Injection mold device

An injection mold and mold technology, applied in the field of injection mold devices, can solve problems such as depression, leakage of injected raw materials, damage to equipment, etc., and achieve the effect of increasing the hardening time of raw materials, prolonging the service life, and avoiding sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

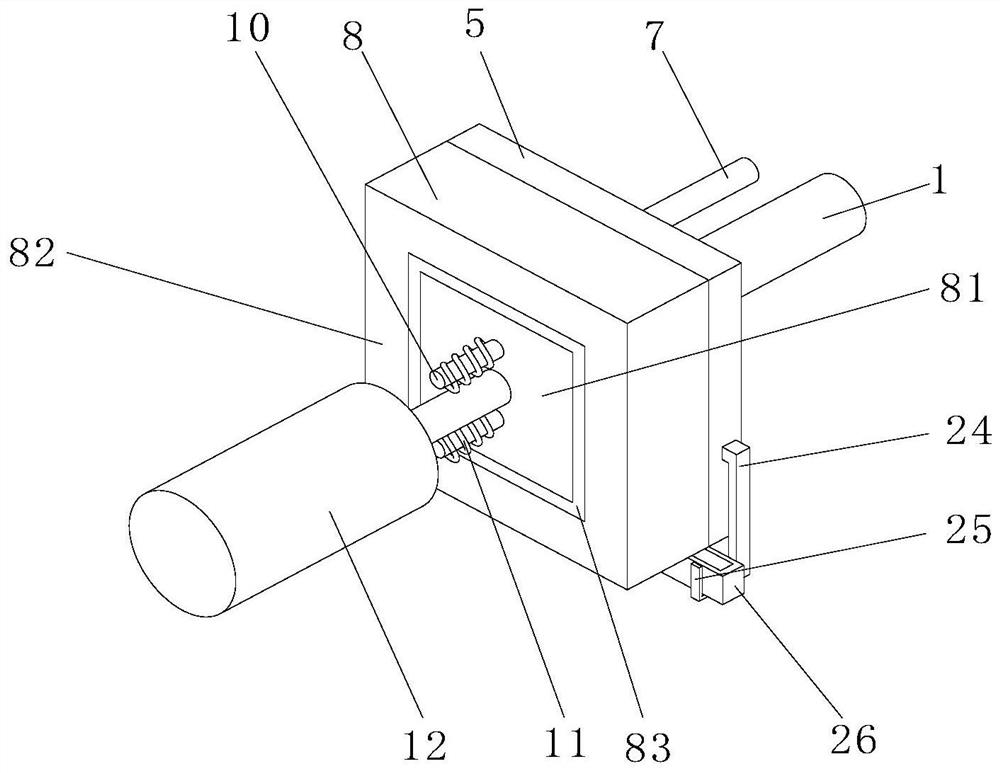

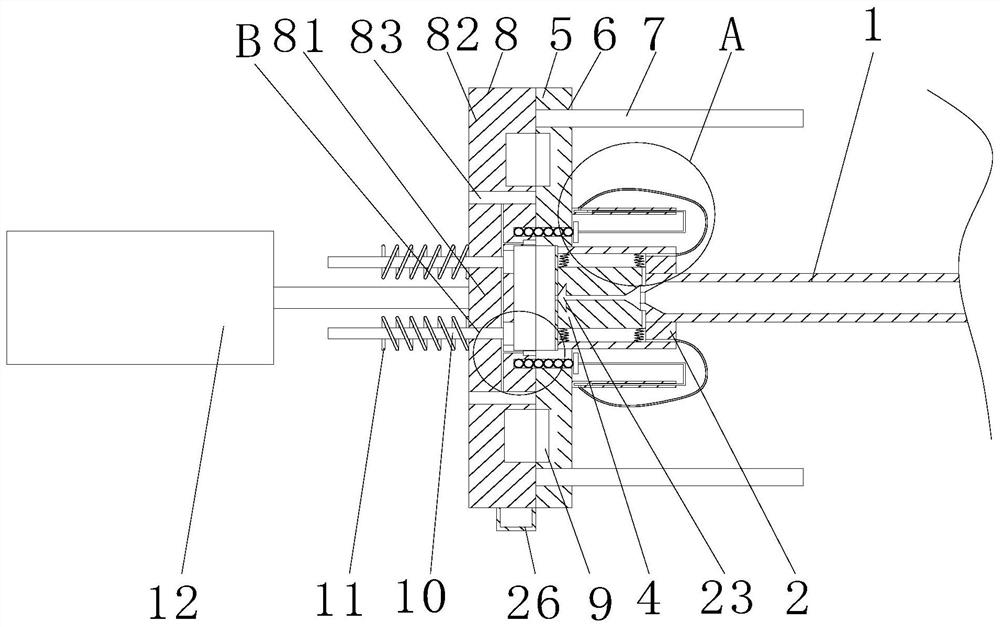

[0038] Example 1: Please refer to Figure 1-7 , an injection mold device, comprising an injection gun head 1, a fixed mold 5, a movable mold 8 and a hydraulic cylinder 12, the injection gun head 1 is a hollow cylinder, and the outer wall of the right end of the injection gun head 1 is fixedly connected with a guide tube 2, The plastic guide cylinder 2 is a hollow rectangular body, the right side of the plastic guide cylinder 2 is provided with a hole and the injection gun head 1 is located in the hole, the top surface and the bottom inner wall of the plastic guide cylinder 2 are fixedly connected with a group of springs A3, two One end of the group spring A3 far away from the inner wall of the plastic guide tube 2 is fixedly connected with a clamp block 4, the clamp block 4 is a quarter ellipsoid, and the front and rear wall surfaces and the left and right wall surfaces of the clamp block 4 are all bonded to the inner wall of the plastic guide tube 2, The gap between the two c...

Embodiment 2

[0045] Example 2: Please refer to Figure 8-9, on the basis of Embodiment 1, the transmission shaft of the hydraulic cylinder 12 is fixedly connected with the connecting plate 27, and the connecting plate 27 is fixedly equipped with a detection sensor 28, the detection sensor 28 corresponds to the position of the outer frame 82, and through the setting of the detection sensor 28, The detection sensor 28 is used to detect the position of the outer frame 82, so that when the outer frame 82 is out of contact with the fixed mold 5 during the injection molding process, a signal is sent in time to cooperate with the control circuit to perform functions such as alarming and retracting the transmission shaft of the hydraulic cylinder 12.

[0046] The right side of the piston rod 15 is fixedly connected with a detection cylinder 29, the detection cylinder 29 is a hollow convex body, a thermometer 30 is fixedly installed in the detection cylinder 29, the detection end of the thermometer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com