Cold water tank water temperature automatic balancing control system for manufacturing monofilament for fishing

A control system and automatic equalization technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of large water fluctuations, affecting the quality and shape of monofilaments, and poor quality of monofilaments, so as to ensure cooling Molding, reduction of temperature difference or rate of temperature change, effect of reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

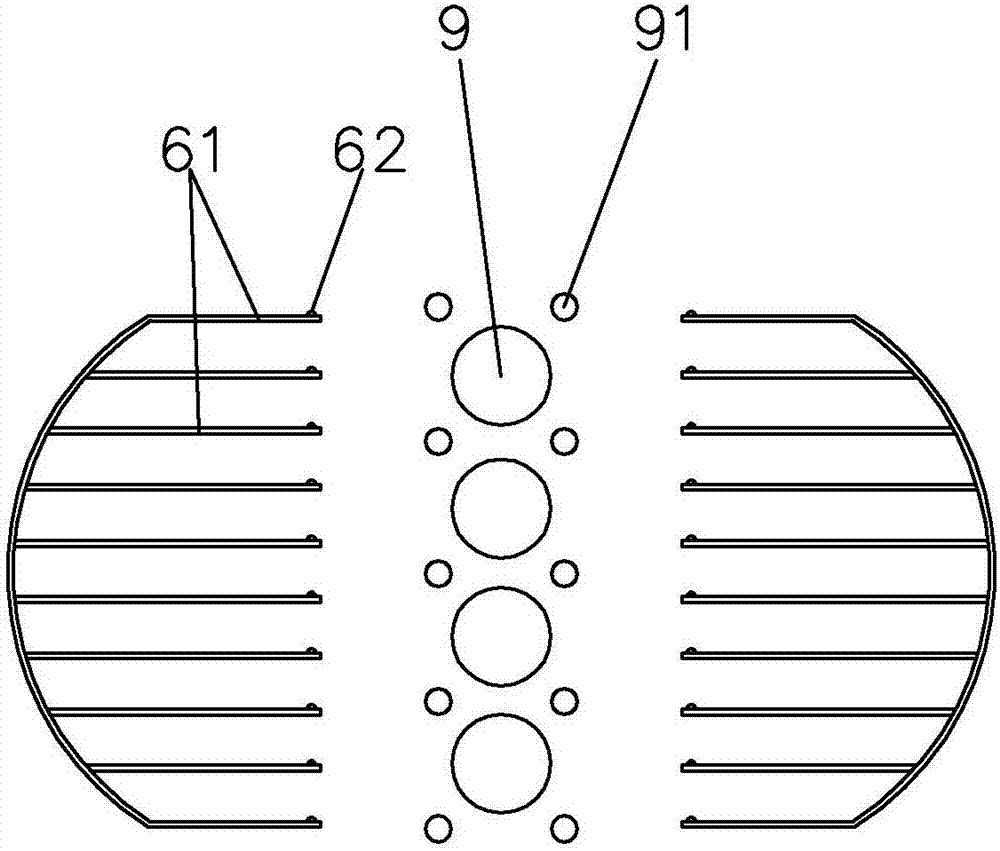

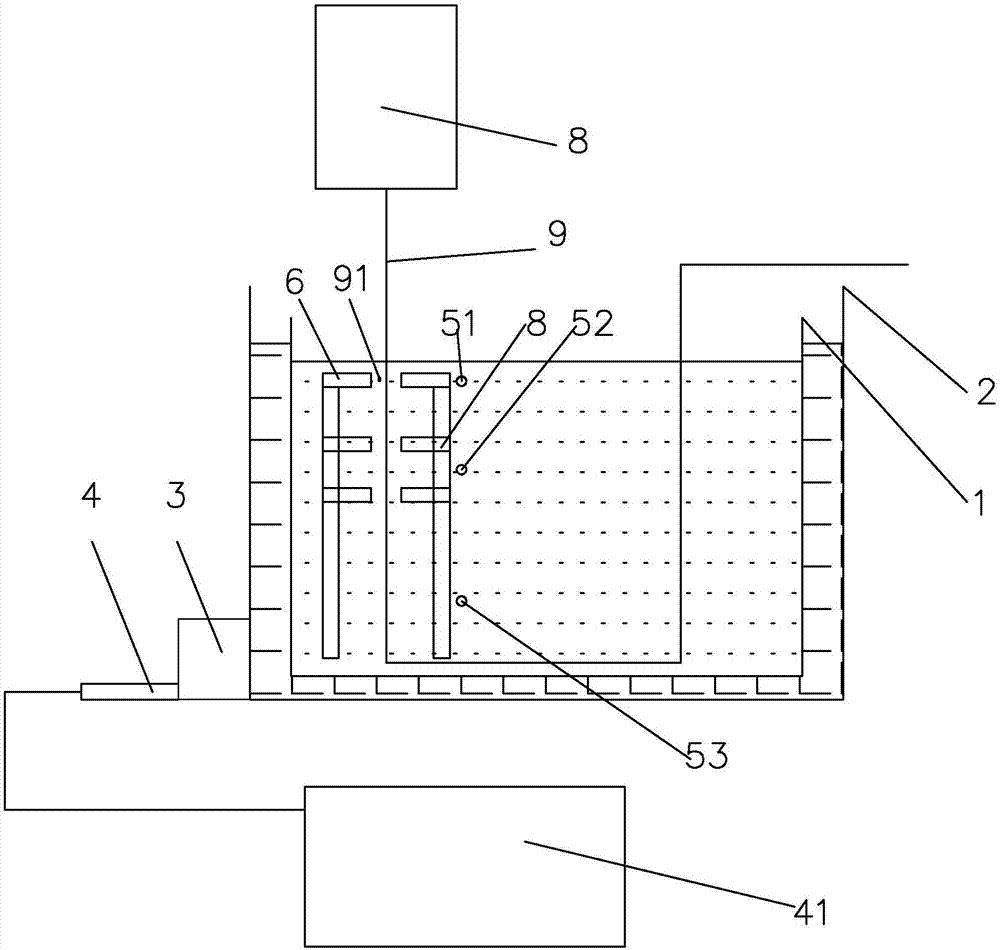

[0021] The invention provides a cold water tank water temperature automatic balance control system for fish monofilament manufacturing. The control system also includes a large cycle temperature control device and a micro cycle temperature control device arranged in the cold water tank; the large cycle temperature control device: it includes a 1 external water pump 3, water pump 3 sends constant temperature water into the bottom of the cold water tank through the water inlet pipe 4; microcirculation temperature control device; it includes the surface layer thermometer 51, the middle layer thermometer 52, the bottom layer that are vertically spaced in the cooling water of the cold water tank Thermometer 53 also includes the micro-spout pipe 6 that surrounds the cooling water body around the high-temperature monofilament, and the monofilament 9 continuously comes out from the melting extruder 7 and enters the cooling water body. The bottom is connected and the bottom water is pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com