Preparation method for early-strength agent for concrete

An early strength agent and concrete technology, which is applied in the field of concrete additive preparation, can solve the problems of slow hardening time, limited strength improvement, and lack of plastic retention performance, and achieve the effects of improving performance, increasing strength, and accelerating hardening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

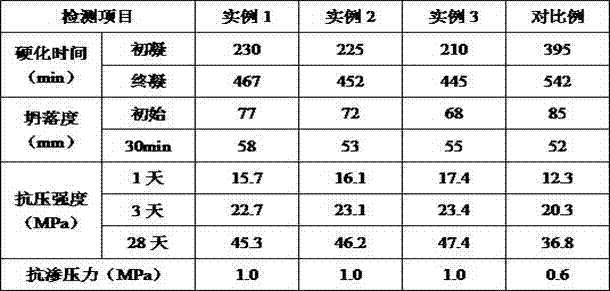

Examples

preparation example Construction

[0022] The preparation method of concrete early strength agent of the present invention, comprises the steps:

[0023] (1) Put cellulose, acetamide and water into the container according to the mass ratio of 4~6:3:8, stir at 150r / min for 10~15min, use sodium hydroxide solution to adjust the pH to 8.0~8.5, at 80 Insulate at ~85℃ for 1~2h;

[0024] (2) After the heat preservation is over, add bromooctadecane with 30-35% cellulose mass, stir evenly, cool down to 60-65°C, let stand for 3-6 hours, filter the mixture in the container while it is hot, and collect The filter residue is washed with water until the washing solution becomes neutral, the washed filter residue is collected, and the washed filter residue is air-dried to collect the air-dried matter;

[0025] (3) According to the mass ratio of 1:3~5, put the air-dried matter and tetrahydrofuran into the reactor, use nitrogen protection, and add 10-15% of the air-dried matter's n-butyllithium dropwise at -80~-75°C , control...

example 1

[0029] The preparation method of concrete early strength agent of the present invention, comprises the steps:

[0030] (1) Put cellulose, acetamide and water into a container at a mass ratio of 4:3:8, stir at 150r / min for 10min, adjust the pH to 8.0 with sodium hydroxide solution, and keep warm at 80°C for 1h;

[0031] (2) After the heat preservation is over, add bromooctadecane with 30% cellulose mass, stir evenly, cool down to 60°C, let it stand for 3 hours, filter the mixture in the container while it is hot, collect the filter residue, and wash the filter residue with water Until the washing solution becomes neutral, collect the washed filter residue, air-dry the washed filter residue, and collect the air-dried matter;

[0032] (3) According to the mass ratio of 1:3, put the air-dried matter and tetrahydrofuran into the reactor, use nitrogen protection, and add 10% n-butyl lithium dropwise at -80°C, and control the dropping time for 1h , then dropwise add dimethylformamid...

example 2

[0034] The preparation method of concrete early strength agent of the present invention, comprises the steps:

[0035] (1) Put cellulose, acetamide and water into a container at a mass ratio of 5:3:8, stir at 150r / min for 13min, adjust the pH to 8.3 with sodium hydroxide solution, and keep warm at 83°C for 1h;

[0036] (2) After the heat preservation is over, add bromooctadecane with 33% cellulose mass, stir evenly, cool down to 63°C, let it stand for 5 hours, filter the mixture in the container while it is hot, collect the filter residue, and wash the filter residue with water Until the washing solution becomes neutral, collect the washed filter residue, air-dry the washed filter residue, and collect the air-dried matter;

[0037] (3) According to the mass ratio of 1:4, put the air-dried matter and tetrahydrofuran into the reactor, use nitrogen protection, and add n-butyllithium with 13% air-dried matter at -78°C dropwise, and control the dropping time to 1h , then dropwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com