Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Effective passivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

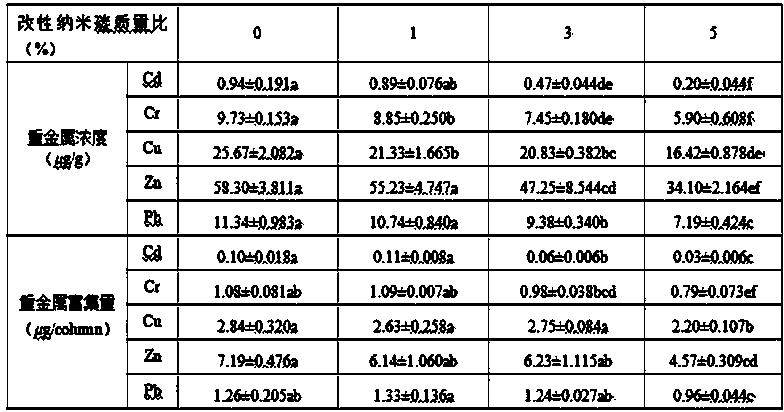

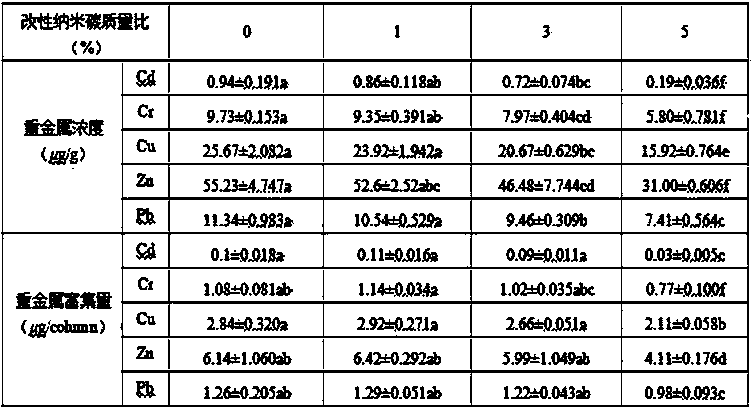

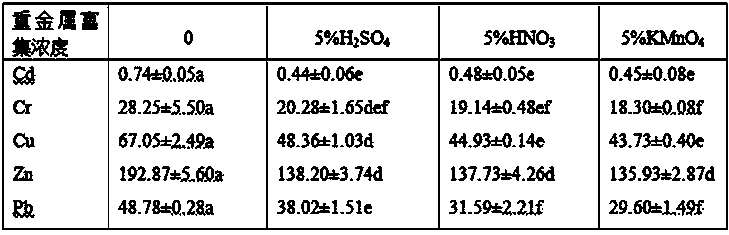

Fixed enrichment method for city life compost heavy metals through modified nanocarbon

InactiveCN103861866AGood effectEffective passivationContaminated soil reclamationSoil sciencePolyvinyl chloride

The invention discloses a fixed enrichment method for city life compost heavy metals through modified nanocarbon. The fixed enrichment method comprises the following steps: modifying the modified nanocarbon with the grain diameter of 20-70nm before being applied so as to obtain various types of modified nanocarbon; then sealing a layer of cotton cloth and a nylon net at the lower end of a PVC (polyvinyl chloride) tube, uniformly and proportionally mixing garbage compost with the modified nanocarbon, wherein each tube is filled with150g of a mixed material; setting the temperature during experiments to be 19-27 DEG C and the relative humidity to be 60% to 72%, and supplementing water for the compost every day, so that the content of water of the compost reaches about 70% of field moisture capacity; sampling 45d for cultivation later, and carrying out morphological analysis on the heavy metals, wherein the addition of the modified nanocarbon is 1-5%(w / w) of the weight of the garbage compost. Experimental results show that the modified nanocarbon is added so that the contents of the heavy metals in a residual form are increased, the conversion of the compost heavy metals from a plant easily-absorbed state to a difficultly-absorbed state is promoted, and the method provides a basis for the application of the modified nanocarbon on passivation and plant enrichment of the heavy metals in garbage compost.

Owner:TIANJIN NORMAL UNIVERSITY

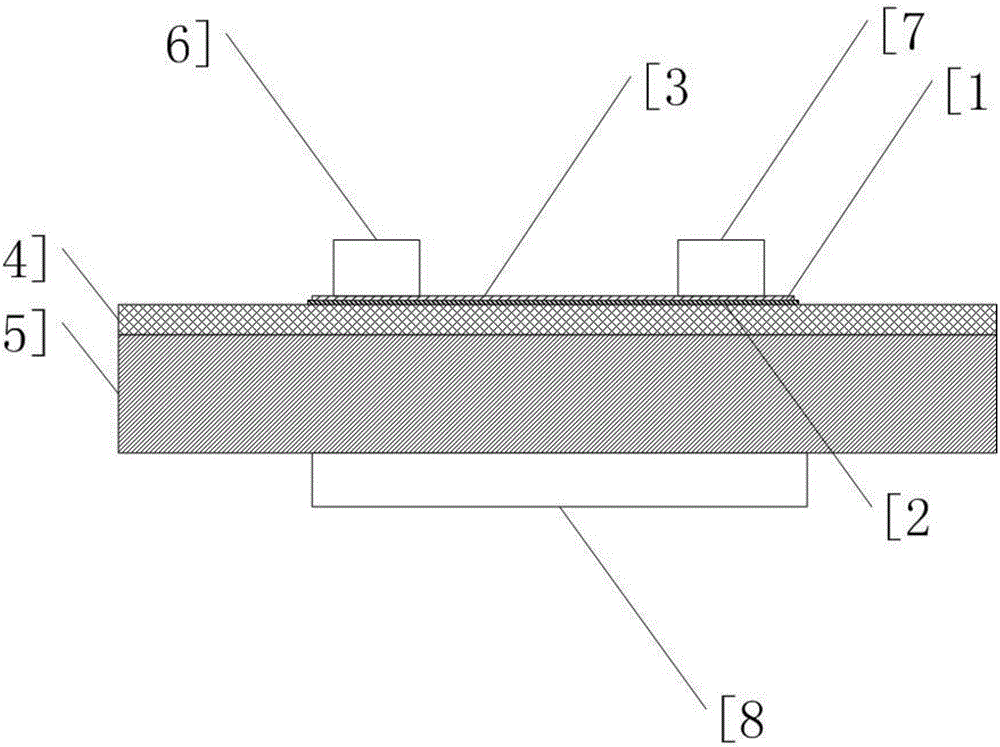

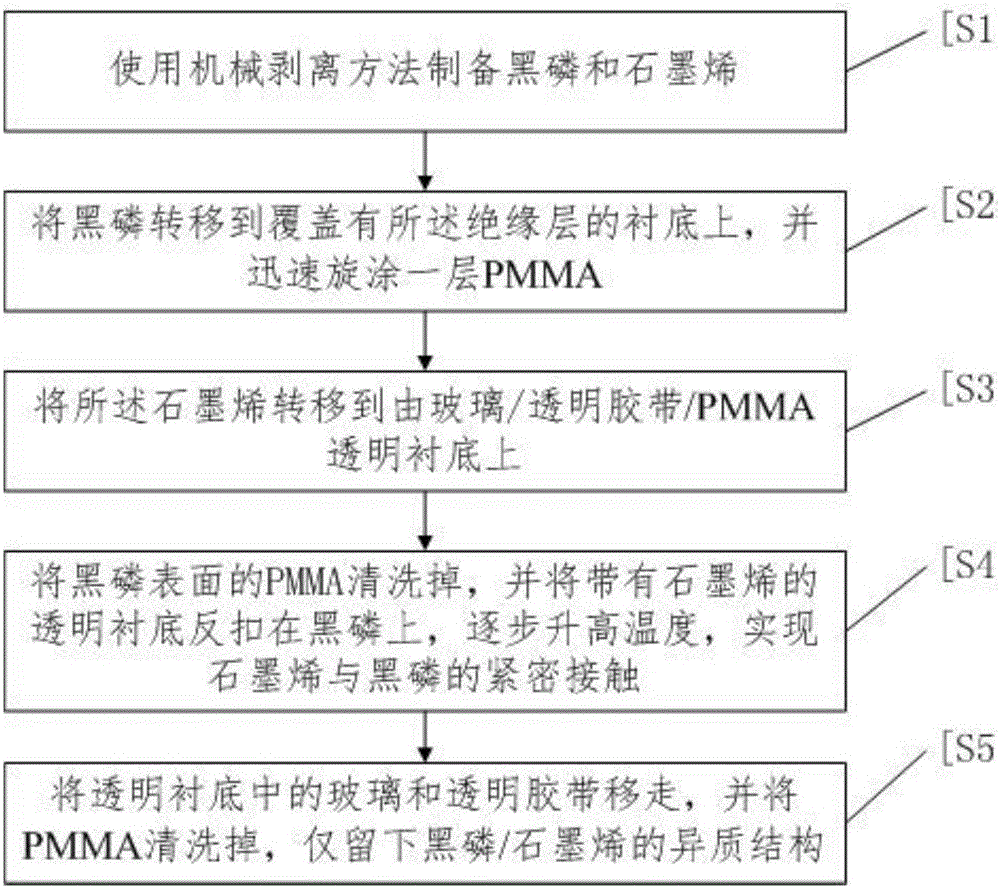

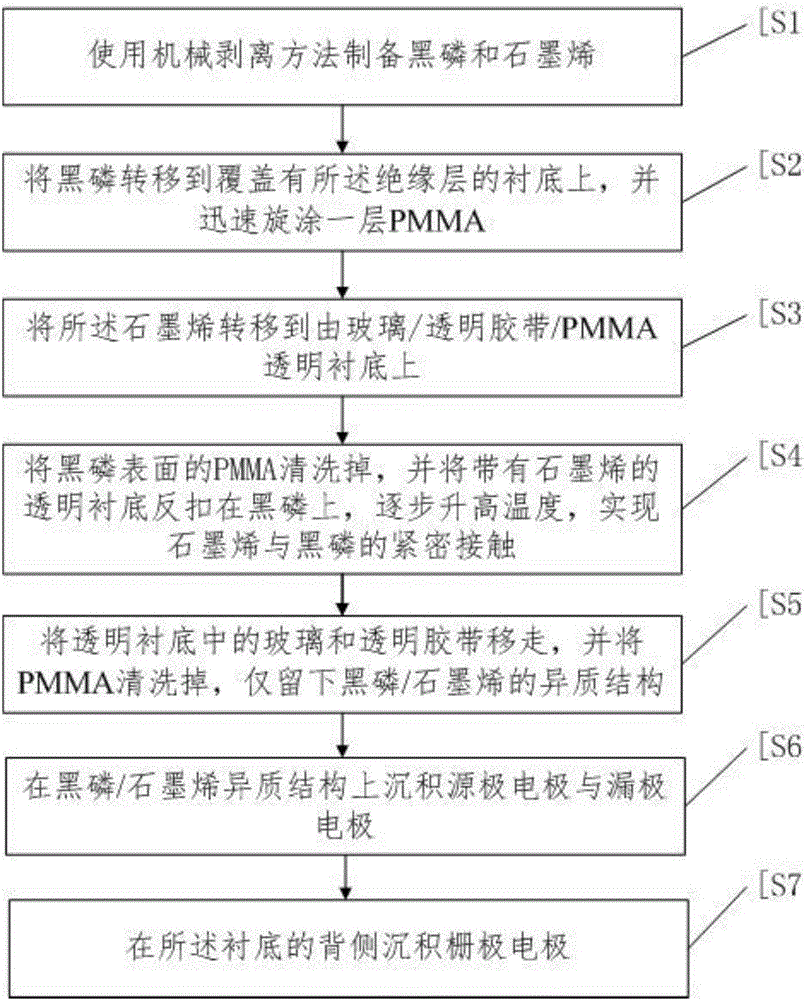

Black phosphorus/graphene heterostructure-based ultraviolet detector and production method thereof

ActiveCN105742394AImprove performanceImprove stabilityFinal product manufactureSemiconductor devicesUltraviolet detectorsBlack phosphorus

The invention discloses a black phosphorus / graphene heterostructure-based ultraviolet detector and a production method thereof. The detector comprises a substrate, an insulating layer and a black phosphorus / graphene heterostructure, wherein the insulating layer covers the substrate; and the black phosphorus / graphene heterostructure is formed by stacking black phosphorus and graphene and is located on the insulating layer. The disadvantages of the black phosphorus are compensated by the black phosphorus / graphene heterostructure; and the performance of the detector can be improved under the premise of not affecting the advantages of the black phosphorus.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Biological soil remediation agent and method for remediating soil

InactiveCN105618478AImprove the growing environmentEffective passivationContaminated soil reclamationSoil remediationBiology

The invention discloses a biological soil remediation agent which is prepared by mixing a solid passivator and a microbic solution according to the volume-weight ratio of 1:(15-30) (L / kg). The solid passivator comprises the following ingredients in percent by mass: 50-60 percent of clay carrier, 15-30 percent of diatomite, 10-15 percent of humic acid and 10-20 percent of charcoal. The microbic solution comprises a non-spore forming bacterium and streptomyces microflavus. The biological soil remediation agent can be used for remediating a soil ecosystem, improving the crop growth environment, effectively passivating heavy metal pollutants, such as lead, and reducing the availability for plants.

Owner:NANJING GAIA BIOLOGICAL ENG CO LTD

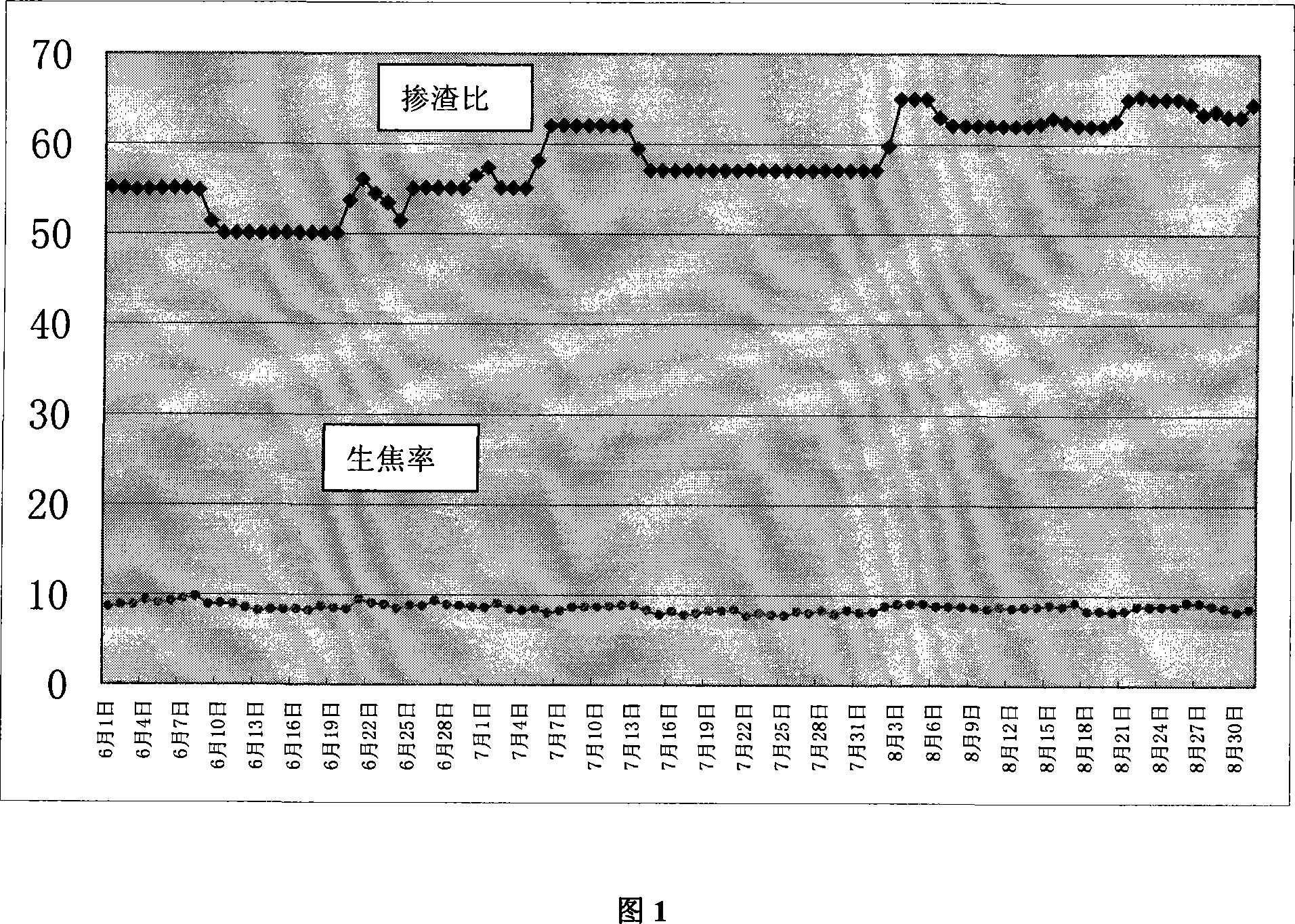

Assistant for catalytic cracking coking-inhibiting yield-increasing and preparing process thereof

InactiveCN101215476AHigh decomposition temperatureLow available metal contentCatalytic crackingSlagActive agent

The invention discloses catalytic cracking anti-coke income-increasing auxiliary agent which is used for catalytic cracking (FCC) devices and is prepared by following components according to the proportion by weight: disperser 5-15%, thermal cracking active agent 5-20%, free radical chain reaction depressor 5-25%, metal passivator 15-60% and dissolvent 25-65%. The invention is oil soluble auxiliary agent and has good compatibility with catalytic cracking mediums, the slag inserting rate of the FCC devices can be increased after the auxiliary agent is added, the light oil yield is increased, and the coke yielding rate is reduced.

Owner:金浦新材料股份有限公司

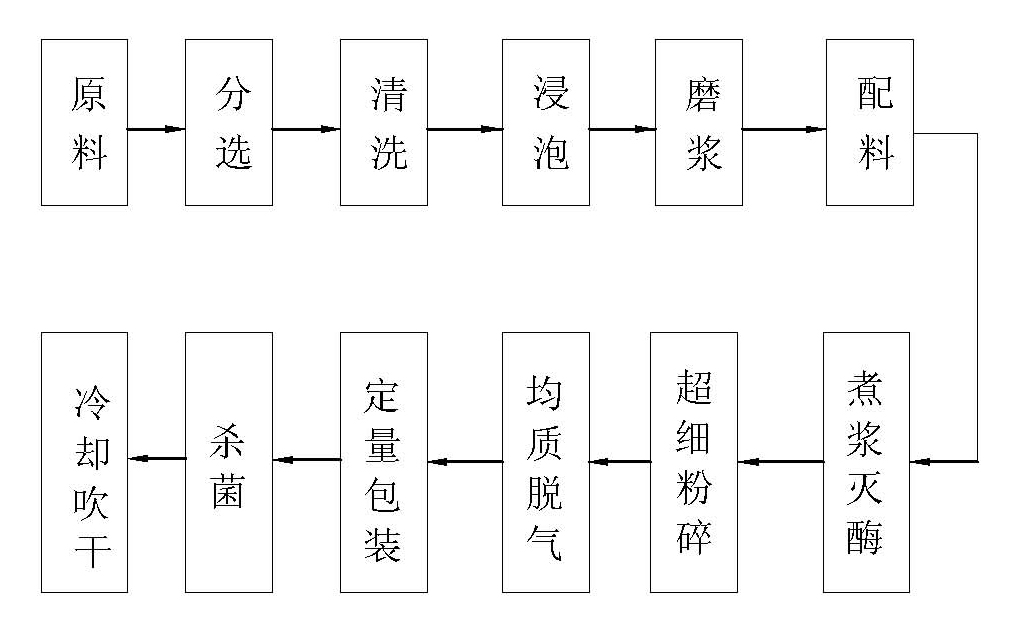

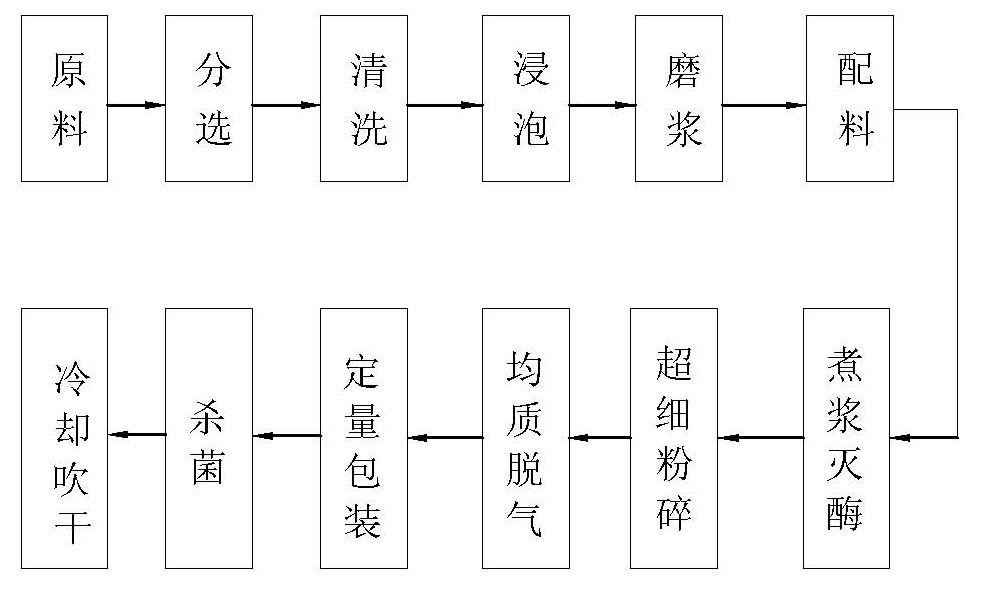

Method for preparing high-concentration soya-bean milk

InactiveCN102138591AWide range of particle sizesRich varietyMilk substitutesFood scienceHigh concentrationDietary fiber

The invention relates to a method for preparing high-concentration soya-bean milk. In the method for preparing the high-concentration soya-bean milk, the high-concentration soya-bean milk is prepared by sorting, cleaning and immersing soybeans, pulping, batching, stewing pulp, deactivating enzyme, performing superfine grinding, homogenizing, degassing, performing quantitative packaging, sterilizing, cooling, and blowing dry sequentially. Compared with the prior art, the method for preparing the high-concentration soya-bean milk has the advantages that: the high-concentration soya-bean milk has high nutritional value by adding abundant edible ingredients, and due to the full utilization of bean dregs, the content of dietary fibers in the soya-bean milk is improved. In addition, in the preparation process, bean immersing water is utilized effectively to realize the zero release of production and protect environment.

Owner:JOYOUNG CO LTD

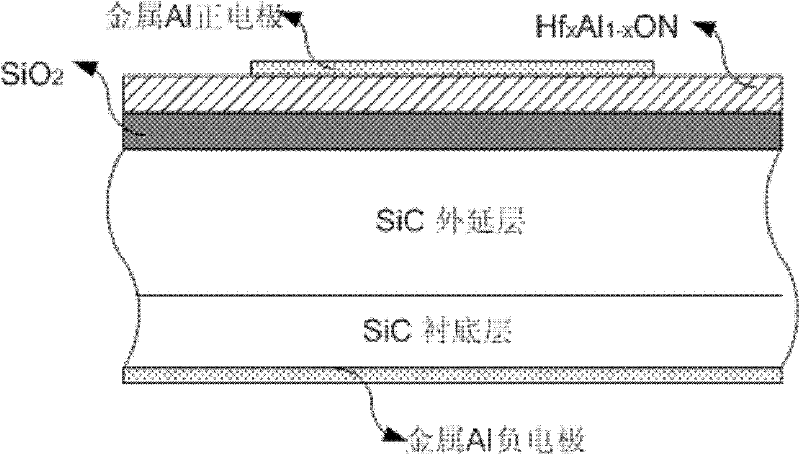

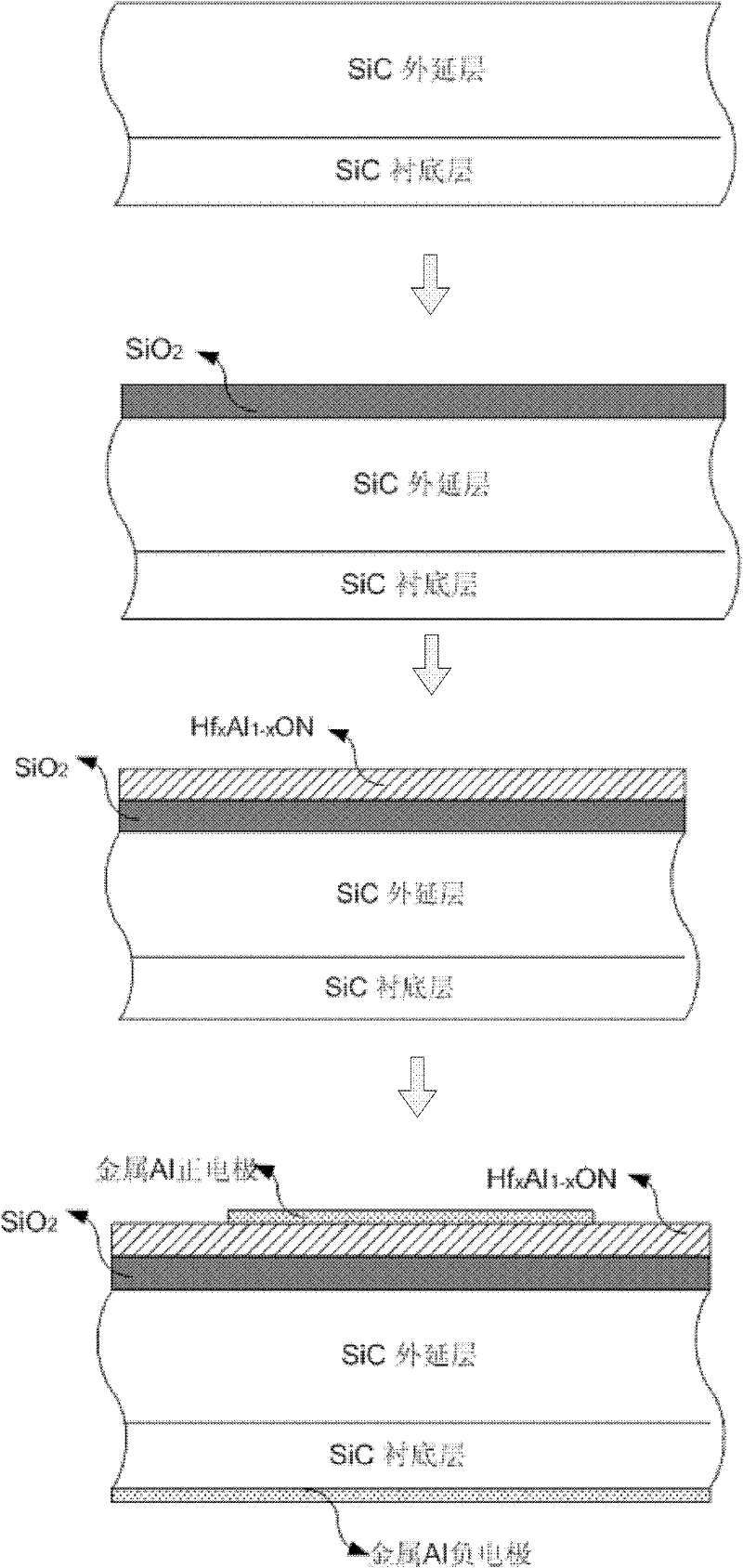

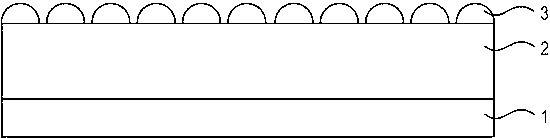

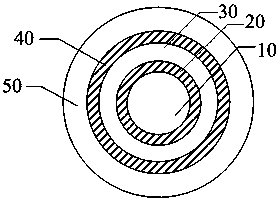

Silicon carbide (SiC) metal oxide semiconductor (MOS) capacitor with composite dielectric layer and manufacturing method for SiC MOS capacitor with composite dielectric layer

InactiveCN102244108ARelax interface stressReduce dangling keysSemiconductor/solid-state device manufacturingSemiconductor devicesOxide semiconductorSic substrate

The invention discloses a silicon carbide (SiC) metal oxide semiconductor (MOS) capacitor with a composite dielectric layer, and mainly solves the problem that the conventional SiC MOS capacitor has high interface-state density and weak voltage endurance. The structure of the capacitor is that: an N-type heavy doping SiC substrate layer, an N-type light doping SiC epitaxy layer, an SiO2 transition layer and an HfxAl1-xON dielectric layer are sequentially arranged from bottom to top; the back of the SiC substrate and the surface of the HfxAl1-xON are sputtered with metal Al to form positive and negative electrodes respectively; the N-type SiC epitaxy layer is 10 to 100 mu m thick, the doping concentration is 1*10<15> to 5*10<15>cm<-3>; the SiO2 transition layer is 1 to 15 mu m thick, and the HfxAl1-xON dielectric layer is 10 to 30 mu m thick. The SiO2 transition layer and the HfxAl1-xON layer form a composite dielectric layer structure so as to reduce the interface-state intensity of the dielectric layer and the SiC interface, reduce the current leakage of the dielectric layer, improve the voltage-resisting capability of the dielectric layer, and improve the reliability of the SiC MOS devices. The invention also discloses a manufacturing method for a SiC power integrated circuit and a SiC power isolation device.

Owner:XIDIAN UNIV

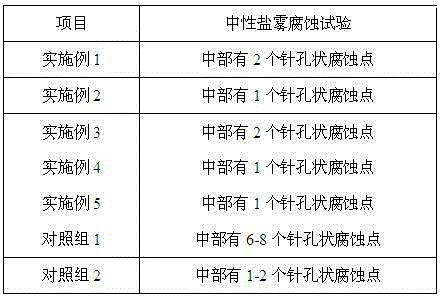

Chromium-free passivation solution for electro-galvanized steel plate and preparation method of passivation solution

ActiveCN104561974AEffective passivationImprove corrosion resistanceMetallic material coating processesChromium freeSodium metasilicate

The invention relates to a chromium-free passivation solution for an electro-galvanized steel plate and a preparation method of passivation solution and belongs to the technical field of metal surface treatment. The passivation solution is prepared from the following components in parts by mass: 8-20 parts of vanadate, 6-12 parts of molybdate, 8-15 parts of phosphoric acid, 3-8 parts of sodium bisulfite, 5-12 parts of phytic acid, 2-6 parts of diphenylolpropane, 2-5 parts of sodium metasilicate, 3-8 parts of ethanediol and 12-22 parts of deionized water. By the chromium-free passivation solution for the electro-galvanized steel plate, a stable complex passivation layer is formed on the surface of a galvanizing layer and has better corrosion resistance and oxidation resistance, especially corrosion resistance reaches the corrosion resistance of the passivation layer obtained by passivating the galvanizing layer through a conventional chromium-containing passivation solution and the chromium-free passivation solution is an ideal alternative product of the chromium-containing passivation solution.

Owner:唐山京华制管有限公司

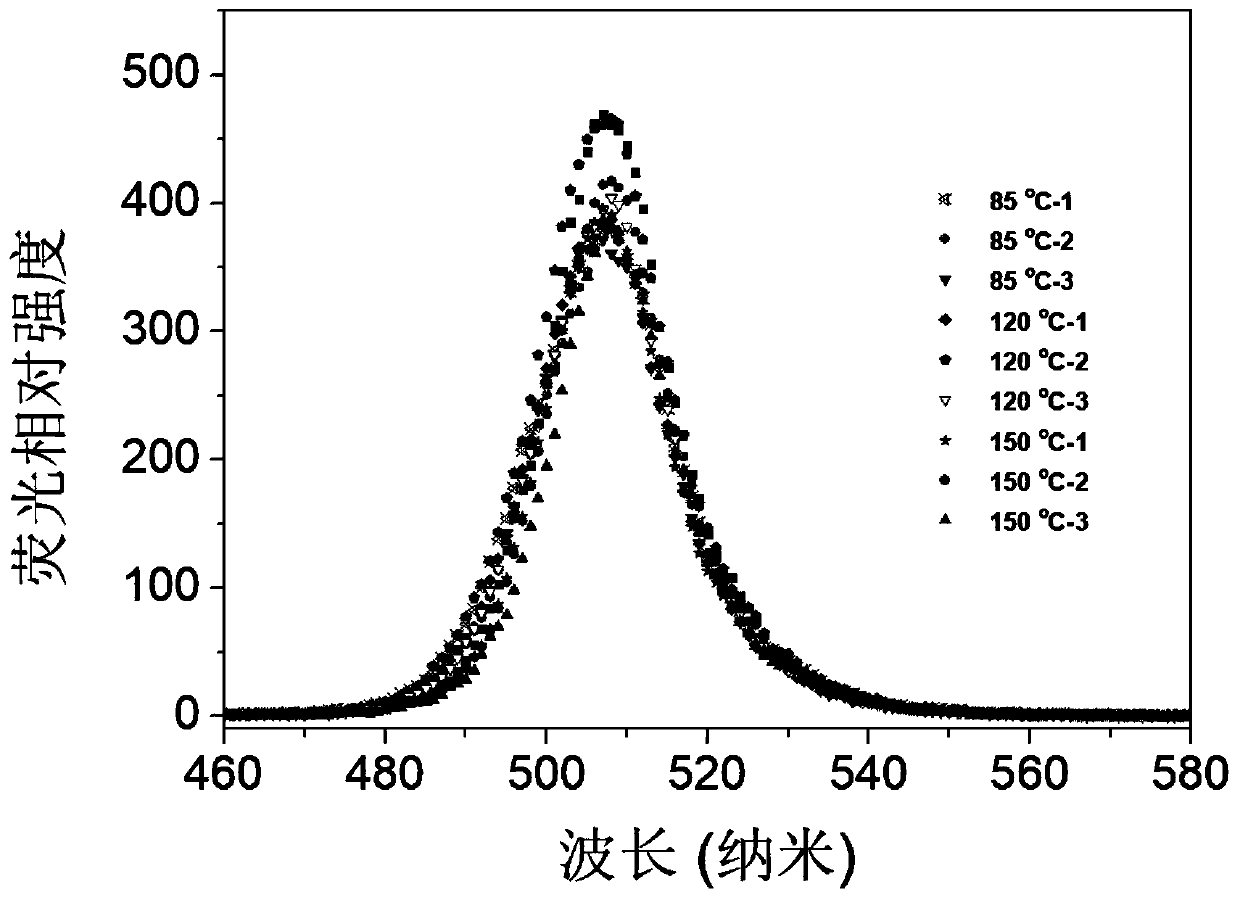

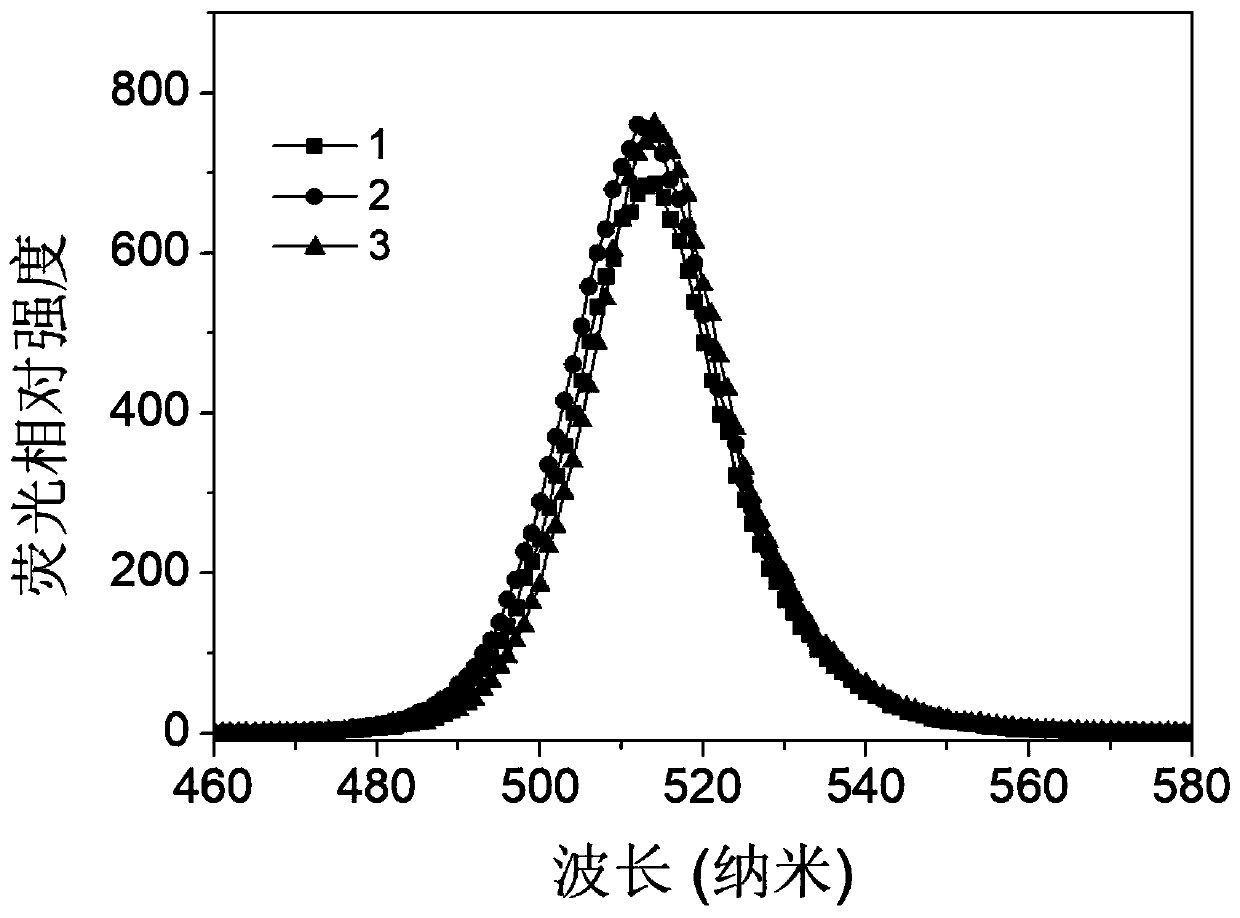

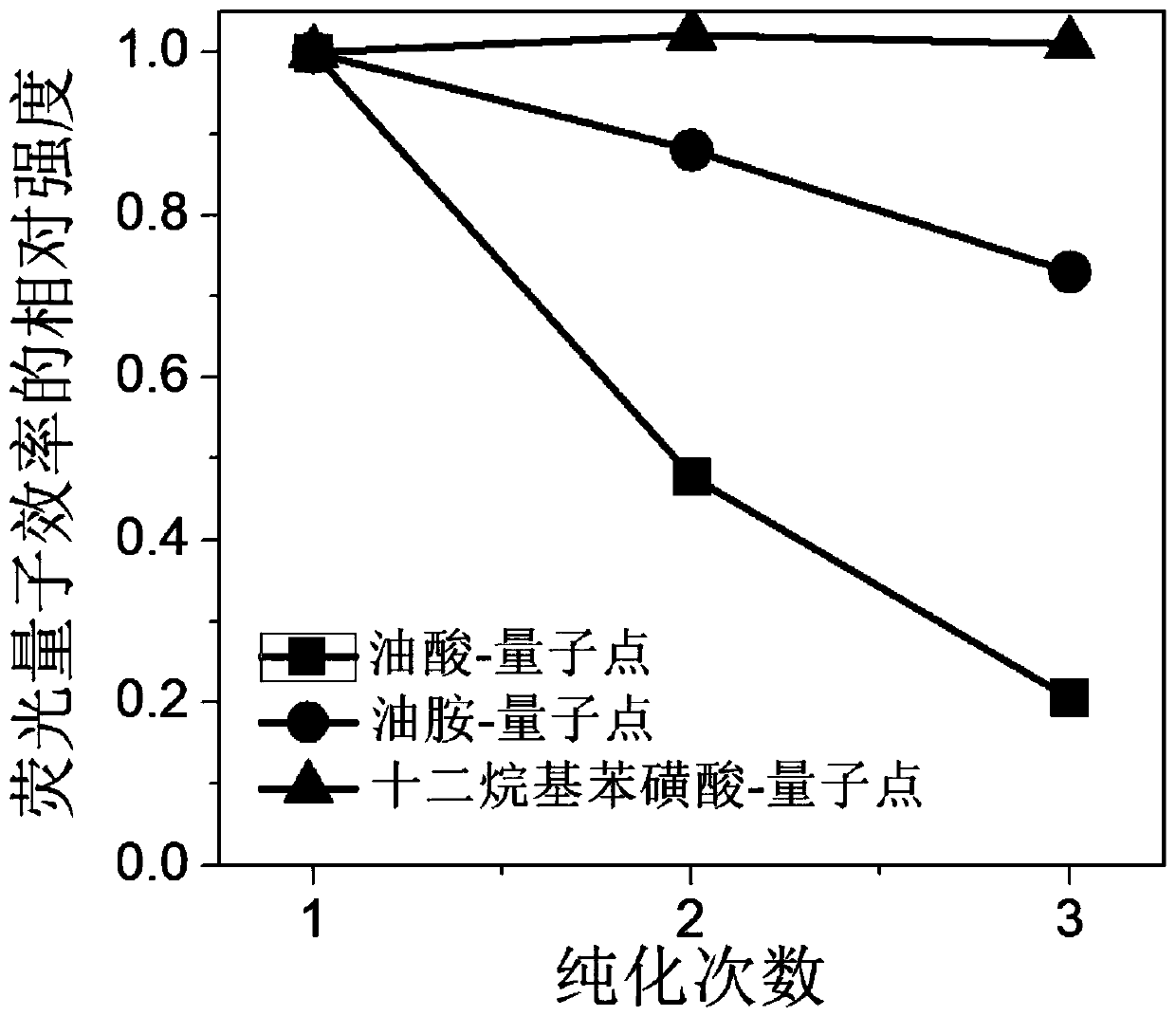

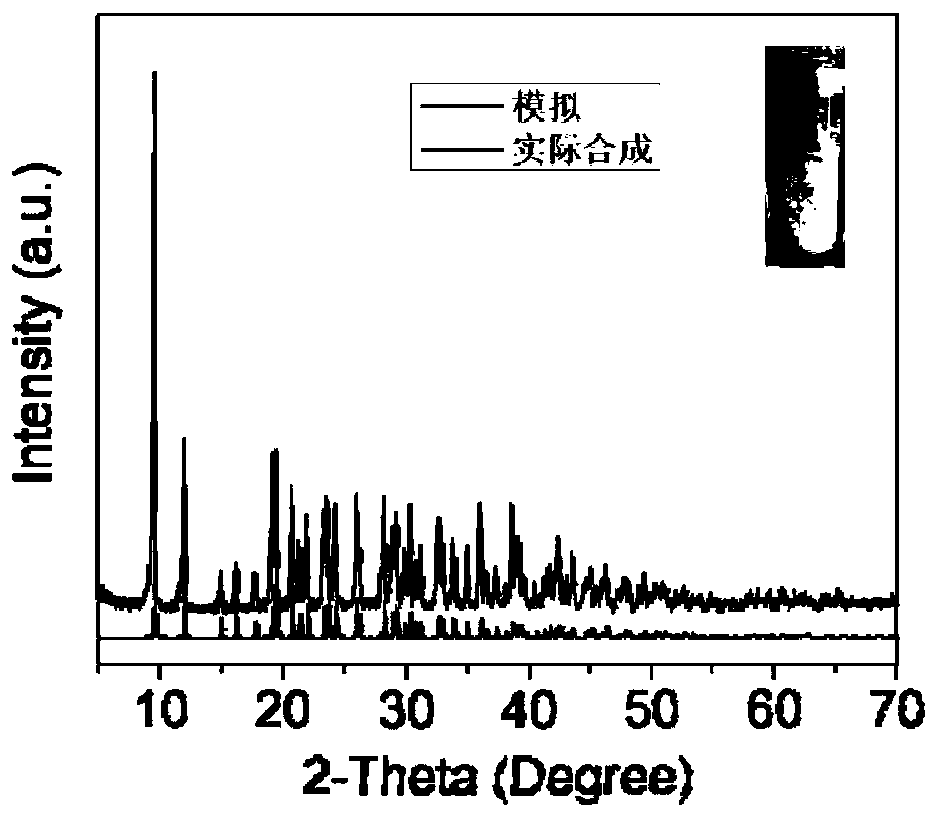

Method for synthesizing highly effective and stable all-inorganic halogen perovskite quantum dot scintillator with equivalent ligands

ActiveCN110157408AThe synthesis method is simple and efficientPassivation of bromine vacanciesMaterial nanotechnologyNanoopticsQuantum dotComputational chemistry

The invention discloses a method for synthesizing highly effective and stable all-inorganic halogen perovskite quantum dot scintillator with equivalent ligands, belonging to the technical field of preparing inorganic semiconductor luminescent materials. The method comprises the following steps: preparing tetra-n-octyl ammonium bromide precursor solution; stirring and heating cesium carbonate, leadacetate, octadecene and 1,4-dodecylbenzene sulfonic acid to react to form a transparent precursor solution under inert gas conditions; quickly adding the tetra-n-octyl ammonium bromide precursor solution into the transparent precursor solution for reaction to obtain a quantum dot solution; adding ethyl acetate to the quantum dot solution for purification, and dispersing the precipitate after centrifugation in toluene solution. The colloidal perovskite quantum dots are obtained by mixing toluene solution of PMMA and quantum dot solution. The quantum dots are coated onto the cleaned glass substrate to form a film. The inorganic halogen perovskite quantum dot prepared by the invention can still maintain high quantum efficiency and stability after being purified for many times.

Owner:NANJING UNIV OF SCI & TECH

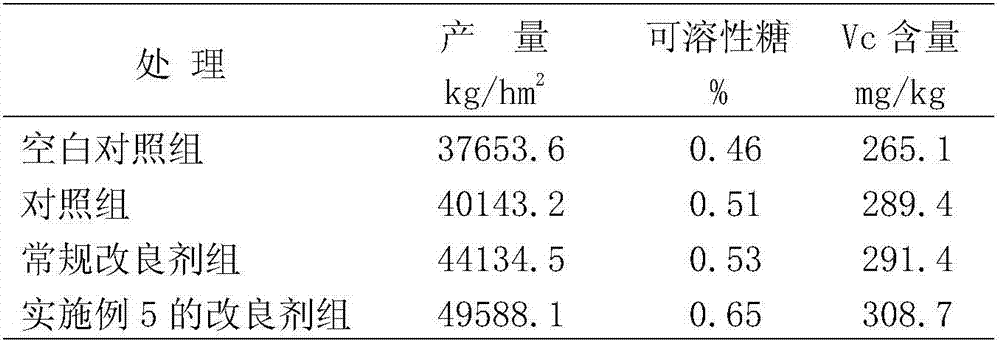

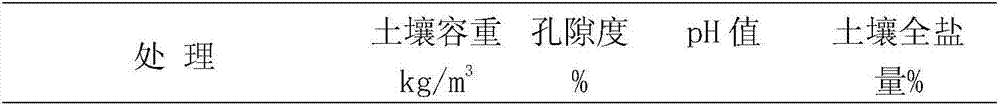

Soil improver prepared from waste materials of ecological fermentation bed and preparation method thereof

InactiveCN106986696AIncrease profitSimple structureBio-organic fraction processingMagnesium fertilisersSodium BentoniteSoil conditioner

The invention belongs to the technical field of ecological agriculture and in particular relates to a soil improver prepared from waste materials of an ecological fermentation bed as well as a preparation method of the soil improver. The soil improver prepared from waste materials of the ecological fermentation bed is prepared from the following components in parts by mass: 90-100 parts of waste materials escaping from the ecological fermentation bed, 20-30 parts of wheat straws, 20-30 parts of corncob powder, 10-15 parts of gulfweed, 10-15 parts of a chitin liquid, 3-4 parts of plant ash, 1-3 parts of shell powder, 3-5 parts of silkworm excrement, 5-10 parts of bentonite, 1-5 parts of seaweed soil, 3-5 parts of humic acid, 0-1 part of microelements and 1-3 parts of an enzymic preparation. The soil improver provided by the invention has the advantages that the utilization of the waste materials escaping from the ecological fermentation bed in a pig raising process is increased, the structure and fertility of soil are improved, and the soil improver is environmental-friendly and ecological and low in price.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI +1

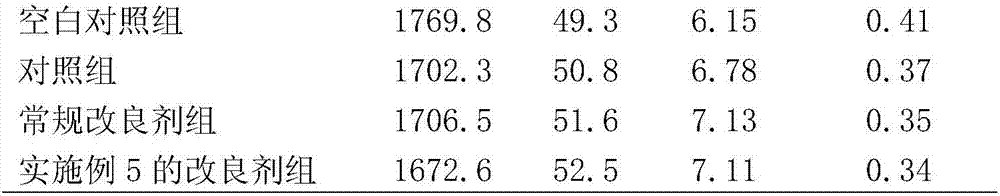

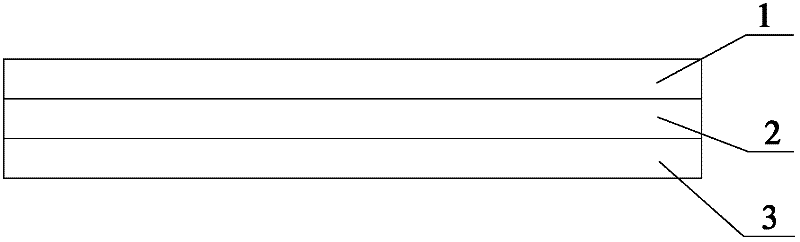

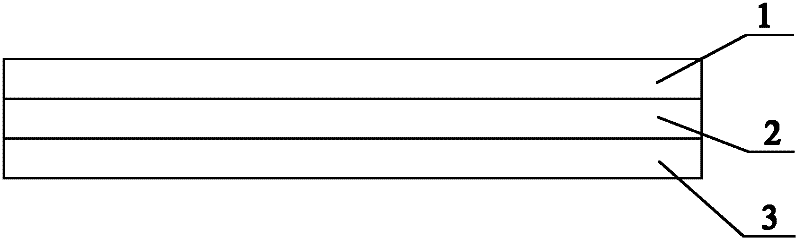

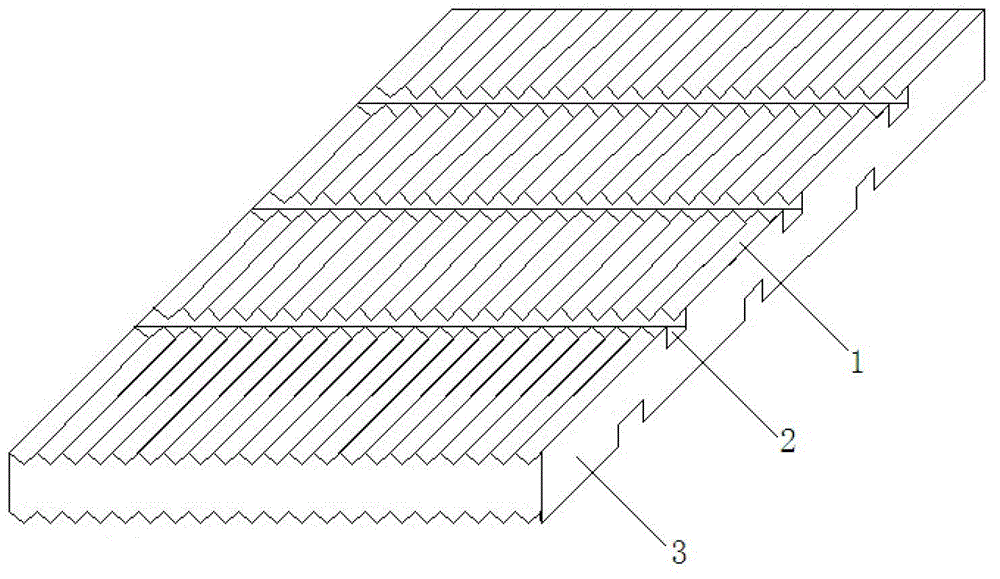

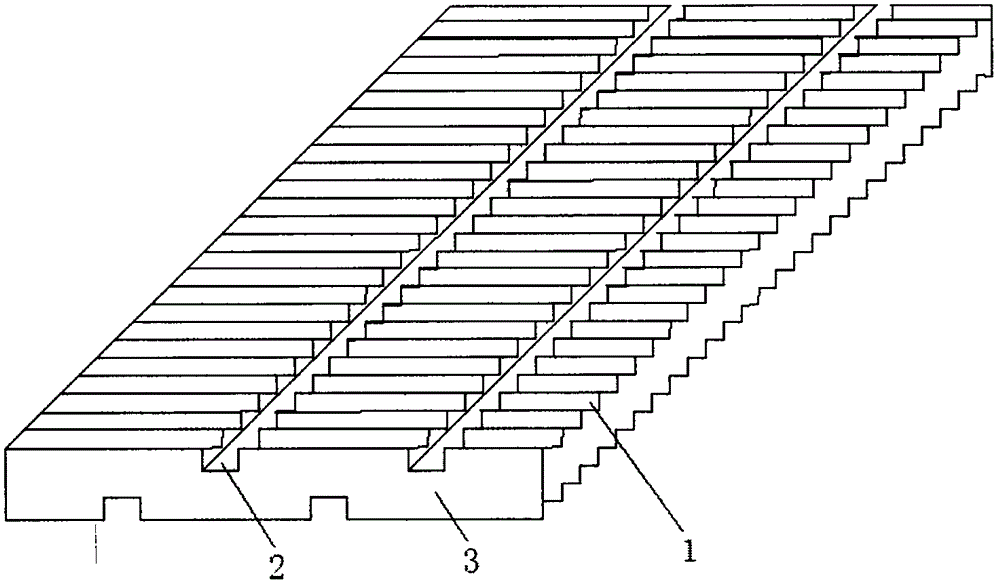

Method of manufacturing thin film cell and thin film cell

ActiveCN103258909AImprove efficiencyGood value for moneyFinal product manufacturePhotovoltaic energy generationGratingTrapping

The invention provides a method of manufacturing a thin film cell and the thin film cell. The method comprises the following steps: a cell layer is deposited on an electricity-conducting substrate; nanometer patterns required by nanometer grating preparation are formed on the cell layer; a nanometer grating is formed on the surface of the cell layer under the protection of the nanometer patterns as a mask; a p-n junction is formed on the surface of the nanometer grating of the cell layer; a top electrode is prepared on the surface of the p-n junction; a dielectric film is deposited on a window region of the cell layer so as to passivate the nanometer grating and form a complete stacked nanometer grating structure; a back electrode is prepared on one side, where the cell layer is not deposited, of the electricity-conducting substrate. The method of manufacturing the thin film cell and the thin film cell have the advantages that the dielectric layer is deposited on the surface of the nano-sized textured cell so as to effectively passivate the nonradiative recombination center on the surface of the cell without damaging the efficient light-trapping effect of the cell, and therefore the nanometer structure is really applied to solar cells, efficiency of the cell is improved, and the high cost performance of the cell is achieved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

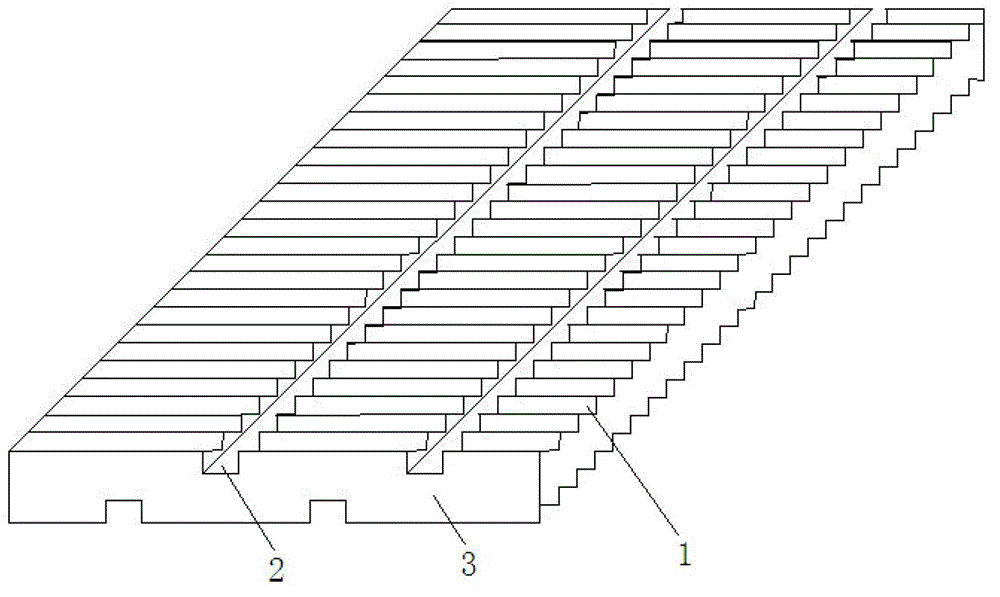

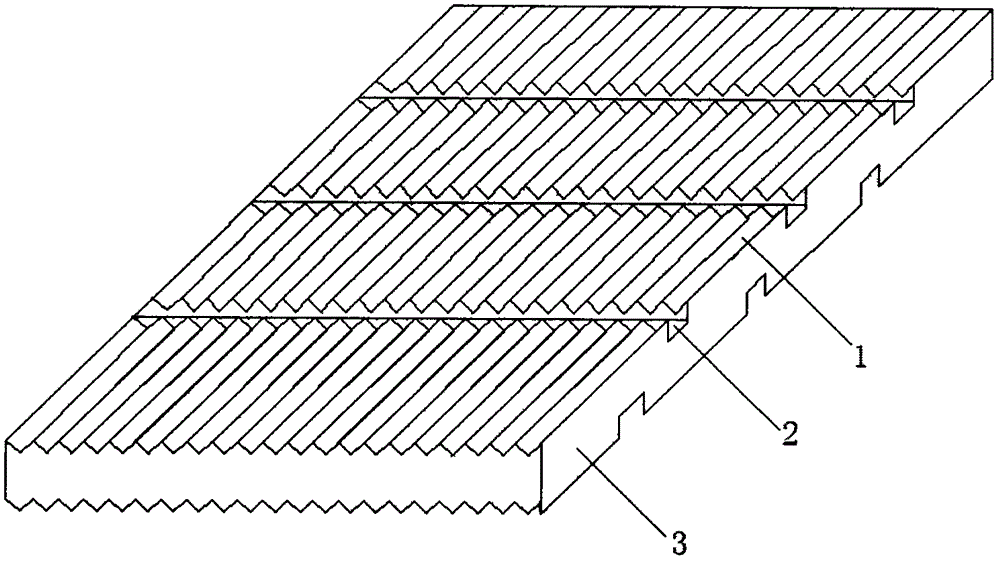

Positive dielectric film of sandwich structure suitable for RIE (reactive ion etching) texture and manufacturing method thereof

ActiveCN102339871AHigh positive charge densityReduce compound ratePhotovoltaic energy generationSemiconductor devicesDielectricInter layer

The invention relates to the technical field of crystalline silicon solar cell technologies, and in particular relates to a positive dielectric film of a sandwich structure suitable for an RIE (reactive ion etching) texture and a manufacturing method thereof. The positive dielectric film comprises a SiO2 (silicon dioxide) film at a bottom layer, wherein a SiNx (amorphous silicon nitride) film at an intermediate layer is covered on the surface of the SiO2 film at the bottom layer; and a SiO2 film at a surface layer is covered on the surface of the SiNx film at the intermediate layer. The manufacturing method of the positive dielectric film comprises the following steps of: 1, using a dry-oxygen oxidation method to grow a SiO2 film layer on a silicon texture; 2, adopting a PECVD (plasma enhanced chemical vapor deposition) method to deposit a SiNx film layer rich in silicon; and 3, adopting the PECVD method to deposit a SiO2 film. According to the invention, a crystalline silicon cell textured by RIE can be passivated effectively, the open-circuit voltage of the cell can be increased by 3-5mV, and the conversion efficiency of the cell can be increased by 0.2%-0.4%.

Owner:TRINA SOLAR CO LTD

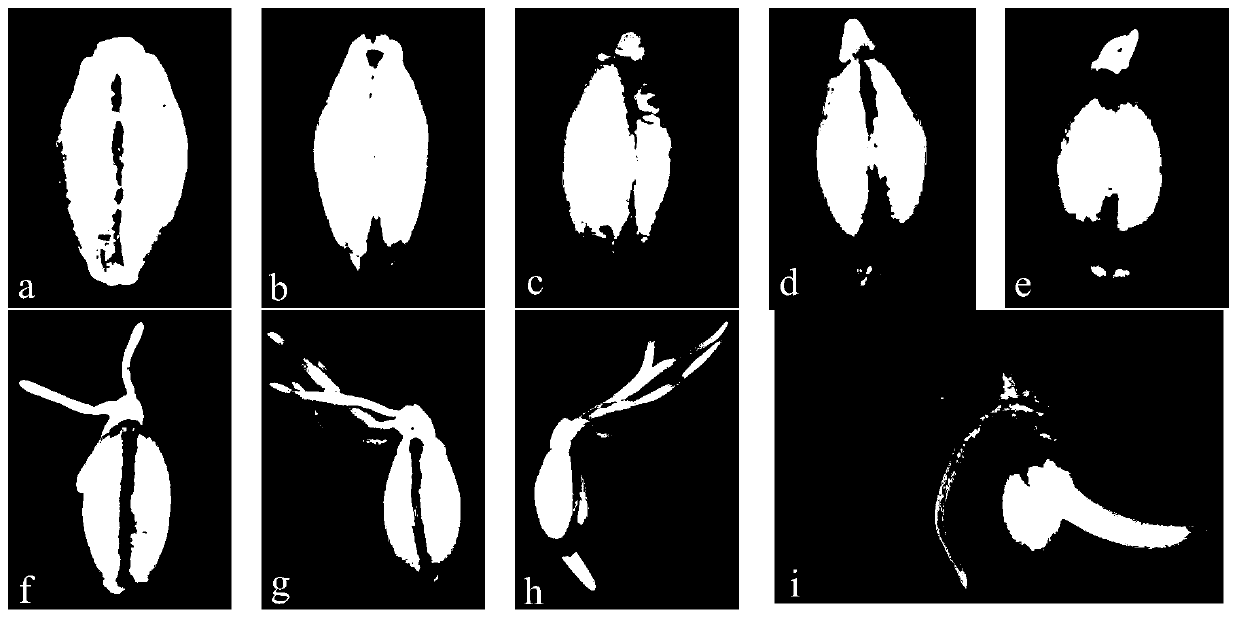

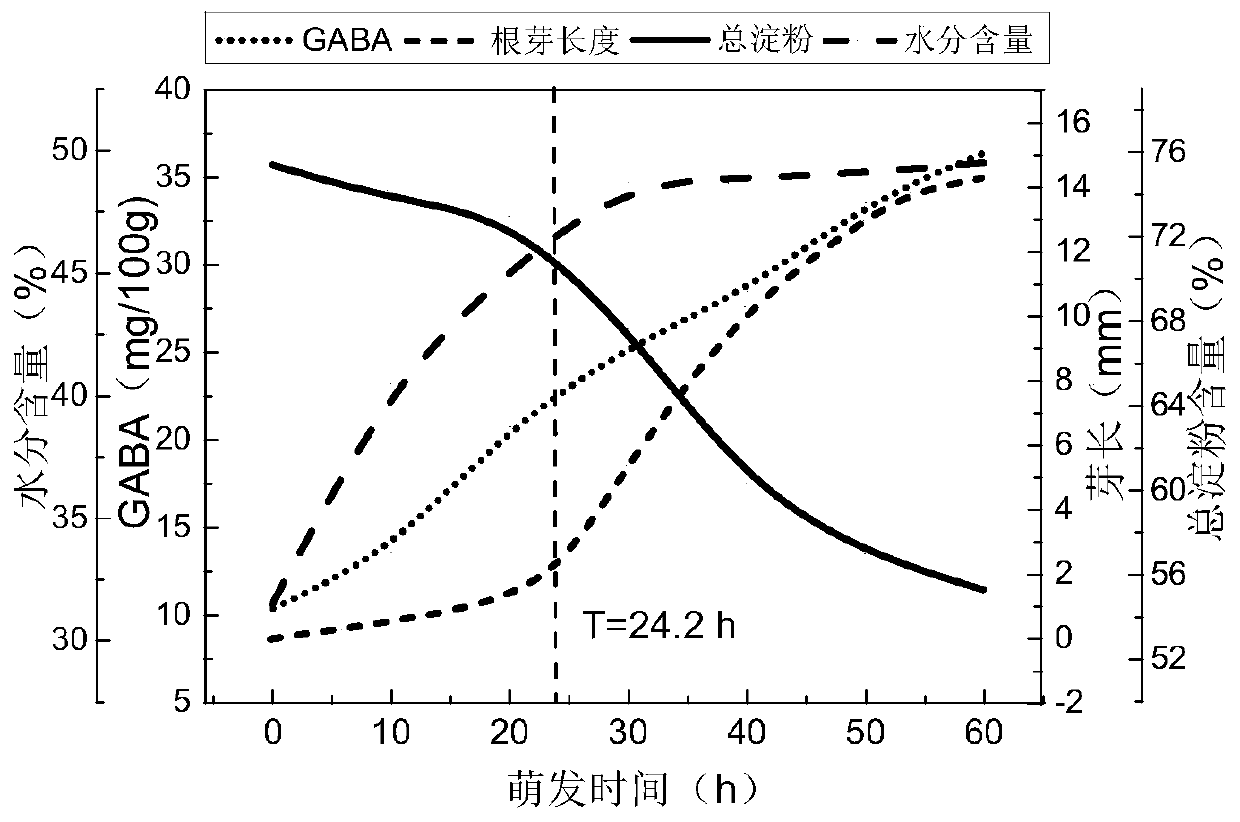

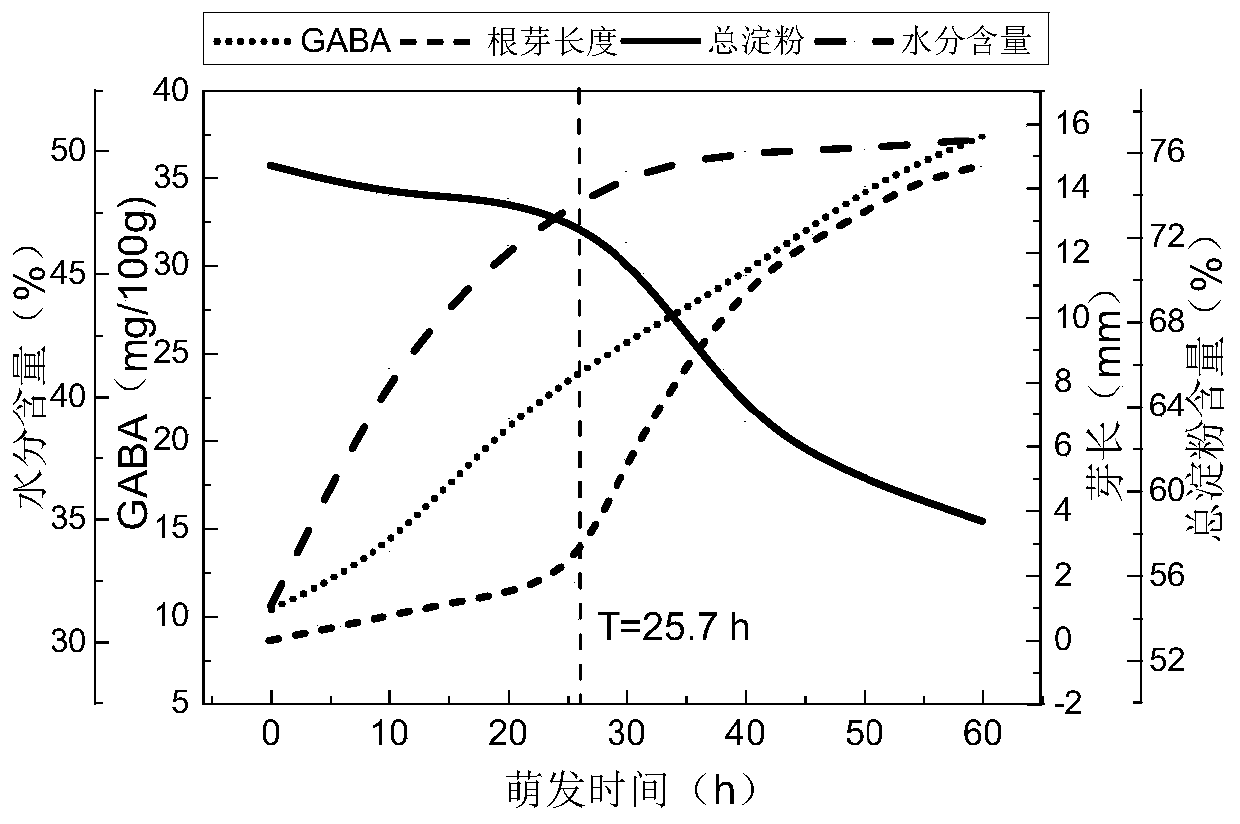

Production method for high yield ripened highland barley powder rich in gamma-aminobutyric acid

ActiveCN110089684AIncrease profitReduce lossesDough/pre-mixesFood thermal treatmentGamma-Aminobutyric acidSterile water

The invention discloses a production method for high yield ripened highland barley powder rich in gamma-aminobutyric acid. The method includes the following steps: placing highland barley seeds into agermination tank after pretreatment, and using sterile water to perform immersing for 3-4 h; pouring the sterile water in the germination tank, and performing germination culture for 24.0-26.8 h so that the seeds can be obtained; performing hot air baking and ripening treatment after the draining of the obtained highland barley seeds, and performing milling to obtain powder. The method studies the change rules of powder yield during the germination of the highland barley seeds, and selects appropriate germination conditions to perform follow-up ripening processing on the germination seeds; and the GABA enrichment ratio of the prepared highland barley ripened powder is 24-38%, and the powder yield is more than 80%, so that the loss of the powder during powder making can be greatly reduced,and the utilization rates of the seeds can be enhanced.

Owner:SOUTH CHINA UNIV OF TECH

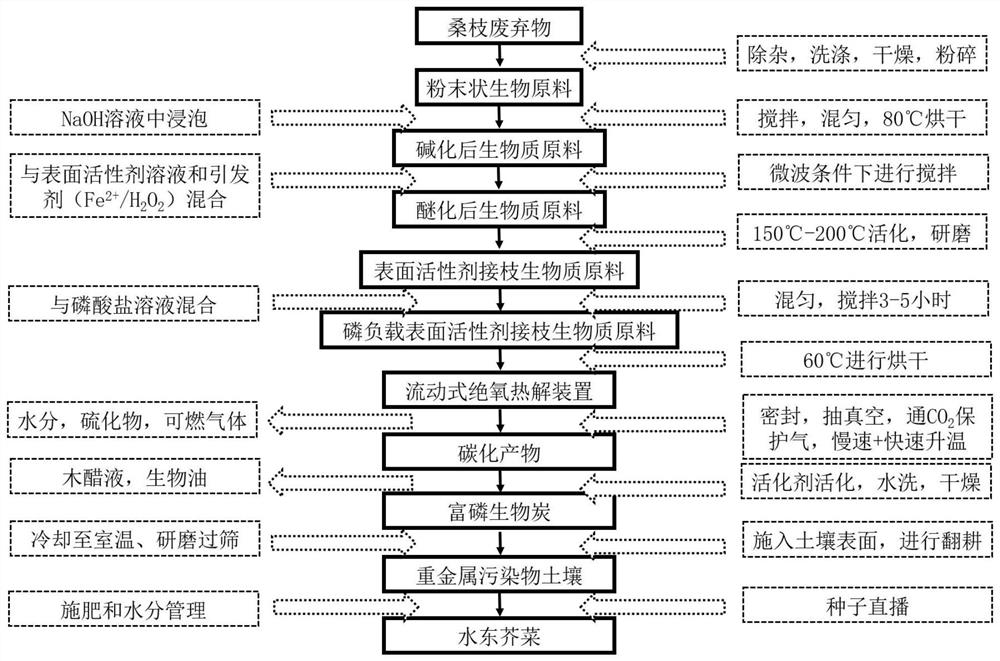

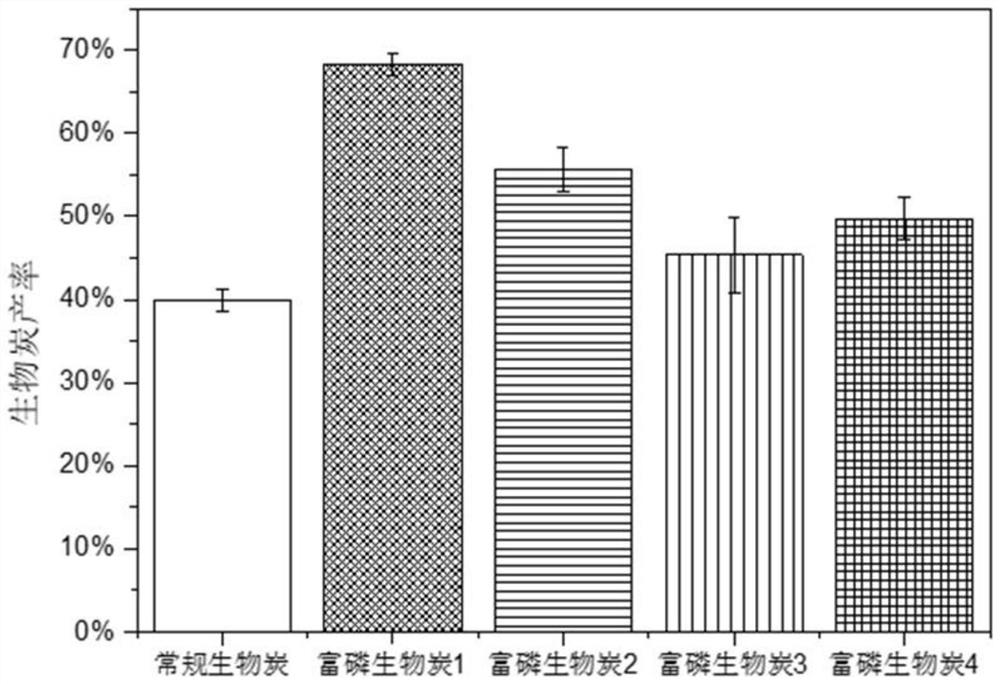

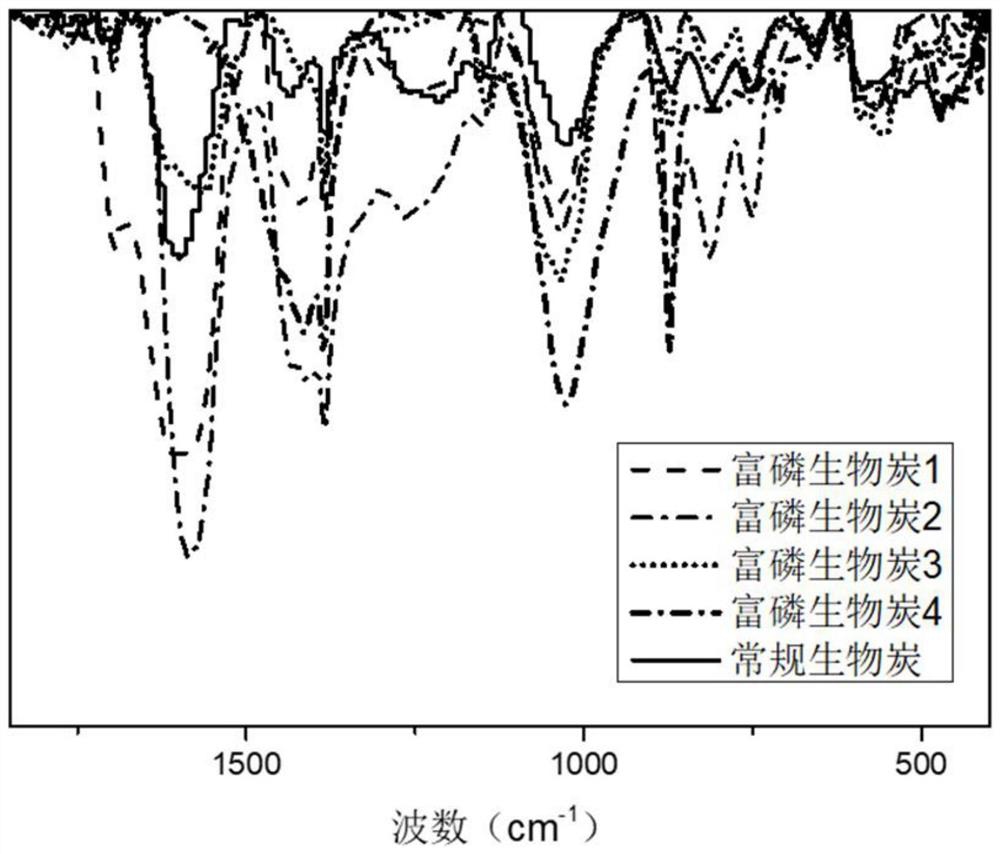

Preparation and application of phosphorus-rich biochar based on mulberry branch waste

ActiveCN113293001AFast pyrolysisReduce pollutionAgriculture tools and machinesOther chemical processesSoil scienceSoil remediation

The invention belongs to the technical field of agricultural waste recycling and resourceful utilization and soil improvement, and particularly relates to preparation and application of phosphorus-rich biochar based on mulberry branch waste. Phosphorus-rich biochar is prepared through continuous pyrolysis, and the prepared phosphorus-rich biochar is applied to pollution treatment of farmland soil heavy metal; the phosphorus-rich biochar can effectively passivate soil heavy metals, inhibits the heavy metal absorption and accumulation process of crops, promotes the nutrition supply of soil to crops, and can be used as an efficient carbon-based soil conditioner for soil remediation. A large amount of mulberry branch waste can be reduced, and effective resource utilization of the mulberry branch waste can be realized.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

Food fresh-keeping method by using biological bacteriostatic agent in combination with ultra high pressure-assisted thermal treatment

ActiveCN103750497AInhibition of germinationEffective passivationFood preservationSpore germinationUltra high pressure

The invention belongs to the field of food preservation and fresh keeping and in particular relates to a food fresh-keeping method by using a biological bacteriostatic agent in combination with ultra high pressure-assisted thermal treatment. The food fresh-keeping method comprises the following steps: (1) carrying out thermal treatment on low acid food; (2) adding the biological bacteriostatic agent to the low acid food subjected to thermal treatment, wherein the biological bacteriostatic agent comprises the following components of 0.1-0.5g / kg of nisin, 0.1-0.5g / kg of chitosan, 0.1-0.5g / kg of muramidase, 0.1-0.4g / kg of epsilon-polylysine, 0.2-1g / kg of allicin and 20-250g / kg of sodium chloride; and (3) carrying out temperature and ultrahigh pressure treatment. By using the food fresh-keeping method, bacterial spores in the low acid food can be effectively passivated and spore germination can be inhibited at 4 DEG C when the low acid food is stored within a shelf life of 20 days, and meanwhile, the losses of textures, flavor, nutrition and color caused by a conventional high temperature and high pressure food sterilization method can be avoided; and the food fresh-keeping method is especially advantageous to the low acid food with pH not less than 4.5.

Owner:INST AGRO PROD PROCESSING ANHUI ACADEMY AGRI SCI

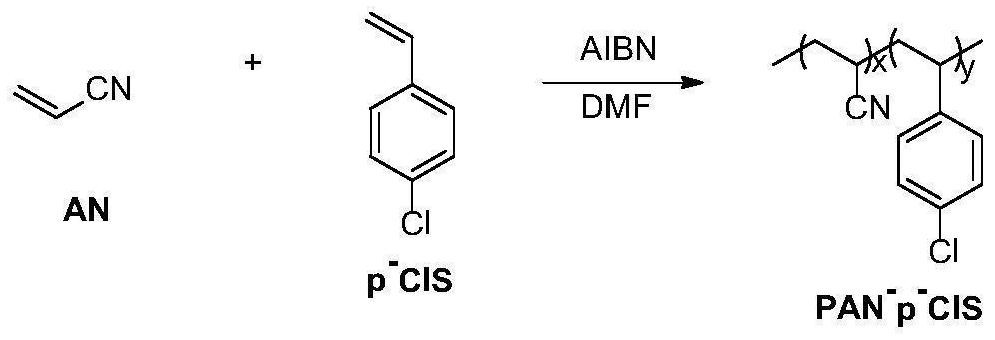

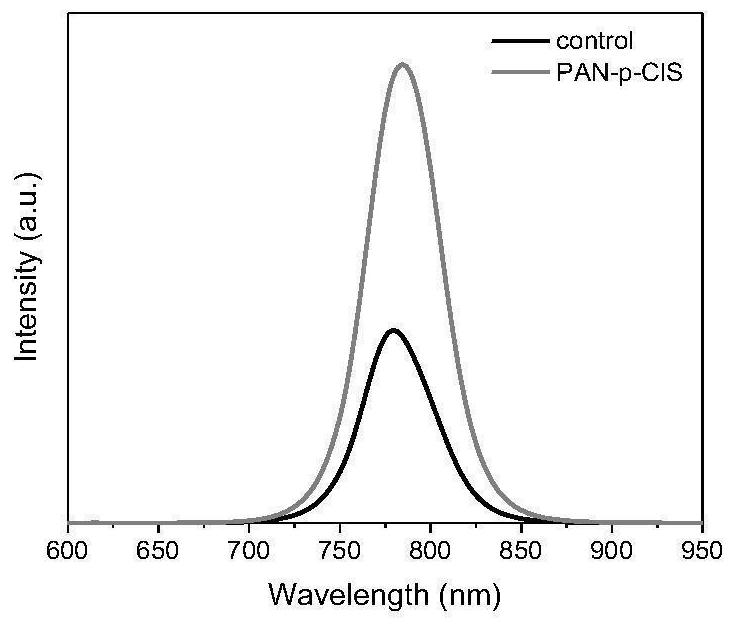

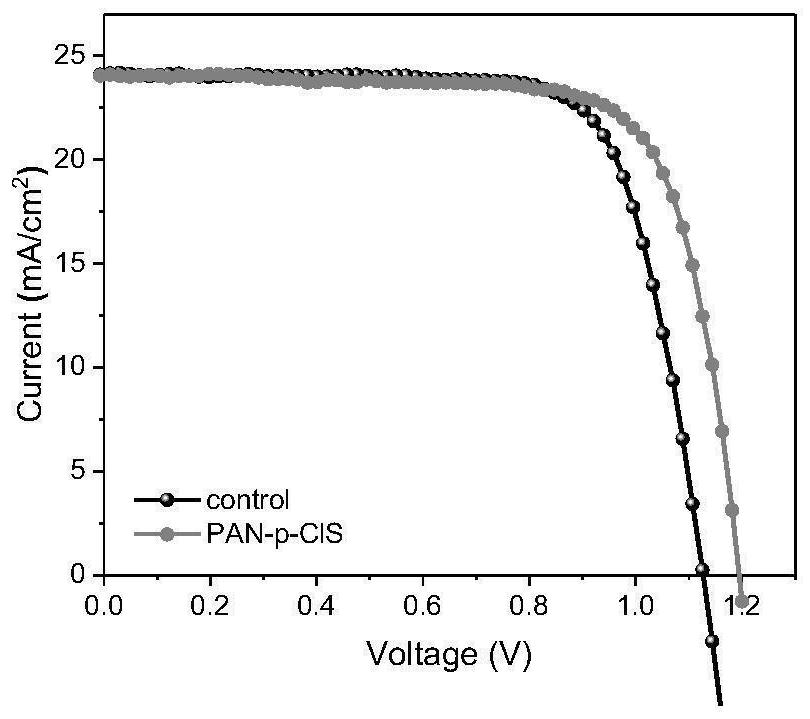

Method for improving open-circuit voltage of organic-inorganic hybrid perovskite solar cell

ActiveCN112635679AEffective passivationReduce defect densitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellSide chain

The invention belongs to a method for improving material performance, and particularly relates to a method for improving an open-circuit voltage of an organic-inorganic hybrid perovskite solar cell. The method comprises the following steps of adding a bifunctional polymer into the organic-inorganic hybrid perovskite precursor; or forming a thin layer containing a bifunctional polymer on the surface of a formed organic-inorganic hybrid perovskite thin film, wherein the bifunctional polymer is the bifunctional polymer of which the side chain contains groups capable of passivating positive electricity defects and negative electricity defects at the same time. By introducing the bifunctional polymer into the perovskite thin film, positive electricity and negative electricity grain boundary defects in the perovskite polycrystalline thin film can be effectively passivated at the same time, a deep energy level defect concentration is reduced, a carrier recombination probability is decreased, and the open-circuit voltage of a perovskite solar cell device is improved. And adopted materials are low in cost and easy to realize in process.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

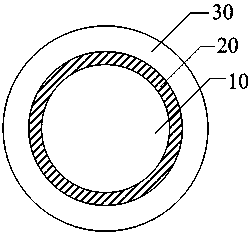

Quantum dot and preparation method thereof

InactiveCN109929552AEffective passivationReduce lattice mismatchMaterial nanotechnologySolid-state devicesLattice mismatchQuantum dot

The invention discloses a quantum dot and a preparation method thereof, wherein the quantum dot comprises a quantum dot core, a metal layer covering the quantum dot core, and a semiconductor shell layer covering the metal layer, and the metal element in the metal layer is one or a plurality of elements selected from Zn, Hg, Al, Ga and In. According to the present invention, the metal layer can bebonded to the quantum dot core by using the ligand on the surface of the quantum dot core as the linker so as to promote the surface activation of the quantum dot core, such that the further growth reaction of the semiconductor shell layer outside the quantum dot can be easily performed; and through the crystal structure formed by bonding the metal atom in the metal layer and the quantum dot core,the surface of the quantum dot core can be effectively passivated, the surface defect can be reduced, and the lattice mismatch between the core and the shell can be reduced, such that the light emitting efficiency and the size uniformity of the quantum dot material can be enhanced.

Owner:TCL CORPORATION

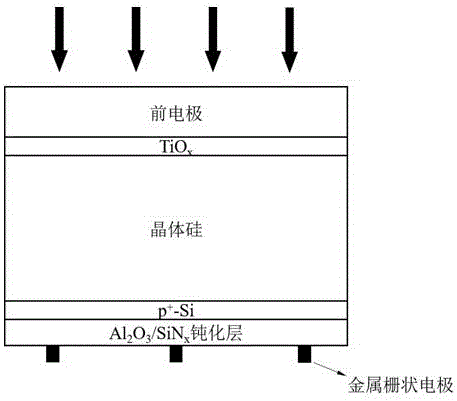

Si/TiOx heterojunction-based double-sided crystalline silicon solar cell

ActiveCN106449845AIncrease the open circuit voltageEffective passivationPhotovoltaic energy generationSemiconductor devicesHeterojunctionGenerating capacity

The invention provides an Si / TiOx heterojunction-based double-sided crystalline silicon solar cell, which comprises a front electrode, a TiOx layer, a crystalline silicon absorption layer, a p-type crystalline silicon heavily doped layer, a passivation layer and a metal gate electrode, wherein the structure of the Si / TiOx heterojunction-based double-sided crystalline silicon solar cell is the front electrode, the TiOx layer, the crystalline silicon absorption layer, the p-type crystalline silicon heavily doped layer, the passivation layer and the metal gate electrode in sequence from a light facing surface; and an n-type doped TiOx and crystalline silicon are utilized by the light facing surface to form a heterojunction while a traditional crystalline silicon preparation technology based on diffusion is utilized by a back surface. The TiOx can well passivate the surface of a silicon wafer, and the TiOx and silicon form a good heterojunction, so that improvement of the open-circuit voltage and the conversion efficiency of the heterojunction cell is facilitated. Existing crystalline silicon solar cell production equipment can be fully utilized by a traditional crystalline silicon preparation technology of the back surface. The sunlight can be fully utilized by the double-sided structure; the actual generating capacity is increased; and the photovoltaic power generation cost is reduced.

Owner:NANCHANG UNIV

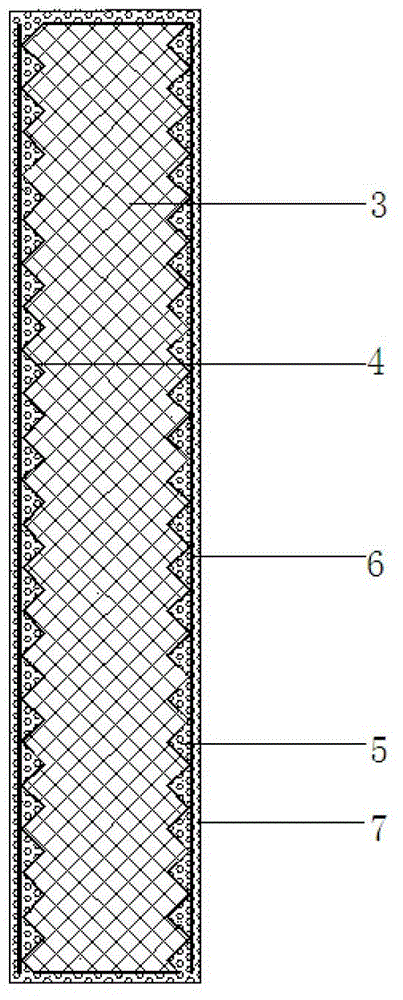

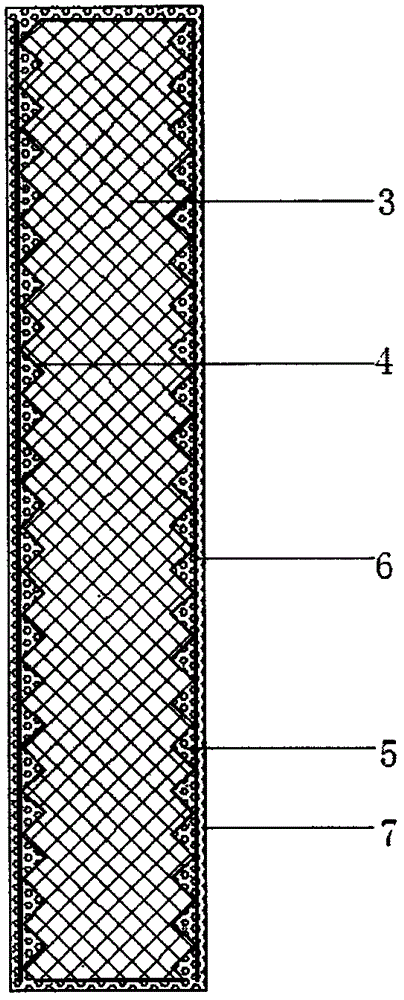

Inorganic light insulating mortar composite XPS (Extruded Polystyrene) insulating board and preparation method thereof

InactiveCN102747790AEffective passivationGood interface technologySynthetic resin layered productsHeat proofingPolystyreneFire resistance

The invention discloses an inorganic light insulating mortar composite XPS (Extruded Polystyrene) insulating board and a preparation method thereof. The composite XPS insulating board comprises an XPS substrate, an interface agent layer and an inorganic light insulating mortar layer, wherein the front surface and the back surface of the XPS substrate are provided with grooves; the inorganic light insulating mortar layer is made of composite gridding cloth; the interface agent layer is arranged on the XPS substrate with the grooves on the front surface and the back surface; and the inorganic light insulating mortar layer made of composite gridding cloth is arranged on the interface agent layer. Compared with the prior art, the prepared A-grade fireproof insulating board is uniform in thermoengineering property, not only has high-efficiency insulating effect, but also has good fire resistance and can be widely used in building wall bodies as the insulating board.

Owner:上海英硕聚合材料股份有限公司

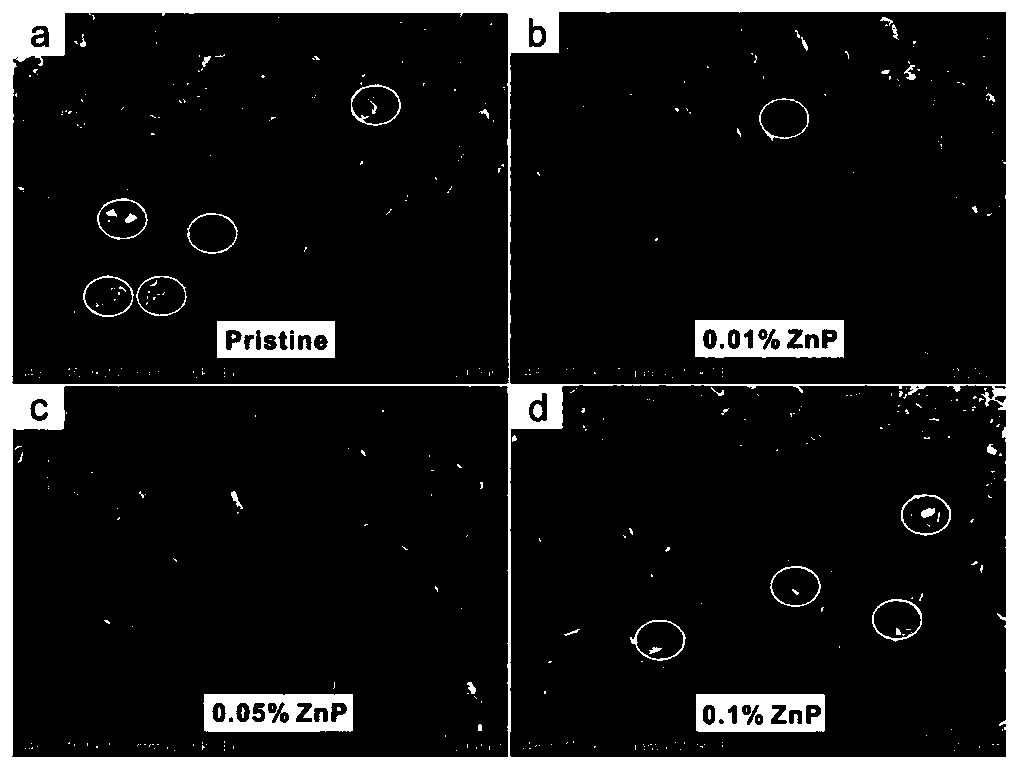

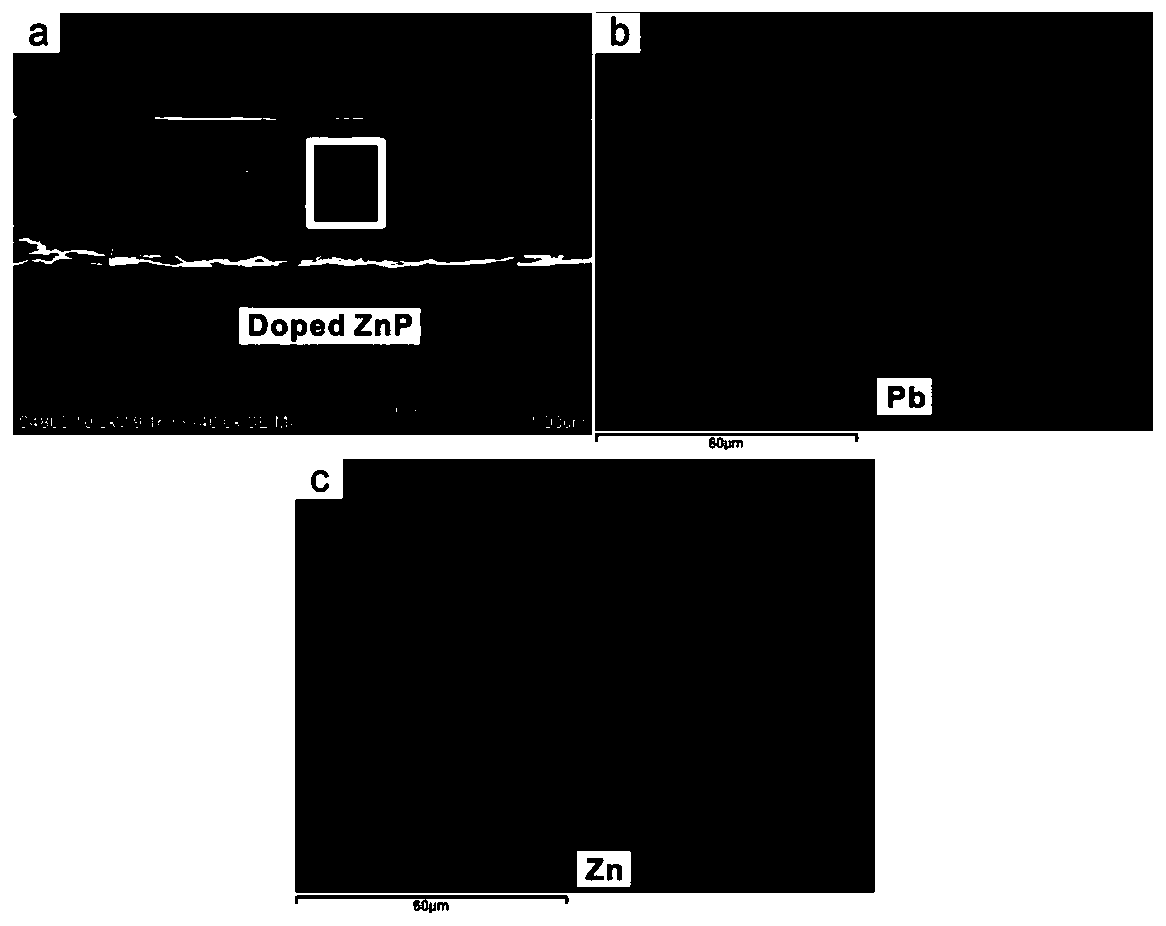

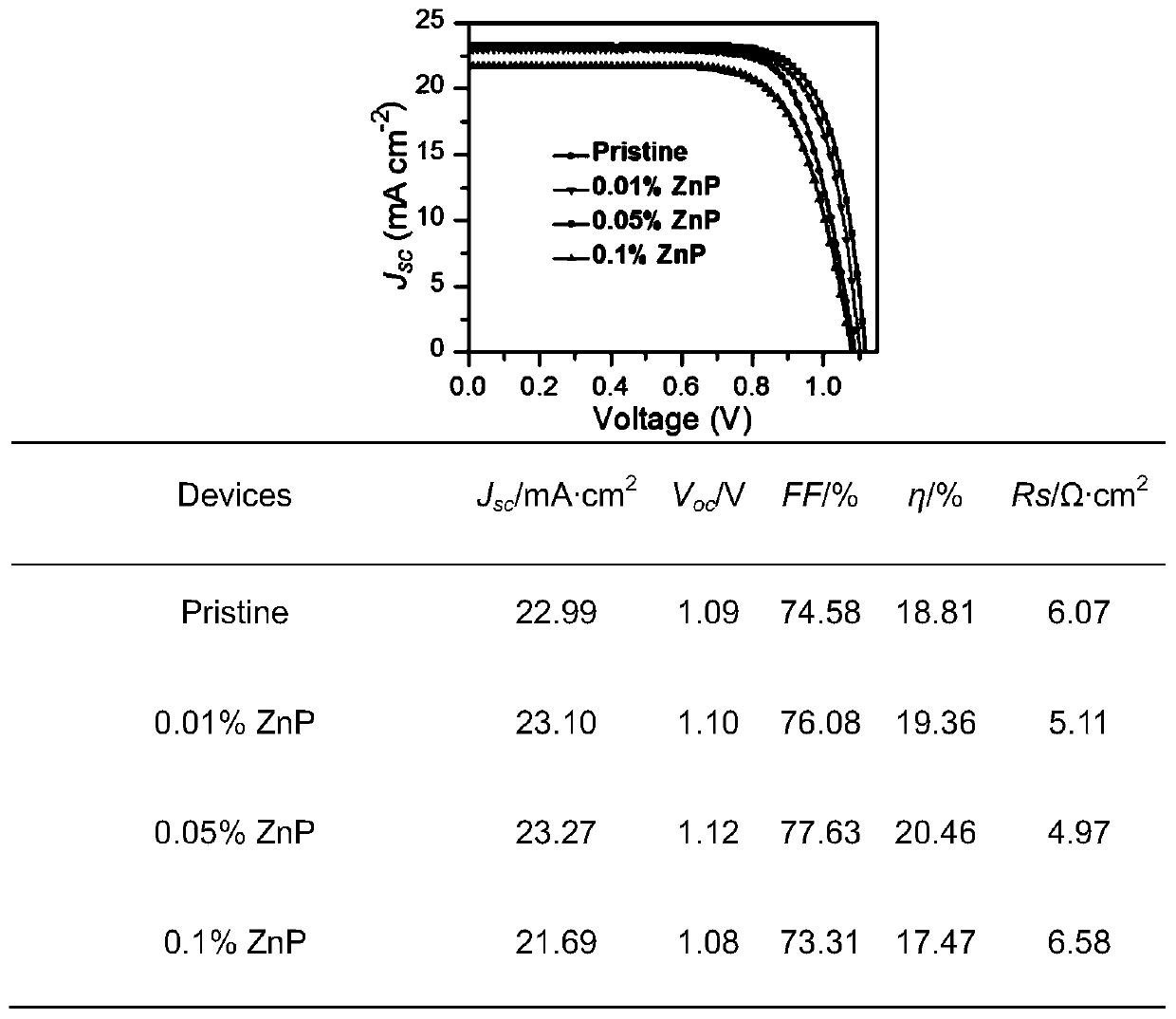

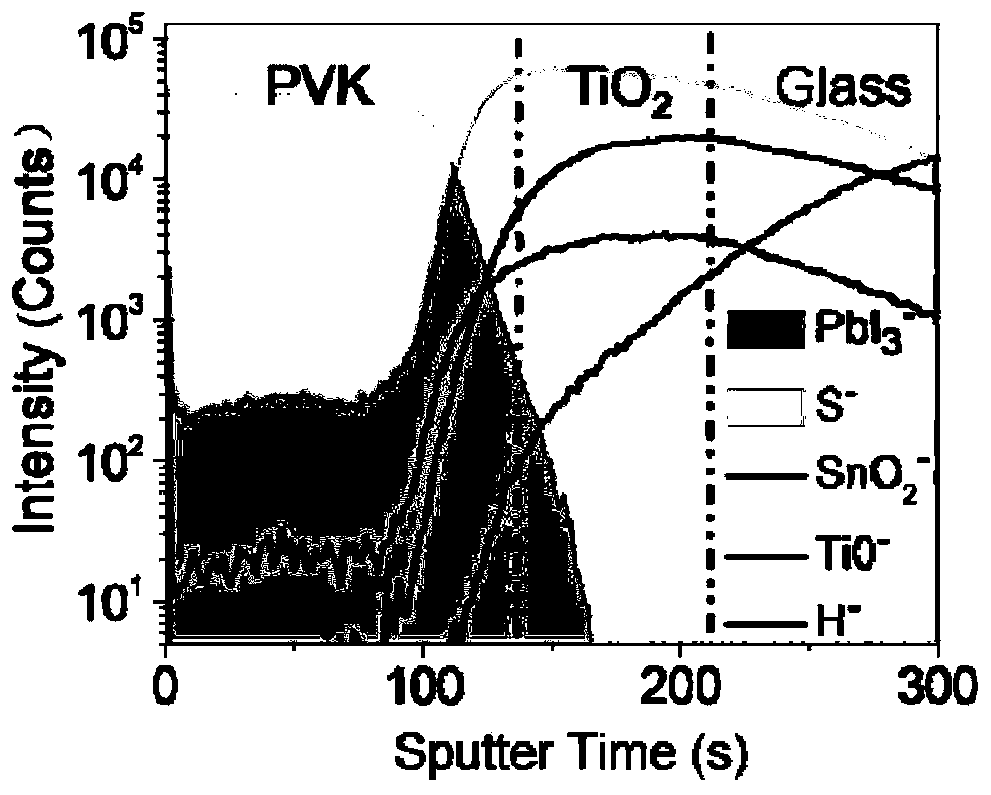

Method for efficiently and stably preparing large-area perovskite solar cell based on porphyrin doping

ActiveCN109860394AGuaranteed conversion efficiencyPrevent cation escapeSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellAmmonium

The invention belongs to the field of preparation of perovskite solar cells, and particularly relates to a method for efficiently and stably preparing a large-area perovskite solar cell based on porphyrin doping. The method is mainly characterized by comprises the following steps that firstly, a simple and convenient porphyrin and porphyrin derivative synthetic path is provided; secondly, a traceamount of porphyrin or a trace number of porphyrin derivatives are added into a perovskite pecursor solution; thirdly, a black and dense perovskite film is formed; and fourthly, a perovskite layer iscoated with the perovskite film containing the porphyrin and porphyrin derivative in a spinning mode, a hole transporting layer and an electrode layer are coated in sequence, and the perovskite solarcell is formed. The method has the beneficial effects that the perovskite film is doped with ammonium-based porphyrin, effective crystallization control over the perovskite film is achieved successfully, because the ammonium-based porphyrin has the properties of a surfactant, the film formation property of the solution is improved after the ammonium-based porphyrin is added into the solution, andthe pinhole-free and uniform large-area perovskite film is prepared through a scrape-coating process.

Owner:LANZHOU UNIVERSITY

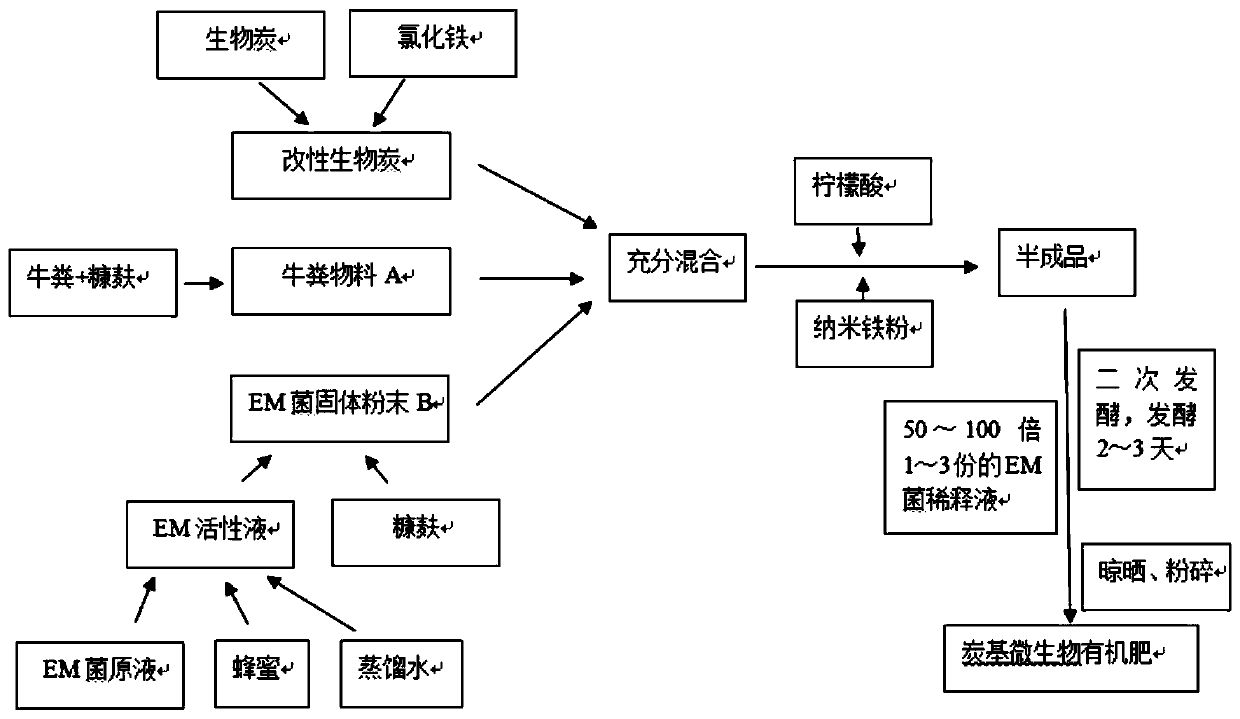

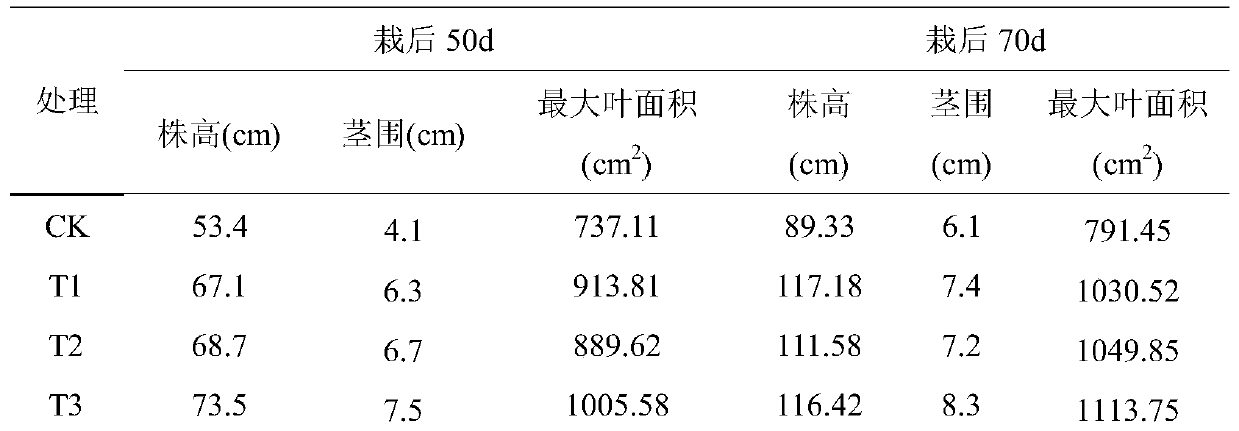

Carbon-based microbial organic fertilizer and preparation method thereof

InactiveCN110615713AImproves soil structure and porosityLoose soilBio-organic fraction processingExcrement fertilisersNutrientChemistry

The invention discloses a carbon-based microbial organic fertilizer and a preparation method thereof. The organic fertilizer is prepared from the following components in parts by weight: 15-25 parts of biochar, 10-25 parts of ferric chloride, 1-5 parts of EM bacteria, 25-40 parts of cow dung, 25-35 parts of bran, 5-10 parts of citric acid, 10-15 parts of nano iron powder, 85-95 parts of distilledwater and 1-10 parts of honey. The preparation method is simple in preparation process and relatively low in cost; the fertilizer can be used for fertilization of land and crops such as fields, facility greenhouses, potted plants and heavy metal pollution, can effectively adjust the pH of facility soil, improve the soil structure and porosity, loosen the soil, promote accumulation and conversion of organic substances, reduce nitrate nitrogen and available phosphorus leaching loss of the soil, and increase the content of organic matters and N, P and K nutrients in the soil. The microbial activity can be improved, heavy metals in the soil can be effectively adsorbed, fixed and passivated, heavy metal pollution and continuous cropping obstacles of the soil can be repaired, and the yield and quality of crops can be improved.

Owner:HOHAI UNIV

Chelated perovskite material, film, device, and preparation method and application thereof

PendingCN111403607AEffective passivationReduce the density of defect statesSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellPhysical chemistry

The invention relates to a chelated perovskite material, a film, a device, and a preparation method and application thereof. The catalyst is prepared by adding a chelating agent into a perovskite solution, wherein the chelating agent comprises a complexing agent or chelating agent capable of generating coordination with metal ions by coordination atoms, or a chelate or complex formed by coordination reaction of the complexing agent or chelating agent and the corresponding metal ions; according to the material, body defects and surface defects of the perovskite thin film are effectively passivated, and non-radiative recombination of carriers is reduced, so that the efficiency and long-term operation stability of the perovskite solar cell are effectively improved.

Owner:EAST CHINA UNIV OF SCI & TECH

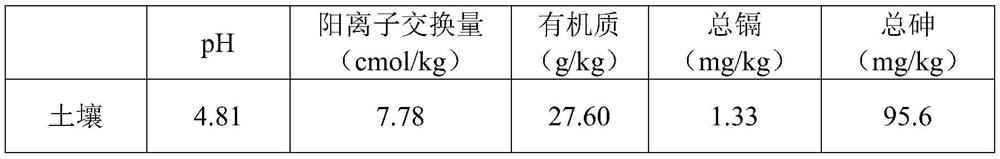

Soil conditioner for treating cadmium and arsenic combined pollution of farmland and application method of soil conditioner

PendingCN112939696AReduced bioavailabilityLarge specific surface areaAgriculture tools and machinesFertilising methodsSoil scienceSoil remediation

The invention relates to the field of farmland soil remediation, in particular to a soil conditioner for treating farmland cadmium and arsenic combined pollution and an application method of the soil conditioner. The soil conditioner is prepared from the following components in percentage by mass: 50%-60% of modified charcoal, 10%-30% of reduced iron powder, 10%-30% of calcium magnesium phosphate fertilizer and 10%-30% of sepiolite. When the soil conditioner is applied, the soil conditioner is uniformly mixed with water through a stirring box to form slurry, then the slurry is sprayed into a rice field through slurry spraying equipment, and then the soil conditioner is fully mixed with soil through ploughing. The soil conditioner provided by the invention can effectively reduce the bioavailability of cadmium and arsenic in farmland soil, reduce the content of cadmium and arsenic in agricultural products produced in a cadmium and arsenic combined pollution farmland, and avoid secondary pollution in the use process.

Owner:湖南中米环保科技有限公司

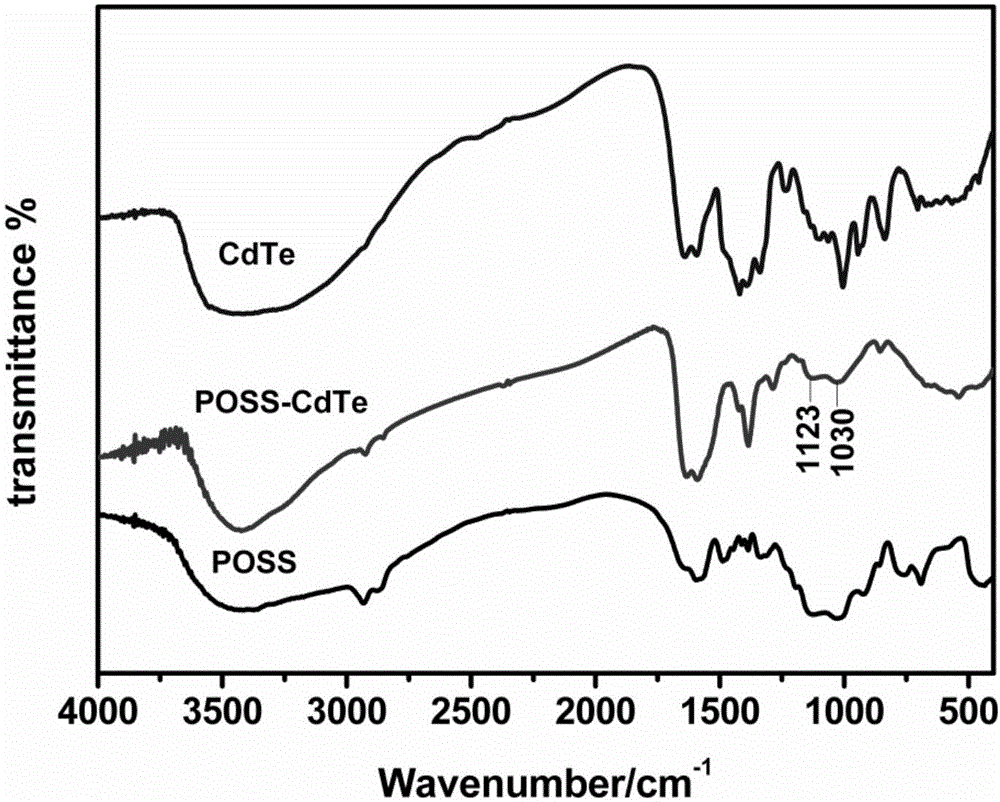

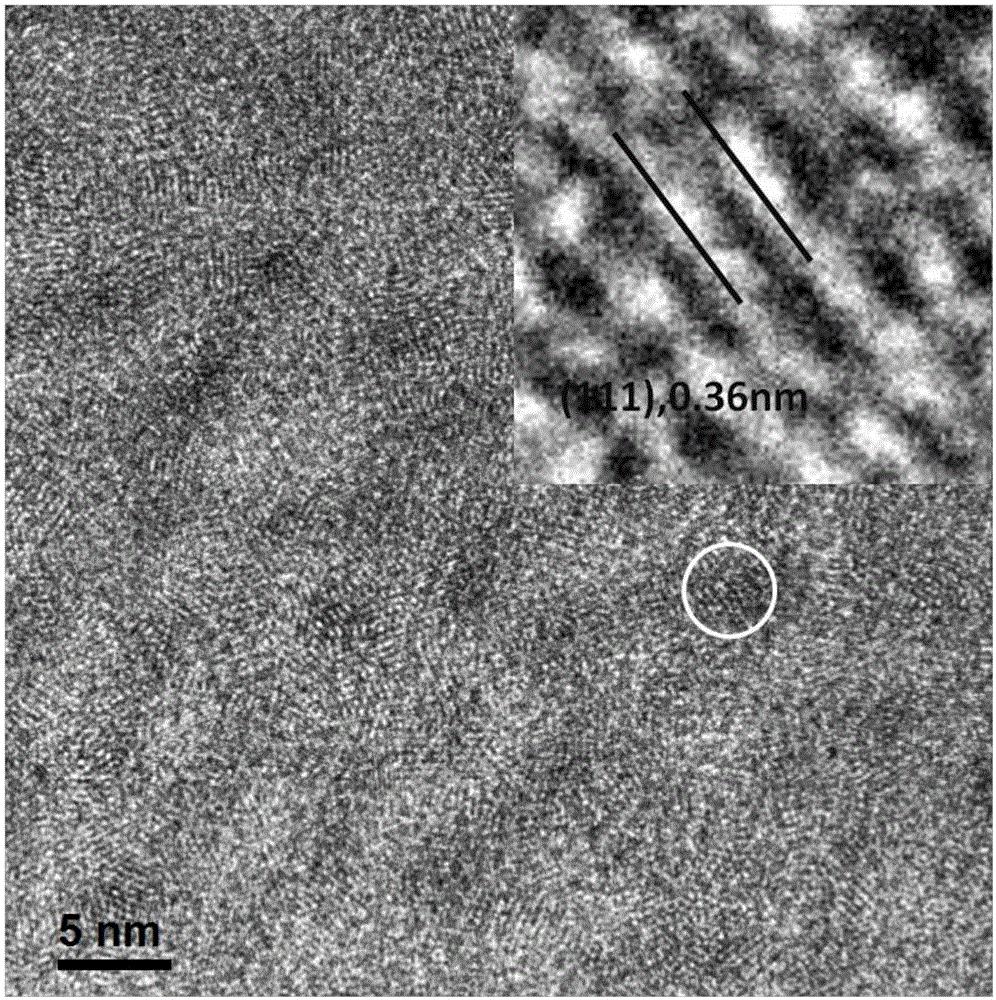

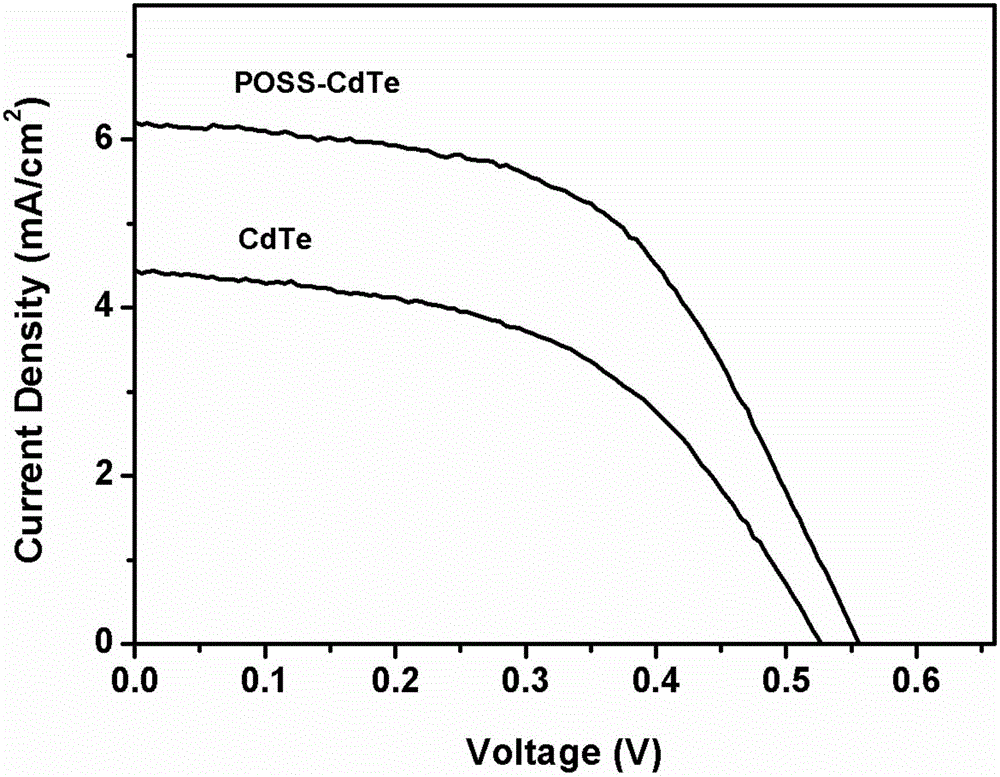

Preparation method of POSS-modified CdTe quantum dot-sensitized solar cell

InactiveCN106486289AImprove stabilityReduce defectsLight-sensitive devicesSolid-state devicesElectron holeReflux

The invention discloses a preparation method of a POSS-modified CdTe quantum dot-sensitized solar cell. The method comprises the steps of carrying out reflux condensation by adopting a water phase method to prepare CdTe quantum dot powder; and then modifying POSS to the surfaces of CdTe quantum dots and assembling POSS-modified CdTe quantum dots into the quantum dot-sensitized solar cell as a photosensitizer. The method is a simple and feasible preparation method of the OA-POSS-modified CdTe quantum dot-sensitized solar cell. The problems of poor quantum dot stability and severe combination of electron holes between a photo-anode and a quantum dot interface are solved. OA-POSS is modified on the surfaces of the CdTe quantum dots, so that the photoelectric characteristics of the CdTe quantum dots can be changed, the quantum dots can be effectively passivated, the defects of the surfaces of the quantum dots are reduced, the stability of the quantum dots is improved and electrons are more effectively injected into TiO2, thereby improving the photoelectric conversion efficiency and the stability of the quantum dot-sensitized solar cell.

Owner:HEBEI UNIV OF TECH

Apple juice processing method for suppressing enzymatic browning

ActiveCN105724991AImprove color qualityInhibits enzymatic browningFood ingredientsBeta-CyclodextrinsEnzyme

The invention discloses an apple juice processing method for suppressing enzymatic browning. The apple juice processing method comprises the following steps: adding 0.002 to 0.008 g / ml of beta-cyclodextrin into apple juice, putting the mixture into an ultrasonic treatment kettle, and performing ultrasonic treatment at the ultrasonic power density of 40 to 100 W / cm2 for 5 to 20 min. According to the processing method, the activity of enzyme can be passivated under relatively lower temperature to suppress the enzymatic browning and avoid the influence caused by thermal processing on the physical and chemical properties of the apple juice, so that the nutritional components and the sensory quality of the apple juice can be better retained.

Owner:HUAZHONG AGRI UNIV

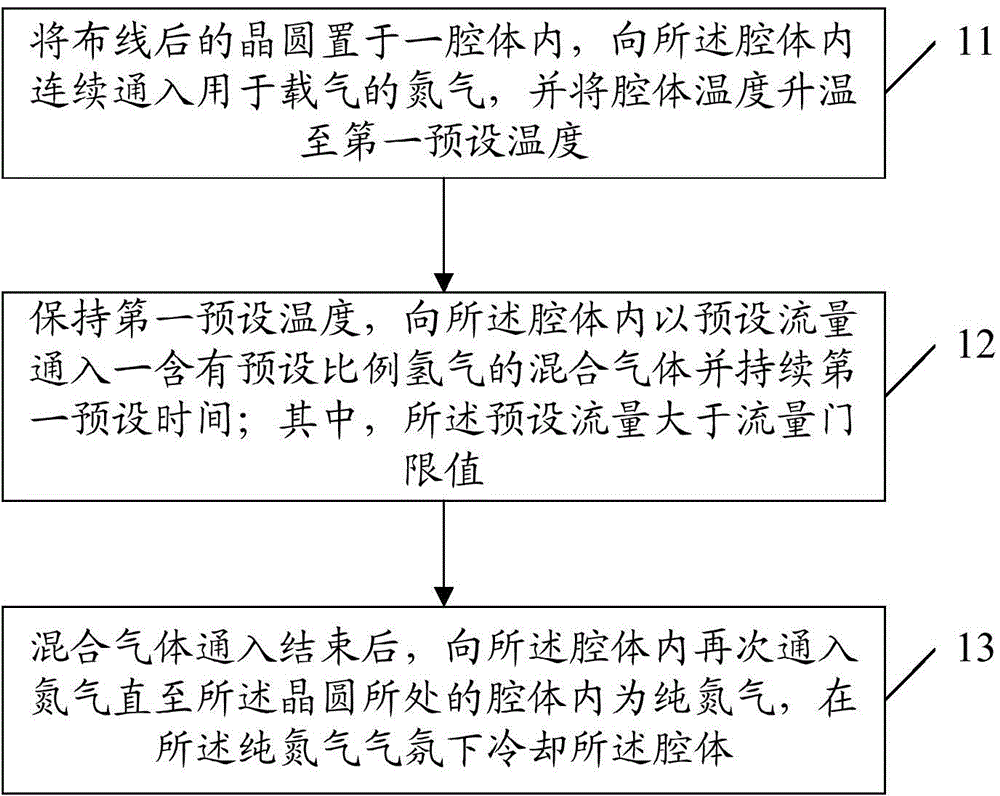

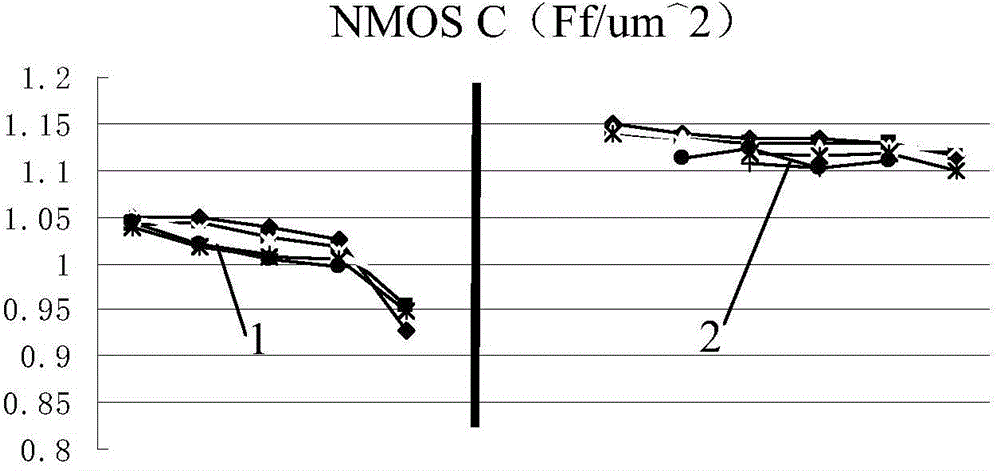

Method of alloying wafer after wiring

ActiveCN106158581ARepair qualityEffective passivationSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceManufacturing technology

The invention provides a method of alloying a wafer after wiring, comprising the following steps: placing a wafer after wiring in a cavity, feeding nitrogen used as a carrier gas into the cavity continuously, and raising the temperature in the cavity to a first preset temperature; keeping the cavity at the first preset temperature, and feeding a mixed gas containing a preset percentage of hydrogen into the cavity at a preset flow rate for a first preset time, wherein the flow rate is greater than a flow rate threshold; and after feeding of the mixed gas ends, feeding nitrogen into the cavity again until the cavity where the wafer is located is filled with pure nitrogen, and cooling the cavity in a pure nitrogen atmosphere. According to the method, by optimizing an alloying menu in a semiconductor manufacturing technology (namely, increasing the flow rate at which a preset percentage of hydrogen is fed during alloying), the Si ((silicon) dangling bond near the interface is passivated effectively, the interface state density is reduced greatly, and the quality of gate oxide is repaired. Therefore, the characteristic of the C-V curve of an NMOS capacitor is changed, frequency failure is improved, and the product yield is improved.

Owner:FOUNDER MICROELECTRONICS INT

Inorganic light-weight heat insulation mortar composite XPS heat insulation plate

InactiveCN105525693AEffective passivationGood interface technologyHeat proofingFire proofingMaterials scienceMesh grid

The invention discloses an inorganic light-weight heat insulation mortar composite XPS heat insulation plate, which comprises an XPS base plate, an interface agent layer and an inorganic light-weight heat insulation mortar layer, wherein grooves are formed in the front side and the back side of the XPS base plate; the inorganic light-weight heat insulation mortar layer is compounded with gridding cloth; the interface agent layer is arranged on the XPS base plate provided with the grooves at the front side and the back side; and the inorganic light-weight heat insulation mortar layer compounded with the gridding cloth is arranged on the interface agent layer. Compared with the prior art, the inorganic light-weight heat insulation mortar composite XPS heat insulation plate has the advantages that the thermal performance of a prepared stage A fireproof heat insulation plate is uniform; the efficient heat insulation effect is achieved; good fireproof performance is also realized; and the inorganic light-weight heat insulation mortar composite XPS heat insulation plate can be used as a heat insulation plate material to be widely used for building wall bodies.

Owner:CHANGZHOU JIHAO TECH DEV

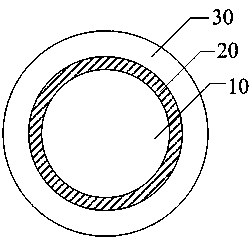

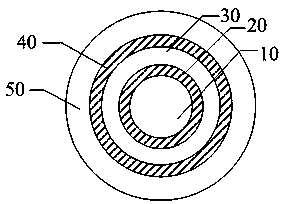

Quantum dot and preparation method thereof

PendingCN109929558AEffective passivationReduce lattice mismatchMaterial nanotechnologyNanoopticsElectrical conductorLattice mismatch

The invention discloses a quantum dot and a preparation method thereof. The quantum dot comprises a quantum dot core, a first metal layer covering the quantum dot core, a first semiconductor shell layer covering the first metal layer, a second metal layer covering the first semiconductor shell layer, and a second semiconductor shell layer covering the second metal layer, wherein the metal elementsin the first metal layer and the second metal layer are independently one or a plurality of elements selected from Zn, Hg, Al, Ga and In. According to the present invention, the metal layer can be bonded to the quantum dot core by using the ligand on the surface of the quantum dot core as the linker so as to promote the surface activation of the quantum dot core, such that the further growth reaction of the semiconductor shell layer outside the quantum dot can be easily performed; and through the crystal structure formed by bonding the metal atom in the metal layer and the quantum dot core, the surface of the quantum dot core can be effectively passivated, the surface defect can be reduced, and the lattice mismatch between the core and the shell can be reduced, such that the light emitting efficiency and the size uniformity of the quantum dot material can be enhanced.

Owner:TCL CORPORATION

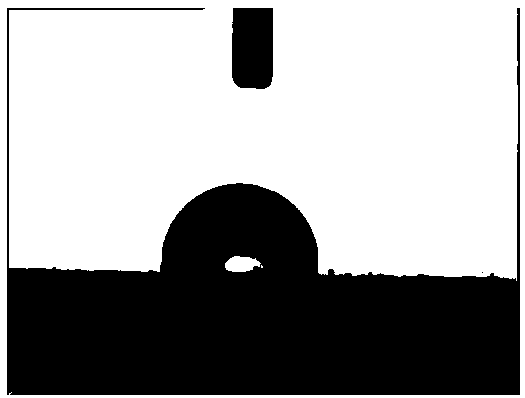

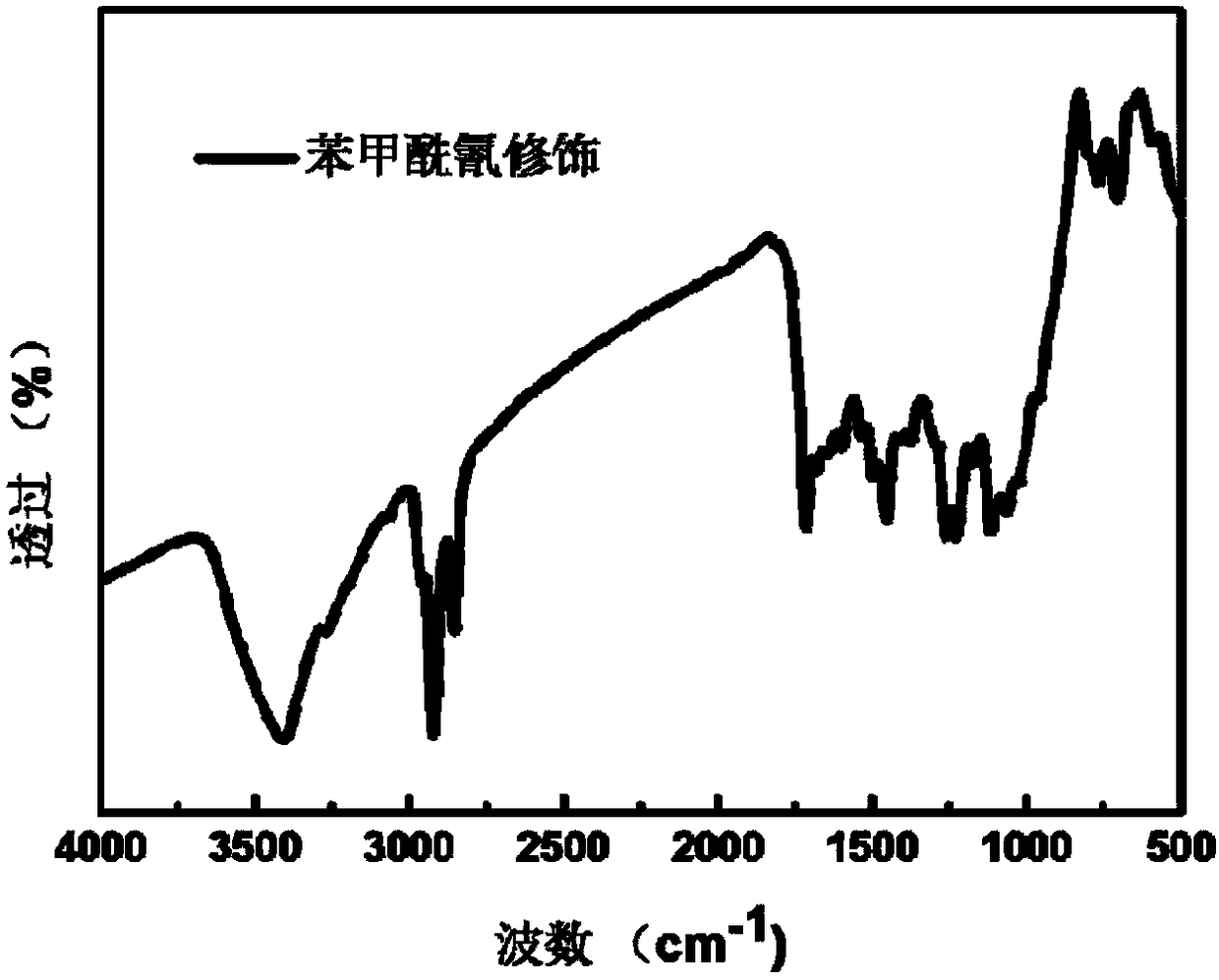

High stability perovskite film and manufacturing method thereof

ActiveCN108470832AImprove stabilityImprove hydrophobicitySolid-state devicesSemiconductor/solid-state device manufacturingCyanidePerovskite solar cell

The invention discloses a high stability perovskite film and a manufacturing method thereof. The high stability perovskite film comprises a perovskite light absorbing layer and a hydrophobic interfacelayer which is formed by modifying a benzoyl cyanide solution and wraps the outer surface of the perovskite light absorbing layer. The manufacturing method comprises the following steps of preparingbenzoyl cyanide into a surface modification solution; and immersing the perovskite film in the surface modification solution for 30 to 1800 seconds, and carrying out annealing processing and drying at70 to 200 DEG C. In the invention, immersive surface modification is performed on a conventional perovskite film, the perovskite light absorbing layer can be passivated, the quality of the perovskitelight absorbing layer is improved, and the defect density of the perovskite light absorbing layer is reduced; the photoelectric conversion efficiency of a perovskite solar cell manufactured by the high stability perovskite film is increased; and benzoyl cyanide is taken as a surface modification material so that the outer surface of the perovskite light absorbing layer forms the hydrophobic interface layer, which is good for enhancing the hydrophobicity of the high stability perovskite film, and then the stability of the manufactured perovskite solar cell is increased.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

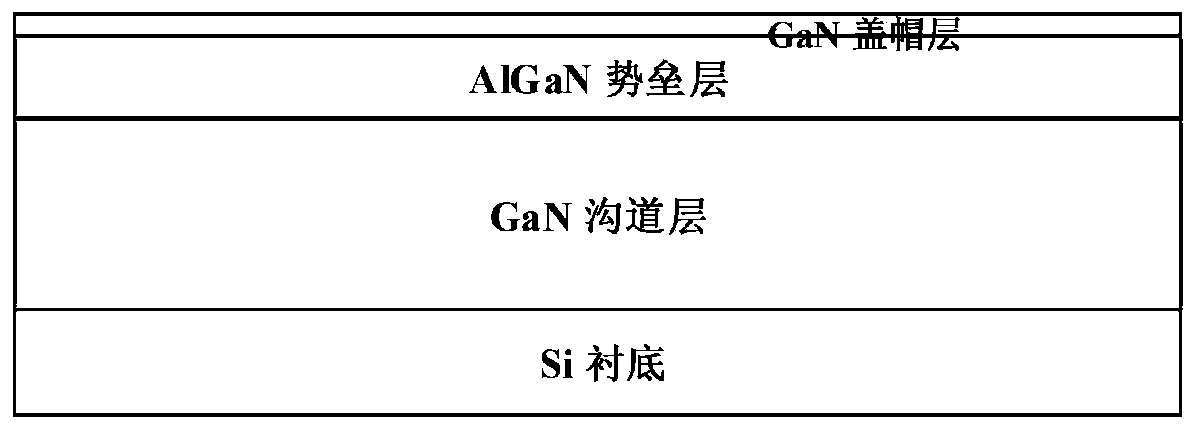

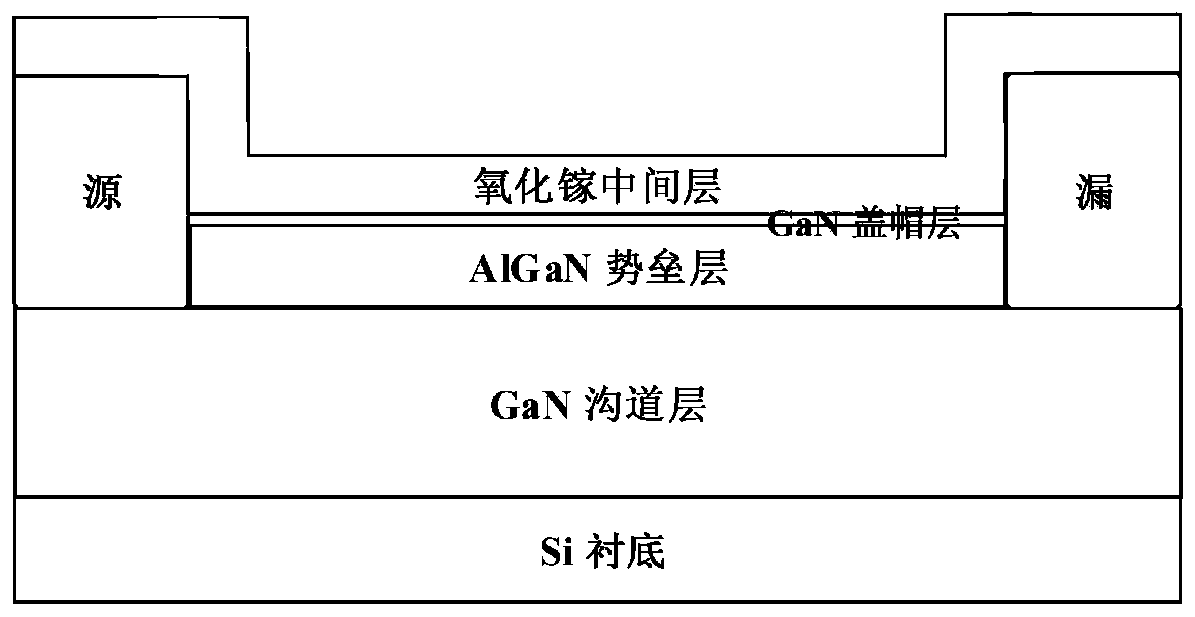

Method for optimizing passivation of gallium nitride high-electron-mobility transistor

InactiveCN110660643AEffective passivationReduce interface defectsSemiconductor/solid-state device manufacturingSemiconductor devicesMetallic electrodeEngineering

The invention belongs to the field of semiconductor manufacturing and discloses a method for optimizing the passivation of a gallium nitride high-electron-mobility transistor. The method comprises thefollowing steps that: a gallium nitride epitaxial layer is grown on a substrate; etching is performed, so that an active region mesa can be formed; a source ohmic contact electrode and a drain ohmiccontact electrode are formed; a natural oxide layer on the surface of the gallium nitride material is removed; gallium oxide is deposited so as to serve as an intermediate layer of a passivation layerand a GaN cap layer; a device passivation layer is deposited on the gallium oxide intermediate layer; and the metal electrode of a gate is formed. With the method of the invention adopted, an interface defect between the gallium nitride cap layer and the passivation layer can be reduced; the passivation effect of the device is improved; the current collapse phenomenon of the gallium nitride high-electron mobility transistor is effectively inhibited; and the breakdown voltage of the device is improved.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

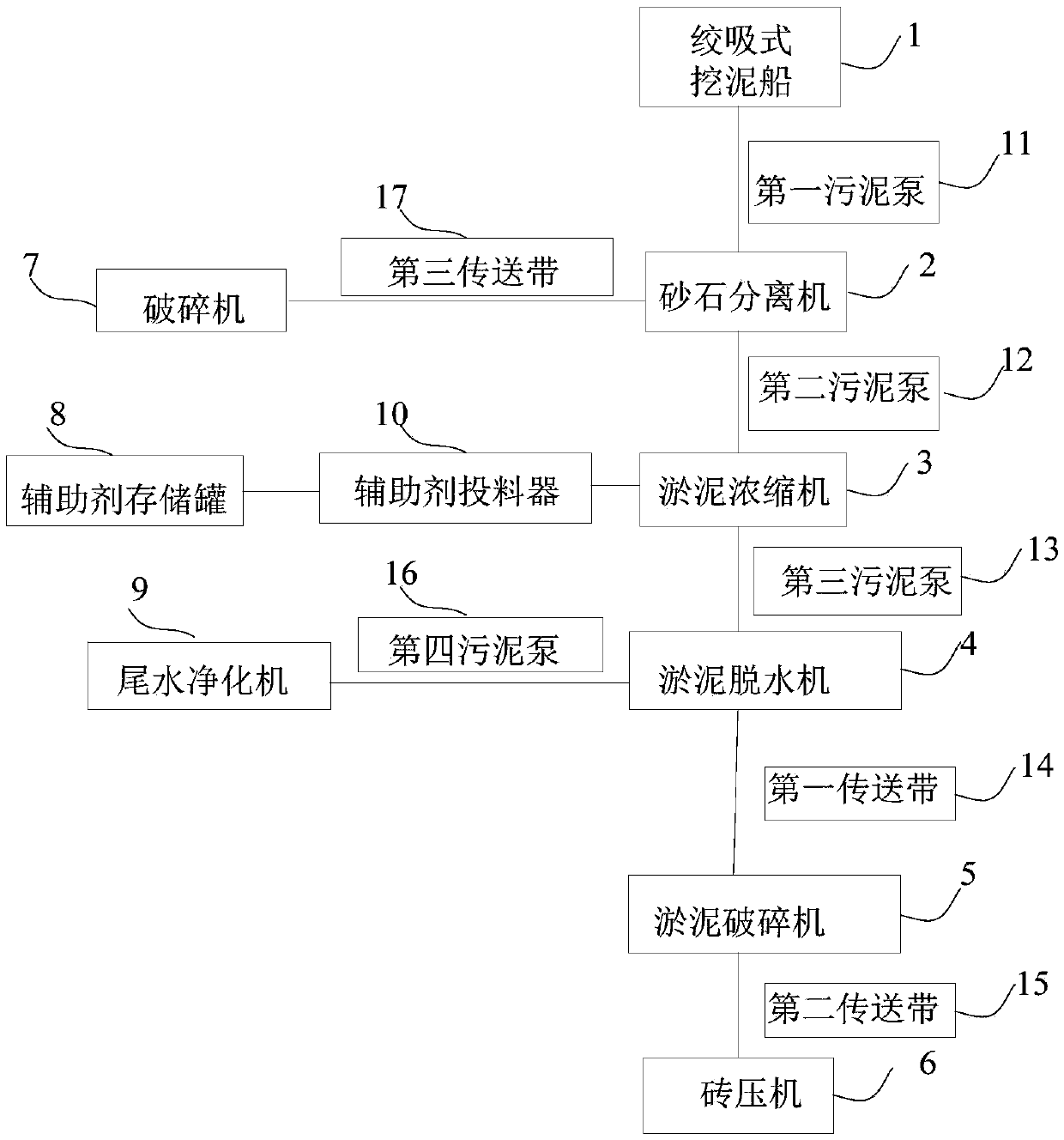

Ecological block prepared by riverway silt, and method and device for preparing ecological block

PendingCN110774415AEnvironmental protection is goodGood compression performanceSludge treatment by de-watering/drying/thickeningCeramic shaping apparatusEcologyPolyacrylamide

The invention relates to an ecological block prepared by riverway silt, and a method and device for preparing the ecological block. The method comprises the following steps that S1, waste in the original riverway silt is removed, sand stone is separated from the original riverway silt, and the riverway silt after pretreatment is obtained; and an accessory ingredient is added into the riverway siltafter pretreatment for passivation regulating to obtain the riverway silt after passivation, and the accessory ingredient comprises calcium oxide, iron salt, polyacrylamide and bentonite; S2, dewatering is conducted on the riverway silt after passivation to obtain a silt cake, and crushing is conducted on the silt cake to obtain scattered base mud with the particle size of no more than 1mm; and S3, the scattered base mud, cement, coarse aggregates and fine aggregates are mixed and pressed and molded for still standing to obtain the ecological block. The device for preparing the ecological block by the riverway silt comprises a cutter-suction dredger, a sand stone separating machine, a silt concentrator, a silt dewatering machine, a silt crusher and a brick press. According to the ecological block, passivation is conducted on the heavy metal ions, and the environmental protection performance and the anti-pressure performance are excellent.

Owner:中建生态环境集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com