the maximum thickness of 200mu m at one time, can shorten the construction period, has high solid content, is not cured by isocyanate, and is favorable for protecting environment.

Owner:洛阳双瑞防腐工程技术有限公司

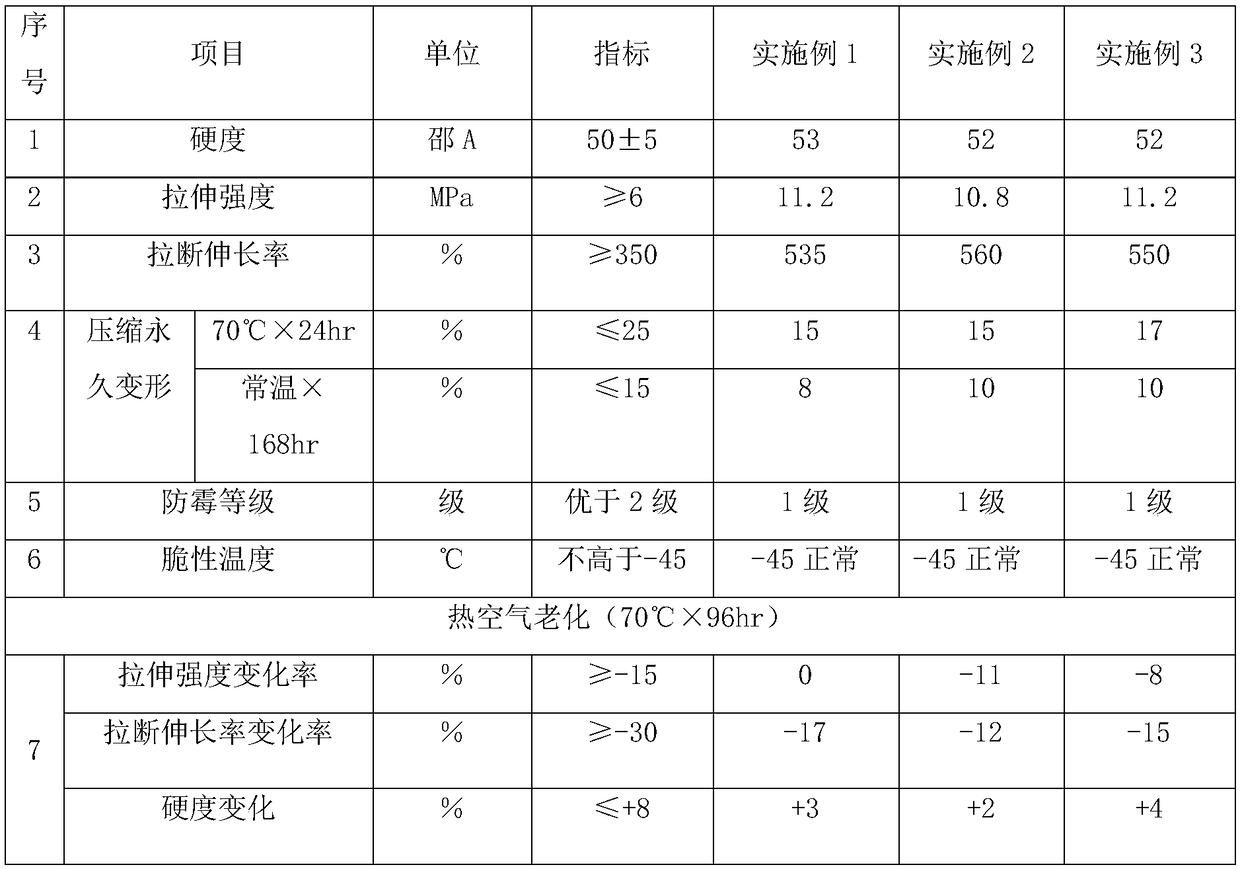

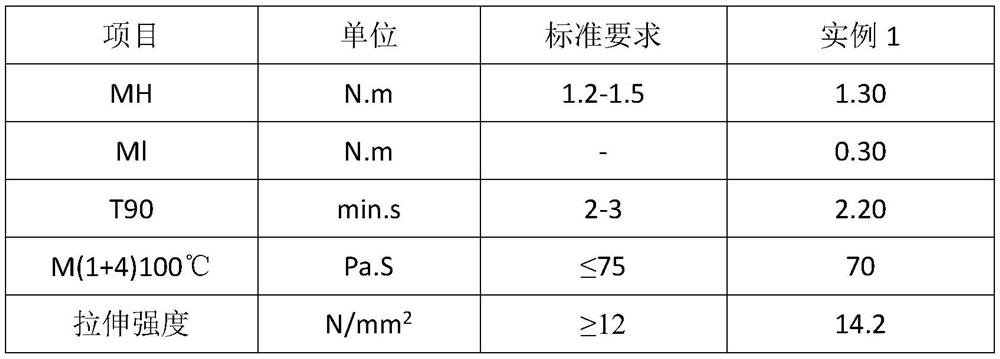

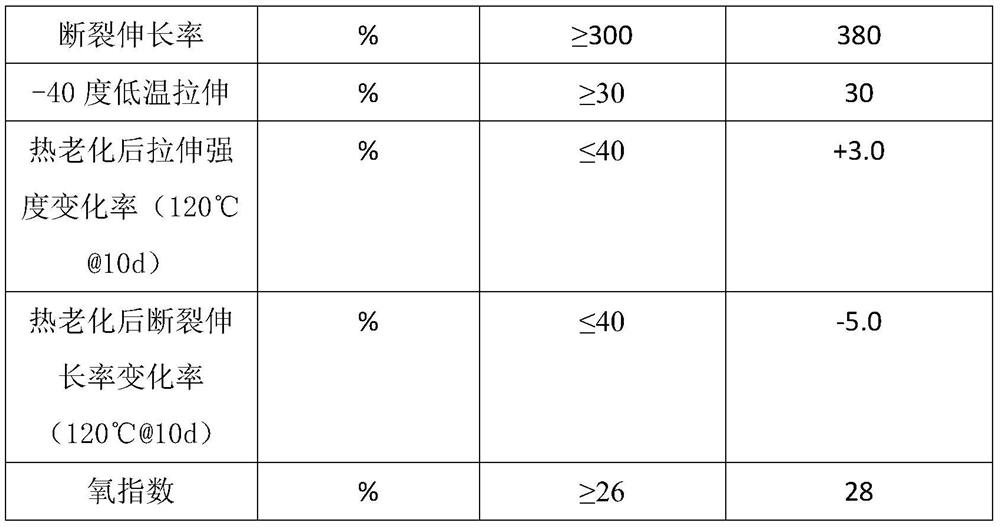

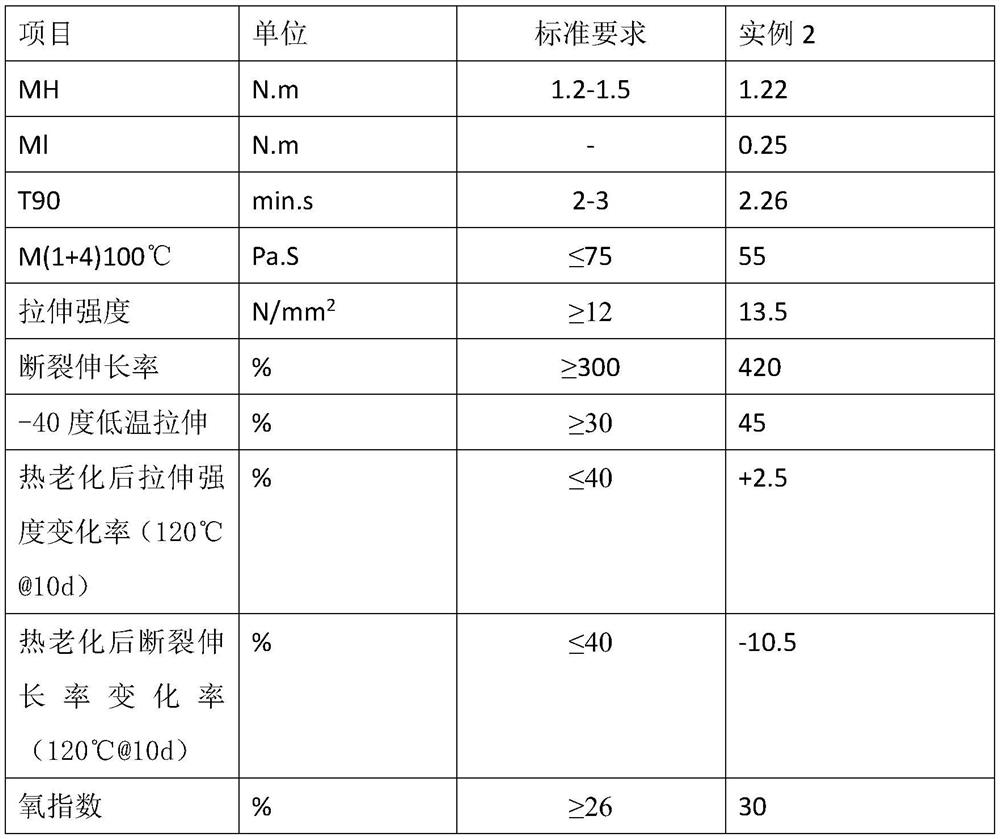

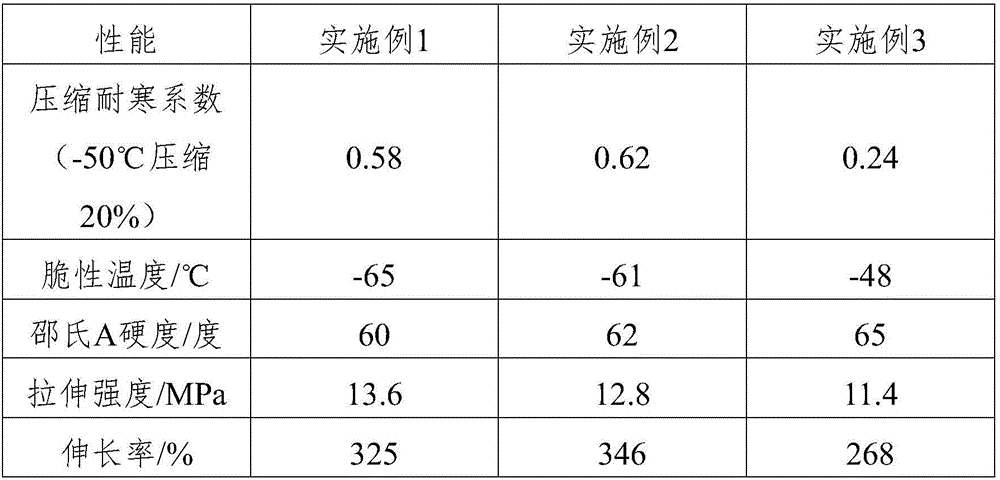

Ethylene-propylene-diene monomer rubber seal strip and preparation method thereof

PendingCN109401085AHigh elongation at breakGood low temperature resistanceOther chemical processesCarbon blackMagnesium

The invention discloses an ethylene-propylene-diene monomer rubber seal strip. The ethylene-propylene-diene monomer rubber seal strip is prepared from, by weight, 150-180 parts of ethylene-propylene-diene monomer rubber, 60-90 parts of carbon black, 8-12 parts of white carbon black, 3-8 parts of a peroxide vulcanizing agent, 6-12 parts of zinc oxide, 12-16 parts of magnesium oxide, 10-18 parts ofparaffin oil, 1-3 parts of an accelerant TMTD, 1-3 parts of stearic acid, 1-3 parts of an anti-aging agent MB and 1-3 parts of a coupling agent. The ethylene-propylene-diene monomer rubber seal stripis high in hardness, tensile strength and elongation at break, great in low-temperature resistance and capable of well meeting utilization requirements.

Owner:陕西秦垒建设集团有限公司

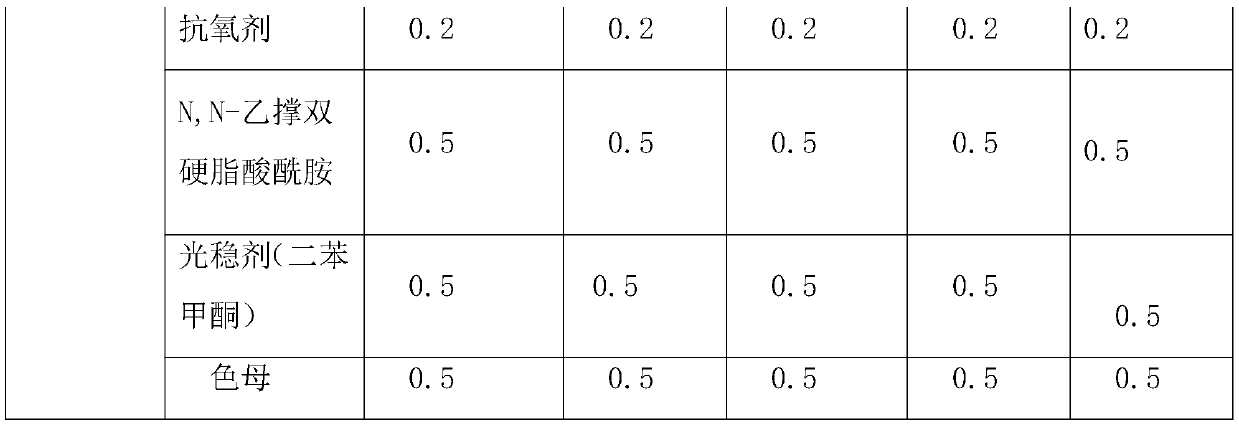

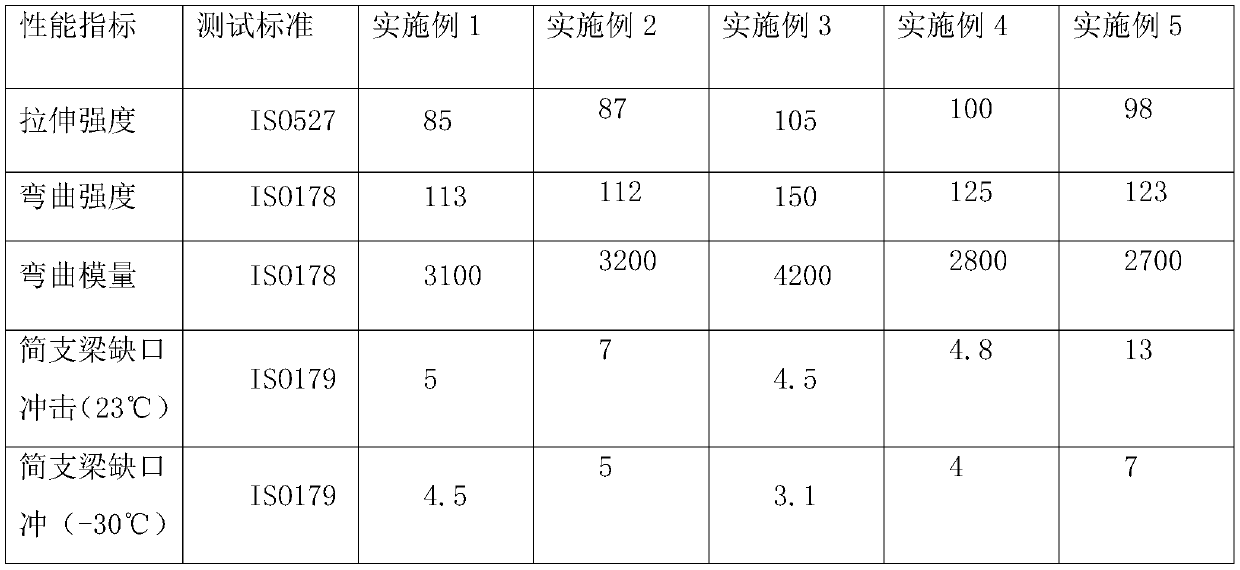

Long glass fiber enhanced polypropylene composite material water meter casing and manufacture method thereof

InactiveCN102504405AGood low temperature resistanceHigh low temperature impact resistanceVolume meteringHeavy metalsAntioxidant

The invention discloses a long glass fiber enhanced polypropylene composite material water meter casing and a manufacture method of the long glass fiber enhanced polypropylene composite material water meter casing. A thermal plastic composite material water meter casing comprises the following ingredients: blending alloy, auxiliary agents, color powder, antioxidants and ultraviolet absorbers, wherein the blending alloy consists of glass fiber, polypropylene and / or polypropylene modified materials. The thermal plastic composite material water meter casing made by adopting an injection molding forming process has the characteristics of high-temperature resistance, low-temperature resistance, impact resistance, creep deformation resistance, water pressure resistance, hydrolysis resistance, no heavy metal, long service life, low cost, environmental-friendly effect and the like, is easy to process and conforms to the industrial standard of the national plastic water meter casing material, so the thermal plastic composite material water meter casing is particularly suitable for large-scale industrial production and wide popularization and application.

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

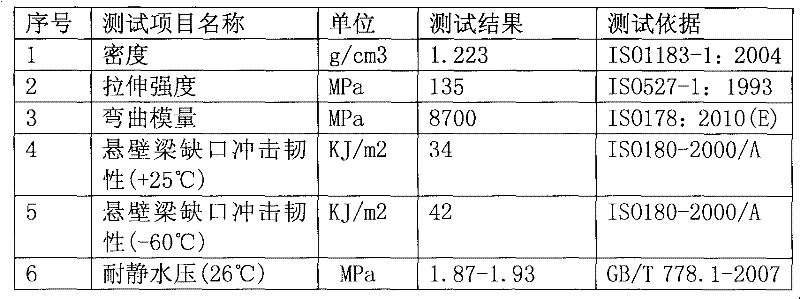

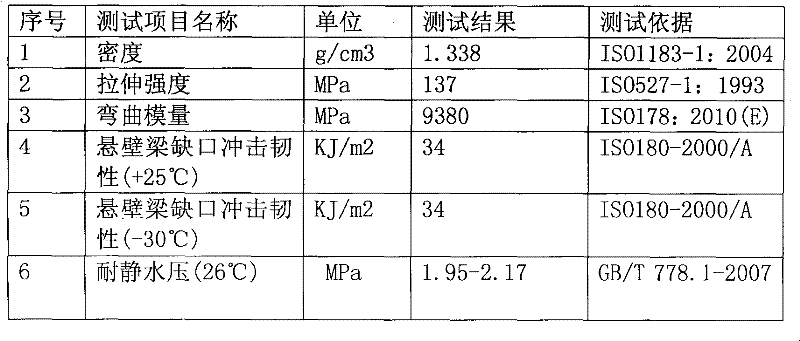

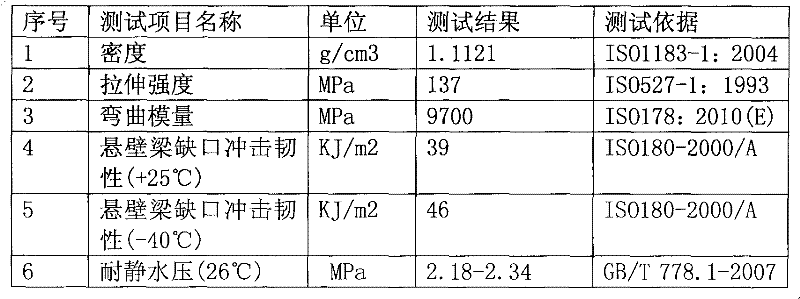

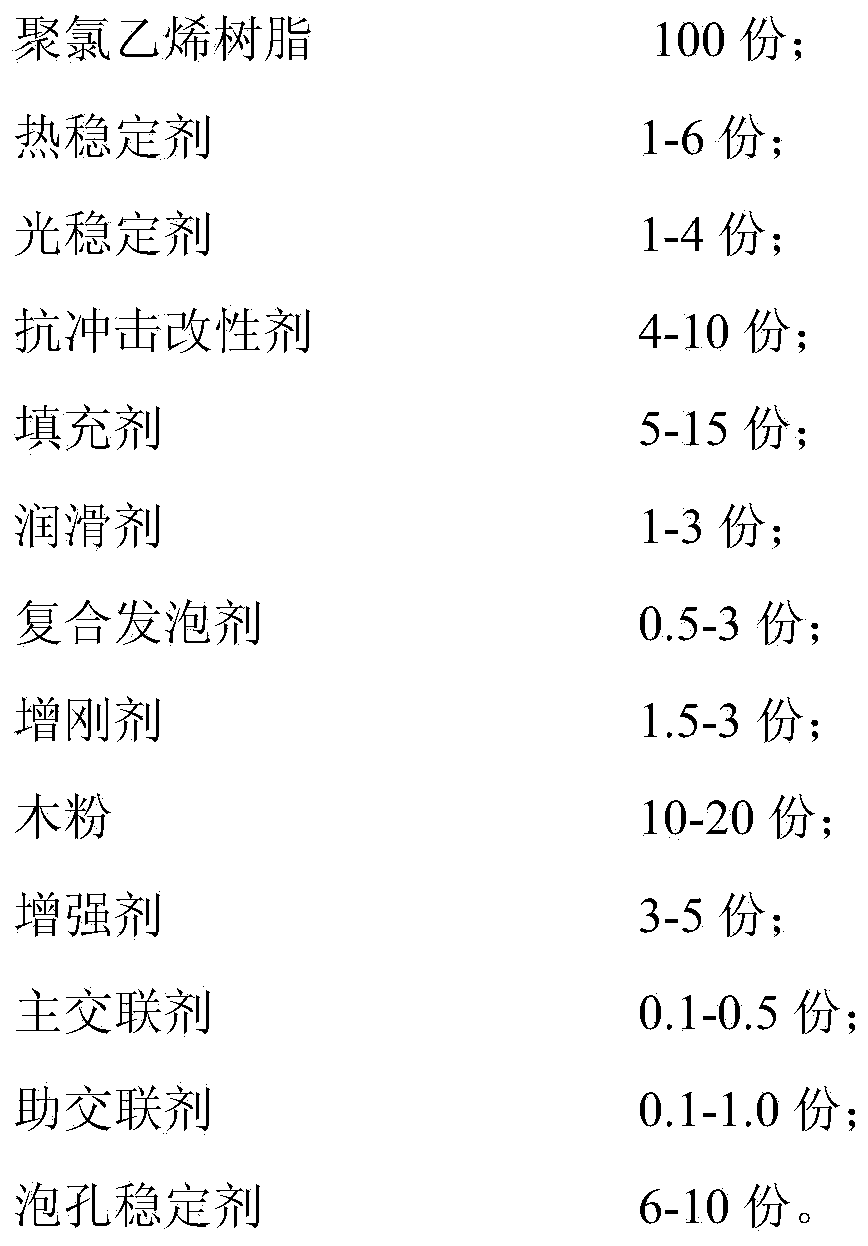

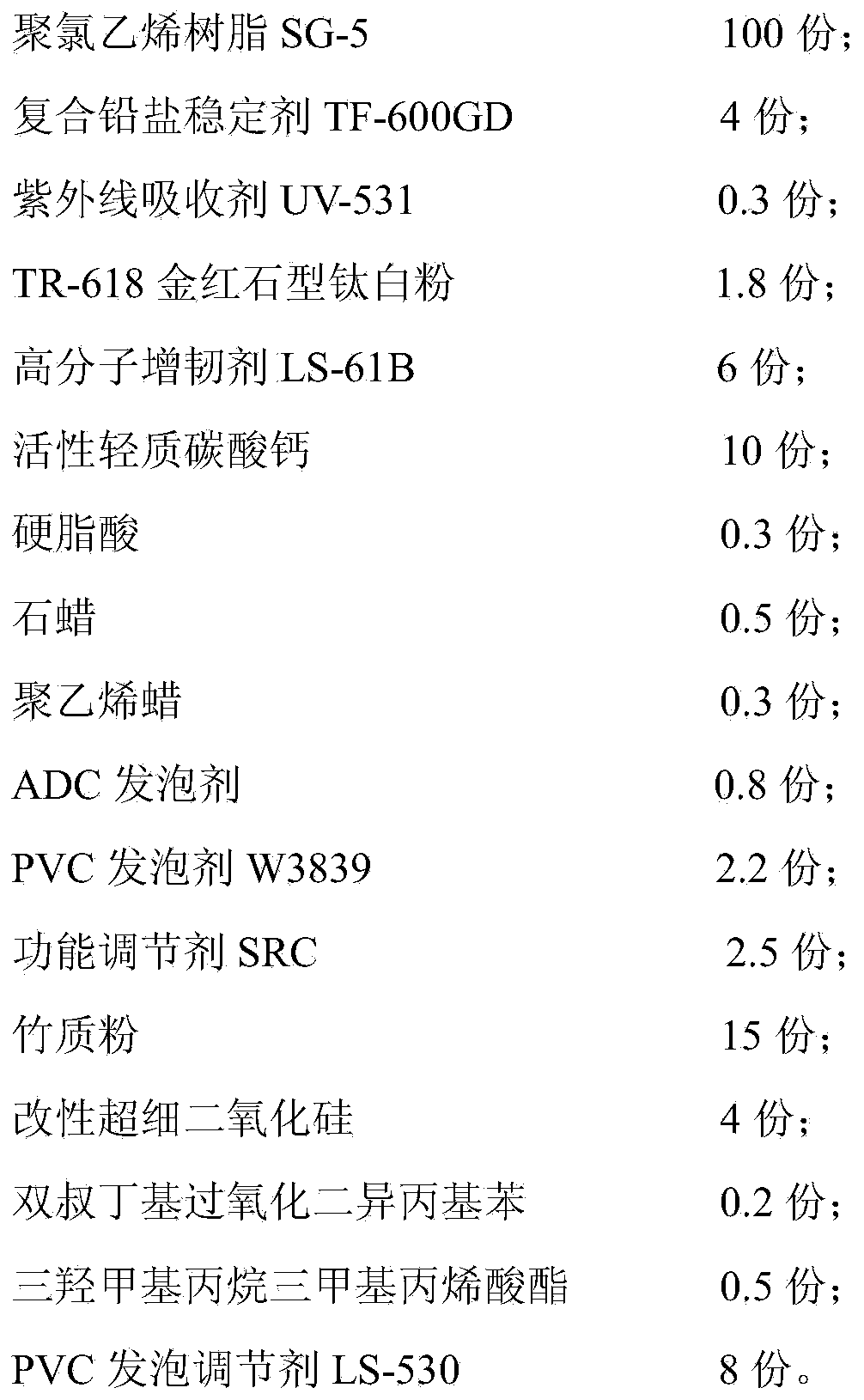

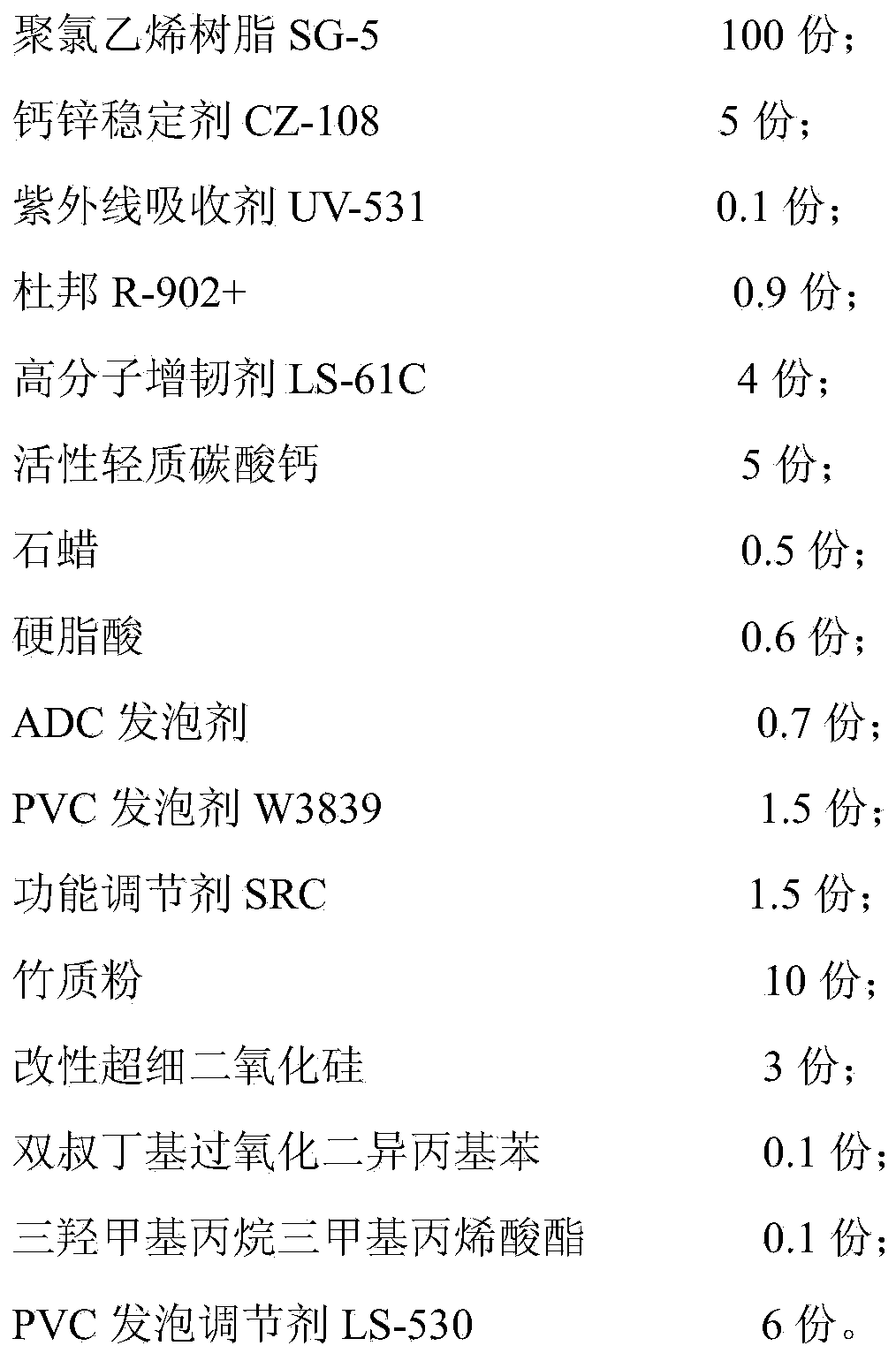

Weather-resistant impact-resistant polyvinyl chloride wood-plastic construction formwork and preparation method thereof

The invention relates to a construction formwork, particularly to a weather-resistant impact-resistant polyvinyl chloride wood-plastic construction formwork and a preparation method thereof. The wood-plastic construction formwork is prepared from polyvinyl chloride resin, a heat stabilizer, a light stabilizer, an impact-resistant modifier, a filling agent, a lubricating agent, a composite foaming agent, a stiffening agent, wood powder, an enhancer, a main cross-linking agent, an auxiliary cross-linking agent and a cell stabilizer. The wood-plastic construction formwork has the characteristics of high weather resistance, high hardness, impact resistance, good rigidity and long service life; the preparation method is simple in technology and easy to implement.

Owner:SHANDONG BODO PLASTICS CO LTD

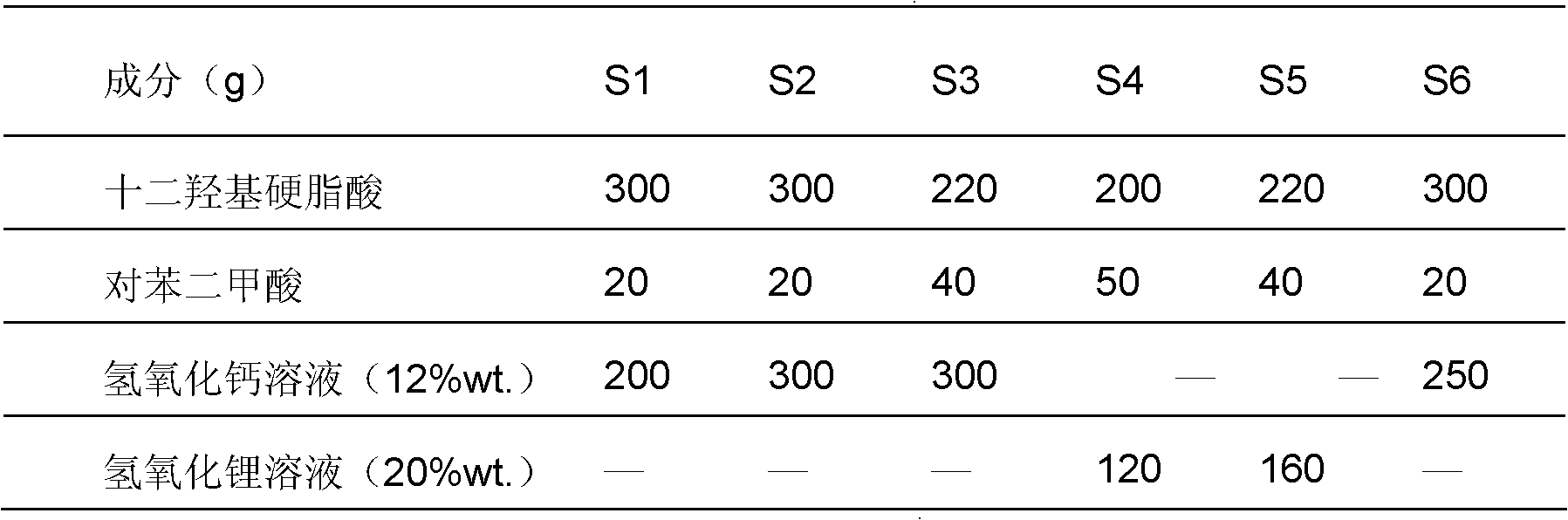

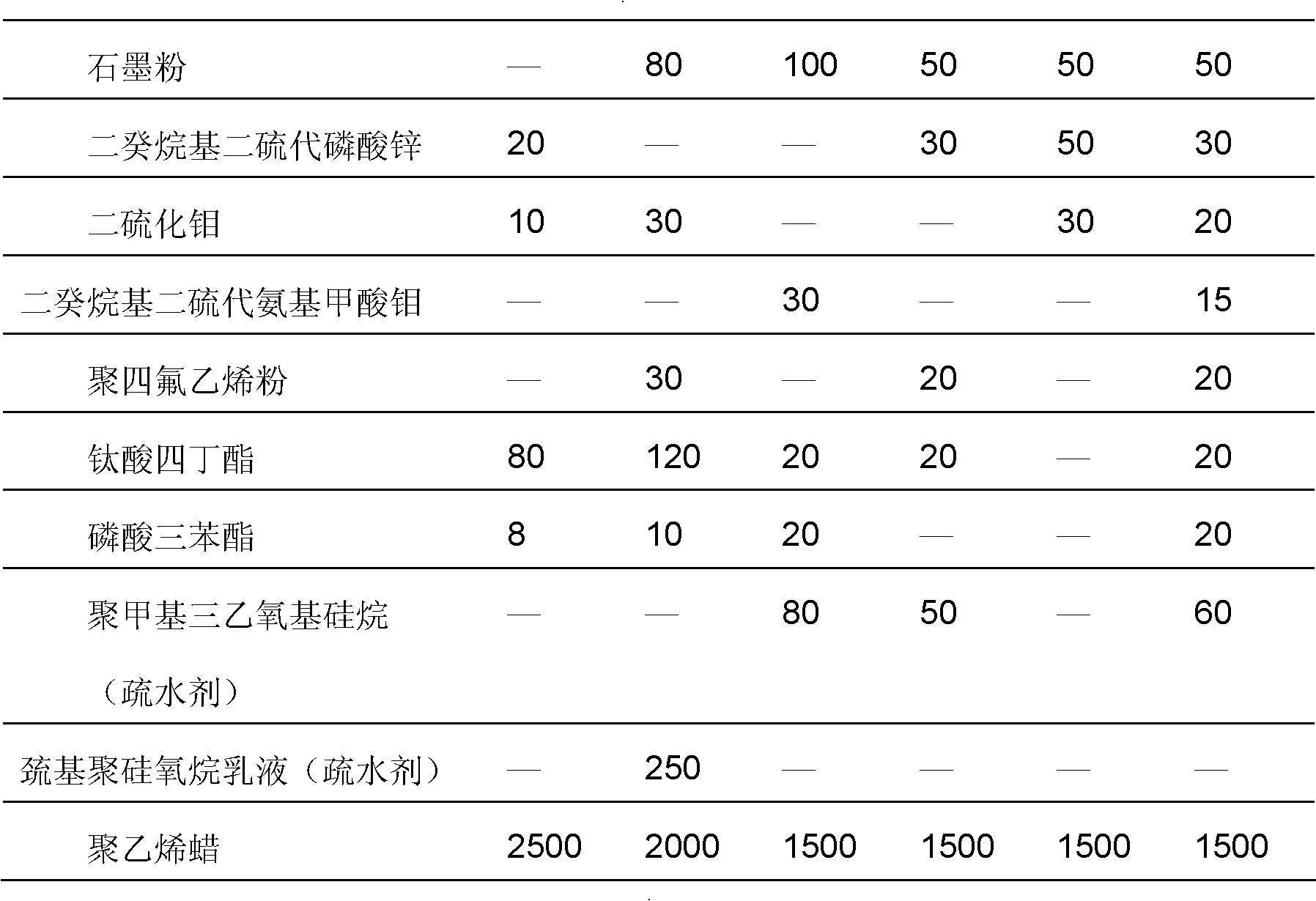

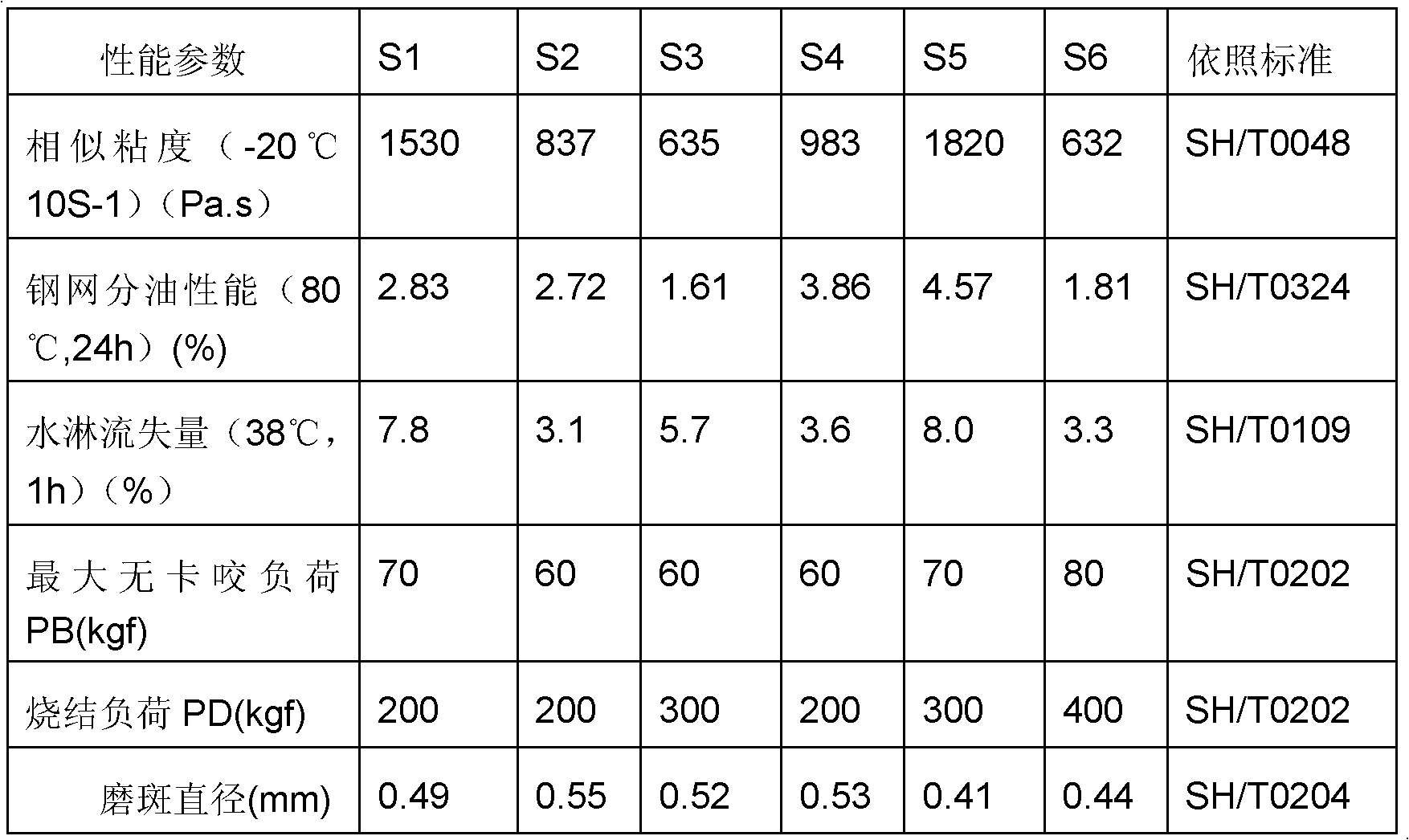

Grease for low speed and heavy duty

InactiveCN101974362AGood low temperature resistanceGood lubrication effectLubricant compositionZincLow speed

The invention relates to grease for low speed and heavy duty. The grease contains 8-20% of thickening agents, 1-4% of graphite powder, 0.3-6% of other extreme pressure additives, 0.3-6% of organic ester and the balance base oil by weight, wherein other extreme pressure additives are one or more of zinc dialkyldithiophosphate, molybdenium disulfide, molybdenum dialkyldithiocarbamate and other organic molybdenum salt containing alkyl; and the organic ester is tetrabutyl titanate, phosphate ester or combination of tetrabutyl titanate and phosphate ester.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Low-temperature oil-resisting nitrile rubber and preparation method and application thereof

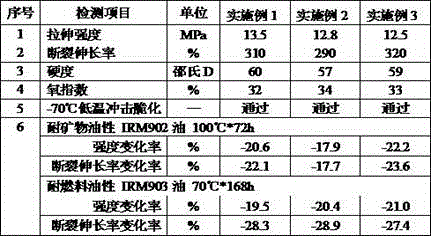

The invention discloses low-temperature oil-resisting nitrile rubber and a preparation method application thereof, and belongs to the technical field of rubber sealing materials. The rubber is prepared from, by weight, 80-120 parts of siloxane modified butadiene-acrylonitrile rubber, 5-10 parts of zinc oxide, 0.5-1.5 parts of stearic acid, 1-3 parts of an anti-aging agent NAPM, 80-120 parts of composite reinforcing agent, 1-5 parts of composite sulfurizing agent, 1-3 parts of an accelerant and 20-40 parts of TP-90 B auxiliaries. The invention further provides the preparation method of the low-temperature oil-resisting nitrile rubber and application of the low-temperature oil-resisting nitrile rubber in an aviation sealing material. The low-temperature oil-resisting nitrile rubber has the excellent low temperature resistance and good oil resistance, has the good physical and mechanical properties and bonding strength, is applicable to the environment under the temperature of subzero 70 to 100 DEG C, achieves the purposes of onboard environment conditions and sealing non-leakage, ensures safety operation of airborne equipment, and meets the requirement for defense-related science and technology weaponry development.

Owner:青岛颐科密封材料有限公司

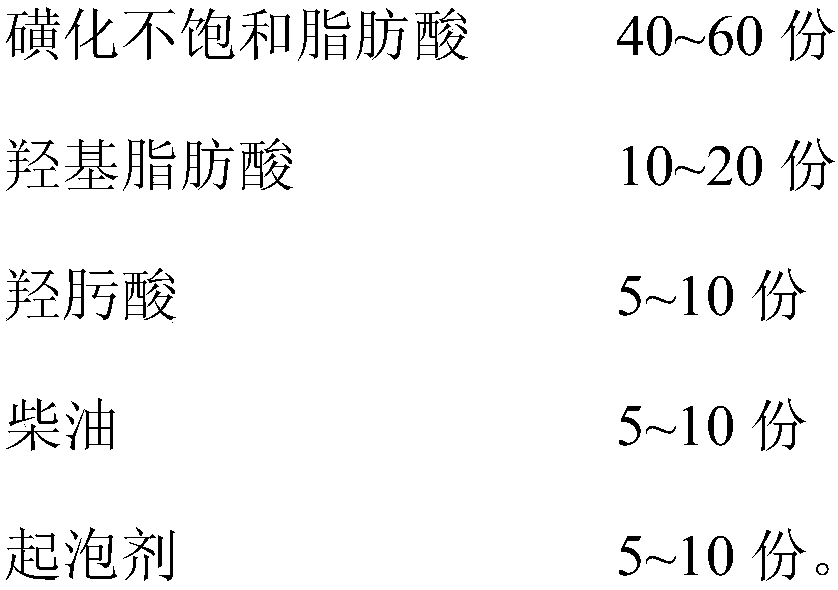

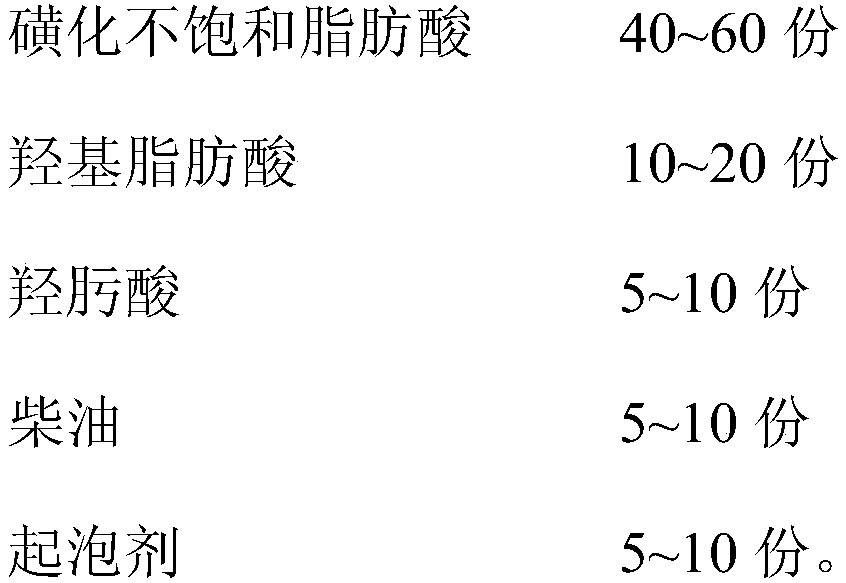

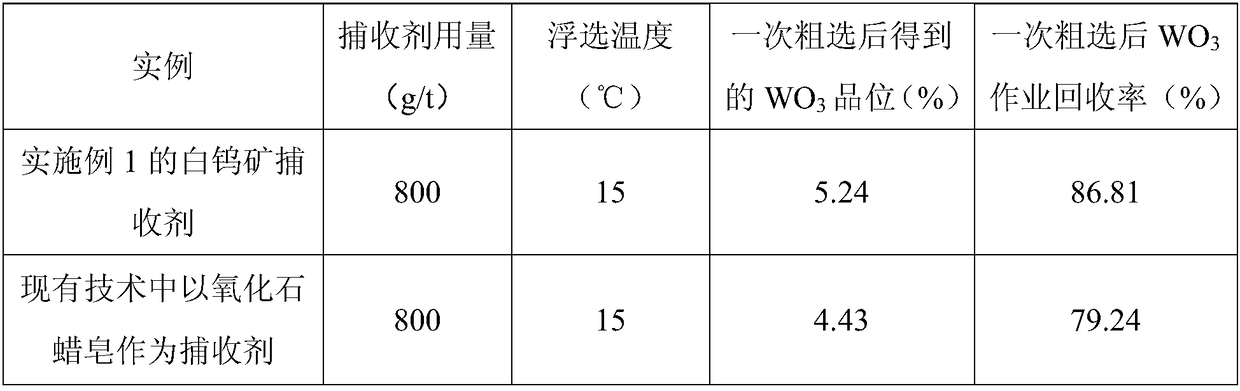

Scheelite flotation collecting agent and preparation method thereof

ActiveCN108480055AGood low temperature resistanceGood choiceFlotationUnsaturated fatty acidScheelite

The invention provides a scheelite flotation collecting agent and a preparation method thereof. The scheelite flotation collecting agent comprises, by weight part, 40-60 parts of sulfonated unsaturated fatty acid, 10-20 parts of hydroxy fatty acid, 5-10 parts of hydroximic acid, 5-10 parts of diesel oil and 5-10 parts of a foaming agent. The scheelite flotation collecting agent is used for flotation of scheelite and is good in low temperature resistance and selectivity and great in collecting capability; and scheelite rough concentrate high in grade and recovery rate can be obtained. The preparation method of the scheelite flotation collecting agent has the advantages of being wide in raw material source and simple in preparation technology. The obtained scheelite flotation collecting agent is good in dissolving property, great in collecting capability and good in selectivity and low temperature resistance and particularly resists to floatation at the low temperature ranging from 12 DEG C to 20 DEG C; the mineral dressing technical index can be effectively increased; economical benefits are remarkable; and good market promotion prospect is achieved.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Oil-resistant, wear-resistant and low-temperature-resistant locomotive-cable irradiation-cross-linking halogen-free flame-retardant cable material

ActiveCN106117764AGood low temperature resistanceHigh oil resistance and wear resistancePlastic/resin/waxes insulatorsInsulated cablesMaleic anhydrideBenzimidazole

The invention discloses an oil-resistant, wear-resistant and low-temperature-resistant locomotive-cable irradiation-cross-linking halogen-free flame-retardant cable material. Raw materials in the formula are mixed in the weigh ratio, extruded and prilled through an internal mixer and a single screw extruder, and the cable material is prepared. The cable material is characterized by being prepared from, by weight, 20-25 parts of linear low density polyethylene, 30-50 parts of ethylene-vinyl acetate copolymers, 10-25 parts of ternary nylon, 15-25 parts of semi-crosslinked powder nitrile rubber, 5-15 parts of maleic-anhydride grafted ethylene-propylene-diene monomer copolymers, 90-110 parts of aluminium hydroxide, 30-50 parts of magnesium hydrate, 5-10 parts of wear-resistant modifying agent, 3-5 parts of zinc borate, 0.8-1.2 parts of trimethoxysilyl-propyl-methacrylate, 3-6 parts of silicone master batches, 0.8-1.2 parts of four (beta-(3,5-ditert-butyl-4-hydroxy phenyl) propionic acid) pentaerythritol, 2-4 parts of 2-mercapto benzimidazole zinc salt and 1.5-3 parts of triallyl isocyanurate. The cable material has the advantages of being remarkable in oil resistance, excellent in wear resistance, good in low temperature resistance and the like, and can be used for producing oil-resistant locomotive cables meeting national standard requirements and European standard requirements.

Owner:中广核三角洲(江苏)塑化有限公司

Cable sheathing material containing modified dickite powder and preparation method thereof

InactiveCN106633227AImprove crack resistance and frost resistanceGood low temperature resistanceRubber insulatorsCarbon blackEpoxidized soybean oil

The invention discloses a cable sheathing material containing modified dickite powder and a preparation method thereof. The cable sheathing material is prepared from the following raw materials in parts by weight: 50 to 60 parts of natural rubber, 20 to 30 parts of butadiene rubber, 10 to 15 parts of polybutylene terephthalate, 15 to 20 parts of stearic acid, 4 to 6 parts of chlorosulfonated polyethylene, 8 to 10 parts of p-tert-butyl-phenolic resin, 4 to 6 parts of microcrystalline wax, 3 to 6 parts of epoxidized soybean oil, 8 to 10 parts of anilmomethyl triethoxy silane, 5 to 7 parts of decabromodiphenyl ether, 1 to 3 parts of nanometer alumina, 3 to 5 parts of zinc borate, 3 to 5 parts of fumed white carbon black, 8 to 10 parts of bentonite, 8 to 12 parts of modified dickite powder, 4 to 7 parts of brucite powder and 3 to 6 parts of tree ash. The cable sheathing material provided by the invention has excellent low-temperature resistance with the lowest temperature reaching minus 65 DEG C on the basis of guaranteeing physical and mechanical performances and flame retardance of the sheathing material.

Owner:ANHUI TIANYUAN CABLE

Organosilicon-modified PVC composite material

The invention relates to the field of organosilicon materials and provides an organosilicon-modified PVC composite material to overcome problems of PVC materials. The organosilicon-modified PVC composite material is prepared by mixing and granulating the following components by weight: 40 to 80 parts of PVC, 0.5 to 10 parts of nanometer calcium carbonate, 0.5 to 50 parts of white carbon black, 0.05 to 5 parts of carbon black, 0.5 to 10 parts of paraffin, 0.1 to 10 parts of lithopone, 0.5 to 10 parts of titanium dioxide, 0.5 to 2 parts of triethyl citrate, 0.1 to 5 parts of pentaerythritol and 0.1 to 5 parts of calcium stearate. The organosilicon-modified PVC composite material has stable performance, excellent low temperature resistance, high tensile strength, good flexibility and long service life.

Owner:河北厚丰有机硅制品股份有限公司

Polyurethane elastomer composition for floor coating and preparation method of polyurethane elastomer composition

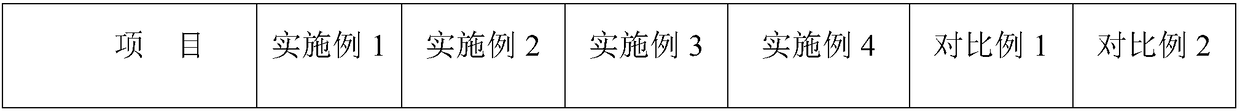

InactiveCN108178823AHigh hardnessGood yellowing resistancePolyurea/polyurethane coatingsPolyurethane elastomerPolyol

The invention relates to a polyurethane elastomer composition for floor coating and a preparation method of the polyurethane elastomer composition, which belongs to the technical field of polyurethanesynthesis. The polyurethane elastomer composition is prepared from the following substances by weight percent: 10 to 25 percent of polyether polyol, 50 to 85 percent of isocyanate, and 5 to 35 percent of chain extender, wherein the polyether polyol is the polyether polyol with a functionality of 2 or 3 and a number-average molecular weight of 300 to 1000. The prepared polyurethane elastomer composition is high in hardness, good in yellowing resistant effect, good in water resistance and excellent in low temperature resistance. The preparation method provided by the invention comprises two steps and is scientific and reasonable, easy in implementation, good in mobility when in production operation, mild in reaction and free from producing bubbles.

Owner:SHANDONG INOV POLYURETHANE

Low-temperature-resistant ceramic tile and preparation method thereof

The invention discloses a low-temperature-resistant ceramic tile and a preparation method thereof. The ceramic tile is prepared from the following raw materials in parts by weight: 36-48 parts of sepiolite, 21-33 parts of firestone, 15-20 parts of limestone, 10-15 parts of construction waste, 8-16 parts of hill sand, 18-26 parts of modified clay, 16-28 parts of alunite, 4-8 parts of a sludge dry powder, 24-36 parts of kyanite, 5-10 parts of a straw powder, 3-5 parts of calcium chloride, 2-4 parts of chromic oxide, and 9-17 parts of a caustic-burned magnesia powder. The ceramic tile has good low temperature resistance, can be used for a long time under a low temperature condition of below -5 DEG C, does not generate brittle rupture, and has the advantages of high strength, good water resistance, strong anti-erosion ability, good weather resistance, and long service life.

Owner:安徽省亚欧陶瓷有限责任公司

Epoxy glue for protecting end part of stator of wind power motor and preparation method thereof

ActiveCN107474772ASmall shrinkageGood low temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryStator

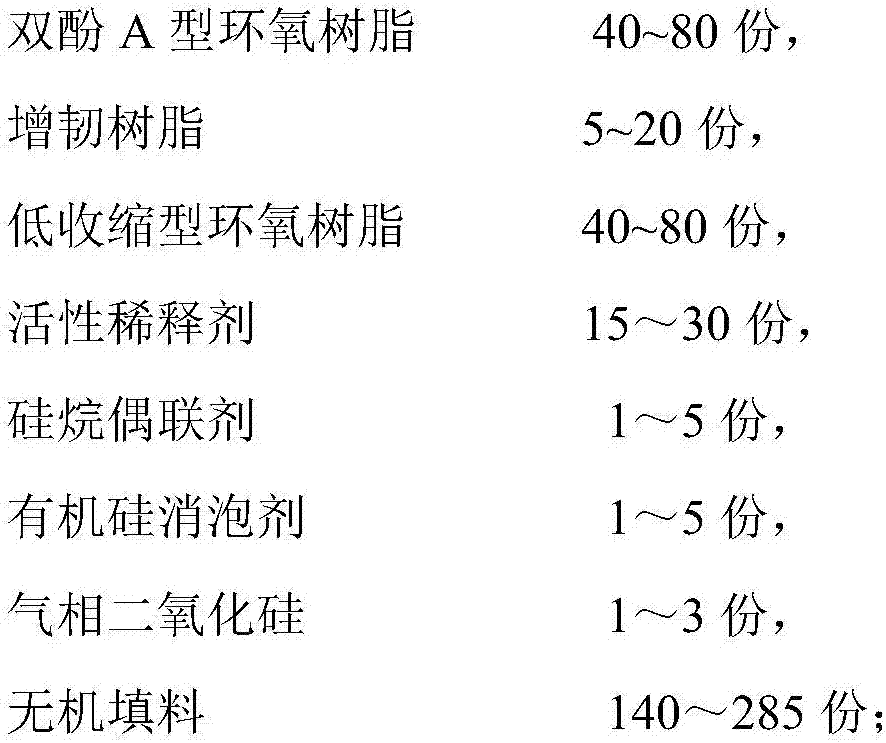

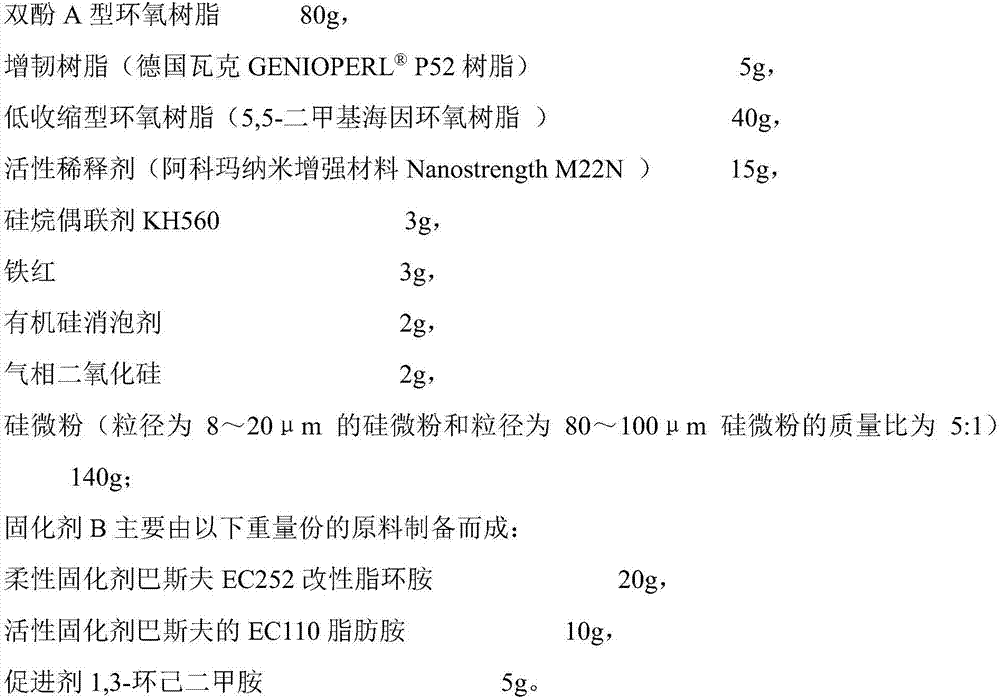

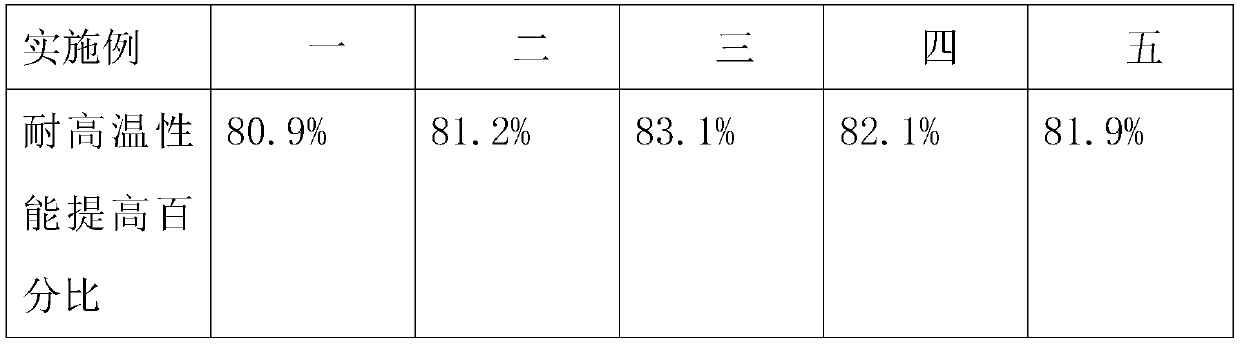

The invention discloses epoxy glue for protecting the end part of a stator of a wind power motor. The epoxy glue comprises double components, i.e., a main agent A and a curing agent B, wherein the main agent A is prepared mainly from bisphenol A epoxy resin, toughened resin, low-shrinkage epoxy resin, a reactive diluent, a silane coupling agent, an organic silicon defoaming agent, fumed silica and an inorganic filler; the curing agent B is prepared mainly from a flexible curing agent, an active curing agent and an accelerant; the toughened resin is epoxy / organic silicon hybrid core-shell rubber structure resin or epoxy / organic silicon hybrid block copolymerization resin. The invention further discloses a preparation method of the epoxy glue, which comprises preparation methods of the main agent A and the curing agent B. The epoxy glue disclosed by the invention has excellent low-temperature resistance and heat resistance, has very good flexibility and toughness, and can effectively prevent a cracking failure of the product in the process of carrying out encapsulation protection on the stator of the wind power motor, which is caused by the temperature drastic change.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

High-temperature-resistant stable protective film material and preparation method thereof

InactiveCN111548544AGood low temperature resistanceGood chemical stabilityFilm materialPolytetrafluoroethylene

The invention belongs to the technical field of protective films. The invention relates to a protective film material, in particular to a high-temperature-resistant stable protective film material anda preparation method thereof. The problem that an existing protective film is poor in high-temperature resistance is solved. According to the following technical scheme, the composition comprises thefollowing raw materials in parts by weight: 30-50 parts of polyethylene, 15-20 parts of calcium carbonate, 7-12 parts of plasticizer, 10 to 15 parts of polyvinyl chloride resin; 10-15 parts of epoxyresin, 2-7 parts of nano-silica, 1-6 parts of an antioxidant, 5-11 parts of polytetrafluoroethylene, 5-11 parts of acrylamide, 2-8 parts of magnesium stearate, 1-7 parts of polyurethane, 10-15 parts of polyetherimide, 5-10 parts of polyolefin, 1-6 parts of a heat stabilizer, 2-7 parts of polyester fibers, 1-6 parts of a scratch-resistant agent and 1-6 parts of a wear-resistant agent. The high temperature resistance can be effectively improved, the service life is prolonged, the strength is good, scratch resistance and wear resistance are achieved, and the preparation method is simple.

Owner:深圳市华中通用技术有限公司

Low temperature-resistant reinforced PP composite material and preparation method thereof

The invention belongs to the field of plastic modification technology and especially relates to a low temperature-resistant reinforced PP composite material and a preparation method thereof. The PP composite material comprises the following components by mass: 25 to 40% of homopolymerized PP, 30 to 49% of copolymerized PP and 15 to 25% of talcum powder and a cold resistant agent, with the balance being an anti-oxidant, a lubricant and a coupling agent. The preparation method comprises the following steps: blending; extrusion; and granulation. The composite material provided by the invention can maintain good toughness at low temperature conditions and meets requirements on usage of the PP composite material at a low temperature.

Owner:QINGDAO DADU NEW MATERIAL TECH

Internal wall paint

ActiveCN104177944AGood heat resistanceGood low temperature resistanceEmulsion paintsSodium silicateLead acetate

The invention relates to an internal wall paint which is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl alcohol, 20-40 parts of lithopone, 40-55 parts of sodium silicate, 40-60 parts of ground calcium carbonate, 80-100 parts of water, 30-40 parts of siliceous limestone powder, 0.1-0.5 part of polyoxyethylene, 8-10 parts of glycerol abietin, 0.1-0.3 part of plasticizer, 0.1-0.3 part of lead acetate, 3-13 parts of tinting pigment, 30-50 parts of sodium silicate, 5-40 parts of talcum powder and 0.3-0.5 part of castor oil. The solid content of the product is 30-40%, and the fineness is 40-60 mu m; the surface drying time is 0.5-1 hour, and the paint does not have the phenomenon of blistering or shedding after being immersed in water for 10 days; the paint has favorable heat resistance, and does not have the phenomenon of sticking or cracking at 90 DEG C for 5 hours; and the product has the advantages of favorable low-temperature resistance (not frozen at -5 DEG C), favorable scrub resistance, favorable stability and smooth and flat coated film, and can be widely produced and used instead of the existing materials.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

Vulcanization composition based on nitrile rubber and butadiene rubber, vulcanized rubber and preparation method and application thereof

PendingCN113493577AGood low temperature resistanceIncreased compression setRolling resistance optimizationCarbon blackPlasticizer

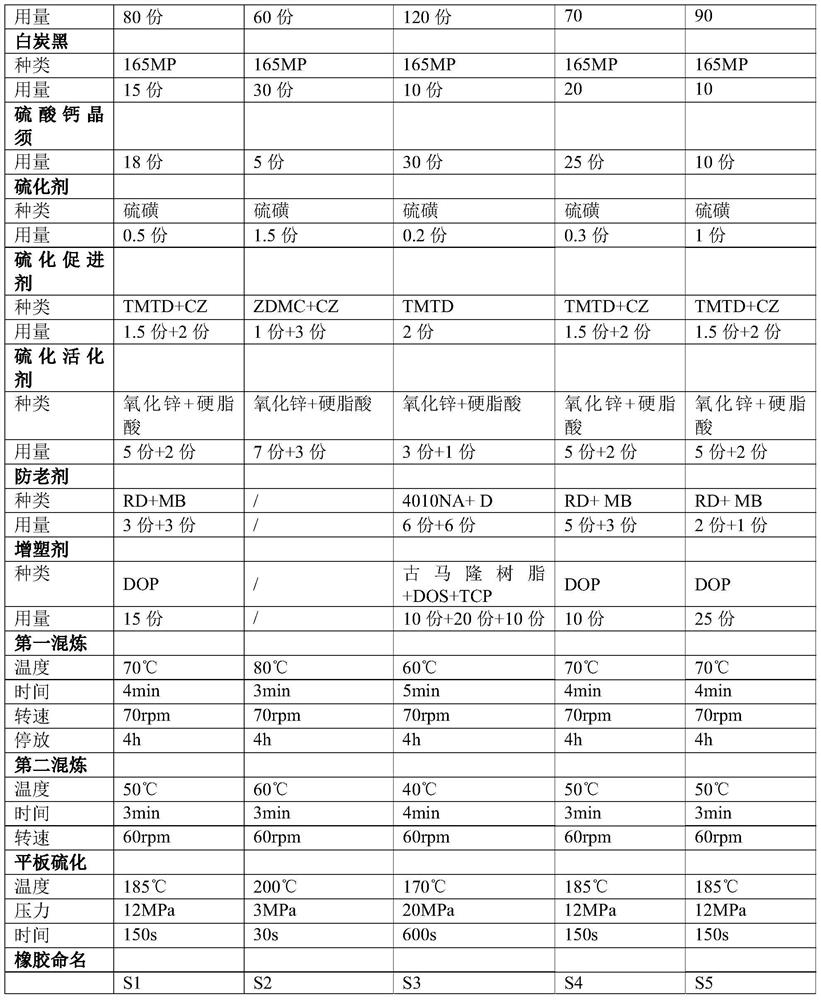

The invention relates to the field of rubber materials, and discloses a vulcanization composition based on nitrile rubber and butadiene rubber, vulcanized rubber and a preparation method and application of the vulcanized rubber, the composition contains a rubber matrix, a reinforcing agent, calcium sulfate whiskers, a vulcanizing agent, a vulcanization accelerator and a vulcanization activator, and optionally contains an anti-aging agent and / or a plasticizer, wherein the rubber matrix is a combination of nitrile rubber and butadiene rubber, and the reinforcing agent is a combination of carbon black and white carbon black. The rubber composition disclosed by the invention has good processability and moderate rubber compound Mooney viscosity, and is suitable for being applied to a high-temperature rapid vulcanization production process; therefore, the further prepared vulcanized rubber has excellent mechanical properties, compression set resistance and low temperature resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Strontium titanate based negative temperature coefficient high-voltage ceramic capacitor material

InactiveCN102115325AExpand the scope of workGood low temperature resistanceFixed capacitor dielectricCapacitanceStrontium titanate

The invention provides a strontium titanate based negative temperature coefficient high-voltage ceramic capacitor material. The material comprises the following components: 80 to 84 percent of strontium titanate SrTiO3, 8 to 10 percent of calcium titanate BiTiO3, 1.5 to 3 percent of bismuth titanate CaTiO3 and 10.5 to 13 percent of MgTiO3. By the adoption of the formula, the working range of a capacitor can be extended to a range between minus 65 degrees to 65 degrees, and the material has better low-temperature resistant performance.

Owner:费金华

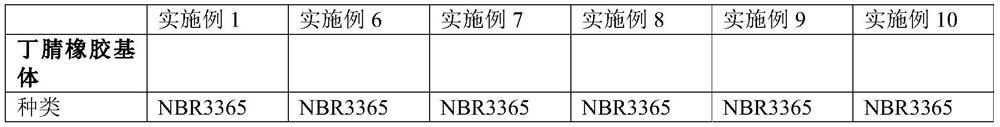

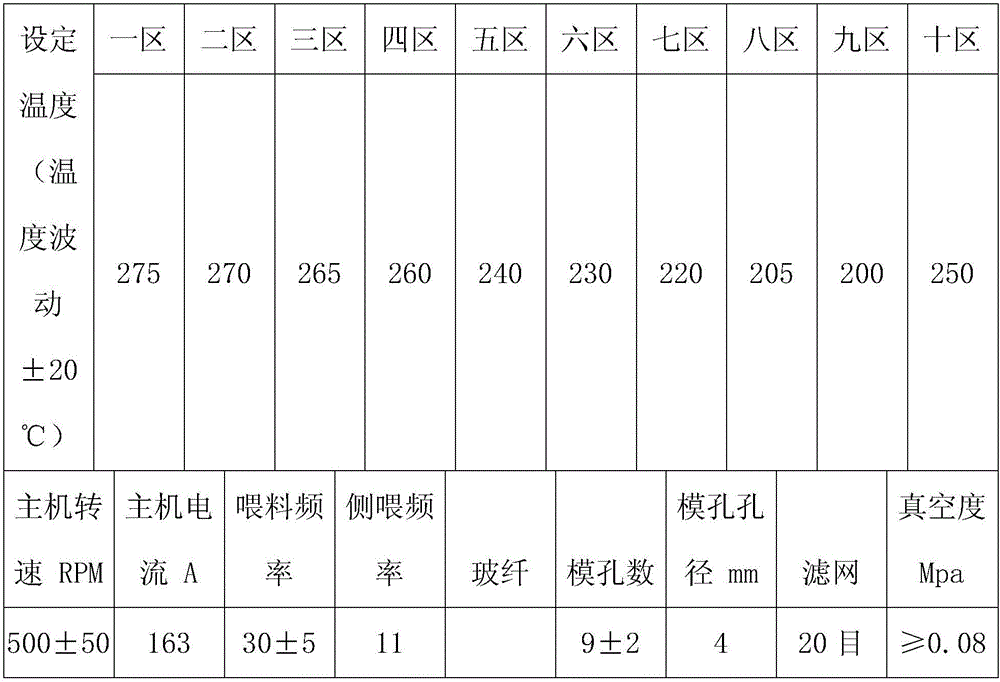

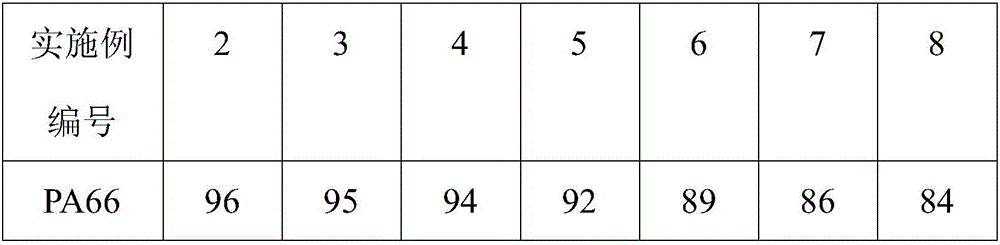

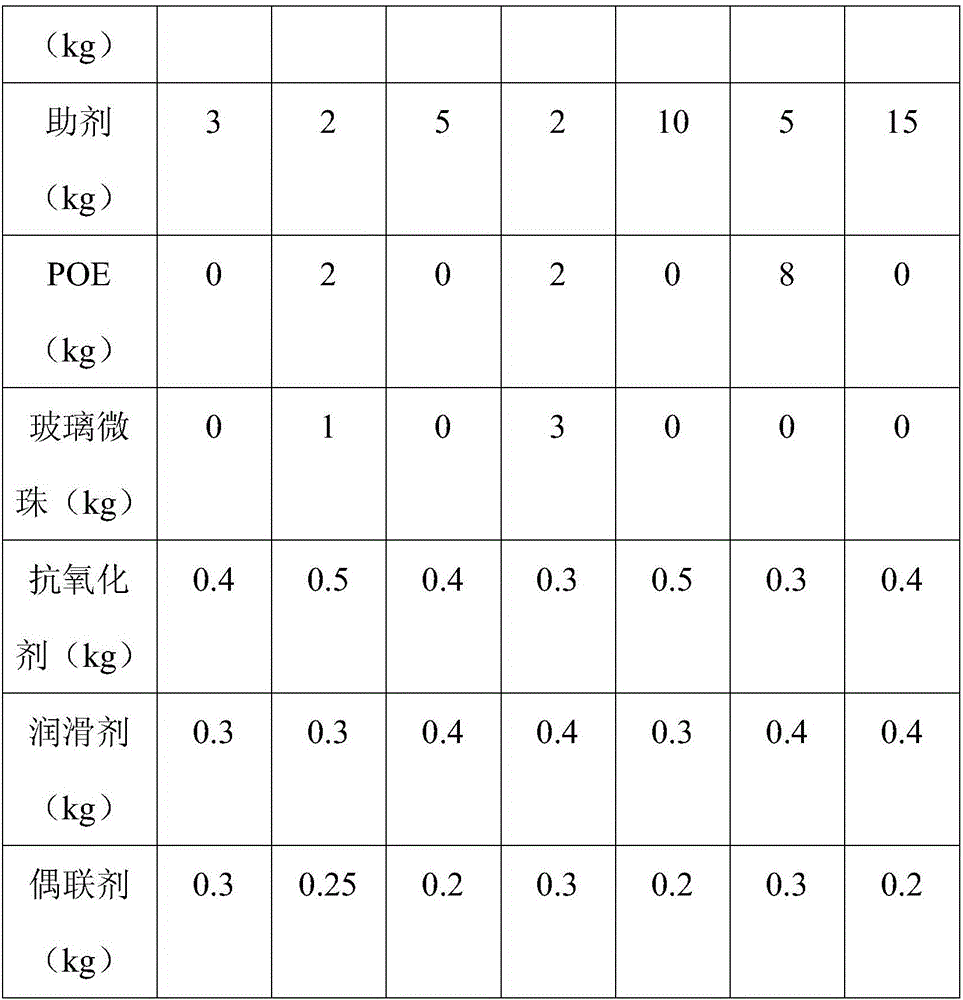

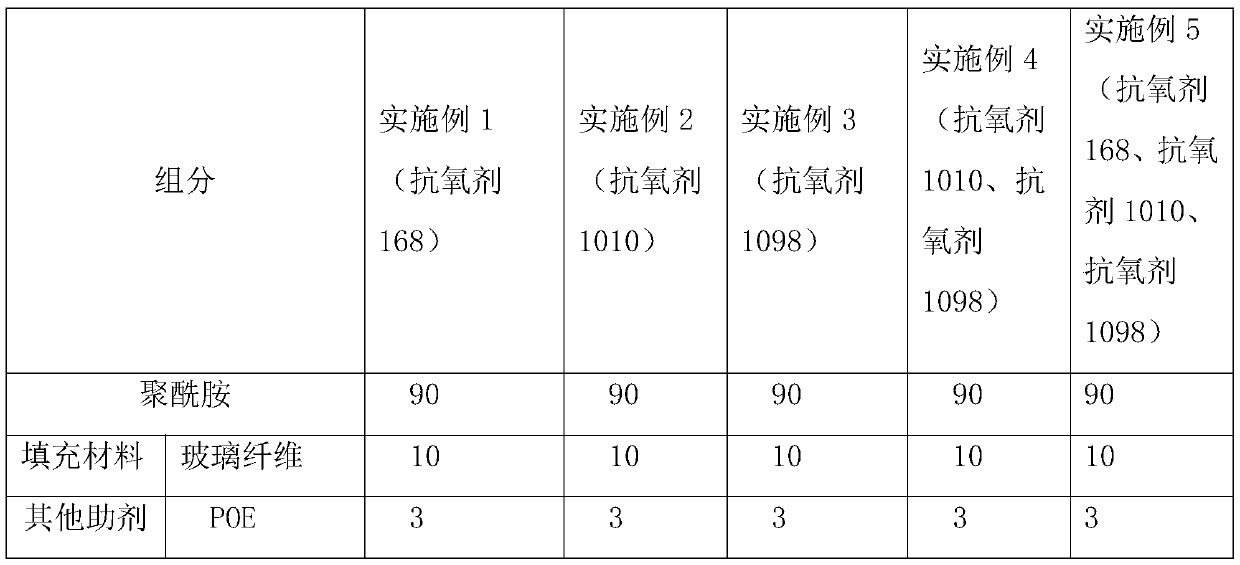

Low-temperature-resistant super-tough polyamide material

The invention discloses a low-temperature-resistant super-tough polyamide material. The low-temperature-resistant super-tough polyamide material is prepared from, by weight, 84-97 parts of PA66, 2-15 parts of auxiliaries, 0-8 parts of POE, 0-3 parts of glass beads, 0.3-0.5 part of antioxidant, 0.1-0.4 part of lubricant and 0.2-0.3 part of coupling agent. The low-temperature-resistant super-tough polyamide material has the advantages of being good in low temperature resistance and super high in toughness.

Owner:NINGBO HUIBANG NOLY TECH CO LTD

Low-temperature-resistant, oil-resistant, torsion-resistant and high-flame-retardant sheath material and preparation method thereof

PendingCN111675860AExtended service lifeImprove low temperature resistancePlastic/resin/waxes insulatorsCross linkerChlorinated paraffins

The invention discloses a low-temperature-resistant, oil-resistant, torsion-resistant and high-flame-retardant sheath material and a preparation method thereof. The low-temperature-resistant, oil-resistant, torsion-resistant and high-flame-retardant sheath material comprises the following components in parts by mass: 60 to 80 parts of chlorinated polyethylene, 20 to 40 parts of chlorosulfonated polyethylene, 0-10 parts of an ethylene-vinyl acetate copolymer, 60-100 parts of talcum powder, 20-40 parts of calcium carbonate, 20-40 parts of magnesium hydroxide, 0-10 parts of a flame retardant, 20parts of carbon black, 6 parts of magnesium oxide, 5 parts of red lead, 10-25 parts of a plasticizer, 10 parts of chlorinated paraffin oil, 1.5 parts of an antioxidant, 5 parts of a cross-linking agent and 4 parts of dicumyl peroxide. By adding the components and proportioning the components according to a specific ratio, the sheath material is ensured to have favorable mechanical properties and processability while prolonged in service life and enhanced in low-temperature resistance, oil resistance, torsion resistance and flame retardancy.

Owner:FAR EAST CABLE +3

Caterpillar track having low-temperature resistance performance

InactiveCN105367835AGood low temperature resistanceImprove low temperature resistanceParaffin waxNatural rubber latex

The invention provides a caterpillar track having good low-temperature resistance performance. According to the technical scheme, the caterpillar track having the good low-temperature resistance performance is prepared from natural rubber latex and water and is characterized in that 2-10 parts of dithio(bis)benzothiazole, 5-10 parts of tetraethylthiuram disulfide, 5-10 parts of hydroxyl silicone oil and 5-10 parts of paraffin wax are further added. Compared with the prior art, the caterpillar track has the advantages that the caterpillar track has the good effect of low-temperature resistance performance by adding the dithio(bis)benzothiazole, the tetraethylthiuram disulfide, the hydroxyl silicone oil and the paraffin wax.

Owner:袁辉

Cold-resistant plasticizer for cables

The invention relates to a cold-resistant plasticizer for cables. The cold-resistant plasticizer comprises 4-methoxy-1, 3-phthalic acid di-(4-chlorphenyl) ester. The cold-resistant plasticizer for the cables has the advantages that the cold-resistant plasticizer is excellent in cold-resistant, flame-retardant and aging-resistant characteristics and is quite suitable to be used in the fields of factories and mines, engineering, harbors and the like in low-temperature operation environments, and the like.

Owner:YANGZHOU LANDU PLASTICS TECH CO LTD

Intensive octopus variabilis overwintering breeding method

ActiveCN104756922AGood low temperature resistanceReduce the color of wastewaterClimate change adaptationPisciculture and aquariaWater qualityPollution

The invention provides an intensive octopus variabilis overwintering breeding method. According to the intensive octopus variabilis overwintering breeding method, octopus variabilis caught in October or November is placed in a breeding pool, wherein the number ratio between the octopus variabilis and the microbial immobilization octopus variabilis nests is 1:1.2, the breeding water temperature ranges from 10 DEG C to 14 DEG C, the salinity is 28-32, the pH is 7.8-8.3, the light intensity is 300-500 Lx, the daily exchange capacity of breeding water is 80%-120%, and the octopus variabilis is fed once every day. The manufactured octopus variabilis nests are a good microbial flora setting material and have the important functions of promoting growth and breeding of flora and purifying water; the microbial flora has good low temperature resistance, effectively decomposes organic matter in water, reduces the chromaticity of waste water, reduces pollution to the environment, and improves the survival rate and the health degree of the octopus variabilis.

Owner:OCEAN UNIV OF CHINA

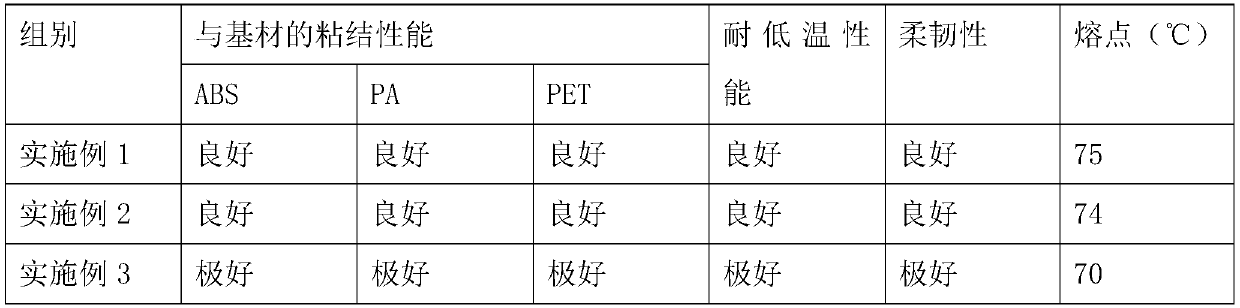

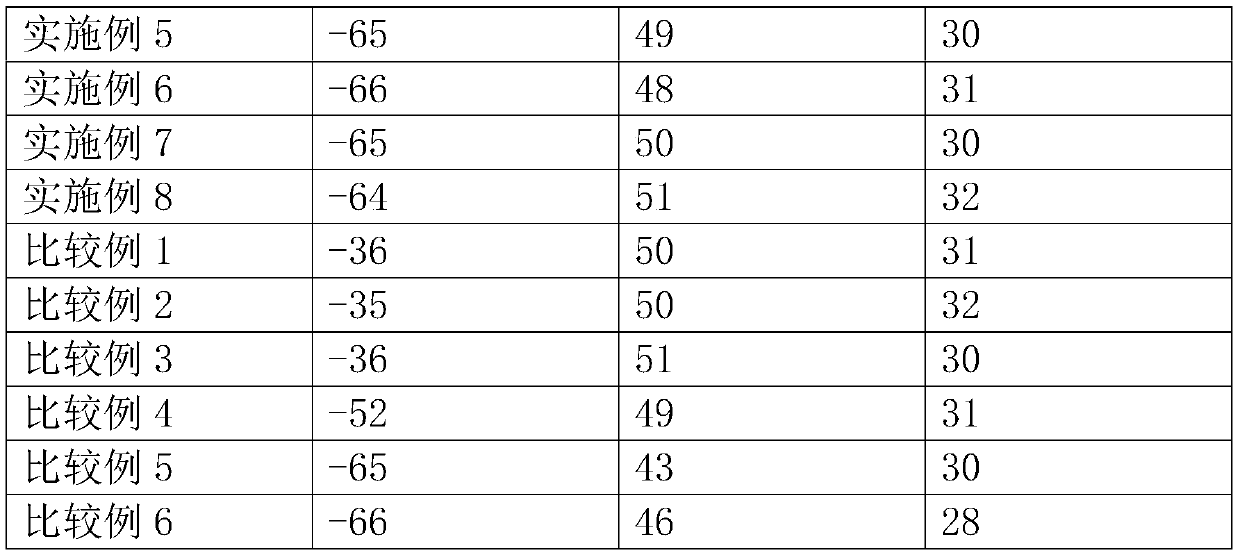

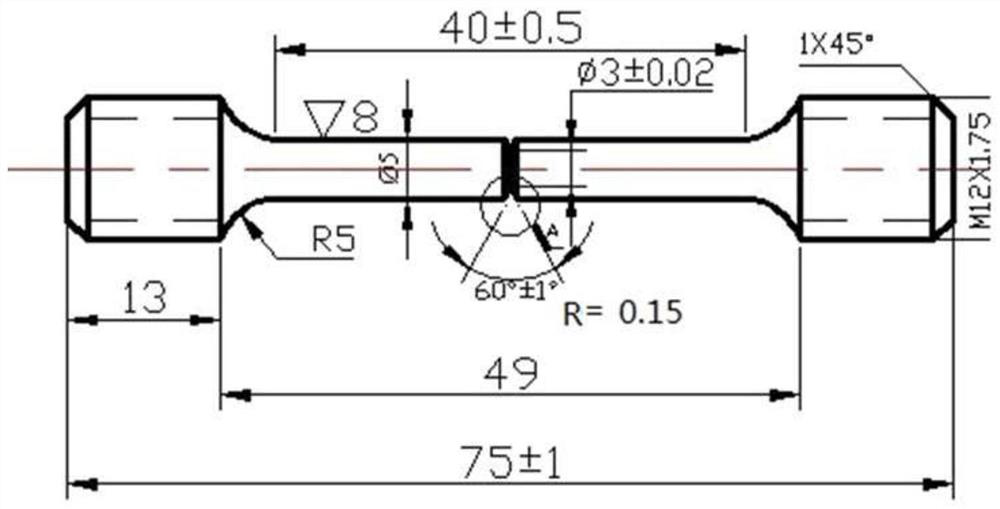

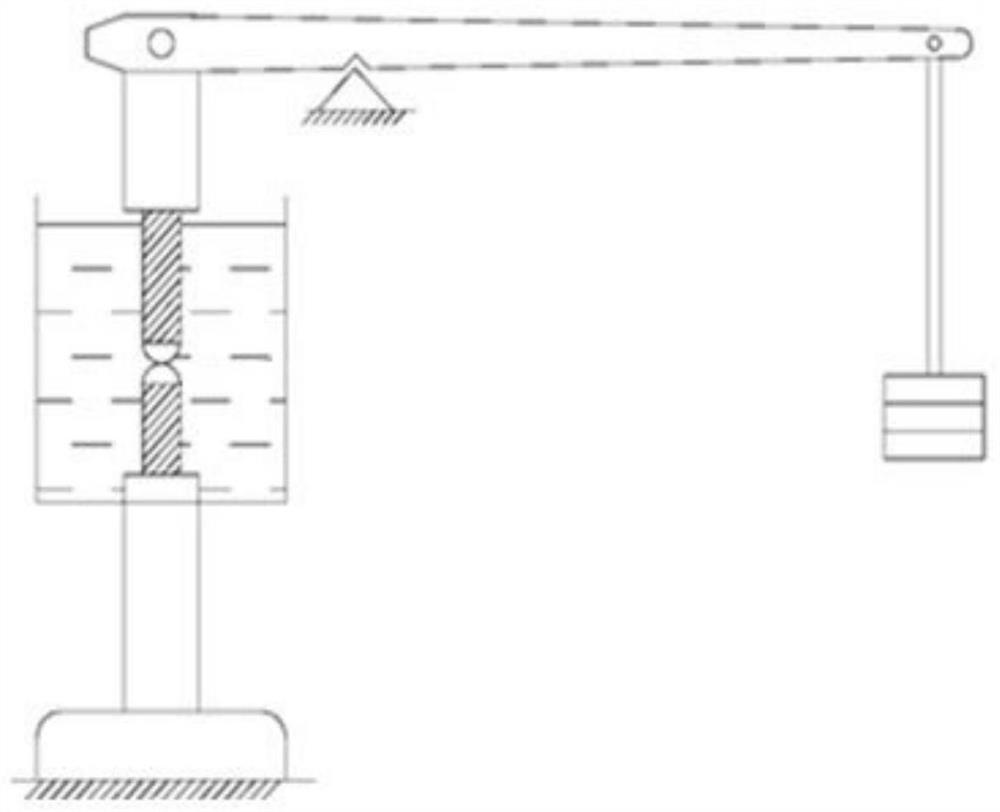

High-precision electronics PUR (polyurethane resin) hot melt glue and preparation method thereof

InactiveCN109735285AGood flexibilityGood low temperature resistancePolyureas/polyurethane adhesivesSolventPolyamide

The invention discloses a high-precision electronics PUR hot melt glue. The high-precision electronics PUR hot melt glue is composed of raw materials of isocyanate, synthetic resin and catalysts, wherein the synthetic resin is prepared by subjecting polyols and long-chain binary acids to reaction under action of chain extender at 140-240 DEG C for 3-18 hours, and the weight ratio of the polyols and the binary acids ranges between 100:75 and 100:225. The prepared high-precision electronics PUR hot melt glue can achieve high adhesion force on most low-polarity plastic base materials such ABS (acrylonitrile butadiene styrene), PA (polyamide) and PET (polyethylene terephthalate), is good in flexibility, outstanding in low temperature resistance, free from solvent, low in melting point, more environmentally friendly, safer, good in technical performance, low in cost and moderate in price, thereby having a broad application prospect.

Owner:SHANGHAI JORLE FINE CHEM

Transformer case material and preparation method thereof

InactiveCN107338382AChemically stableImprove wear resistanceTransformers/inductances casingsSodium BentoniteTransformer

The invention provides a transformer casing material and a preparation method thereof, and relates to the field of power materials. The transformer casing material includes the following raw materials in parts by weight: dolomite, bentonite, molybdenum disulfide, aluminum tripolyphosphate, boron nitride, lead sulfate, nano Silicon carbide, magnesium oxide, stainless steel, aluminum hydroxide, expanded graphite, silicon nitride, quartz glass, diatomite and ceramic matrix composite material; the preparation method comprises the following steps: (1) weighing raw materials; (2) ball milling; ( 3) Stirring and molding into a mold. The invention solves the problems of poor corrosion resistance, poor electromagnetic radiation shielding performance and low mechanical strength existing in the existing transformer casing.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Carbon nanotube silicone rubber

PendingCN110591637AExcellent performanceGood low temperature resistanceNon-macromolecular adhesive additivesCorrosion resistantCarbon black

The invention discloses carbon nanotube silicone rubber. The carbon nanotube silicone rubber is composed of the following components, in parts by weight: 6-10 parts of siloxane, 1-10 parts of borate,3-6 parts of high-quality carbon black, 1-3 parts of copper powder, 1-3 parts of titanium oxide, 3-6 parts of titanium dioxide, 1-10 parts of ethyl orthosilicate, 4-8 parts of phthalate, and 1-2 partsof carbon nanotubes. A preparation method of a novel glass curtain wall sealant comprises the following steps: mixing the components according to the above ratios, and performing stirring for uniformdispersion to obtain the finished product. Compared with the prior art, the sealant provided by the invention has excellent performance such as heat resistance, aging resistance, stress resistance and corrosion resistance, the Tg is lower than -60 DEG C, and the sealant has fairly good low-temperature resistance, good elasticity, and great application prospects.

Owner:YANCHENG ZENGCAI SCI & TECH

Green drain pipe for municipal garden

The invention relates to the technical field of garden drainage, and provides a green drain pipe for a municipal garden for the problem of easy embrittlement and cracking of polypropylene. According to the technical scheme, the drain pipe is prepared from a drain pipe composition, wherein the drain pipe composition is prepared from, by mass, 100 parts of polypropylene, 10-15 parts of urea formaldehyde, 33-44 parts of polyacrylonitrile and 15-22 parts of cellulose acetate. The polyacrylonitrile, the cellulose acetate and the urea formaldehyde are added into the polypropylene, and mixing is carried out in a specific proportion, which effectively improves the low temperature resistance of the drain pipe composition, so that the drain pipe composition is better applied to cold regions, and theapplicability of the prepared drain pipe is wider.

Owner:广东天濠建设工程有限公司

12.9-grade delayed-fracture-resistant weather-proof bolting steel and production method

InactiveCN112695241AExcellent toughnessGood low temperature resistanceFurnace typesHeat treatment furnacesAtmospheric corrosionDelayed fracture

The invention discloses 12.9-grade delayed-fracture-resistant weather-proof bolting steel and a production method. The steel comprises the following components according to the mass percentages: 0.35-0.45% of C, 0.10-0.40% of Si, 0.50-0.90% of Mn, less than or equal to 0.012% of P, less than or equal to 0.005% of S, 0.80-1.20% of Cr, 0.20-0.50% of Cu, 0.80-1.20% of Ni, 0.10-0.50% of V, Nb and Ti, 0.10-0.50% of Mo, 0.015-0.045% of Alt and the balance Fe and inevitable impurities. By designing the components and production technology parameters, the strength of the steel reaches a 12.9 grade, and meanwhile, the steel has excellent atmospheric corrosion resistance performance and delayed fracture resistance performance.

Owner:NANJING IRON & STEEL CO LTD

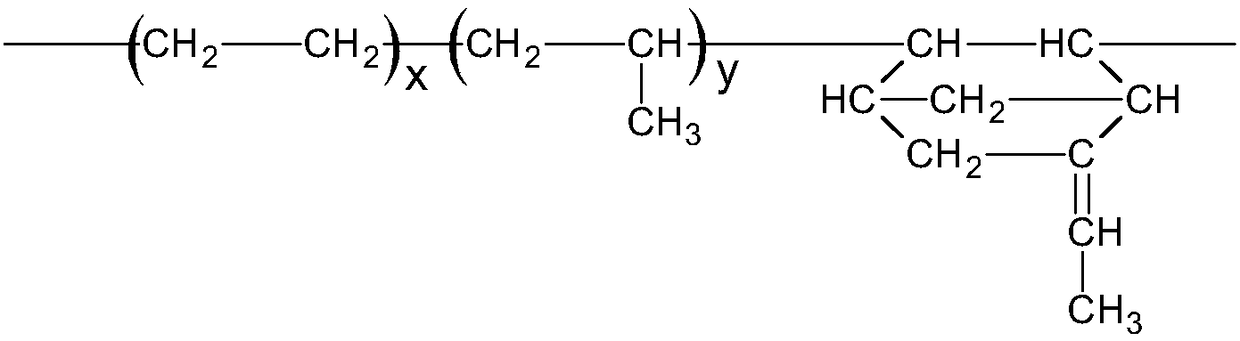

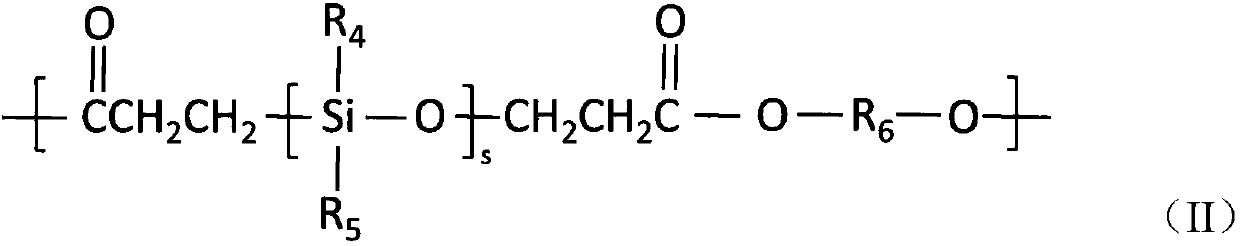

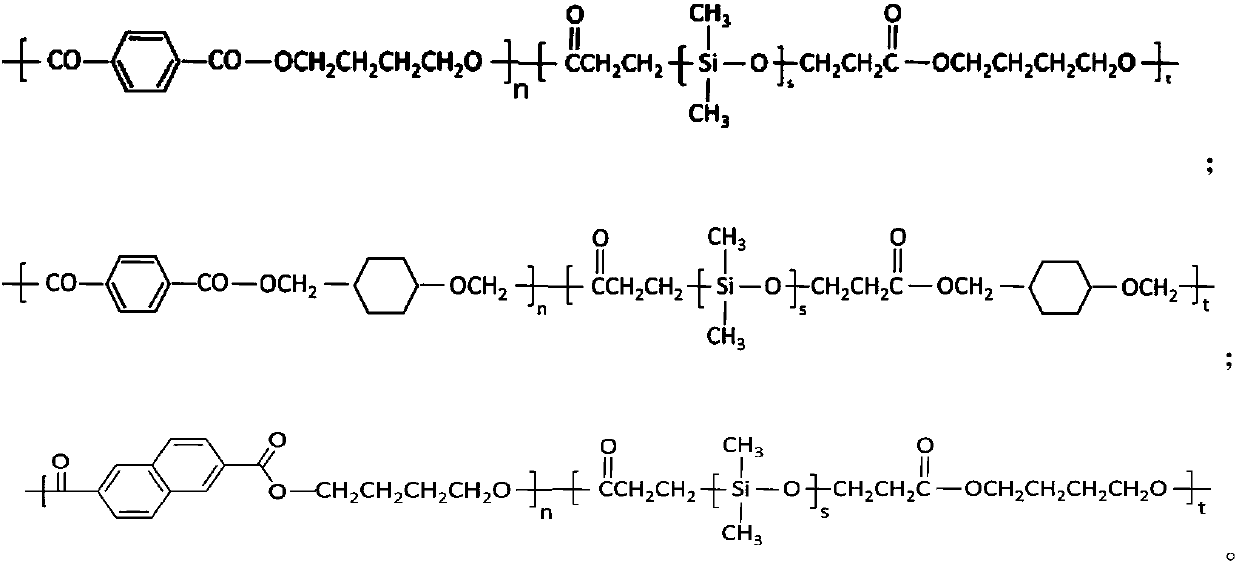

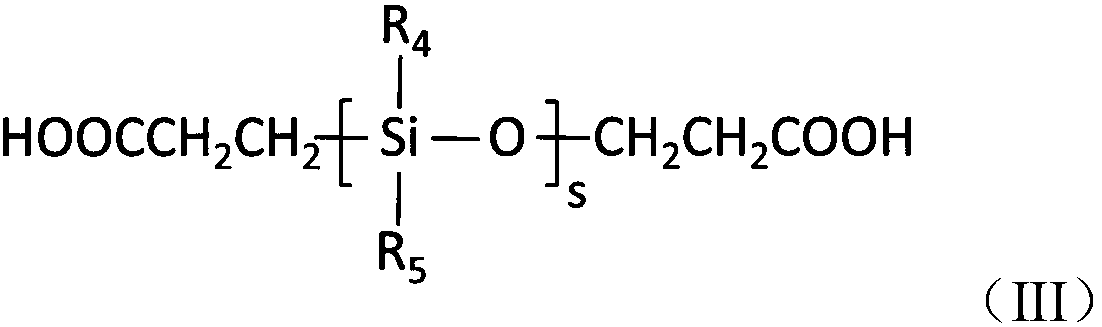

Polyester block copolymer as well as preparation method and application thereof

ActiveCN109553776AGood low temperature resistanceGood low temperature impactChemistrySurface tension

The invention discloses a polyester block copolymer which is characterized in that the structure of the polyester block copolymer is shown in the specification formula (I), and the invention also discloses a preparation method of the polyester block copolymer. According to the method, a silicon-containing unit is polymerized into a polyester molecular chain by a copolymerization method, and the obtained copolymer has excellent low-temperature resistance and relatively low surface tension, so that the characteristic that the polyester resin is not resistant to low temperature is improved, and application spaces of the polyester block copolymer in fiber, films, blow molding and engineering plastics are expanded. The formula (I) is An-Bt.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com