Grease for low speed and heavy duty

A low-speed heavy-duty, grease technology, applied in the field of grease, can solve the problems of difficult to meet the use requirements of the boom, the wear of the boom steel plate and slider, and the inability to withstand the high load of the boom. Low temperature performance, extended service life, good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Some raw materials:

[0024] Mercapto polysiloxane emulsion: provided by Nanjing Hualiming Chemical Co., Ltd.;

[0025] Polymethyltriethoxysilane: provided by Zhejiang Quzhou Zhengbang Silicone Co., Ltd.;

[0026] Polyethylene wax: provided by Jiande Huachen Chemical Co., Ltd.;

[0027] Graphite powder: provided by Qingdao Dongkai Graphite Co., Ltd.

example 1-6

[0029] Take by weighing monobasic fatty acid or lauryl hydroxystearic acid, be selected from at least one dibasic acid in terephthalic acid and C2-C8 dibasic acid, base oil, 12% calcium hydroxide and / or lithium hydroxide, placed in a reactor and heated to 80°C, saponified for 3 hours. Then heat up to 210°C, keep warm for 15 minutes, add base oil to adjust the amount of soap, and cool to 120°C. Add graphite powder, extreme pressure additives, organic ester and optional hydrophobic agent, grind and disperse, dewater and degas by low-pressure distillation, and cool naturally to form fat. Six samples S1-S6 are obtained respectively.

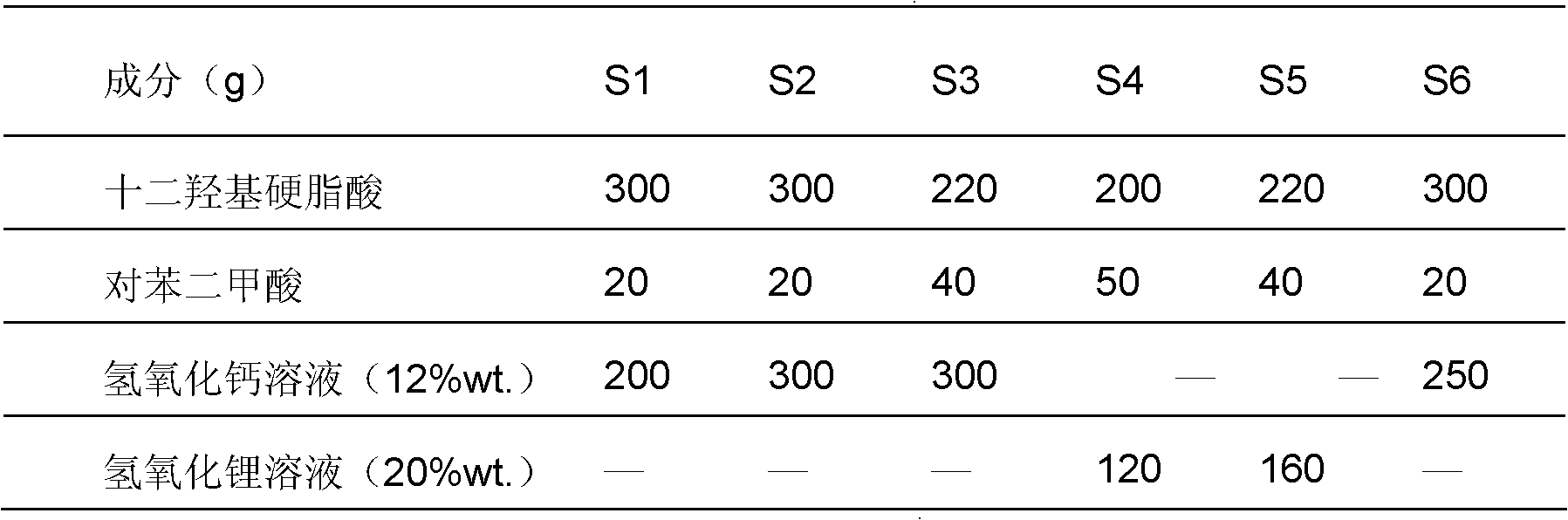

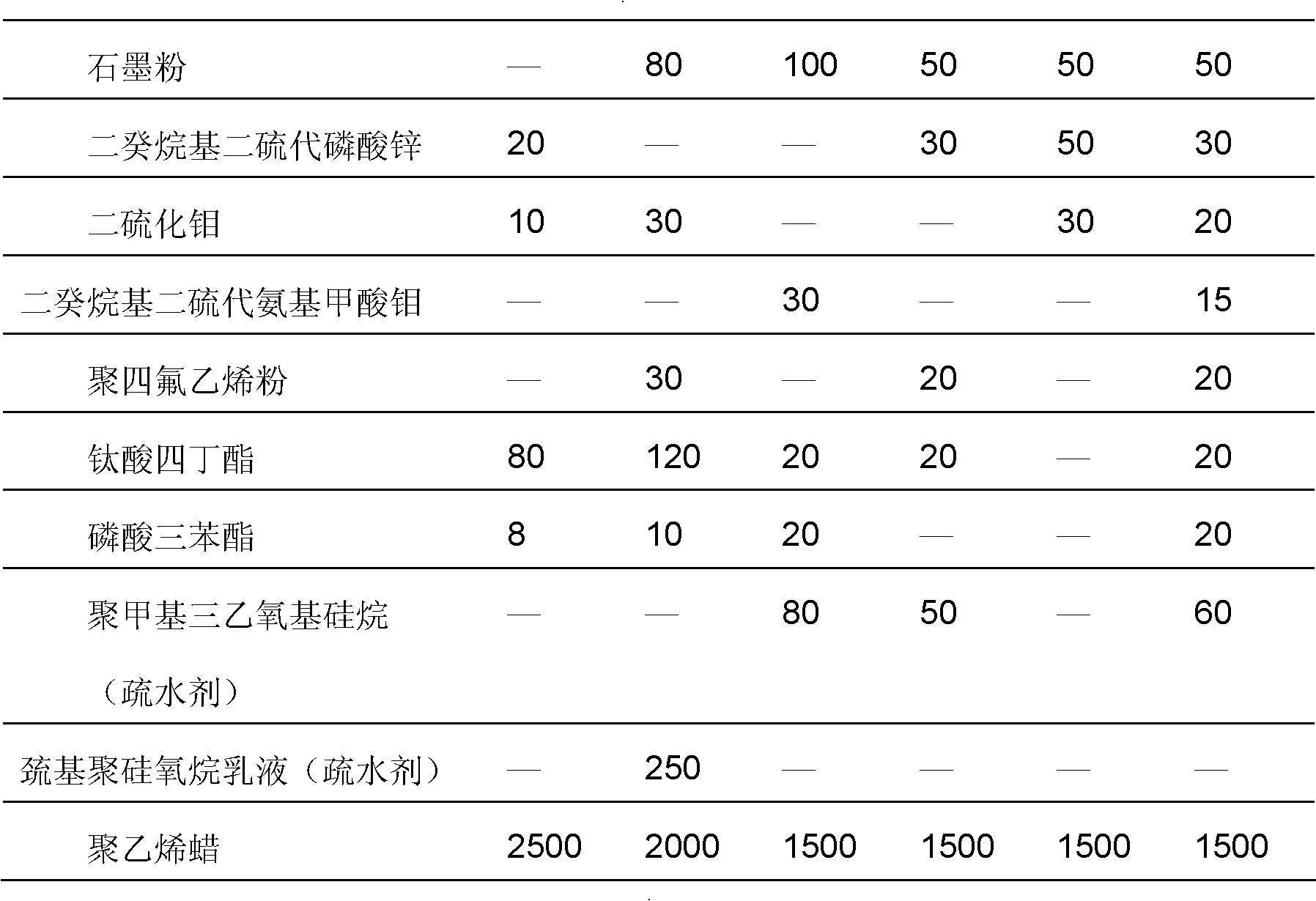

[0030] Table 1. The raw material formula of embodiment 1-6

[0031]

[0032]

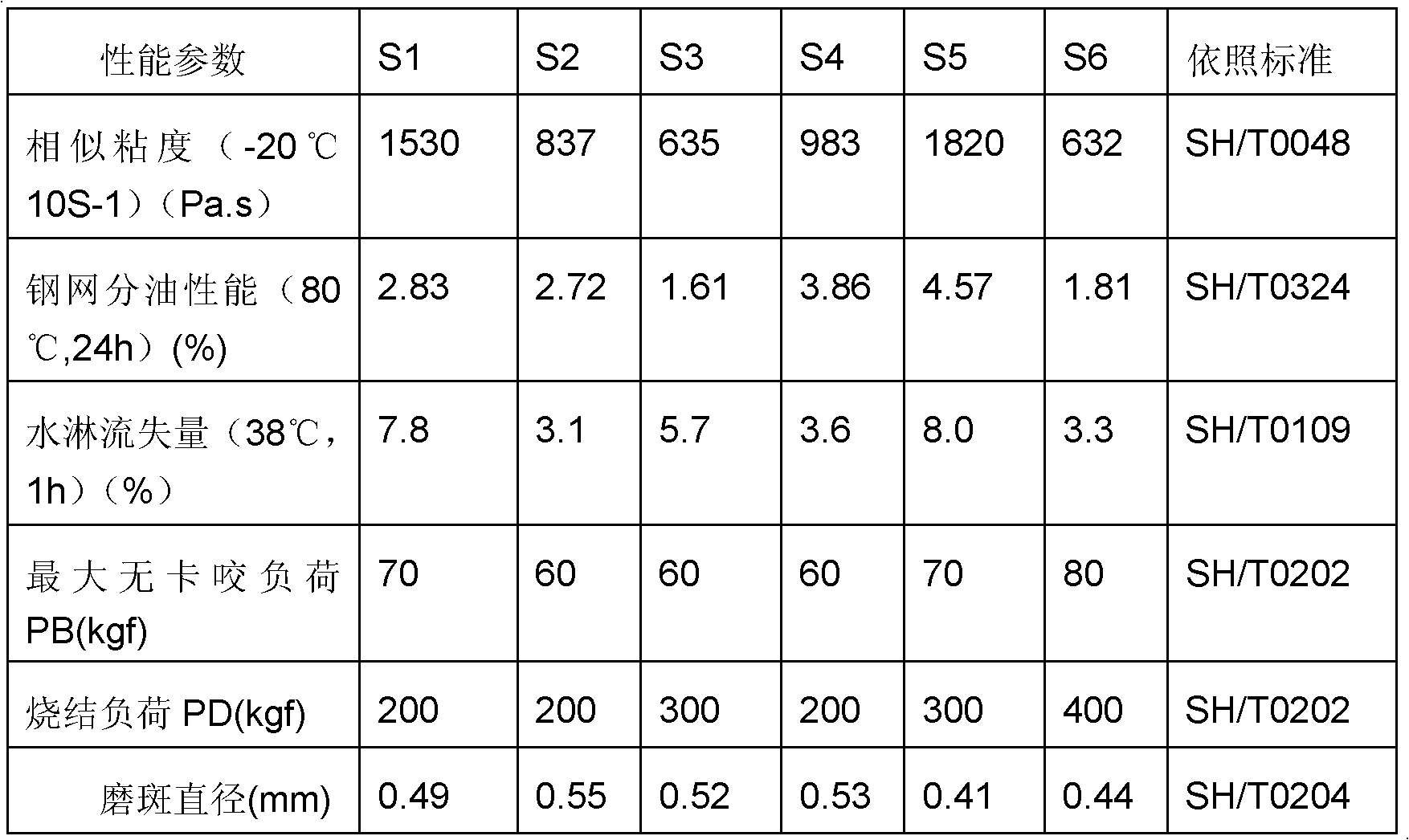

[0033] Table 2. Performance parameters of embodiment samples S1-S6

[0034]

example 1

[0035] Examples 1 and 5 lack hydrophobic agent and PTFE powder, showing poor water washout resistance, so the service life will be shorter; Example 1 lacks graphite and other extreme pressure additives in low percentages, showing poor extreme pressure. Pressure wear resistance; In addition to adding graphite powder, example 2 and example 4 also added didecyl zinc dithiophosphate and molybdenum disulfide, and the extreme pressure wear resistance is slightly poor; In addition to adding graphite powder, example 3 also Molybdenum didecyl dithiocarbamate was added, which showed better extreme pressure wear resistance; Example 5 only added an appropriate amount of extreme pressure additives, so the extreme pressure performance was better, but the water shower resistance and oil separation performance And low temperature performance is relatively poor; Example 6 adopts eight kinds of additives to add in appropriate proportion simultaneously, shows good overall performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com