Process of preparing nano composite ceramic coating in super-gravitational field

A ceramic coating and nano-composite technology, which is applied in the surface technology of materials and the field of supergravity field, can solve the problems of non-densification and limitation of coatings, and achieve the effects of low preparation temperature, compact structure, and controllable composition and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Al 2 o 3 -Y 2 o 3 Nano-micron composite ceramic coating

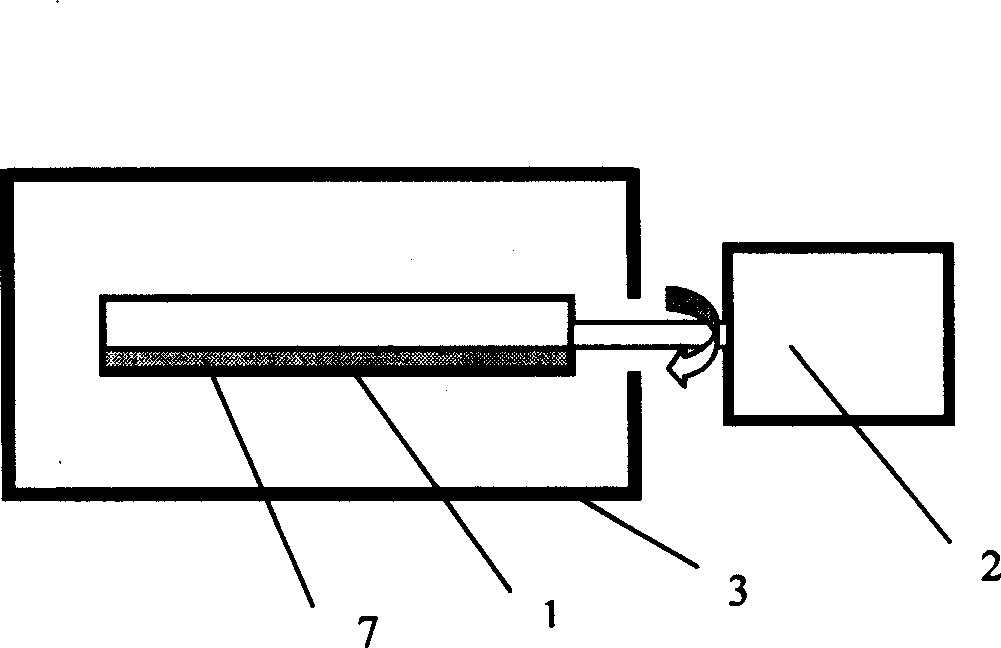

[0018] Prepare 0.1mol / L Al(NO 3 ) 3 +1wt%Y(NO 3 ) 3 Aqueous solution, and then add ammonia water dropwise to the solution and vigorously stir until the pH value of the solution is approximately equal to 10, and continue to stir with a magnetic stirrer for 2h to obtain Al 2 o 3 -Y 2 o 3 colloidal solution. Thereafter, add 3% polyvinyl alcohol to the colloidal solution, heat it in a water bath at 80°C for 1 hour to fully dissolve it, and then add 50% Al to the colloidal solution. 2 o 3 Nano-powder and micro-powder, wherein nano-powder accounts for 70%, among 30% of micro-powder, 70% has a particle size of 10 μm, and 30% has a particle size of 74 μm. Use a high-energy ball mill to ball-mill the mixed solution for 4-6 hours. Al can be obtained 2 o 3 -Y 2 o 3 Sol-gel+Al 2 o 3 powder mixture. Inject this mixture into figure 2 Tube neutralization of the device image 3 in the sample com...

Embodiment 2

[0019] Example 2: ZrO 2 -Y 2 o 3 Nano-micron composite ceramic coating

[0020] Prepare 0.1mol / L Zr(NO 3 ) 4 +8wt%Y(NO 3 ) 3 Aqueous solution, then add ammonia water dropwise to the solution and stir vigorously until the pH value of the solution is approximately equal to 10, and continue to stir with a magnetic stirrer for 2h to obtain ZrO 2 -Y 2 o 3 colloidal solution. Thereafter, add 3% polyvinyl alcohol to the colloidal solution, heat it in a water bath at 80° C. for 1 h to fully dissolve it, and then add 50% ZrO to the colloidal solution. 2 -6%Y 2 O Nanopowder and micropowder, of which 70% are nanopowder, 30% are micropowder and the particle diameter is 10μm, and the mixed solution can be milled for 4-6h with a high-energy ball mill to obtain ZrO 2 -Y 2 o 3 Sol-gel+ZrO 2 -6%Y 2 O powder mixture. Inject this mixture into figure 2 Tube neutralization of the device image 3 in the sample compartment of the device. Gradually adjust the speed of centrifuge b...

Embodiment 3

[0021] Example 3: ZrO 2 -Y 2 o 3 Composite ceramic coating with aluminum silicate fibers

[0022] Add 10% aluminum silicate fibers to the mixed solution in Example 2, and use the same steps to obtain ZrO that is uniform and dense, and has a thickness of 120 μm. 2 -Y 2 o 3 Nano-micron ceramic coating compounded with aluminum silicate fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com