High stability perovskite film and manufacturing method thereof

A high-stability, perovskite technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as poor stability of perovskite films, improve photoelectric conversion efficiency, reduce defect state density, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The present embodiment 1 provides a kind of preparation method of high stability perovskite film, comprises the following steps:

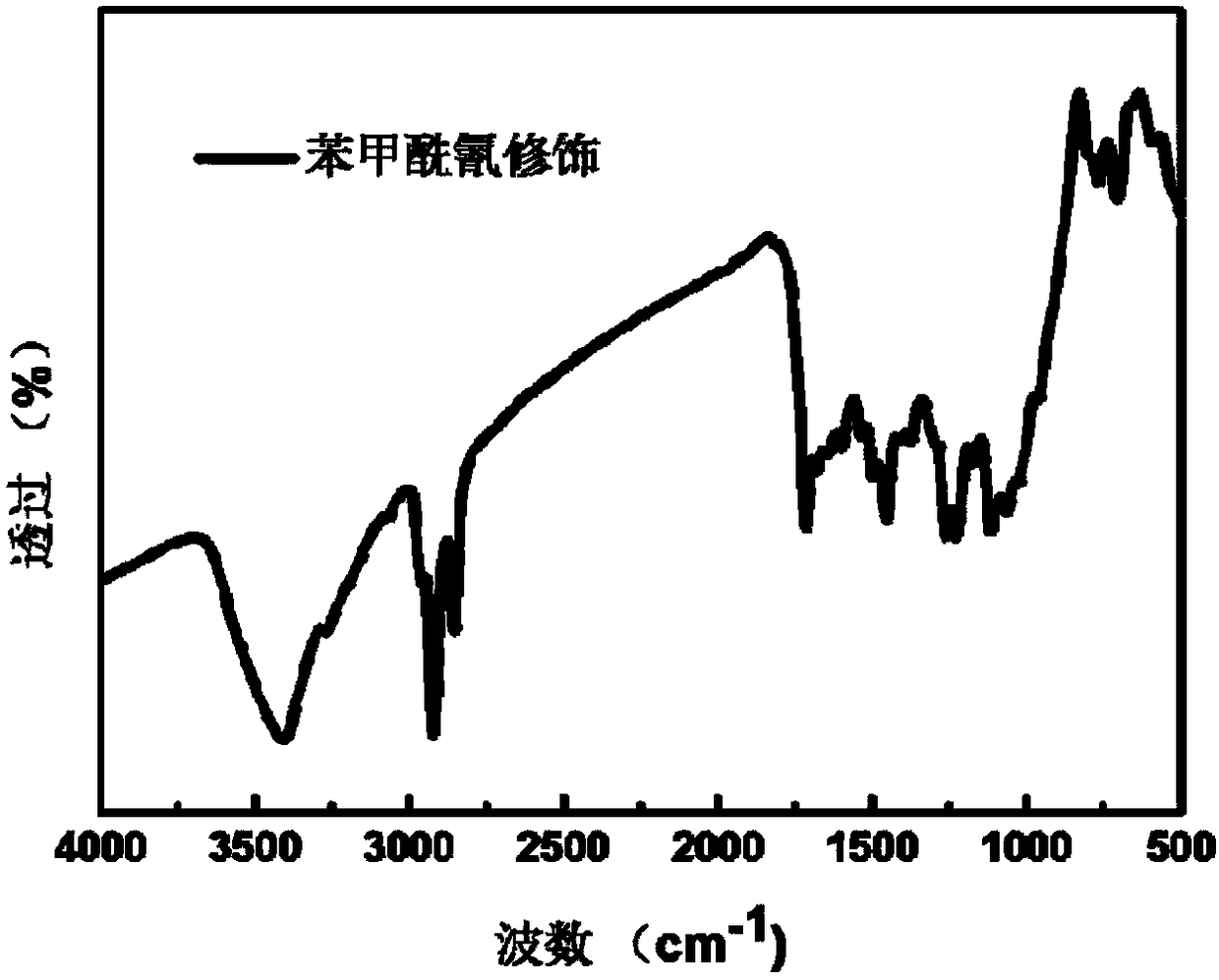

[0031] (1) Benzoyl cyanide is mixed with a surface modification solution;

[0032] Wherein, the surface modification solution is a dilution of at least one of ether, chlorobenzene and toluene of benzoyl cyanide, and the dilution factor is 0 times.

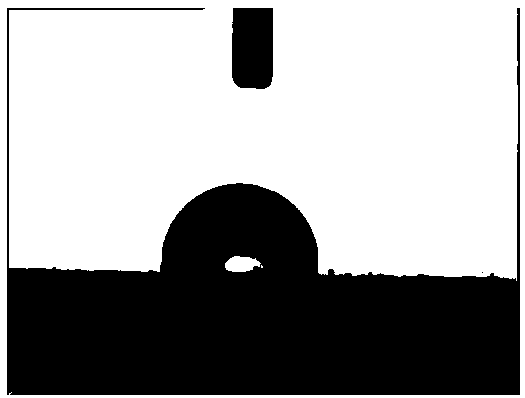

[0033] (2) Soak the conventional perovskite film in the surface modification solution for 30-1800 seconds, anneal and dry it at 70-200° C. to obtain a high-stability perovskite film.

Embodiment 2

[0035] Example 2 provides a method for preparing a high-stability perovskite film, which is basically the same as Example 1, except that the dilution concentration of the diluent is 10 times.

Embodiment 3

[0037] Example 3 provides a method for preparing a high-stability perovskite film, which is basically the same as Example 1, except that the dilution concentration of the diluent is 100 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com