Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Controllable ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ceramic-based composite material environment barrier coating by laser cladding

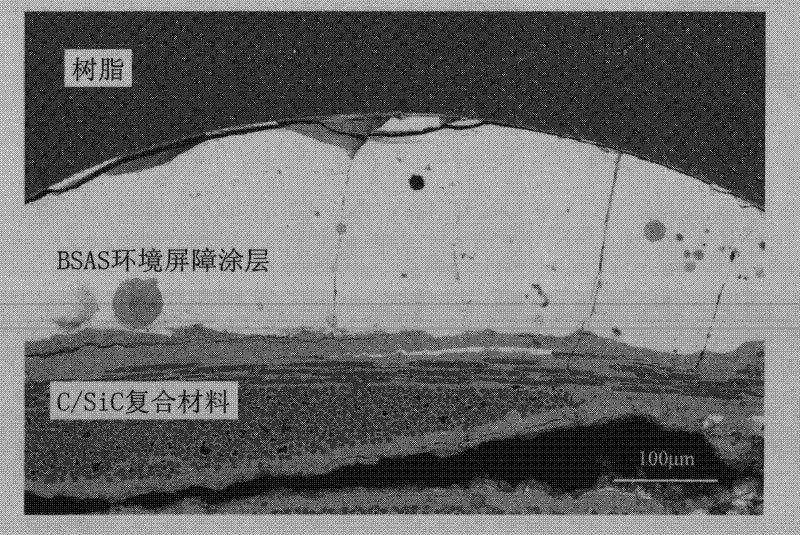

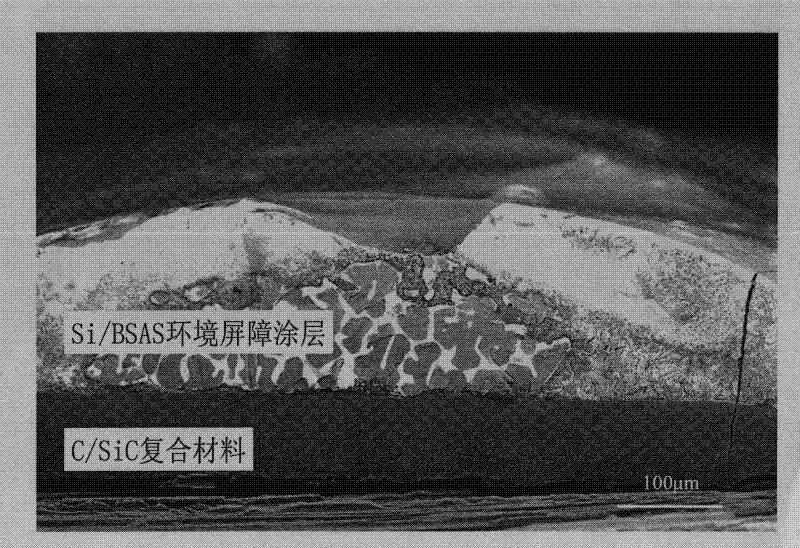

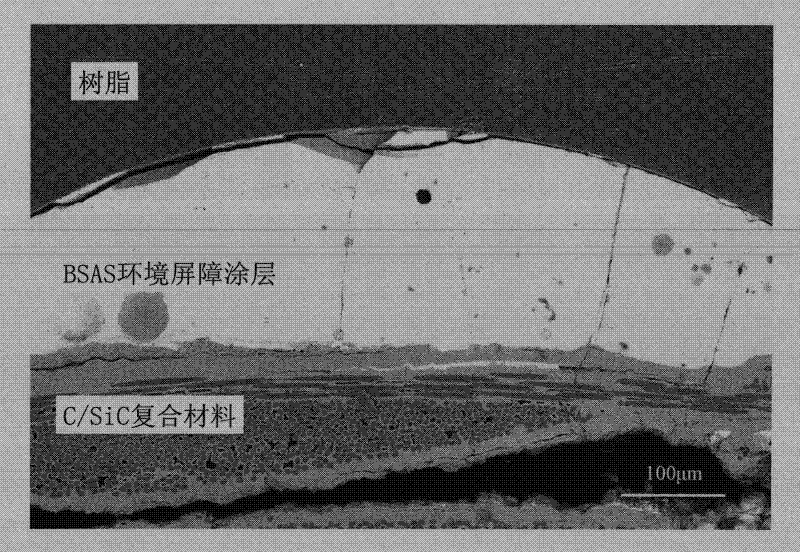

The invention relates to a method for preparing a ceramic-based composite material environment barrier coating by laser cladding, which has the technical characteristics that: 1, a composite material to be coated is processed to a required size and completely washed in an ultrasonic washing machine; 2, the environment barrier coating material powder, a bonding agent and a solvent are mixed uniformly according to a certain ratio to form pulp; 3, the pulp is uniformly brushed on the surface of the composite material and dried; and 4, the membrane coated with the coating pulp is placed on a laser processing worktable, laser cladding is performed by a certain process, and thus, the environment barrier coating is prepared. The interface of the obtained coating is firmly bonded, the coating is uniform and compact, and the quality of the coating is improved obviously. In the invention, the process is simple, area-selectable cladding can be performed, the processing period is short, and high-performance environment barrier coating can be prepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

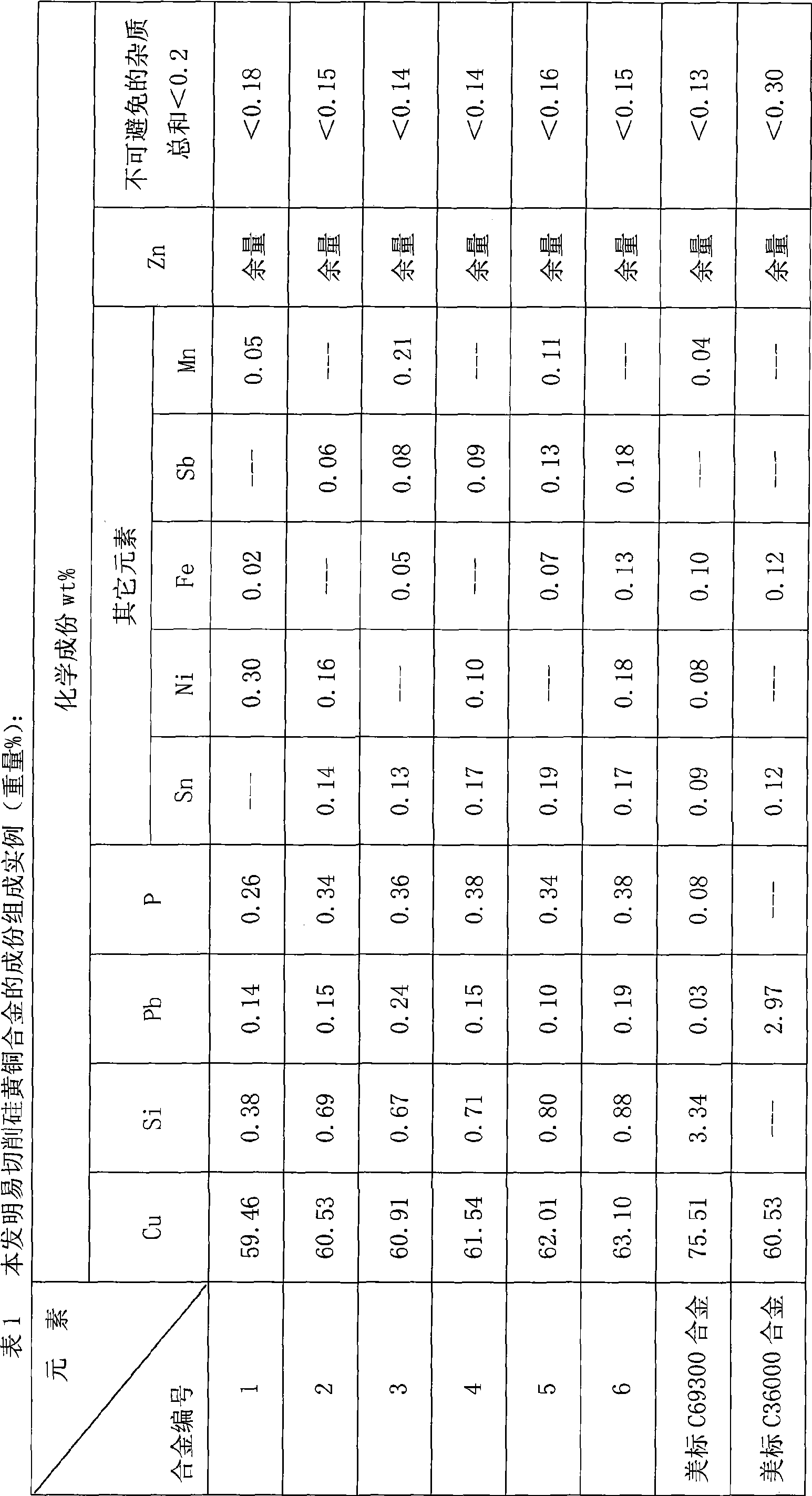

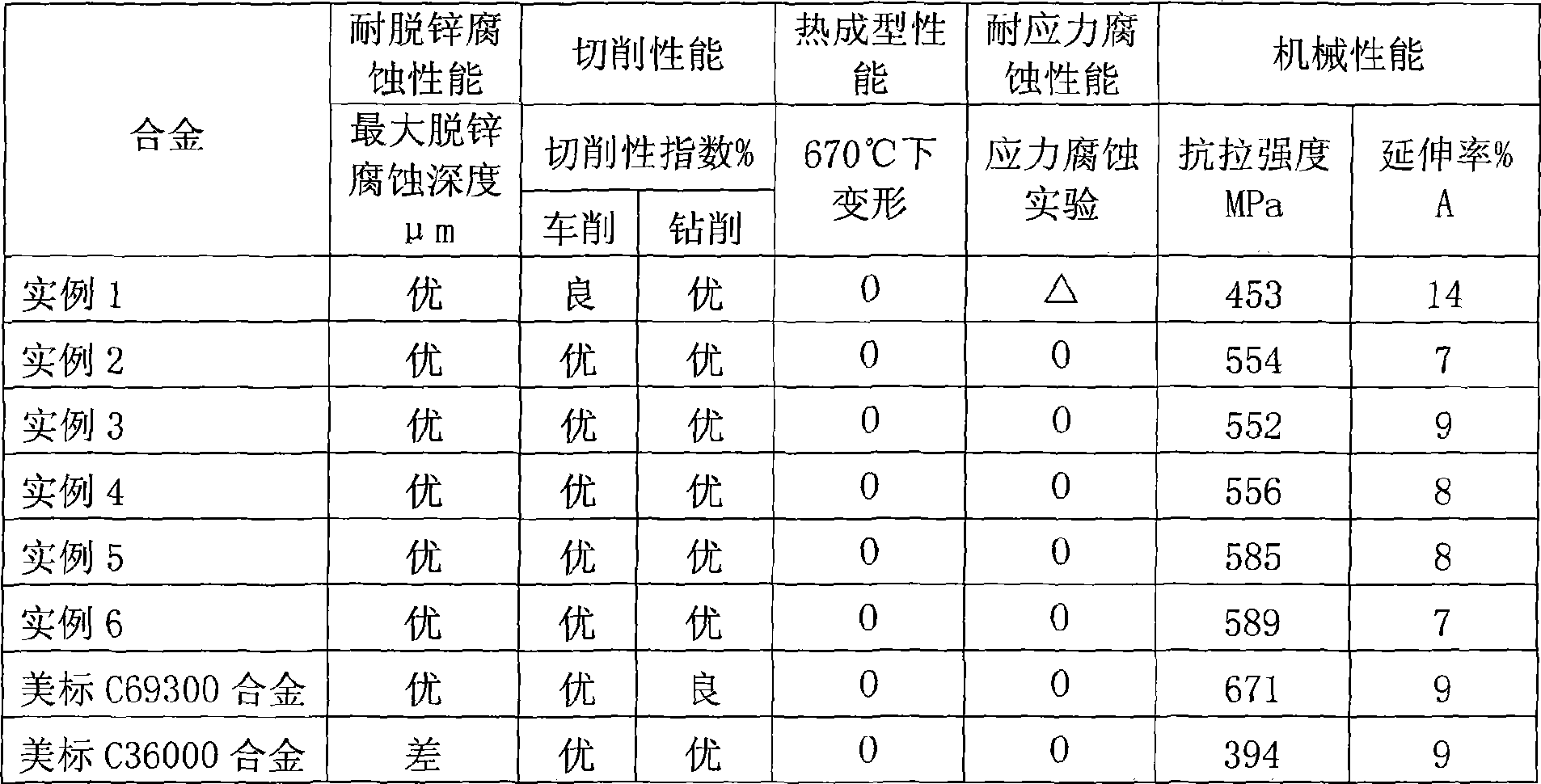

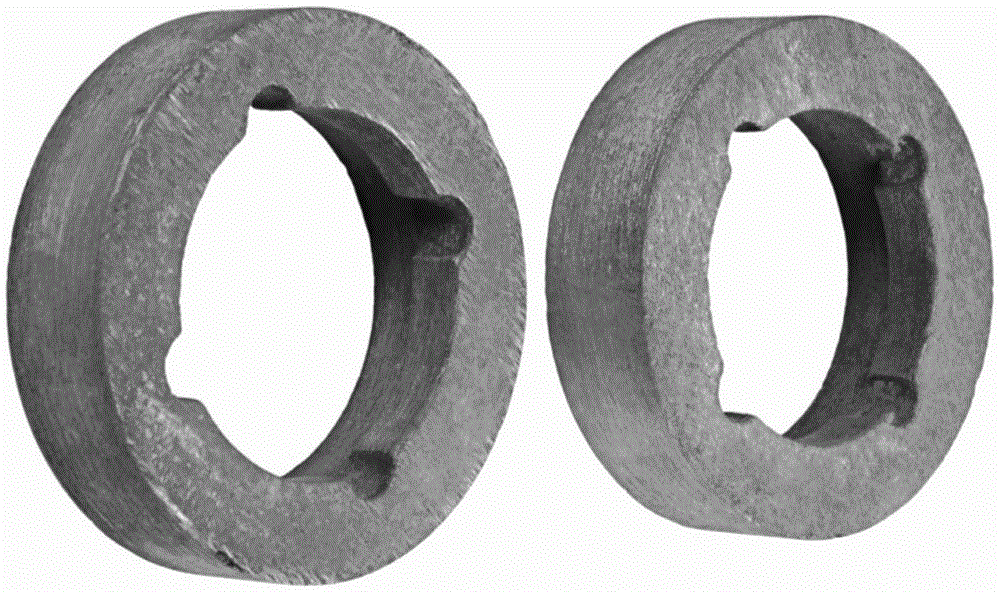

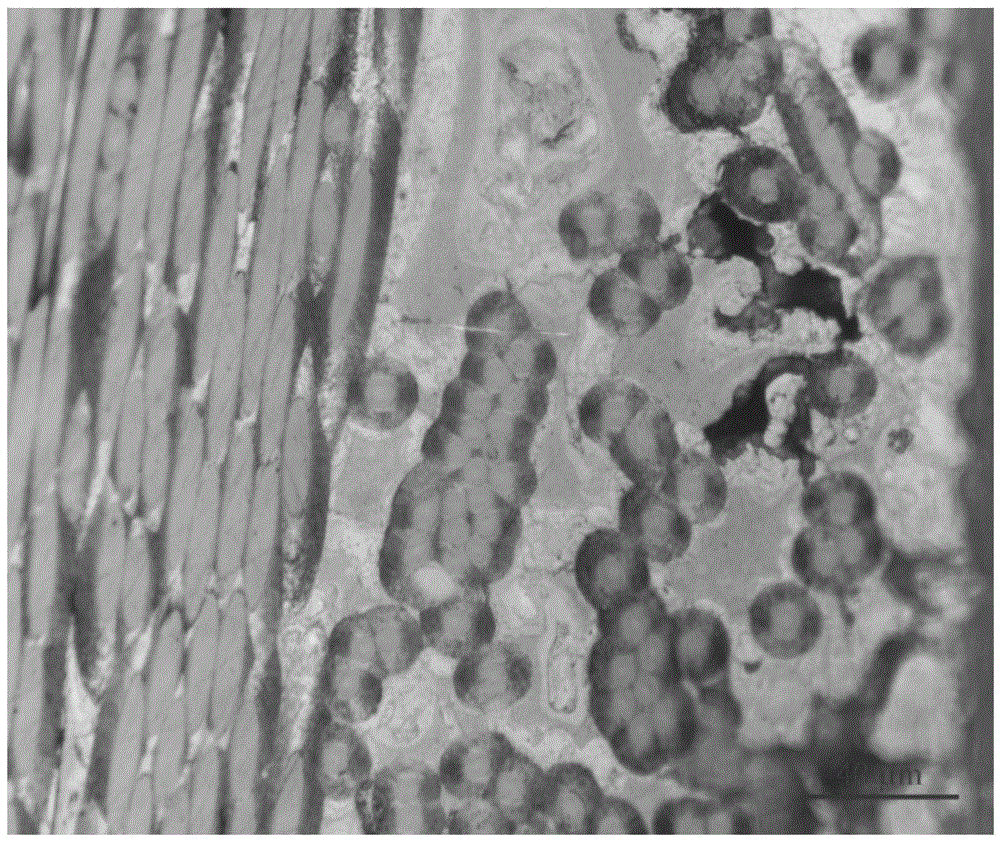

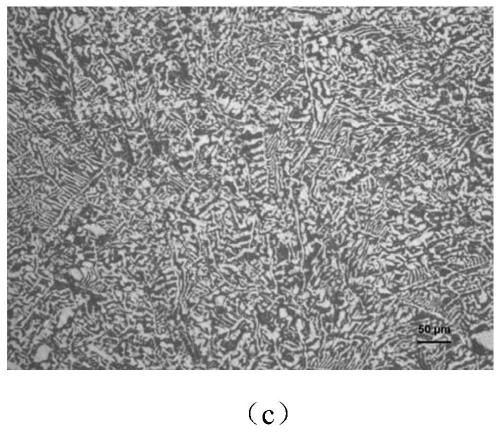

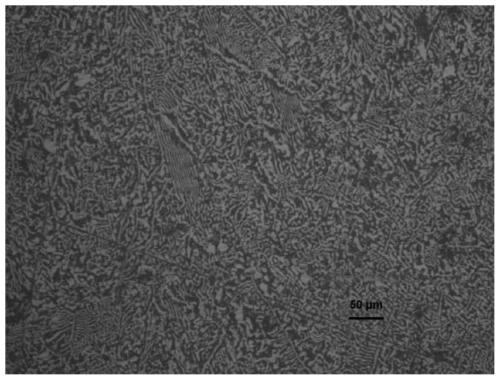

Easily-cut silicon brass alloy and preparation method thereof

ActiveCN101445885AExcellent machinabilityExcellent resistance to dezincificationManganeseStress relief

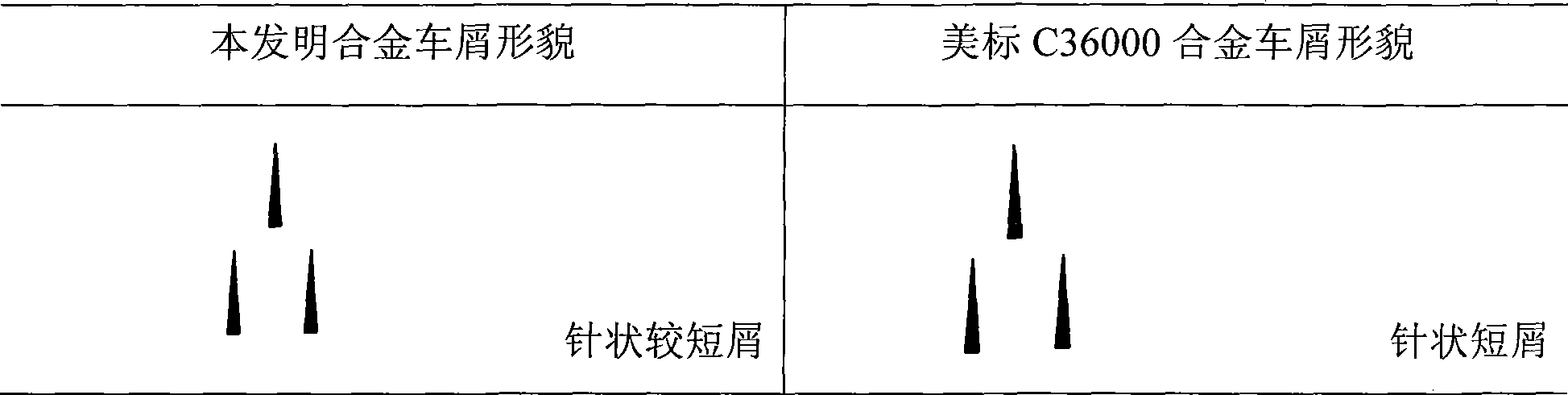

The invention discloses an easily-cut silicon brass alloy and a preparation method thereof. Chemical components of the silicon brass alloy include 59.2-63.5wt% of copper, 0.35-0.9wt% of silicon, 0.04-0.25wt% of lead and 0.22-0.38wt% of phosphor, other elements account for 0.005-1.1wt%, and the rest include zinc and inevitable impurities, wherein, the total amount of the copper, the zinc, the silicon, the lead and the phosphor is larger than 98.7wt%, and the other elements include at least one element selected from a group consisting of tin, nickel, iron, stibium and manganese. The preparation method is as follows: a method for alloying and for purifying and refining a covered and protected alterative scarfing cinder is adopted for smelting the easily-cut silicon brass alloy, then intermediate heat treatment is carried out at a temperature of 560-660 DEG C after coldworking with a working rate ranging from 4 percent to 25 percent, and a final finished product resulting from the working undergoes stress relief annealing at a low temperature of 380 DEG C. The invention has the advantage that the easily-cut silicon brass alloy has high tensile strength, excellent thermal formability, dezincing resistance, safe and sanitary performance and remarkable excellent cutting performance; meanwhile, the preparation process of the easily-cut silicon brass alloy is simple, the cost is low, and the easily-cut silicon brass alloy can be easily recycled.

Owner:NINGBO POWERWAY ALLOY MATERIAL

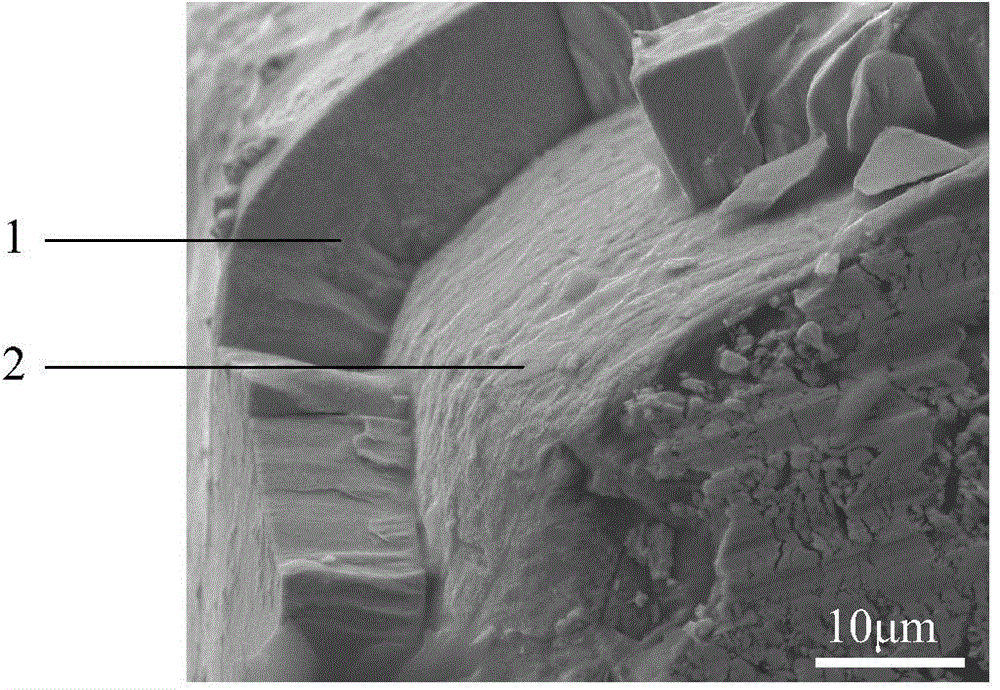

Preparation method and application of carbon/ceramic composite material

ActiveCN105565837AThere is no problem of large distribution gradientReduce wearBraking discsActuatorsCeramic compositeMetallurgy

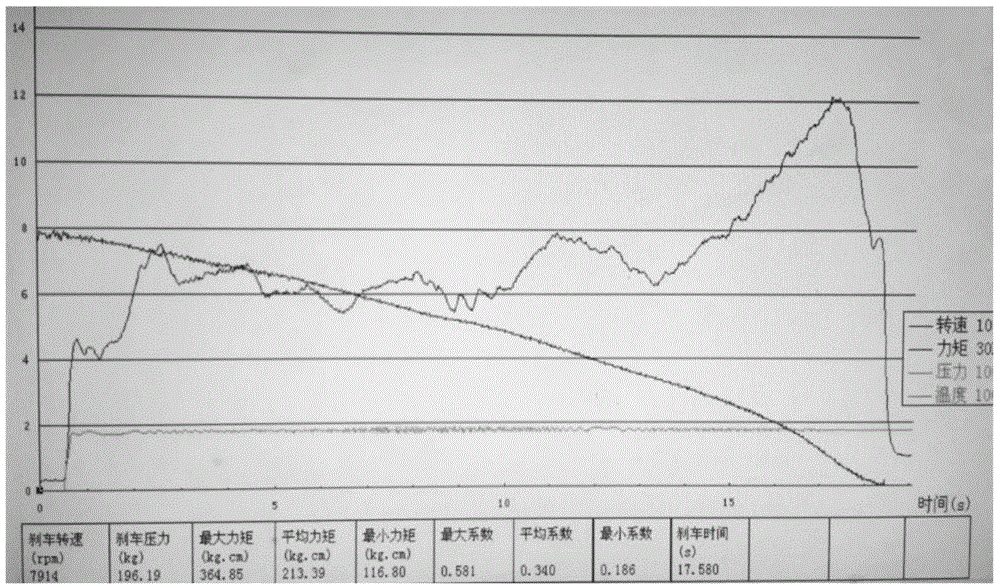

The invention relates to a preparation method and application of a carbon / ceramic composite material, in particular to a preparation method and application of a carbon / ceramic composite material needed for braking a high-momentum delivery system. The preparation method includes: using a C / C composite material of 1.2-1.5 g / cm3 in density as a raw material; disposing the raw material in impregnation liquid I for impregnation, pyrolyzing in a protective atmosphere after impregnation, repeating impregnating-pyrolyzing operations until a carbon / ceramic composite material of 1.85-1.9 g / cm3 in density is obtained; treating the carbon / ceramic composite material obtained at high temperature until density of the carbon / ceramic composite material is lowered to 1.82-1.88 g / cm3 to obtain a pre-finished product; disposing the pre-finished product in impregnation liquid II, decomposing in a protective atmosphere after impregnation is completed, polishing after decomposing, and repeating impregnating-decomposing-polishing operations until a carbon / ceramic composite material finished product of 1.93-2.0 g / cm3 is obtained.

Owner:HUNAN BOWANG CARBON CERAMIC CO LTD

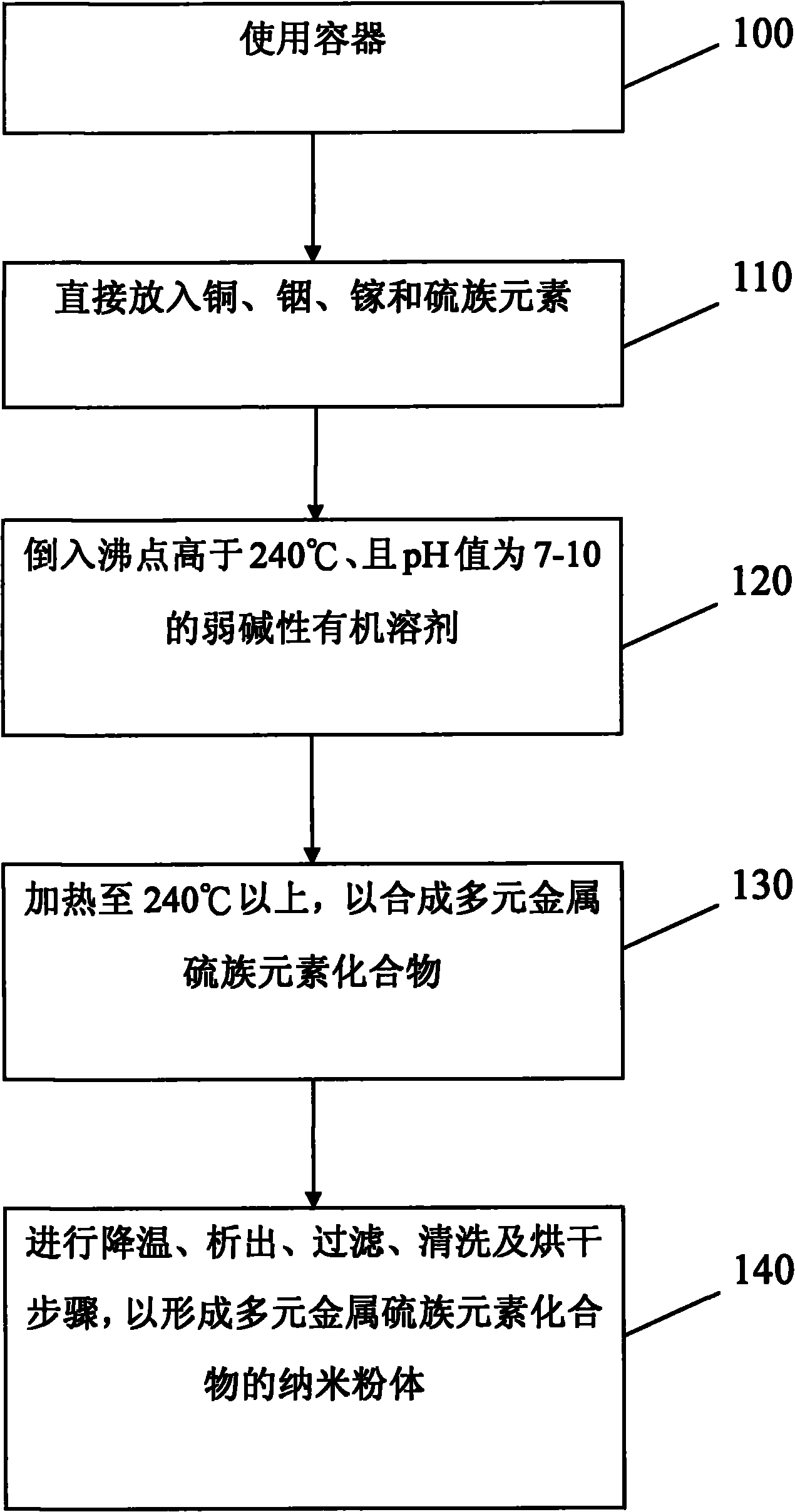

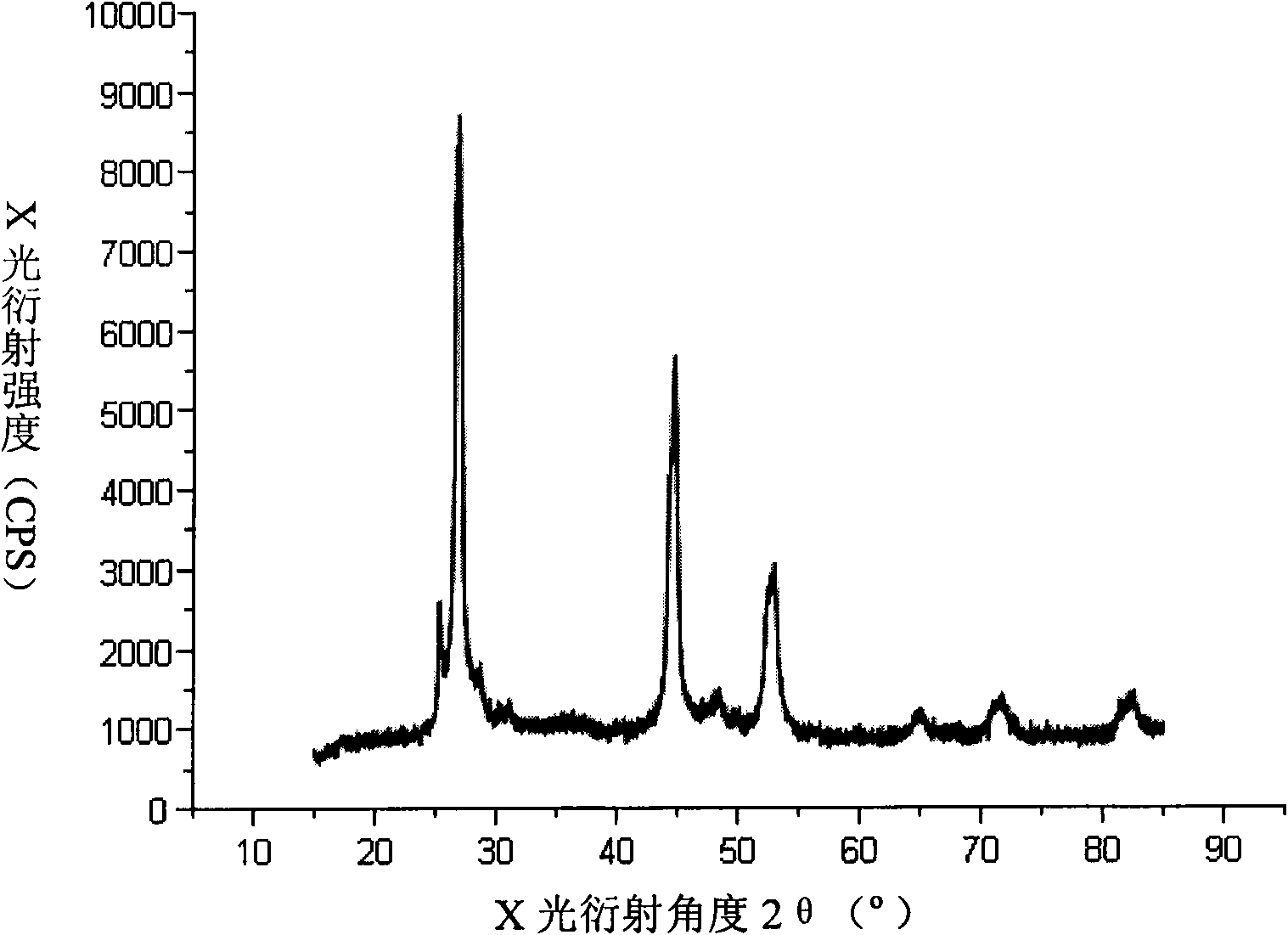

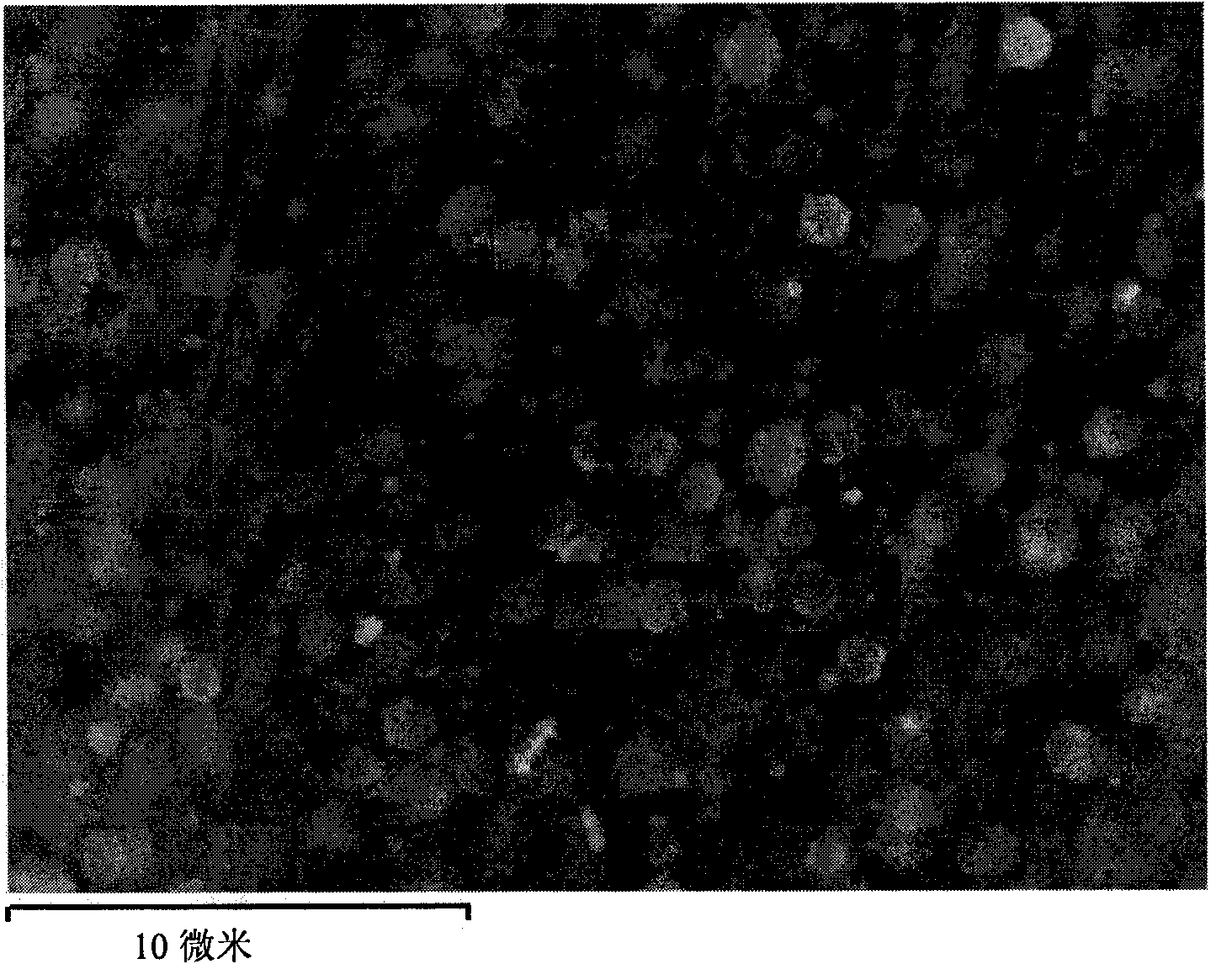

Preparation methods of multi-element metal chalcogen compound, target and coating material

InactiveCN101870458ALow costIncrease production capacityGallium/indium/thallium compoundsVacuum evaporation coatingIndiumSynthesis methods

The invention relates to preparation methods of a multi-element metal chalcogen compound, a target and a coating material. The preparation method of the multi-element metal chalcogen compound comprises the following steps of: synthesizing an elementary substance powder selected from forming elements at normal pressure with a liquid phase synthesis method, wherein the used organic solvent in the synthesis process is an aromatic amines compound with a boiling point higher than 240 DEG C and pH value of 7-10, and thereby producing a copper-indium-gallium-selenium element compound through chelation reactions at high temperature. The compound can be particularly applied to the solar energy field of semiconductor films, can be directly coated into a film and sputtered to a film through producing a target, the selenylation process is unneeded, the production procedure can be reduced, the consistency of the film components is improved, and the product yield and the efficiency are enhanced.

Owner:钟 润文 +1

A kind of method for preparing magnesium-lithium alloy coating by precursor polymer

The invention provides a preparation method of a magnesium-lithium alloy surface coating. Using ceramic precursor polymers such as polysilazane, polycarbosilane and polysiloxane as the base material, with fillers such as B4C powder, SiC powder, SiO2 powder, Al2O3 powder and a small amount of additives, the preparation is carried out as follows: 1. Add a certain amount of fillers and additives to the precursor solution, and mix it in a ball mill to form a uniform slurry; 2. Apply the slurry to the surface of the treated magnesium-lithium alloy by brushing or spraying; 3. Put the Put the painted sample into a nitrogen or vacuum furnace, and cure it at 150°C to 200°C for 0.5 to 2 hours; 4. Brush (or spray) and cure the sample to obtain a reinforced coating . The present invention forms a high polymer with a three-dimensional network through the cross-linking reaction of the precursor molecules, and forms a dense coating on the surface of the magnesium-lithium alloy through the addition of fillers. The coating has excellent corrosion resistance and corrosion resistance. Grinding and heat resistance and other properties. The invention is an ideal method for preparing the magnesium-lithium alloy coating with low cost and high benefit, and broadens the application of the magnesium-lithium alloy in the fields of aerospace, automobile, electronics and the like.

Owner:JIAMUSI UNIVERSITY

Method for making light tye composite hollow metal microball

InactiveCN1333387AElectromagnetic characteristic modulationThe size is easy to controlLiquid/solution decomposition chemical coatingManufacturing technologyChemical plating

The preparation method of a new-type functional material-light compound hollow metal microsphere, belonging to the field of electromagnetic wave absorbing material manufacture technology, includes the following steps: 1. screening out hollow ceramic microsphere with required grain size; 2. making a series of surface treatment to make said microsphere possess excellent metal binding site; 3. making sensitization treatment and making activating treatment to make surface of said ceramic microsphere obtain a layer of uniformly-distributed active initiating layer; 4. making the hollow ceramic microspheres which are treated by means of activation uniformly disperse in chemical plating solution under the condition of electromagnetic stirring, and making chemical plating so as to obtain the invented light compound hollow metal microsphere using hollow ceramic microsphere as core template.

Owner:SOUTHEAST UNIV

Composite coating having antibacterial performance and biocompatibility as well as preparation method and application of composite coating

ActiveCN108904893AExtended service lifePlay does not affectMolten spray coatingSurgeryBiocompatibility TestingMaterials science

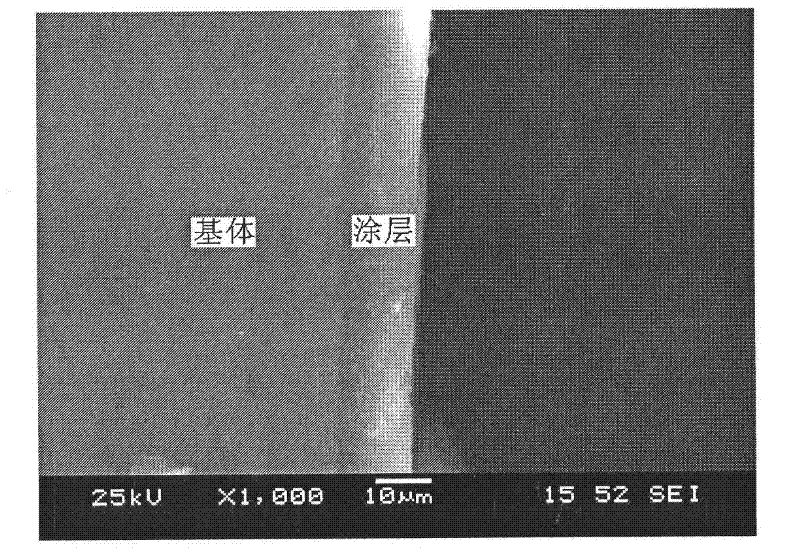

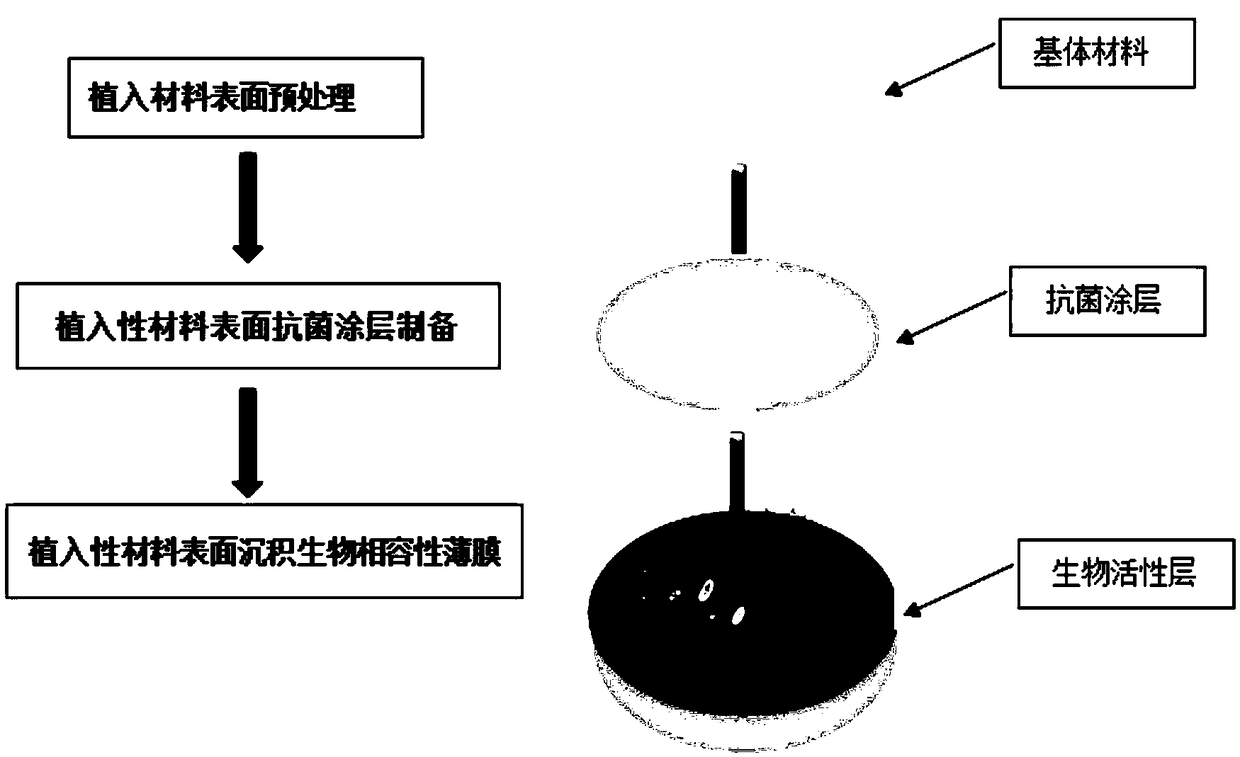

The invention provides a composite coating having antibacterial performance and biocompatibility. The composite coating includes an antibacterial coating and a biocompatibility coating, wherein the antibacterial coating is 2-1000nm thick; and the biocompatibility coating is 2-500nm thick. With the application of a mode of combining the antibacterial coating and the biocompatibility coating, the service life of the coating (the composite coating) is prolonged; the composite coating, which is simple in process, can be continuously and rapidly prepared by a large area; a better antibacterial effect can be achieved, so that antibacterial elements can be released at moderate speed; the biocompatibility coating, under the conditions, can avoid influence to release of antibacterial elements and development of antibacterial performance; and therefore, the composite coating is an ideal coating of implantable medical apparatuses.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

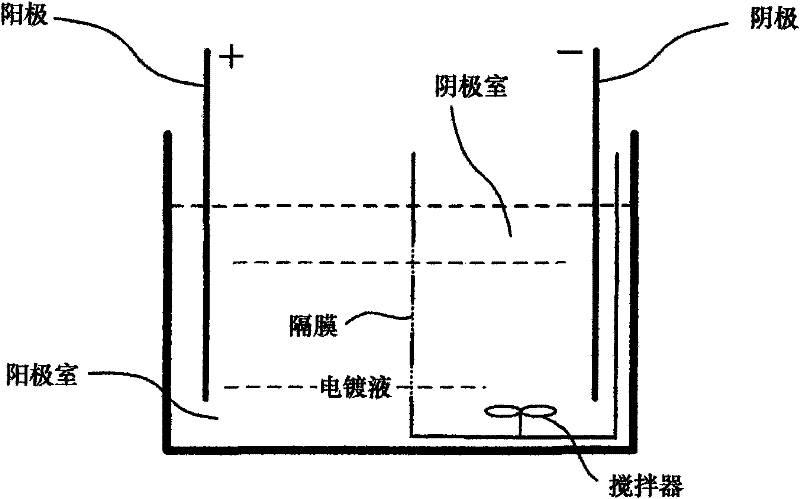

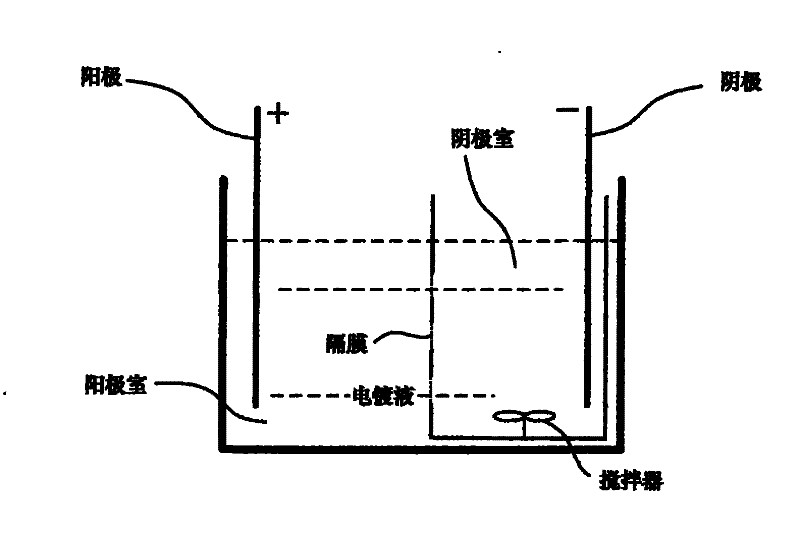

Method for low temperature aqueous solution electrochemical codeposition of nickel iridium alloy

The invention relates to a method for low temperature aqueous solution electrochemical codeposition of nickel iridium alloy, and the method is characterized in that: nickel salts comprise 0.001-0.1mol / L of nickel sulfate, 0.035-0.05mol / L of nickel chloride and 0.005-0.5mol / L of nickel sulfamate, iridium salt is 0.005-0.1mol / L of trichloride iridium containing water crystal, the complex is 0.1-0.5mol / L of citric acid, additives comprise 0.001-0.01mol / L of saccharin, 0.0005-0.01mol / L of gelatin, 0.0001-0.005mol / L of lauryl sodium sulfate, 0.0001-0.005mol / L of naphthyldisulfnate, 0.0001-0.005mol / L of coumarin and 0.0001-0.005mol / L of paratoluene sulfonamide, and the nickel salts, the iridium salt, the complex and the additives are dissolved in deionized water; the plating solution pH is 2-12, deposition temperature is 25-90 DEG C, the current density is 20-100mA / cm<2>, agitation and nitrogen protection are needed in the deposition process, stirring speed of a stirrer is 10-1000 rpm, electrochemical codeposition of nickel iridium alloy can be performed on the surface of an electrode of a pretreated workpiece, and nickel iridium alloy having the advantages of homogeneous composition, fine crystalline grains, good bonding and excellent corrosion resistance can be obtained, the iridium content is 0.1-50at%, and the alloy thickness is 0.1 to 100 mu m.

Owner:CHANGZHOU UNIV

Process of preparing nano composite ceramic coating in super-gravitational field

The process of preparing nanometer composite ceramic coating in super-gravitational field includes: pouring solution for making composite ceramic coating into centrifuger, increasing the rotation speed of the centrifuging tank gradually to 1000-2000 rpm, maintaining the rotation speed for 1-100 min, raising the heating temperature gradually to 200-1000 deg.c under stable rotation speed, maintaining the temperature for 10-600 min, and cooling to room temperature. The super-gravitational field generated in the centrifuger applies one force perpendicular to the substrate surface to the colloid particle, chemical precipitate, ceramic powder, ceramic fiber, metal powder and metal fiber inside the solution to extrude them to the surface of the substrate; and the gradually raised temperature makes the solvent volatilize and the precipitate pyrolyze, oxidize, sinter, etc., so as to form controllable compact nanometer composite ceramic coating.

Owner:UNIV OF SCI & TECH BEIJING

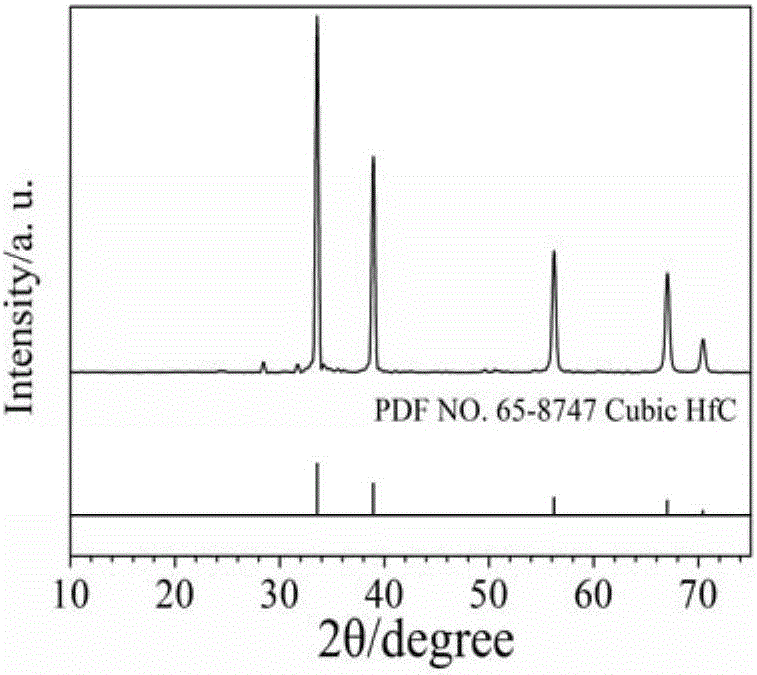

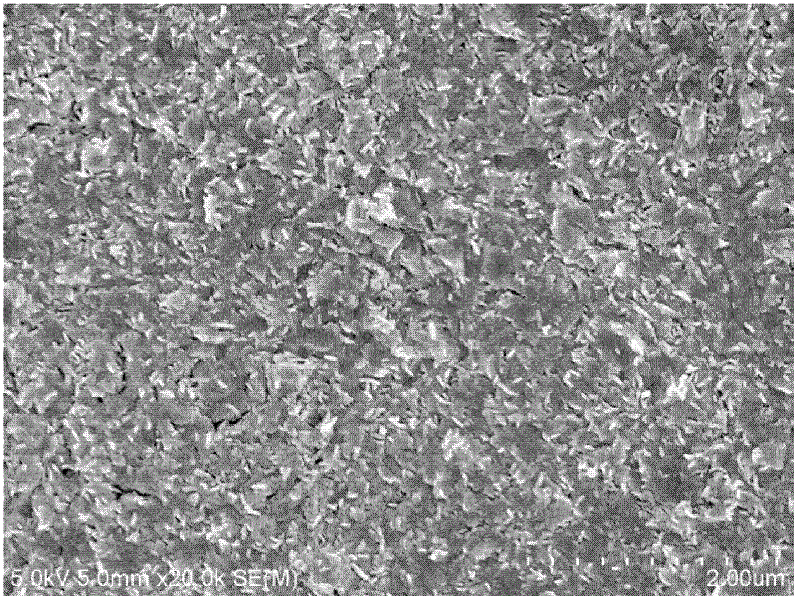

Method for preparing superhigh temperature carbonized hafnium ceramic nano-powder

ActiveCN106588018AGood dispersionSolve the problem of difficult sinteringMaterial nanotechnologyDispersityRoom temperature

The invention relates to a method for preparing superhigh temperature carbonized hafnium ceramic nano-powder. Anhydrous saccharose is evenly dispersed in deionized water, a mixed template is added, stirring is carried out, an even and transparent precursor solution is obtained, and the solution is poured into a hydrothermal still; the hydrothermal still is placed in an electric heating air blowing drying box for reacting after being sealed, then the product is cooled to room temperature, and filtering, separation, washing and drying are carried out; finally, the product is mixed with hafnium powder, a vacuum carburizing reaction is carried out, and HfC nano particles are prepared. Compared with the prior art, the prepared carbonized hafnium ceramic nano-powder is good in crystallinity and dispersity and controllable in morphology.

Owner:SHANGHAI JIAO TONG UNIV

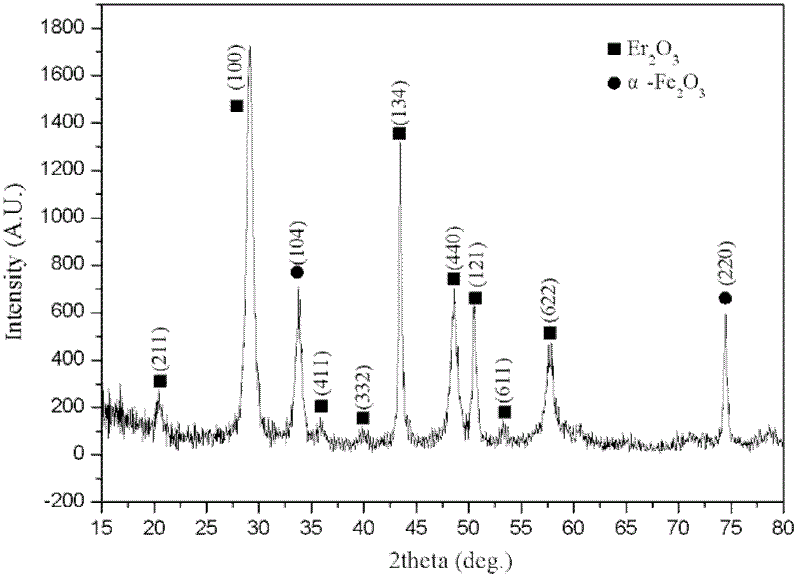

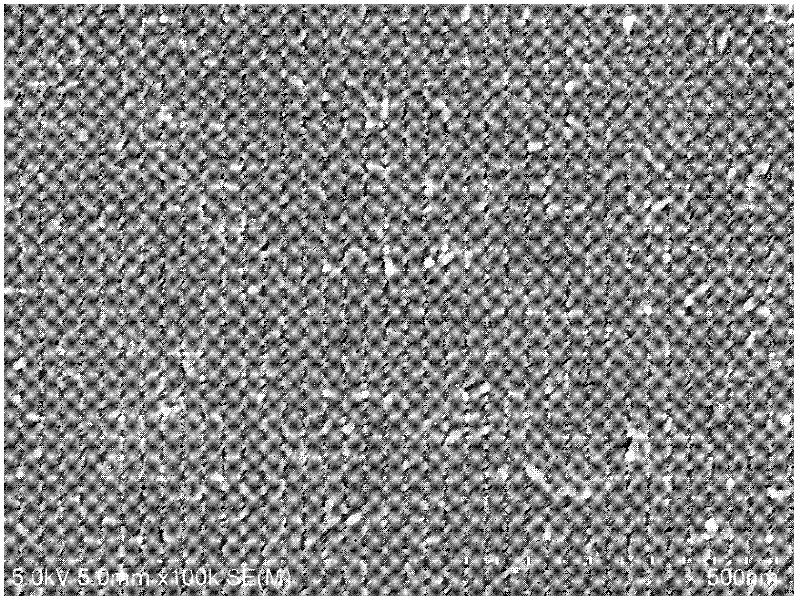

Method for preparing tritium resistance Er2O3 coating by using chemical solution method

InactiveCN102618871AQuality improvementLow costMetallic material coating processesChemical solutionNitrate

The invention relates to a method for preparing a tritium resistance Er2O3 coating by using a chemical solution method. The method comprises: mixing ethanol and terpineol according to a volume ratio of 20:1-10:1; stirring the resulting mixed solution with a magnetic stirrer at a room temperature; adding erbium nitrate to the mixed solution in a dropwise manner after the mixed solution is uniformly stirred; stirring for 4-8 hours with the magnetic stirrer at a temperature of 80-90 DEG C to obtain a transparent light red erbium nitrate gel; coating the erbium nitrate gel on a substrate; placing the substrate coated with the erbium nitrate gel in a high temperature tube quartz furnace, and carrying out high temperature sintering for 3-5 hours under inert atmosphere at a temperature of 600-800 DEG C to obtain the tritium resistance Er2O3 coating. The tritium resistance Er2O3 coating of the present invention is flat and compact, and has good adhesion with the substrate.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

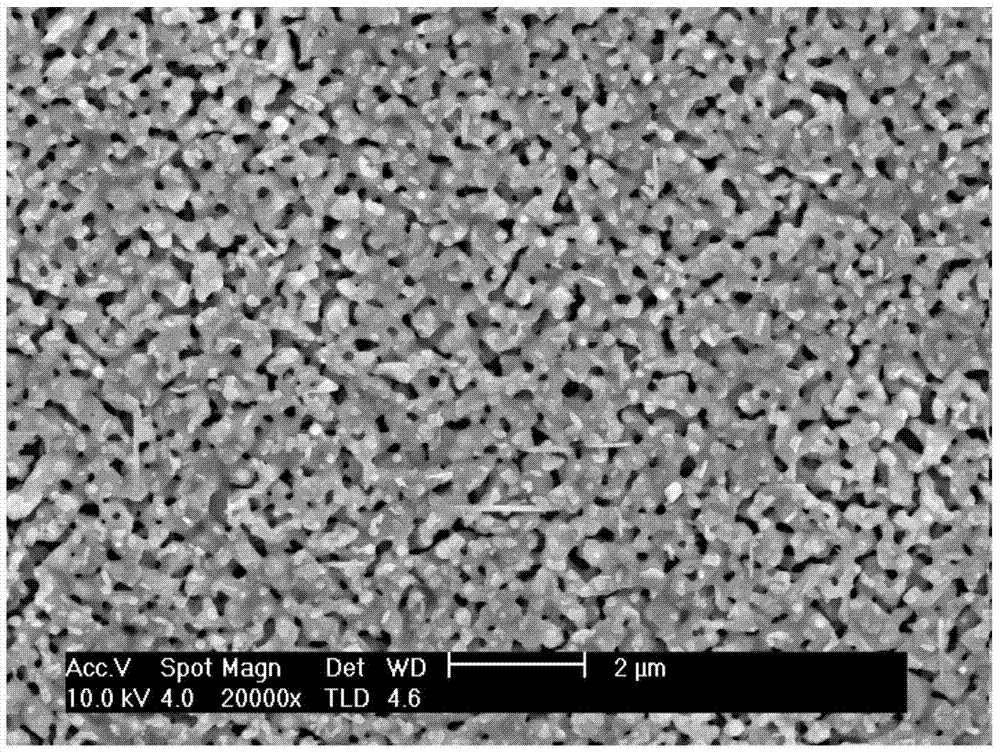

Method for preparing YBCO (Yttrium Barium Copper Oxide) coating conductor barrier layer

InactiveCN102242357AQuality improvementReduce surface roughnessSolid/suspension decomposition chemical coatingYttrium barium copper oxideElectrical conductor

The invention discloses a method for preparing an YBCO (Yttrium Barium Copper Oxide) coating conductor barrier layer. The method comprises the following steps of: firstly preparing a precursor liquid, mixing aluminium isopropoxide with deionized water according to a mole ratio of Al:H2O=1:50-1:100, stirring the precursor liquid by using a magnetic stirring apparatus at 80-90 DEG C, dropwise adding hydrochloric acid to the uniformly stirred precursor liquid and regulating a pH value to be 2-4; stirring the precursor liquid by using the magnetic stirring apparatus at 80-90 DEG C again to obtain transparent Al2O3 gel; coating the Al2O3 gel on a substrate; and placing the substrate coated with the Al2O3 gel in a high-temperature tubular quartz furnace, and carrying out a low-temperature thermal treatment at 300-500 DEG C under an inert atmosphere for 5-10h to obtain an amorphous alumina film. The amorphous alumina film prepared by the method disclosed by the invention is smooth and compact.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

High-purity bismuth-lead alloy and preparation method thereof

The invention discloses a high-purity bismuth-lead alloy and a preparation method thereof. The preparation method comprises the steps that a compounding step is carried out, specifically, according tothe composition design of the bismuth-lead alloy, massive lead materials and bismuth materials are used as raw materials for compounding and mixing; a smelting step is carried out, specifically, themixed raw materials are smelted under vacuum; a cooling step is carried out, specifically, alloy melt obtained after smelting is subjected to cooling; a filtering step is carried out, specifically, the alloy melt after cooling is subjected to filtration treatment; and a casting step is carried out, specifically, the filtered alloy molt is casted into a mold under vacuum and cooled to obtain an alloy ingot. According to the high-purity bismuth-lead alloy and the preparation method thereof, through the combination of high-temperature vacuum melting and low-temperature vacuum casting, oxides andother metal impurities in the lead and bismuth raw materials can be efficiently and advantageously removed, so that the purity of the alloy reaches above 99.998%. And through timing electromagnetic stirring and controlling of the weight of a single alloy ingot, the overall composition of the alloy is uniform and controllable, and the problem of excessive composition segregation is avoided.

Owner:安泰天龙钨钼科技有限公司 +1

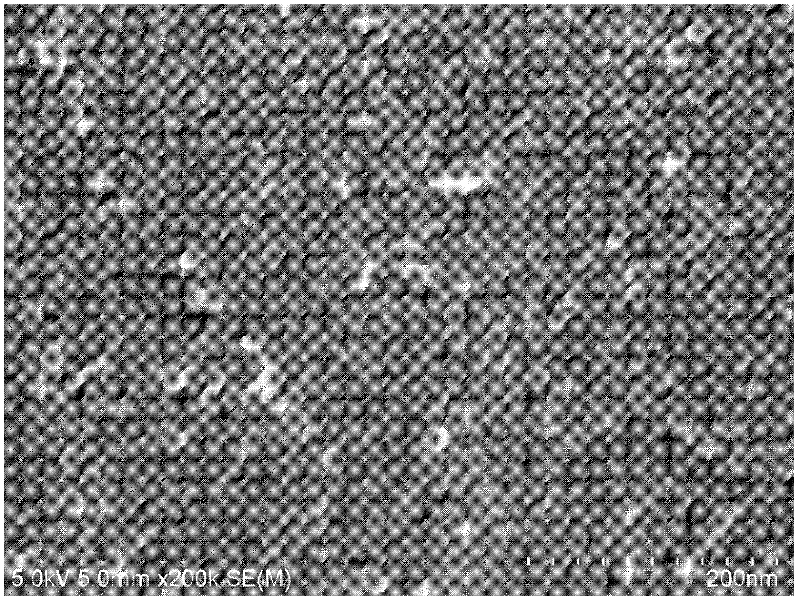

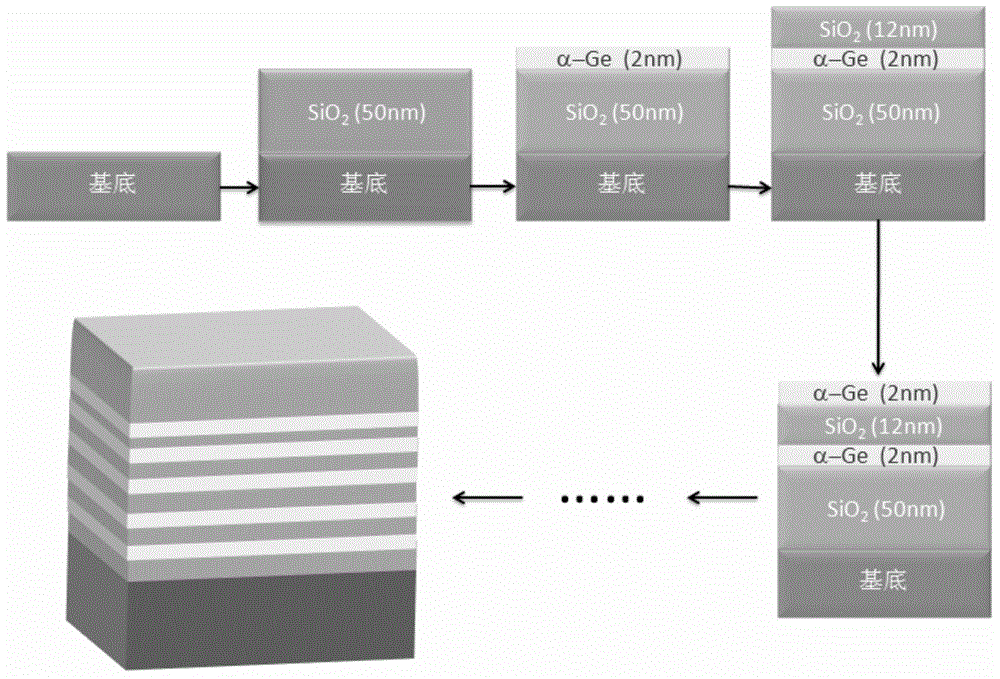

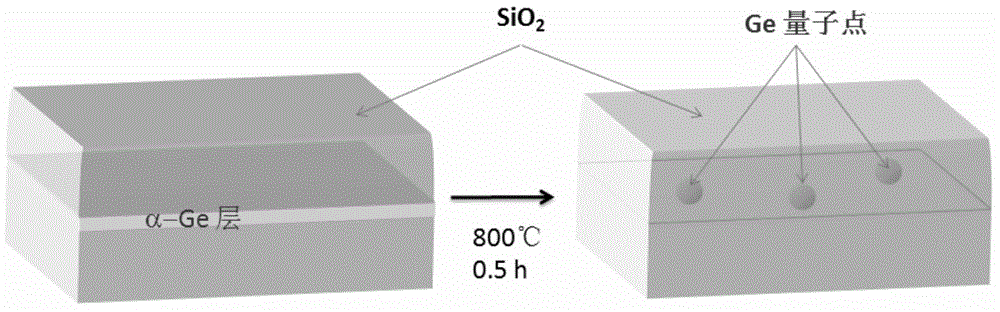

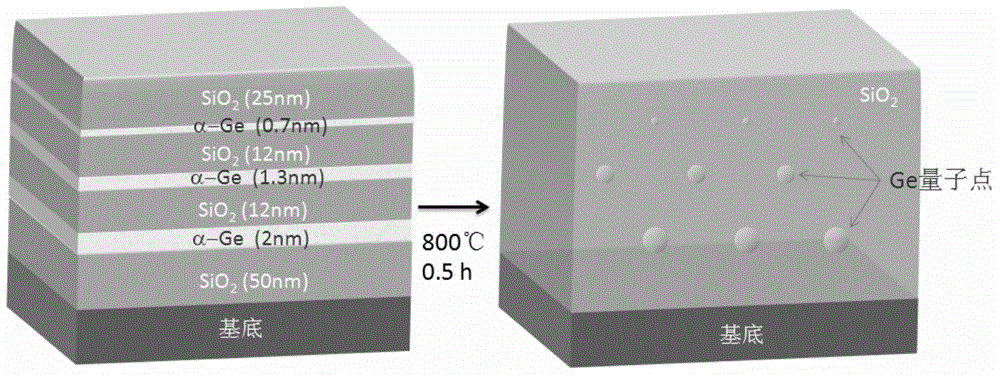

Layer-like germanium quantum dot material and preparation method thereof

InactiveCN104419906AUniform sizeControllable ingredientsMaterial nanotechnologyVacuum evaporation coatingQuantum dotBand gap

The invention provides a layer-like germanium quantum dot material and a preparation method thereof. The method comprises the following steps: alternately depositing a SiO2 layer and a Ge layer on a substrate, and annealing. The method disclosed by the invention can be used for preparing a Ge quantum dot material which is in layer-like distribution. The germanium quantum dot material disclosed by the invention is uneven in size of Ge quantum dots and has the advantages of being controllable in ingredients and structure, adjustable in band gap and the like.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

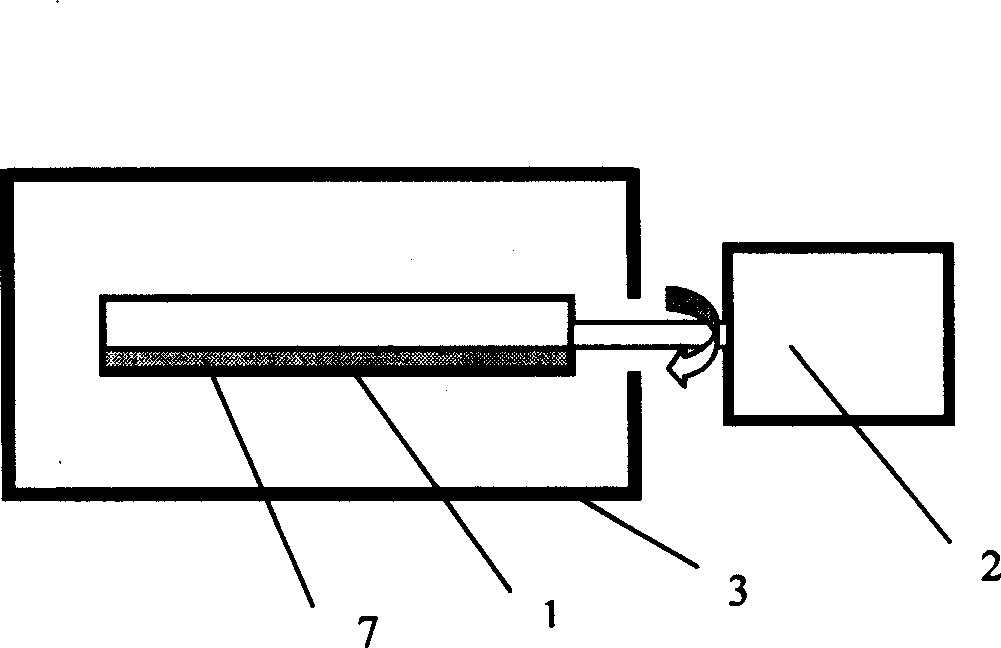

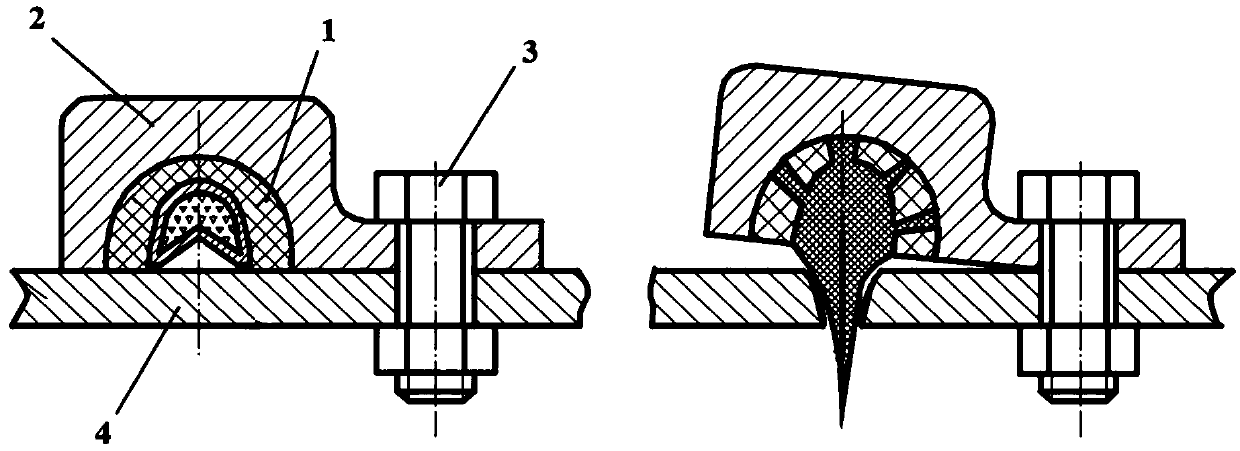

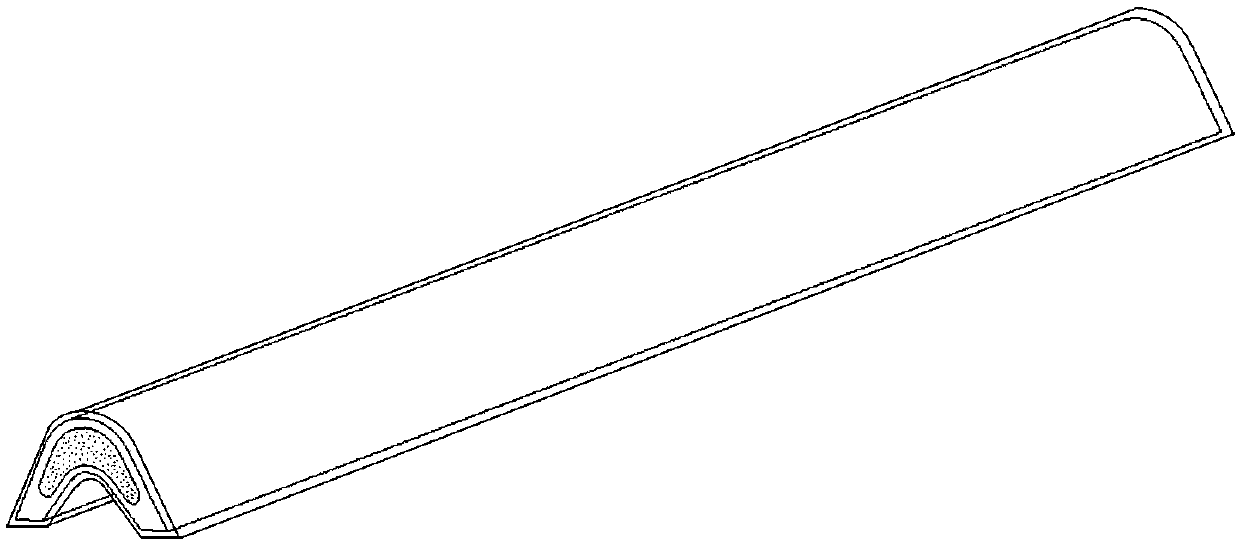

Method for protecting thin-wall energy gathering cutting ropes by using Parylene micro-nano films

InactiveCN110965045ALow deposition temperatureFilm composition is easy to controlChemical vapor deposition coatingMicro nanoDetonator

The invention discloses a method for protecting thin-wall energy gathering cutting ropes by using Parylene micro-nano films. A chemical vapor deposition method is adopted to coat Parylene films with micro-nano-scale thicknesses on the outer surfaces of the thin-wall energy gathering cutting ropes for damp prevention, salt mist prevention and mould prevention of the thin-wall energy gathering cutting ropes to enable the protecting performance to meet environmental test requirements stated by the GJB344-87 general design specification for insensitive electric detonators. After experimental tests, the thin-wall lead pipe energy gathering cutting ropes still achieve high reliability, and can be applied to interstage separation of multistage propulsion rockets, window casting and slitting of mother-son bullet shells.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of humic acid coated urea

ActiveCN105237314AWide variety of sourcesLow costUrea compound fertilisersFertilizer mixturesCoated ureaPotassium

The invention discloses a preparation method of humic acid coated urea. The preparation method comprises following steps: humic acid raw powder and trisodium phosphate are added into a sodium hydroxide or a potassium hydroxide aqueous solution for 1h of reaction at 100 DEG C so as to obtain a sodium humate or a potassium humate aqueous solution; polyvinyl alcohol is added for mixing, and an obtained mixed solution is dried until water content is lower than 10% so as to obtain a dry product; the dry product is smashed into particles with a particle size of 80 to 200 meshes, and is taken as a coating agent; at normal temperature, the coating agent is mixed with urea particles at a certain ratio; an obtained mixture is subjected to treatment in a roller for 10 to 30min, and is subjected to sieving and packaging so as to obtain humic acid coated urea. The preparation method is capable of realizing direct coating after pelleting in urea plants, and is suitable for coating processing in value-adding factories using commercial urea. Introduction of humic acid is capable of improving product functions, urea is provided with long-term stability, utilization ratio is increased greatly, the preparation method is beneficial for energy saving and environmental protection; long-term application is capable of restoring soil, increasing soil organic matter content, and improving soil self adjustment ability, and is beneficial for agricultural sustainable development.

Owner:LIAONING PUTIAN TECH

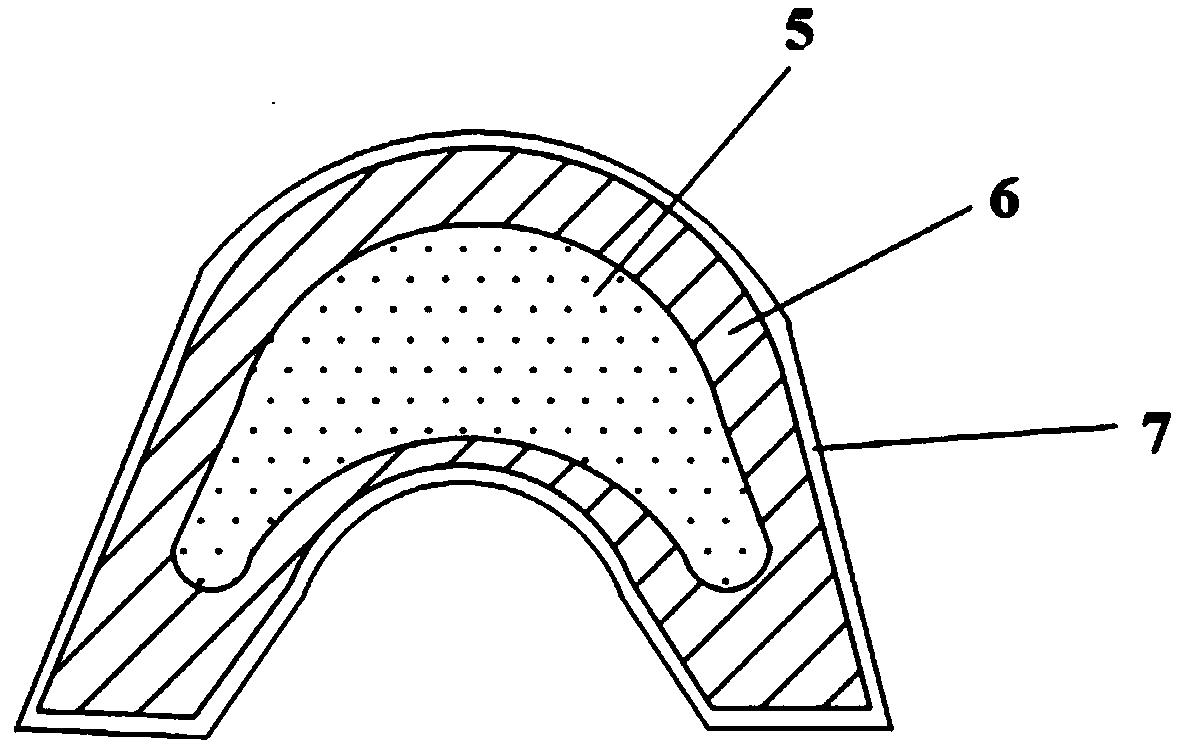

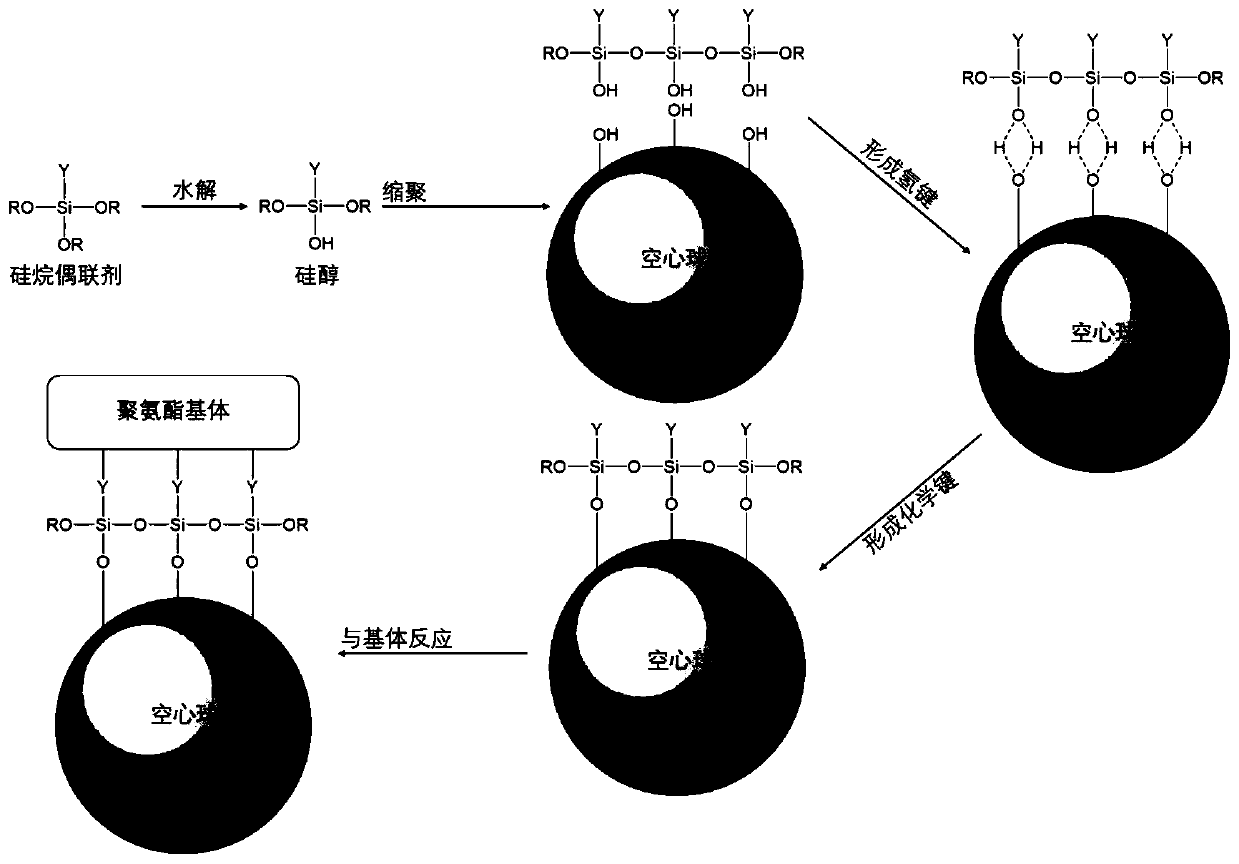

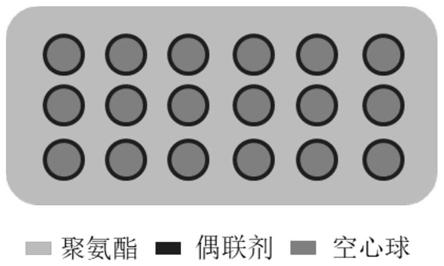

Preparation method of novel hollow sphere filled polyurethane-based composite material

The preparation method of the novel hollow sphere filled polyurethane-based composite material comprises the following steps: cleaning the surface of a hollow sphere to remove impurities and dirt on the surface, and drying for later use; wherein the used surface modifier is a silane coupling agent, and the silane coupling agent needs to be hydrolyzed; adding the hollow spheres into the hydrolyzedsilane coupling agent solution, stirring at a proper temperature, then putting the hollow spheres into a drying oven for drying, and taking out for later use; and adding the modified hollow spheres into a casting mold, sequentially adding isocyanate, hydroxyl-terminated polyester or hydroxyl-terminated polyether and other assistants, stirring to uniformly distribute the hollow spheres in the matrix, curing at room temperature, and demolding to obtain the hollow sphere filled polyurethane-based composite material. The production process is reasonable in design, and operation steps are simple and convenient; the components and the structural design of the composite material are controllable; the composite material has excellent mechanical and acoustic properties.

Owner:HARBIN ENG UNIV

Laser repairing method for propeller shaft

PendingCN112981389AAvoid deformationLow dilution rateMetallic material coating processesHeat-affected zonePropeller

The invention relates to a laser repairing method for a propeller shaft. According to the method, the propeller shaft is repaired through laser cladding, specifically, heating is conducted on a metal surface by means of a high-energy laser beam, a substrate surface and added alloy powder are quickly heated and melted under the heat action to form a metallurgical bonding surface cladding layer with an extremely low dilution rate, the propeller shaft is repaired by means of a laser cladding technology, more excellent abrasion resistance and corrosion resistance are achieved, deformation of the propeller shaft can be avoided due to quick heating and quick cooling of laser, low heat input, a small heat affected zone and low distortion, the dilution rate of the cladding layer is smaller than 5%, the cladding layer is in firm metallurgical bonding with a substrate, and the good cladding layer with controllable cladding layer components and dilution can be obtained.

Owner:DANYANG HONGTU LASER TECH

Method for preparing hollow beads

InactiveCN108483930AThe size is easy to controlControllable ingredientsGlass shaping apparatusEnergy consumptionCombustion

The invention relates to a method for preparing hollow beads and belongs to the field of environment protection. The method comprises the following steps: preparing powder aggregate from solid wastes,a modifier, a foaming agent and a fluxing agent, feeding the powder aggregate into an ejection combustion device, carrying out melting, and swelling and rapid condensation procedures, so as to obtainan inorganic hollow bead material with different granule sizes and different structures, wherein the powder aggregate comprises the following percentage by weight: 15-95% of solid wastes, 3-70% of the modifier, 1-5 parts of the foaming agent and 1-10% of the fluxing agent. By adopting the method, the defects that a conventional hollow bead preparation method is high in energy consumption, relatively high in cost, uncontrollable in product quality and in addition relatively high in production process control requirement, can be overcome, and by adopting the method for preparing the hollow beads, solid wastes can be treated, the environment can be protected, and a product is excellent in quality, low in price and controllable in property.

Owner:ZEROWASTE ASIA PTE LTD

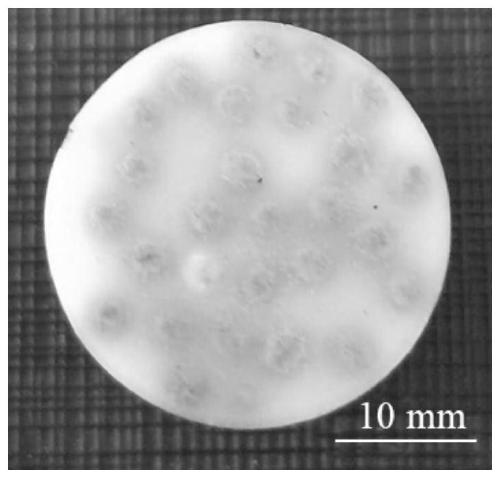

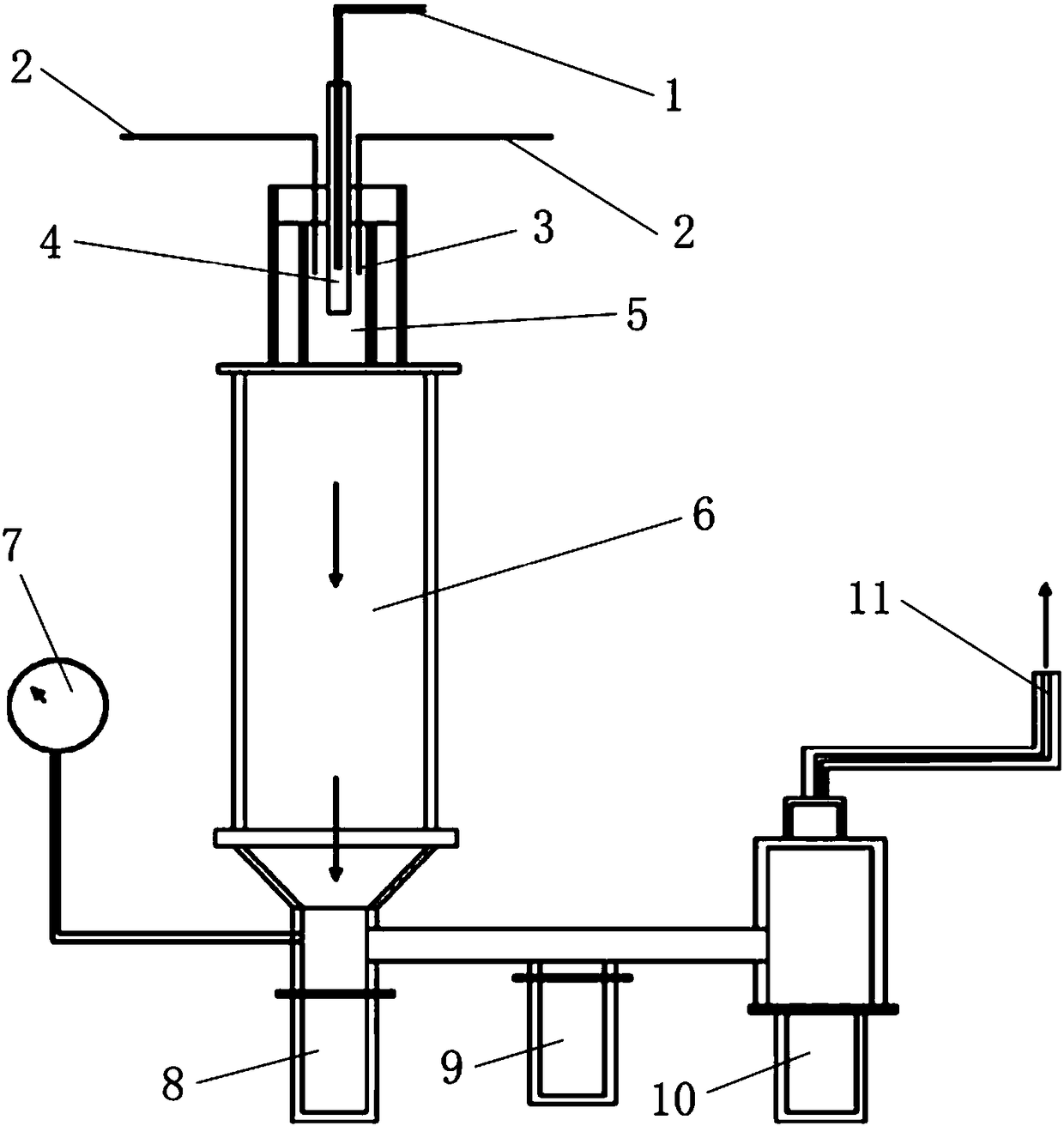

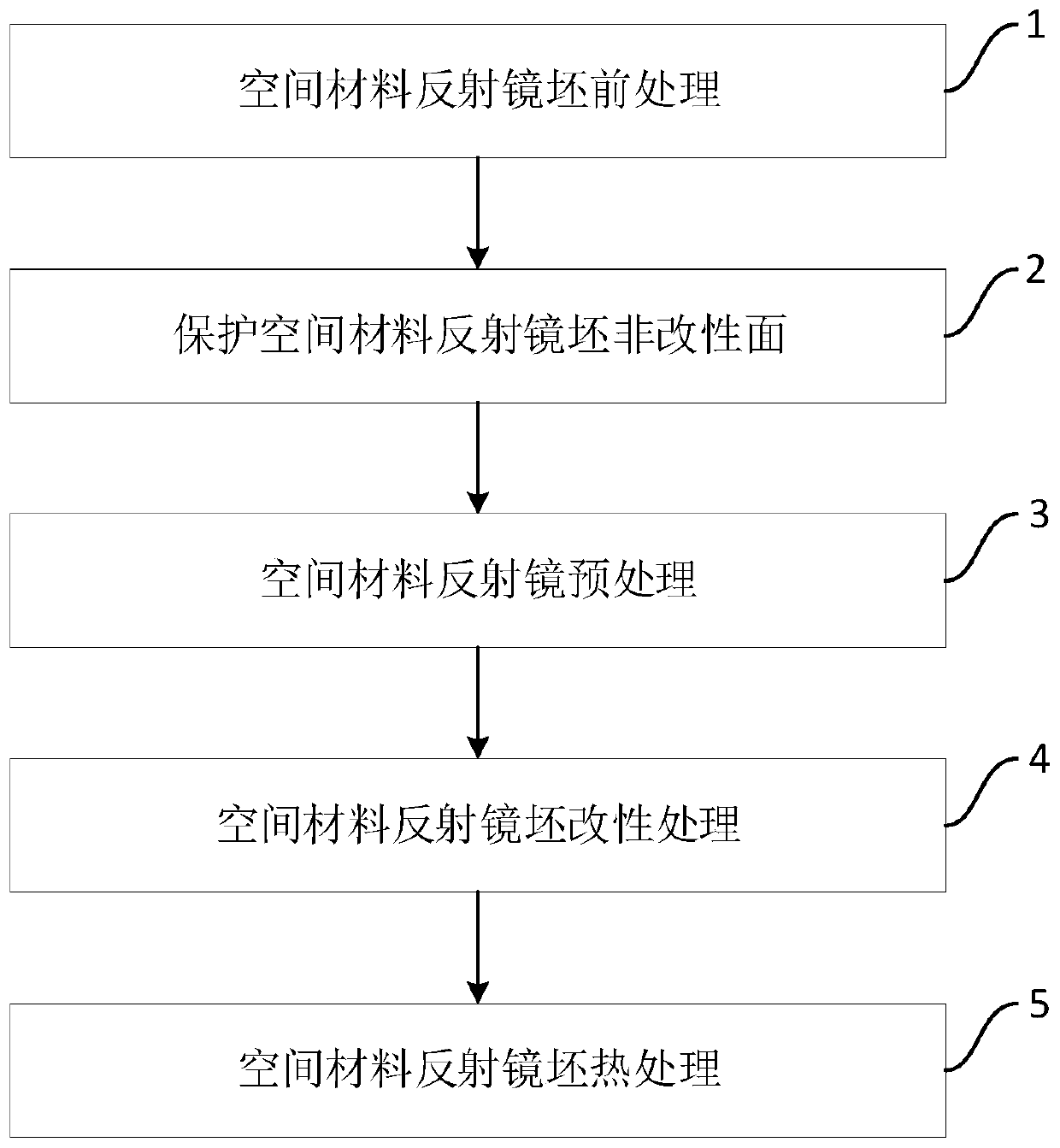

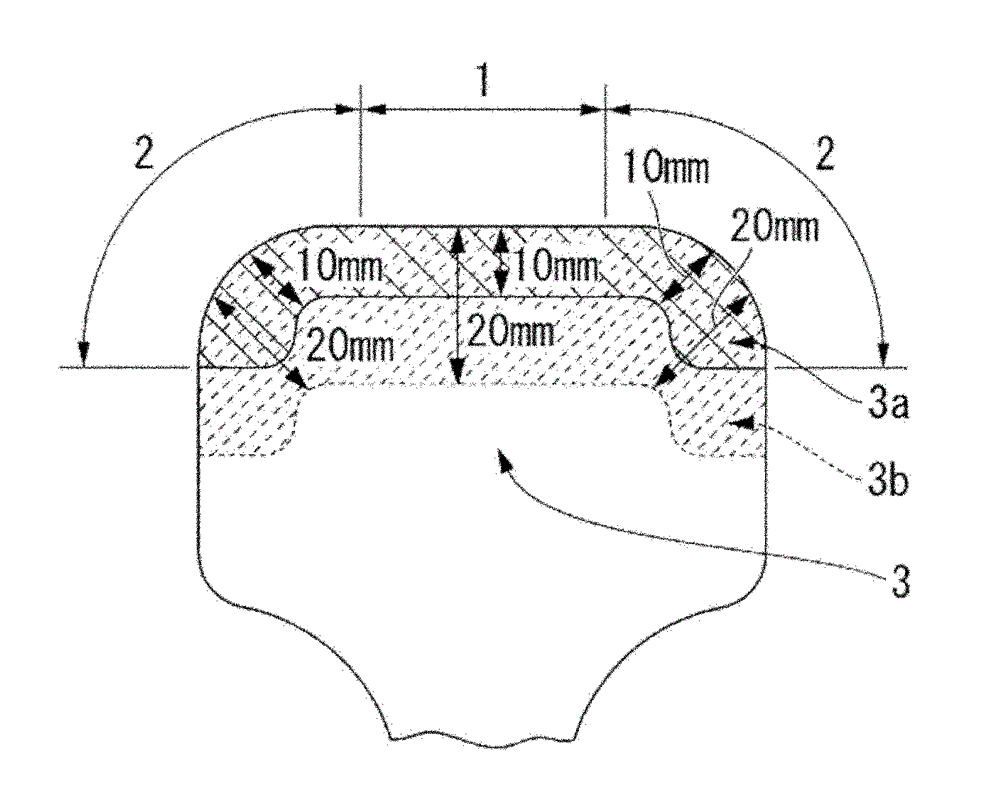

Modification treatment method for surface of space material reflector blank

InactiveCN110777370AAchieve surface modificationStable deposition rateLiquid/solution decomposition chemical coatingInvestigating material hardnessThermal dilatationAlloy

The invention discloses a modification treatment method for surface of a space material reflector blank. The modification treatment method comprises the steps that S1, the reflector blank is pretreated, specifically, a zinc dipping solution is used for treating the modified surface of the space material reflector blank, and a transition layer is generated on the modified surface of the space material reflector blank; and S2, modification treatment is conducted, specifically, the pretreated space material reflector blank is treated through a modification treatment solution, and a nickel-phosphorus alloy modified layer is deposited on the modified surface of the space material reflector blank. By means of the modification treatment method for the surface of the space material reflector blank, the nickel-phosphorus alloy modified layer with the microhardness being HV 400-780, the melting point being not lower than 890 DEG C, the thermal expansion coefficient being (7.8-9.4) * 10<-6> / DEG Cand the porosity being lower than 5% can be deposited on the surface of the reflector blank through a chemical deposition method, the surface defect grade of the nickel-phosphorus alloy modified layer is IV, the modification treatment method is suitable for optical ultra-precision machining, and an ultra-smooth surface with the root mean square value being 0.049 lambda, the roughness being superior to 2nm and the surface defect grade being IV can be obtained through optical precision polishing.

Owner:CHANGCHUN UP OPTOTECH

Pearlite rail having superior abrasion resistance and excellent toughness

This pearlite rail consists of a steel including: in terms of percent by mass, C: 0.65 to 1.20%; Si: 0.05 to 2.00%; Mn: 0.05 to 2.00%; P‰¤ 0.0150%; S‰¤ 0.0100%; Ca: 0.0005 to 0.0200%, and Fe and inevitable impurities as the balance, wherein a head surface portion which ranges from surfaces of head corner portions and a head top portion to a depth of 10 mm has a pearlite structure, a hardness Hv of the pearlite structure is in a range of 320 to 500, and Mn sulfide-based inclusions having major lengths in a range of 10 to 100 µm are present at an amount per unit area in a range of 10 to 200 / mm 2 in a cross-section taken along a lengthwise direction in the pearlite structure.

Owner:NIPPON STEEL CORP

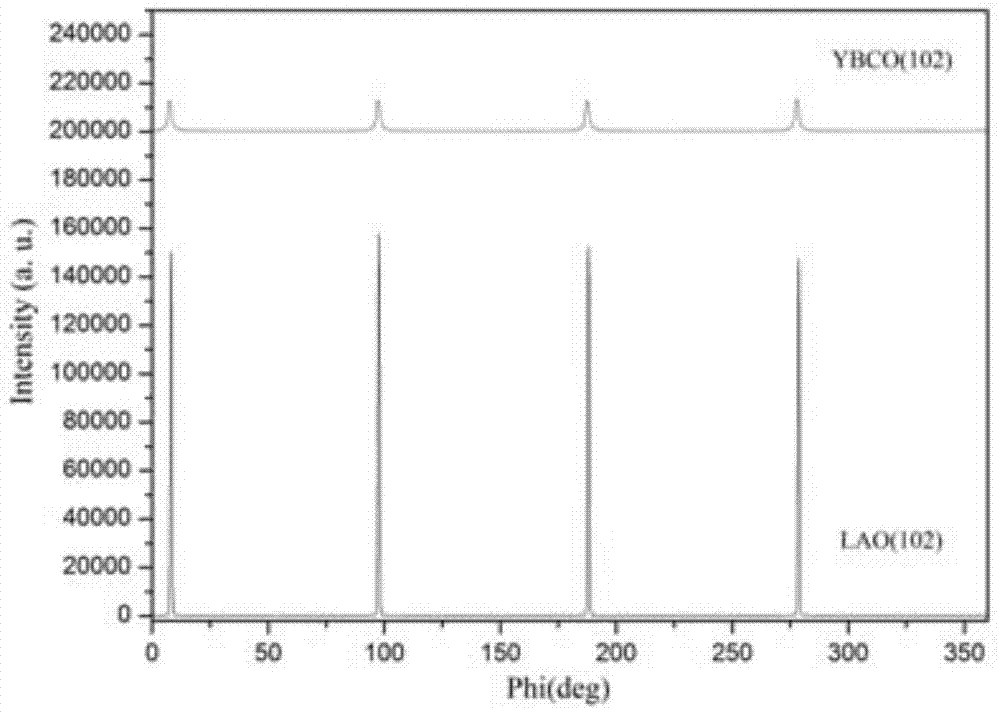

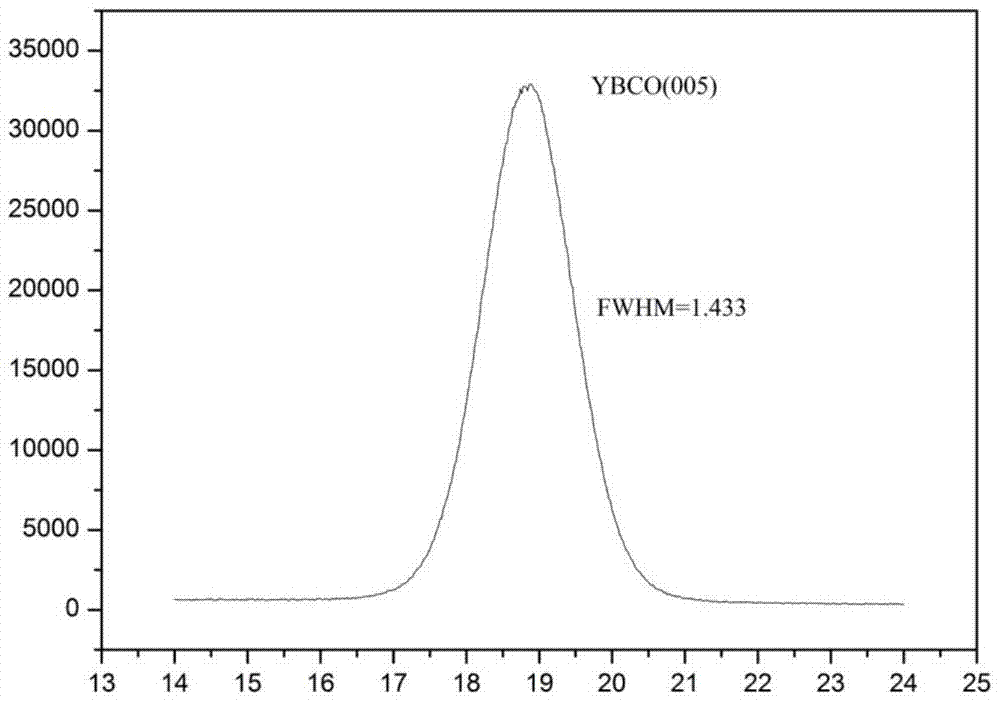

A kind of preparation method of yttrium barium copper oxide high temperature superconducting tape

InactiveCN105386020BSimple structureLow costSolid/suspension decomposition chemical coatingChemical solutionBarium titanate

Provided is a method for preparing an yttrium barium copper oxide high-temperature superconducting strip. The method comprises the steps that barium acetate and tetrabutyl titanate are mixed and dissolved in a mixed solution of ethylene glycol monomethyl ether, glacial acetic acid and acetylacetone according to the molar ratio of Ba to Ti of 1:1, and precursor liquid with the total concentration of Ba ions to Ti ions of 0.1 mol / L to 0.3 mol / L is prepared after even mixing; then the precursor is smeared to an NiW alloy base band; a thin film obtained after smearing is subjected to thermal treatment, and a barium titanate (BaTiO3) thin film with biaxial texture is obtained; and then a YBa2Cu3O7-x(YBCO) superconducting layer is prepared on a BaTiO3 buffer layer through a chemical solution method, and the high-temperature superconducting strip with the structure of NiW / BaTiO3 / YBCO is prepared.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

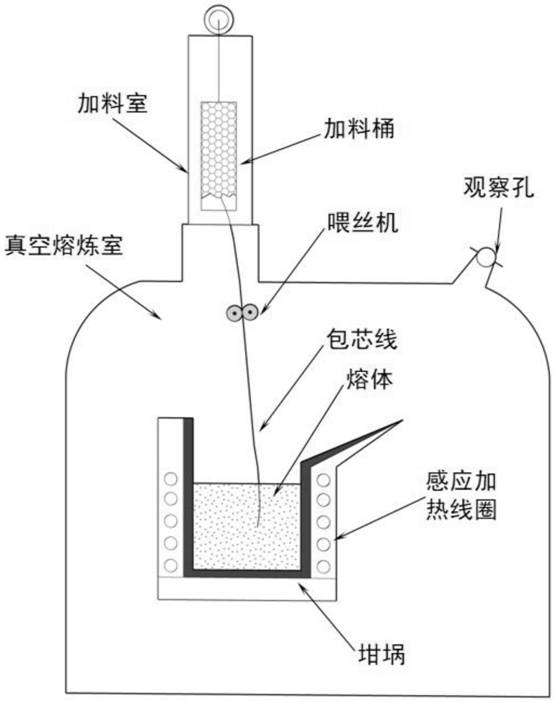

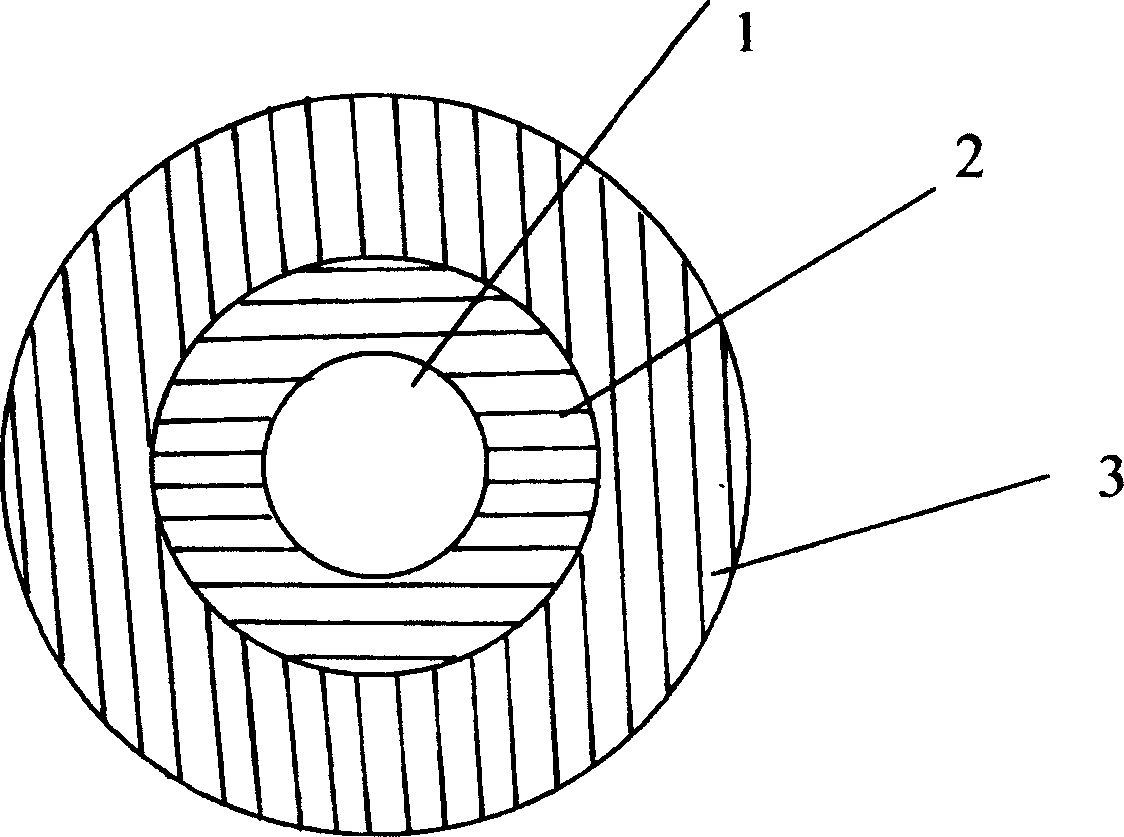

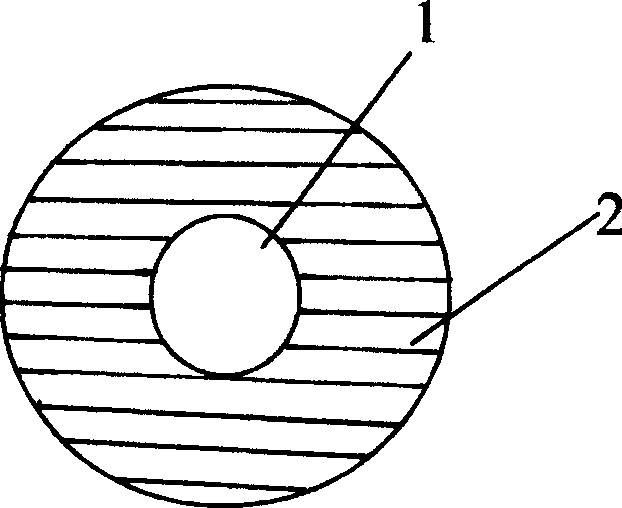

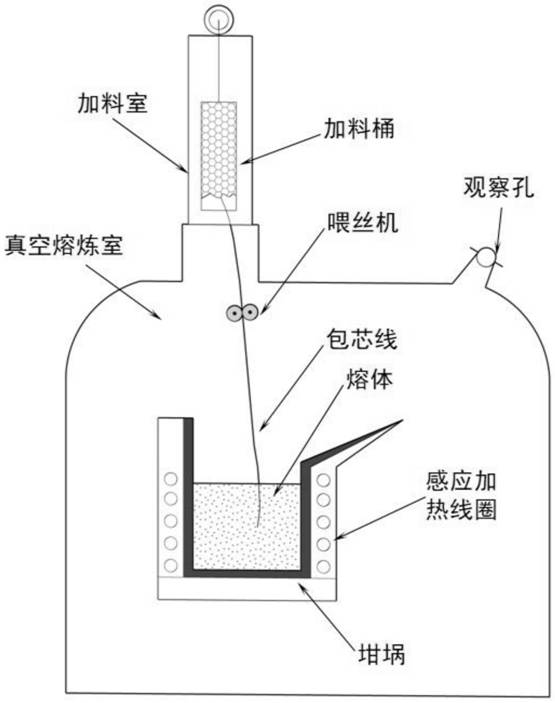

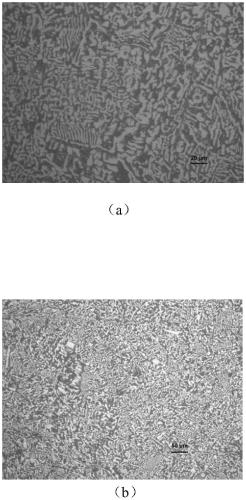

Preparation method of low-oxygen-content Zr-based bulk amorphous alloy

The invention discloses a preparation method of a low-oxygen-content Zr-based bulk amorphous alloy. The oxygen content in the Zr-based amorphous alloy is reduced by adding a twisted wire composite wire. The oxygen content in the Zr-based amorphous alloy is controlled and reduced by utilizing the special twisted wire composite wire (Al, Ti, Ca and Y composite twisted wire), the composite twisted wire is prevented from being gasified and removed by forming a composite deoxidized product through an oxidation reaction in a solution through a reasonable control process, so that the low-oxygen content control of the Zr-based bulk amorphous alloy is realized, the process is high in operability, controllable in component and suitable for industrial production, compared with a traditional smelting and deoxidizing process, the Zr-based bulk amorphous alloy is low in oxygen content and high in amorphous forming capacity, the performance of the Zr-based amorphous alloy is improved and stabilized, and industrial application and popularization can be achieved.

Owner:CHANGZHOU STREAM LIQUID METAL CO LTD

Process for producing iron phosphate

The invention relates to a preparation method of iron phosphate. The current iron phosphate production method has disadvantages such as complex process, high production cost, and difficulty in component control. The present invention uses iron source compound and phosphoric acid as raw material, and simple organic matter as catalyst, mixes raw material and catalyst, and reacts at 80°C-160°C for 20 minutes to 2 hours to synthesize iron phosphate with chemical formula FexPO4, wherein 0.90 ≤x≤1.10. The raw materials and catalysts used in the method of the invention are common chemical raw materials, and the reaction is carried out at relatively low temperature and normal pressure. The required equipment is simple and the energy consumption is small, so the cost of the product is relatively low. Because the reaction is carried out at low temperature, the volatilization of elements is avoided, and the composition of the product is easy to control.

Owner:HANGZHOU DIANZI UNIV

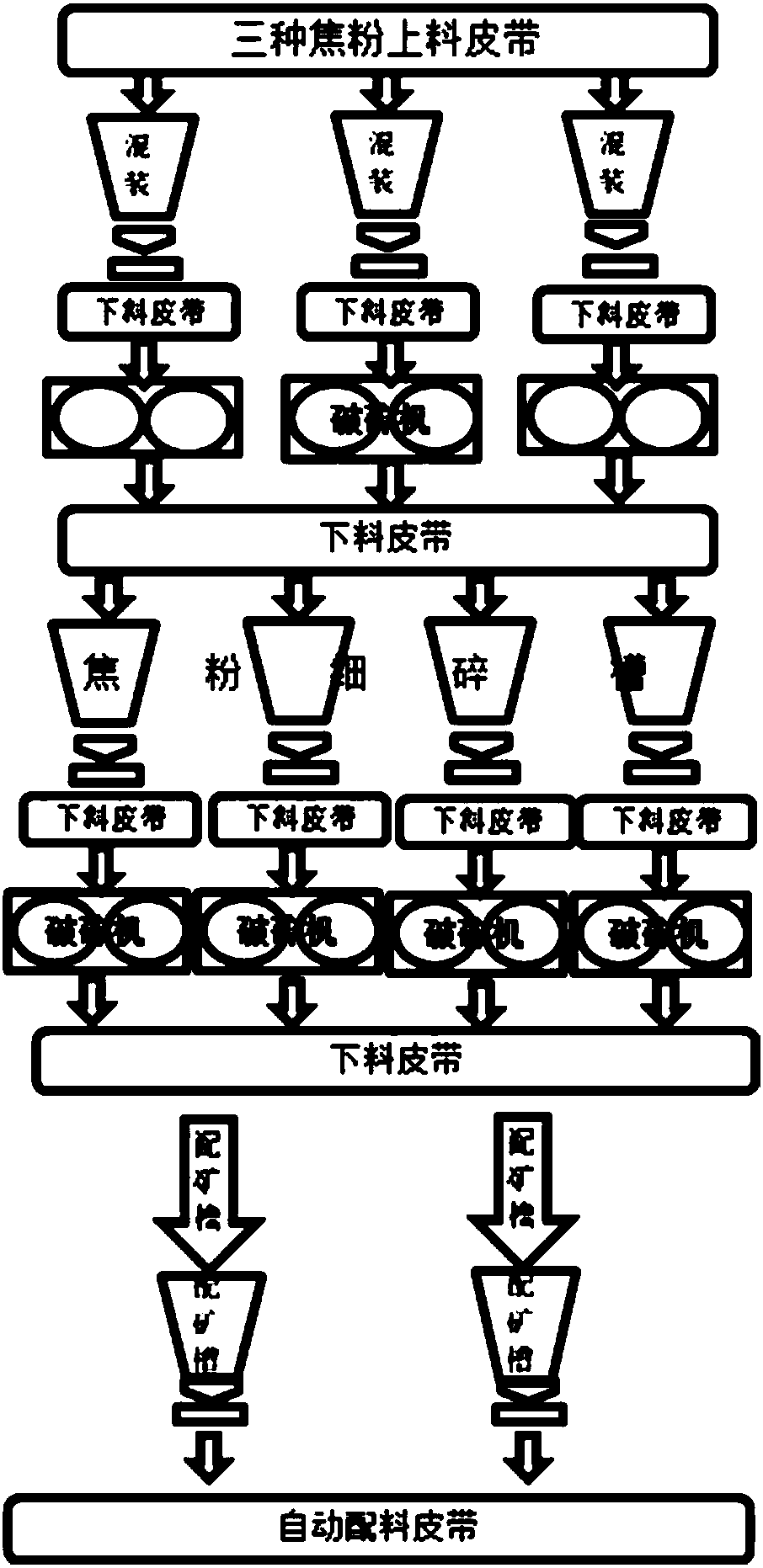

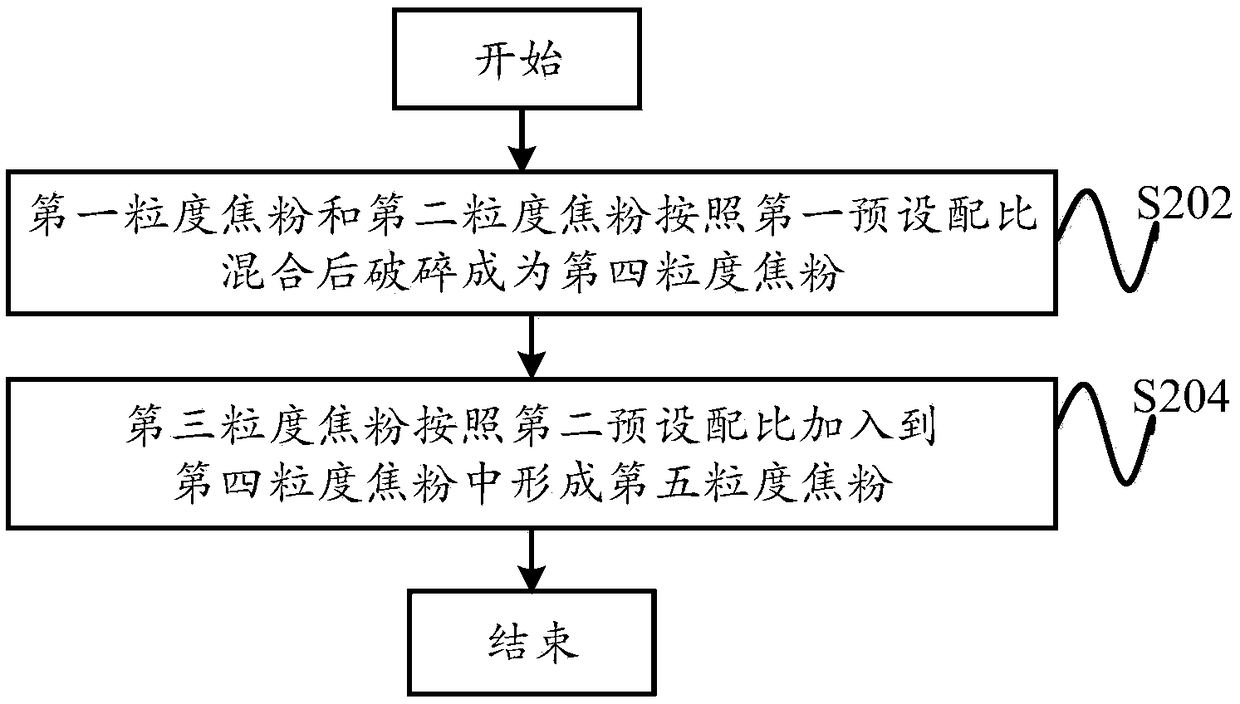

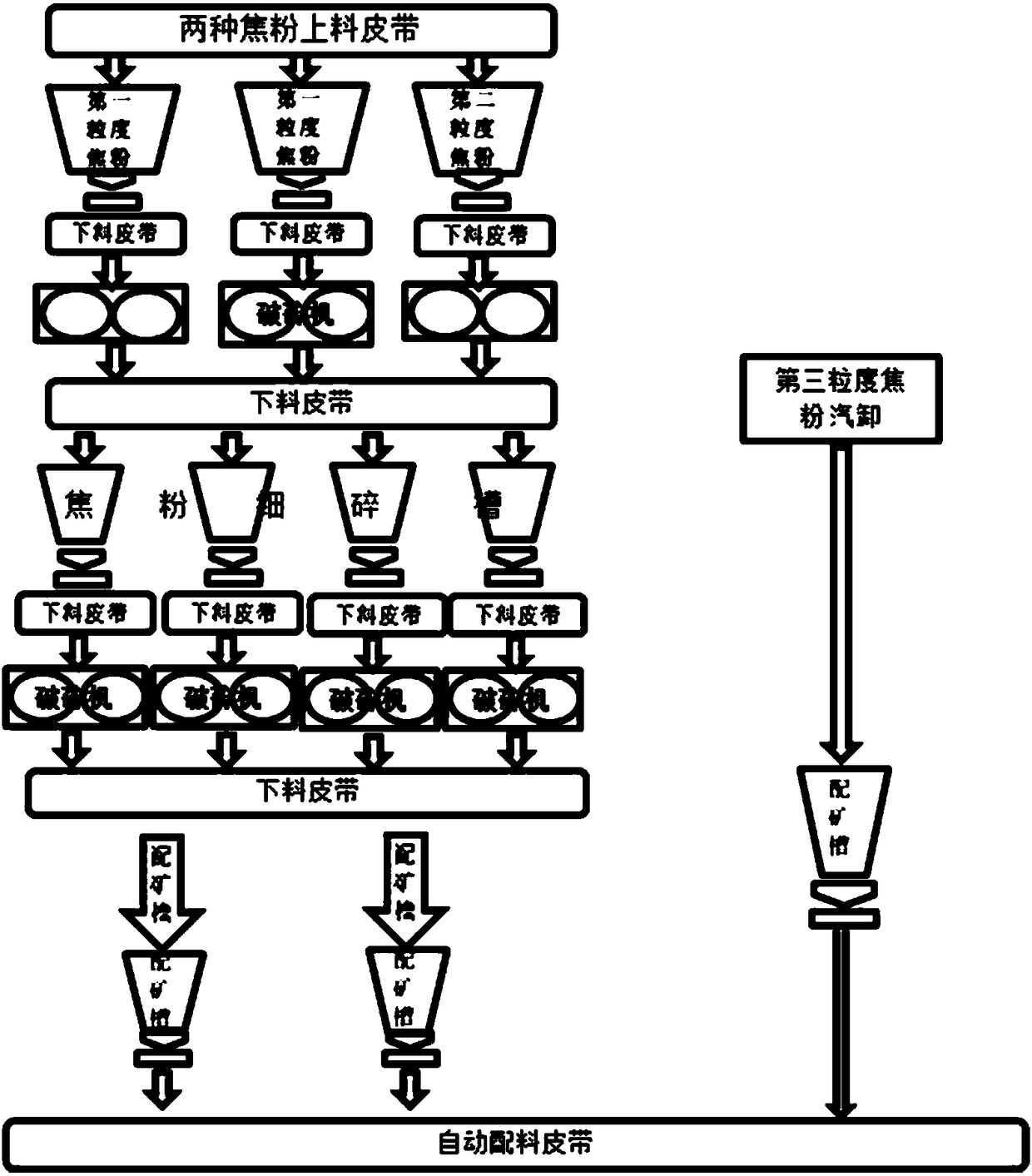

Method for mixing uniformly and crushing coke powder

InactiveCN108246479AControllable ingredientsImprove stabilityGrain treatmentsMetallurgySize composition

The invention provides a method for mixing uniformly and crushing coke powder. The coke powder comprises first-particle size coke powder, second-particle size coke powder and third-particle size cokepowder. The method for mixing uniformly and crushing the coke powder comprises the following steps: mixing the first-particle size coke powder and the second-particle size coke powder according to a first preset ratio, then crushing into fourth-particle size coke powder; adding the third-particle size coke powder into the fourth-particle size coke powder according to a second preset ratio to formfifth-particle size coke powder, wherein the particle size composition of the fifth-particle size coke powder is as follows: 71.3% of the coke powder with the particle size of 0-3mm, 20.5% of the cokepowder with the particle size of 3mm-5mm and 8.2% of the coke powder with the particle size being greater than 5mm. According to the technical scheme adopted by the invention, three types of coke powder are put into tanks by class and are mixed and crushed in proportion, so that the particle sizes and the components of the coke powder are uniform and controllable during using, and the stability of the FeO content of sintered ore is further improved.

Owner:BAOTOU IRON & STEEL GRP

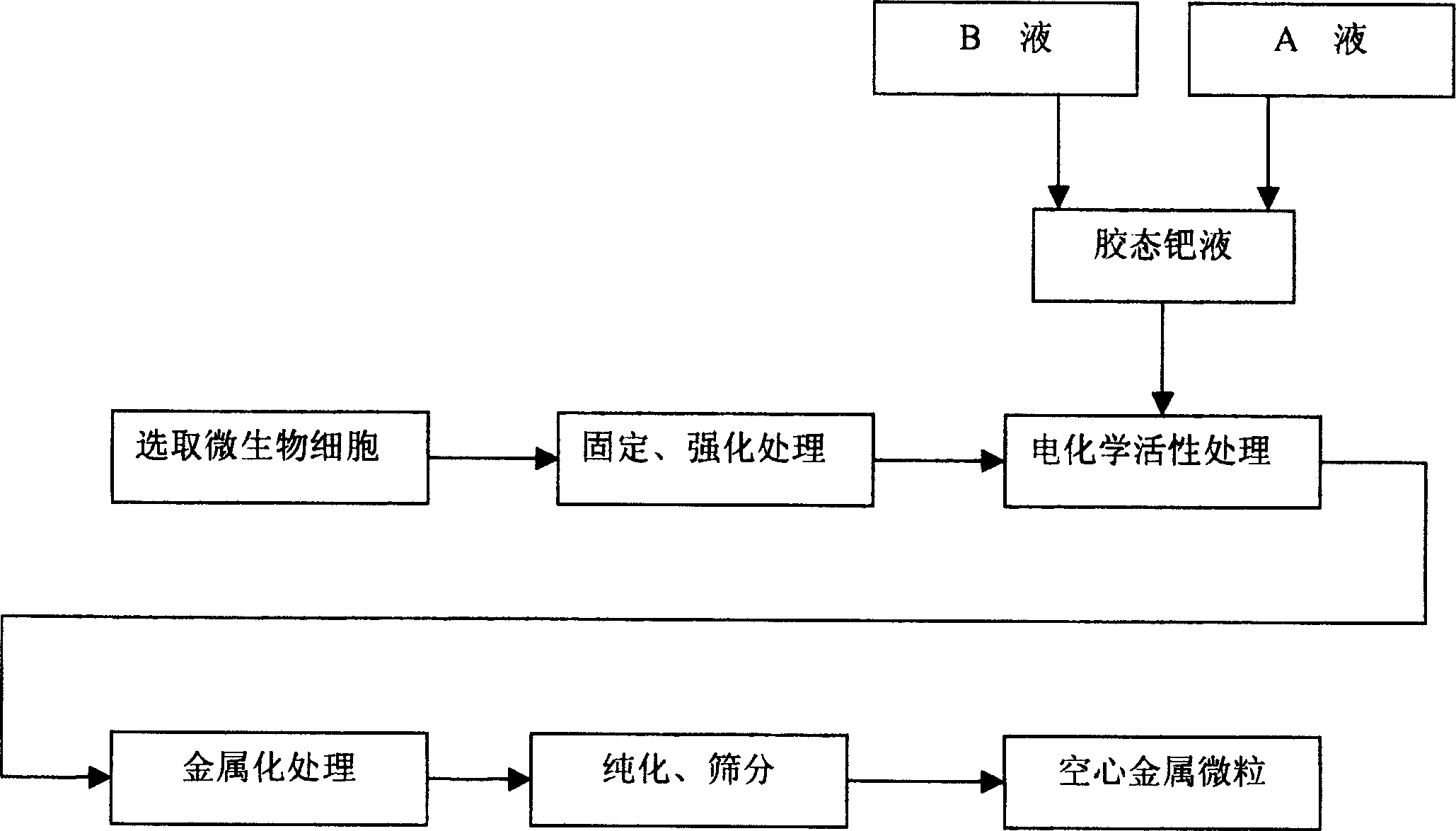

Hollow metal particle with microbe cell template and its preparation process

InactiveCN1238145CVarious shapesEasy to get materialsLiquid/solution decomposition chemical coatingChemical platingMetal particle

Owner:BEIHANG UNIV +1

Preparation method of SnO2/Fe3O4 composite nano catalyst

PendingCN114160151AImprove catalytic abilityImprove magnetic propertiesWater/sewage treatment by irradiationWater treatment compoundsNano catalystHydration reaction

A preparation method of a SnO2 / Fe3O4 composite nano-catalyst relates to the technical field of composite nano-catalysts, and comprises two processes of precursor room temperature preparation and hydrothermal reaction, firstly, at room temperature, ferric oxide hydrate (FeOOH) powder is added into a stannous chloride (SnCl2) aqueous solution, after ultrasonic dispersion, a proper amount of NaOH is added, and after stirring and mixing, a reaction precursor is obtained; and then, transferring the precursor into a reaction kettle, and carrying out hydrothermal reaction to obtain the SnO2 / Fe3O4 composite nano catalyst. According to the preparation method, stannous chloride (SnCl2) is taken as a reducing agent, common ferric oxide hydrate (FeOOH) is taken as an iron source, the SnO2 / Fe3O4 nano composite material is successfully prepared through a hydrothermal reaction, and the composite material has good magnetic performance and visible light absorption characteristics and is expected to be used in the fields of magnetic optical device manufacturing or sewage treatment catalysts and the like.

Owner:合肥中镓纳米技术有限公司

A kind of preparation method of Zr-based bulk amorphous alloy with low oxygen content

The invention discloses a method for preparing Zr-based bulk amorphous alloy with low oxygen content. The oxygen content in the Zr-based amorphous alloy is reduced by adding skeined composite wires. Use a special twisted wire composite wire (Al, Ti, Ca, Y composite twisted wire) to control and reduce the oxygen content in the Zr-based amorphous alloy, and prevent the gasification of the composite twisted wire through a reasonable control process. Oxidation reaction, forming composite deoxidation products and removing them, so as to realize the control of low oxygen content of Zr-based bulk amorphous alloys. This process has strong operability and controllable components. The alloy has low oxygen content and strong amorphous forming ability, which is beneficial to improving and stabilizing the properties of the Zr-based amorphous alloy, and can be popularized and applied industrially.

Owner:CHANGZHOU STREAM LIQUID METAL CO LTD

A kind of high-purity bismuth-lead alloy and preparation method thereof

The invention discloses a high-purity bismuth-lead alloy and a preparation method thereof. The preparation method comprises the steps that a compounding step is carried out, specifically, according tothe composition design of the bismuth-lead alloy, massive lead materials and bismuth materials are used as raw materials for compounding and mixing; a smelting step is carried out, specifically, themixed raw materials are smelted under vacuum; a cooling step is carried out, specifically, alloy melt obtained after smelting is subjected to cooling; a filtering step is carried out, specifically, the alloy melt after cooling is subjected to filtration treatment; and a casting step is carried out, specifically, the filtered alloy molt is casted into a mold under vacuum and cooled to obtain an alloy ingot. According to the high-purity bismuth-lead alloy and the preparation method thereof, through the combination of high-temperature vacuum melting and low-temperature vacuum casting, oxides andother metal impurities in the lead and bismuth raw materials can be efficiently and advantageously removed, so that the purity of the alloy reaches above 99.998%. And through timing electromagnetic stirring and controlling of the weight of a single alloy ingot, the overall composition of the alloy is uniform and controllable, and the problem of excessive composition segregation is avoided.

Owner:安泰天龙钨钼科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com