Inorganic light-weight heat insulation mortar composite XPS heat insulation plate

A technology of thermal insulation mortar and thermal insulation mortar layer, applied in thermal insulation, building components, fire protection, etc., can solve the problems of convenience, property loss, casualties, etc., and achieve the effects of enhancing flexural strength, improving occlusal degree, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

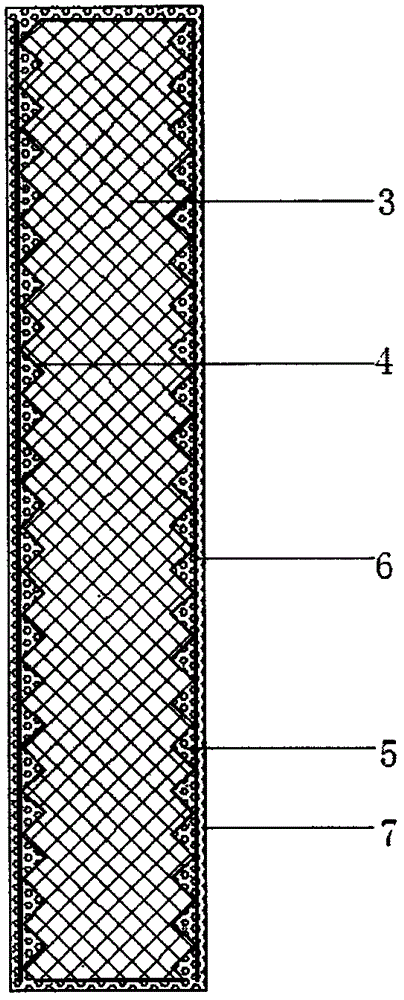

[0030] Inorganic lightweight thermal insulation mortar composite XPS thermal insulation board of the present embodiment is as figure 1 , 2 As shown; it includes an XPS substrate 3 with grooves 1 and 2 on the front and back sides, an interface agent layer 4, and an inorganic lightweight thermal insulation mortar layer; the interface agent layer 4 is arranged on the XPS substrate 3, and the inorganic lightweight thermal insulation mortar layer The mortar layer is set on the interface agent layer 4 . The inorganic lightweight thermal insulation mortar layer is an inorganic lightweight thermal insulation mortar layer of composite grid cloth, specifically including an inorganic lightweight thermal insulation mortar filling layer 5, an intermediate alkali-resistant coating grid cloth layer 6 and an inorganic lightweight thermal insulation mortar coating Layer 7; the interface agent layer 4 in the grooves 1 and 2 of the XPS substrate 3 is filled with an inorganic lightweight thermal...

Embodiment 2

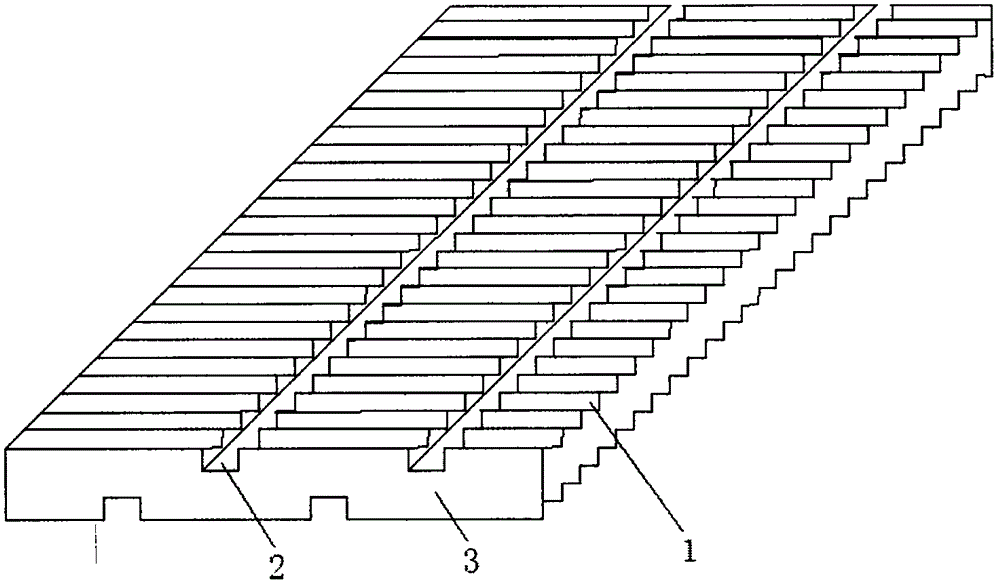

[0043] Inorganic lightweight thermal insulation mortar composite XPS thermal insulation board of the present embodiment is as figure 1 , 3 Shown; Its structure is basically the same as embodiment 1, and difference is:

[0044] In this embodiment, the XPS substrate 3 with grooves 1 and 2 on the front and back is specifically: a plurality of continuous longitudinal V-shaped grooves 1 (5 mm ± 0.2 mm in depth and 5 mm ± 5 mm in width) respectively arranged on the front and back of the XPS substrate 3 0.2mm), perpendicular to the direction of the V-shaped groove 1, U-shaped grooves 2 with a spacing of 400mm (the depth is 10mm±0.2mm, and the width is 10mm±0.2mm); The grooves 1 correspond to the peaks and valleys, and the U-shaped grooves 2 are equidistant from each other. This XPS substrate 3 is a B1 grade XPS substrate with an average thickness of 40 mm.

[0045] The preparation method is as follows:

[0046]Step 1. Use the B1 grade XPS substrate with an average thickness of 40...

Embodiment 3

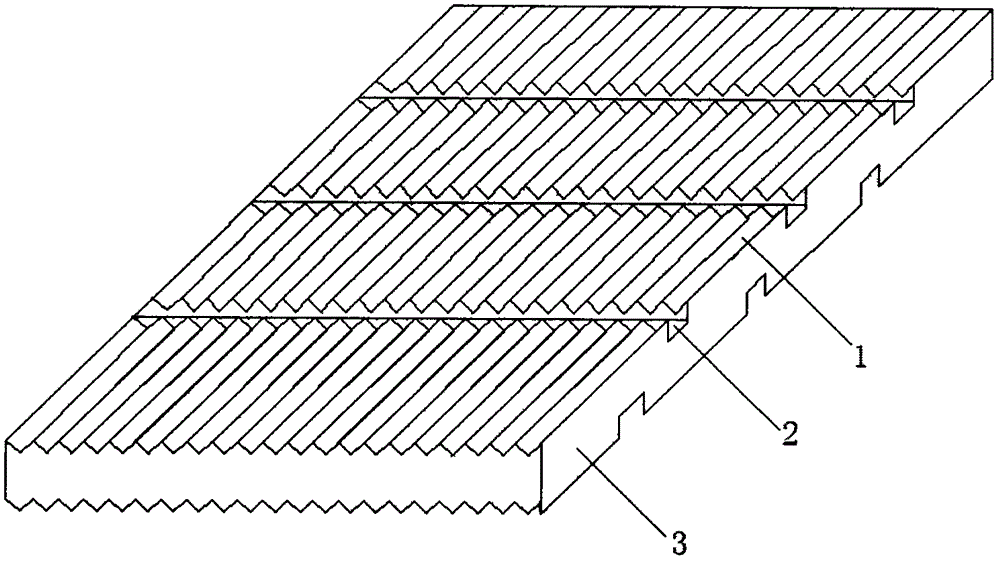

[0056] Inorganic lightweight thermal insulation mortar composite XPS thermal insulation board of the present embodiment is as figure 1 , 4 Shown; Its structure is basically the same as embodiment 1, and difference is:

[0057] In this embodiment, the XPS substrate 3 with grooves 1 and 2 on the front and back sides is specifically: the front and back sides of the XPS substrate 3 are respectively provided with a number of continuous V-shaped grooves 1 at an oblique angle of 45 degrees (the depth is 5 mm ± 0.2 mm, The width is 5 mm ± 0.2 mm), and the U-shaped groove 2 with a distance of 440 mm is arranged perpendicular to the direction of the V-shaped groove 1 (the depth is 10 mm ± 0.2 mm, and the width is 10 mm ± 0.2 mm); the front and back sides of the XPS substrate 3 The peaks and valleys of the V-shaped grooves 1 correspond to each other, and the U-shaped grooves 2 are equidistant from each other. This XPS substrate 3 is a B1 grade XPS substrate with an average thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com