Pumping agent suitable for lightweight aggregate concrete

A light aggregate concrete and pumping agent technology, which is applied in the field of building material manufacturing, can solve the problems of restricting the widespread use of light aggregate concrete, slump loss of light aggregate concrete, and poor pumping performance of light aggregate concrete. Achieve the effect of reducing bleeding and layering segregation, improving antifreeze ability and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

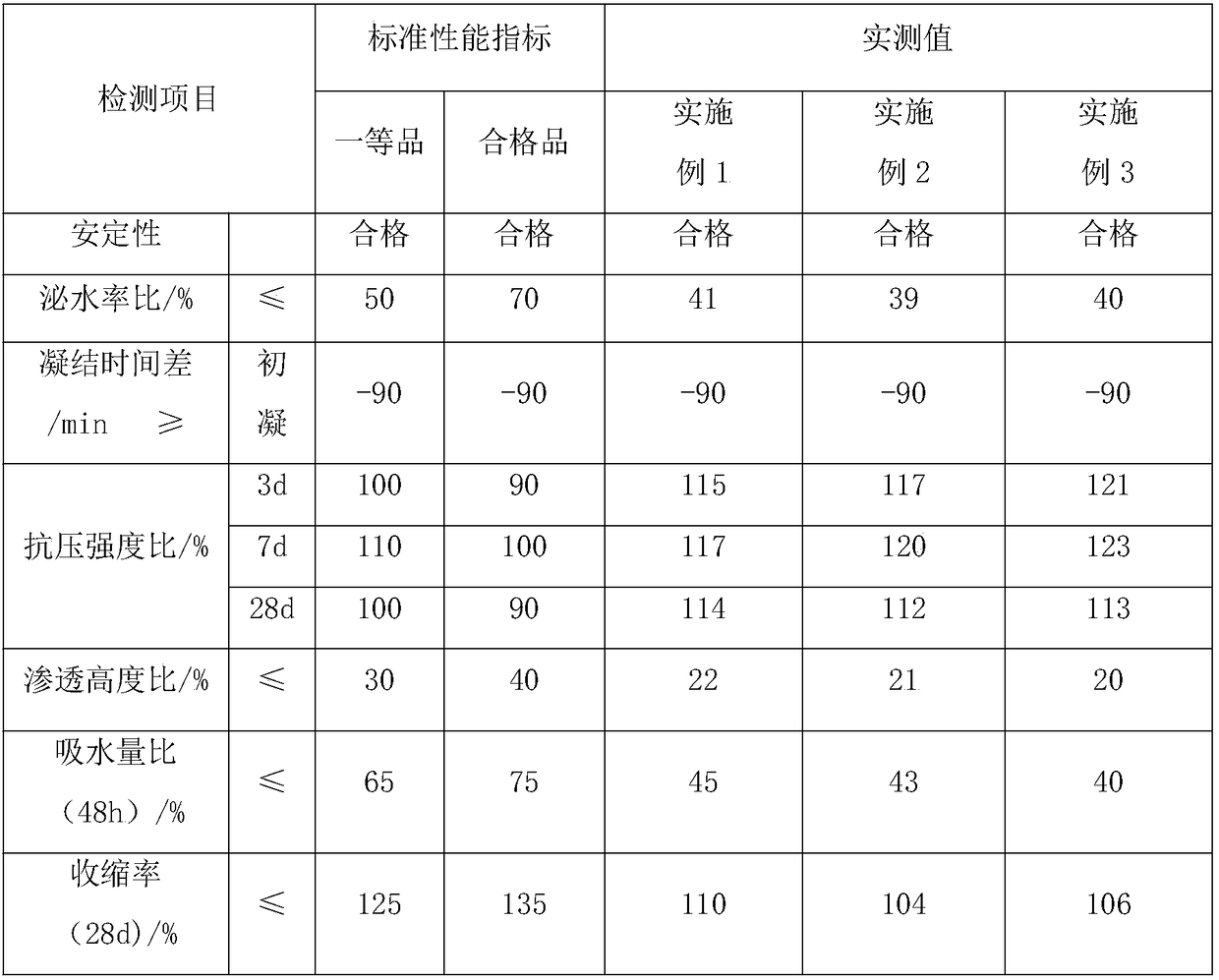

Embodiment 1

[0016] The pumping agent suitable for light aggregate concrete in this embodiment is composed of the following raw materials according to the percentage of the total weight of raw materials: 75% silica fume, 15% lignin fiber, 1% retarder, cellulose Ether 5%, dispersant 1%, air-entraining agent 0.3%, sodium glucoheptonate 1%, zinc stearate 1.7%.

[0017] Each component of the pumping agent suitable for light aggregate concrete in this embodiment is a commercially available product. Specifically, the retarder in this embodiment is preferably sodium gluconate, and the retarder can also be selected from sugar calcium, sugar Powder, sodium tripolyphosphate, maltodextrin, sodium hexametaphosphate, sucrose any one.

[0018] The pumping agent suitable for light aggregate concrete in this embodiment is weighed according to the percentage of the total weight of the above-mentioned raw materials, and then added to a single-horizontal shaft forced mixer and stirred at the same time, and i...

Embodiment 2

[0028] The pumping agent suitable for light aggregate concrete in this embodiment is composed of the following raw materials according to the percentage of the total weight of raw materials: 62% silica fume, 20% lignin fiber, 3% retarder, cellulose Ether 7%, dispersant 3%, air-entraining agent 0.6%, sodium glucoheptonate 3%, zinc stearate 1.4%.

[0029] In this embodiment, the upper component is taken according to the proportion. The preparation method and raw materials of this embodiment are the same as those in Example 1; the retarder in this embodiment is preferably sodium gluconate, and the retarder can also be calcium sugar or powdered sugar. , sodium tripolyphosphate, maltodextrin, sodium hexametaphosphate, sucrose; the air-entraining agent in the present embodiment is preferably sodium dodecylsulfonate, and AOS air-entraining agent or saponin can also be selected Any one of the glycoside powders, wherein the AOS air-entraining agent refers to sodium α-olefin sulfonate; ...

Embodiment 3

[0031] The pumping agent suitable for light aggregate concrete in this embodiment is composed of the following raw materials according to the percentage of the total weight of raw materials: 50% silica fume, 25% lignin fiber, 5% retarder, cellulose Ether 10%, dispersant 4%, air-entraining agent 0.9%, sodium glucoheptonate 4%, zinc stearate 1.1%.

[0032] In this embodiment, the upper component is taken according to the ratio, and the preparation method and raw materials of the present embodiment are the same as in Example 1; the retarder in this embodiment is preferably sodium gluconate, and the retarder can also be selected from sugar calcium, Any one of powdered sugar, sodium tripolyphosphate, maltodextrin, sodium hexametaphosphate, sucrose; the air-entraining agent in this embodiment is preferably sodium dodecyl sulfonate, and AOS air-entraining agent or Any one of the saponin powders, wherein the AOS air-entraining agent refers to sodium α-olefin sulfonate; the preferred p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com