Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Change thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material of modified micro plant fiber powder and natural rubber and its prepn process and application

The present invention discloses one kind of composite material of modified micro plant fiber powder and natural rubber and its preparation process and application. The composite material includes natural rubber or latex 100 weight portions, modified micro plant fiber powder 1-60 weight portions, sulfur 0.5-3.3 weight portions, promoter 1.2-4.3 weight portions, antiager 1-3 weight portions and other assistant. The preparation process includes mixing, forming, vulcanizing and other steps. The composite material has high tensile strength, high tearing strength, high ageing resistance, high virus permeation resistance, etc. and may be used widely in making urinary catheter, blood transfusion tube, condom, medical gloves and other products.

Owner:JINAN UNIVERSITY

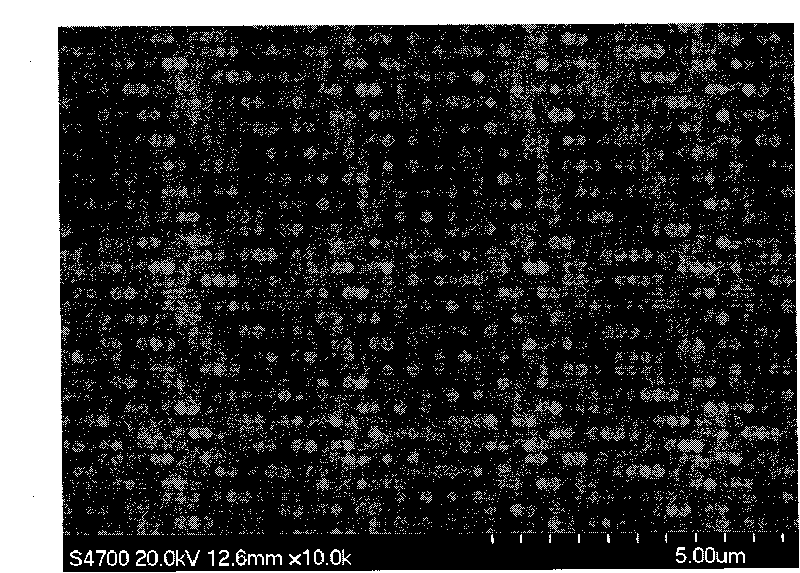

Self-assembly method of inorganic nano particle hybridization organic membrane

InactiveCN101700473AChange thicknessChange in mechanical strengthSemi-permeable membranesDifferential pressureBasal membrane

The invention relates to a self-assembly method of inorganic nano particle hybridization organic membrane. The method comprises steps of: respectively dissolving polycation and polyanion in a dissolvent, preparing to form a membrane casting solution, standing and defoaming; adding inorganic nano particle into a polyanion solution to prepare a polymer nano particle solution; soaking or dynamically filtering polyanion nano particle solution or polycation solution on the surface of a substrate or basal membrane for 10 to 60 minutes to form a thin membrane layer. The substrate or the basal membrane is soaked or dynamically filtered in the polycation solution or polyanion nano particle solution for 10 to 60 minutes; the polyanion nano particle solution reacts with the polycation to form the thin membrane layer; the substrate or the basal membrane is soaked in deionized water, and the membrane surface is rinsed and dried. When the polycation or the polyanion nano particle solution is filtered on the basal membrane, the transmembrane differential pressure thereof is 0.01 to 0.3MPa or minus 0.02 to minus 0.09MPa. The membrane forming method is simple; the thin membrane prepared on the substrate is compact and uniform; the membrane formed on the basal membrane has excellent penetration and vaporization separating property and mechanical strength.

Owner:BEIJING UNIV OF TECH

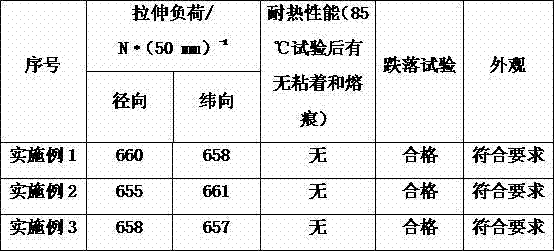

Plastic weaving bag production process

InactiveCN103572392ARaw material ratio is reasonableImprove performanceBox making operationsPaper-makingProcess engineeringWinding machine

The invention discloses a plastic weaving bag production process and relates to the field of packing materials. The process comprises five technological processes of raw material burdening, mixing, drawing, weaving, printing-cutting and sewing. In the process method, raw material proportions in the raw material burdening process are reasonable, the performances of all the raw materials are fully played, the combined performances are greatly improved, a filling master batch adopts nano-calcium carbonate, and the mechanical properties and stability of the materials are improved; by reasonably controlling the parameters such as temperature, time and retraction ratio in the drawing process, manufactured ribbon-like filaments are excellent in quality and good in mechanical properties without being easily broken, and massive electric energy is saved by adopting a cam-combined energy-saving winding machine for winding and molding; after all steps of the weaving process, yarns are uniformly arrayed with less crossing and twisting, and a cloth surface has no wrinkles and is more attractive and reasonable in density; by reasonably controlling the needle pitch in the sewing process, the sewing direction strength of a weaving bag is high and the weaving bag has good falling performance.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

Preparation of shell micro-powder reinforced super-high molecular weight polyethylene fibre composite non woven cloth

InactiveCN101082182AImprove impact resistanceChange thermal stabilityMacromolecular adhesive additivesTextiles and paperFiberPolymer science

The present invention relates to superfine shell powder reinforced composite weftless fabric of ultrahigh molecular weight polyethylene (UHMWPE) and its making process. Adding superfine shell powder into the laminated material can raise bullet-proof performance via making the fiber absorb even more impact energy of bullet and raise the heat resistance. The making process of the reinforced composite weftless fabric includes the following steps: 1. pre-treating shell powder to make its surface contain functional group; 2. modifying the pre-treated shell powder for homogeneous dispersing in the base adhesive; 3. mixing the modified shell powder and adhesive; 4. spreading UHMWPE; 5. spreading adhesive onto UHMWPE; and 6. stoving. Test shows that the superfine shell powder reinforced composite weftless fabric of UHMWPE has 5 deg.c raised use temperature and about 20 % raised impact resistance.

Owner:DONGHUA UNIV

Microwave modification method of plant fiber and application thereof

InactiveCN101725032AIncrease polarityHigh tensile strengthPhysical treatmentVegetal fibresFiberFilling materials

The invention discloses a microwave modification method of plant fiber and application thereof. The method comprises the steps of: firstly smashing the plant fiber; preprocessing the smashed plant fiber with coupling agent; and processing the preprocessed plant fiber by means of microwave radiation, so that the coupling agent is grafted at the surface of the plant fiber to obtain the microwave-modified plant fiber, wherein the microwave-modified plant fiber can be used as filling material of composite material for the field of high molecular material. The modification method is environment-friendly, and has no pollution, low production cost and remarkable economic benefit; and the microwave-modified plant fiber has obvious polarity change, wherein the nonpolarity is obviously enlarged, thereby obviously improving the interface consistency with non-polarity high molecule substances and improving the combination property of the composite material.

Owner:JINAN UNIVERSITY

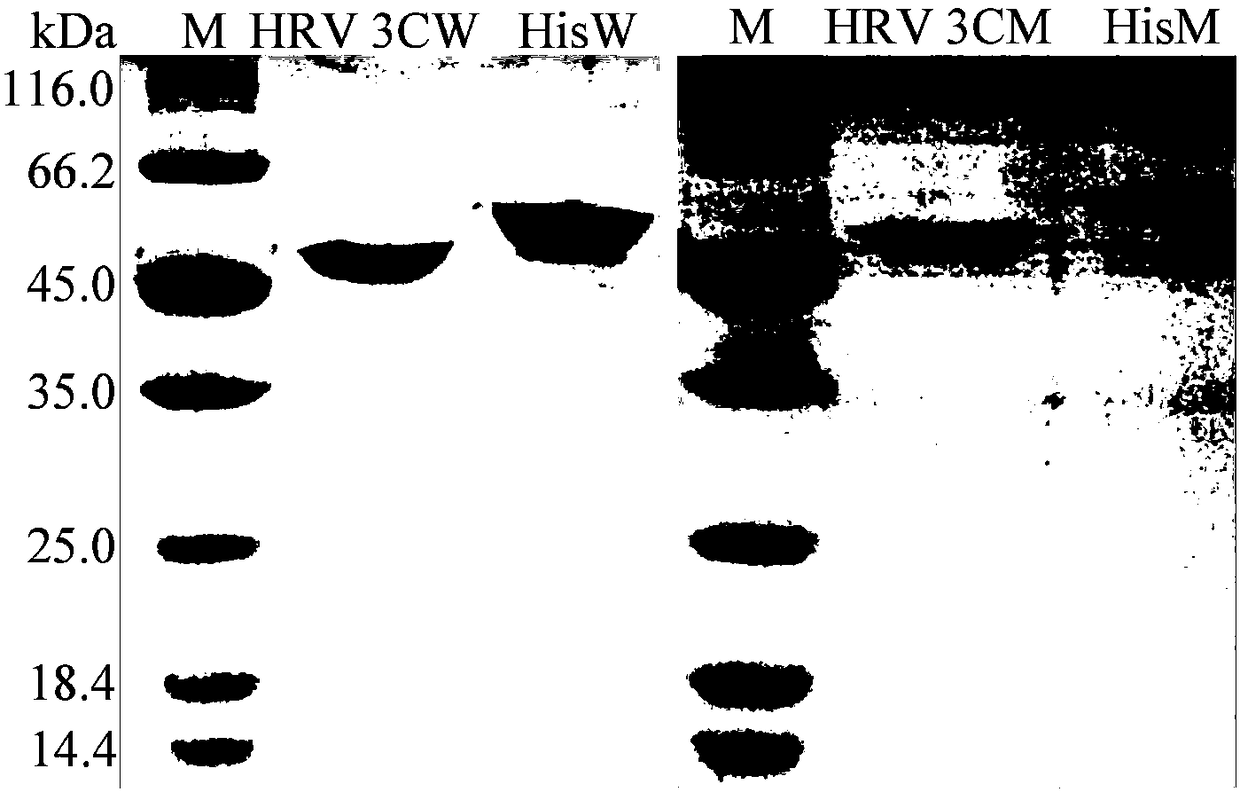

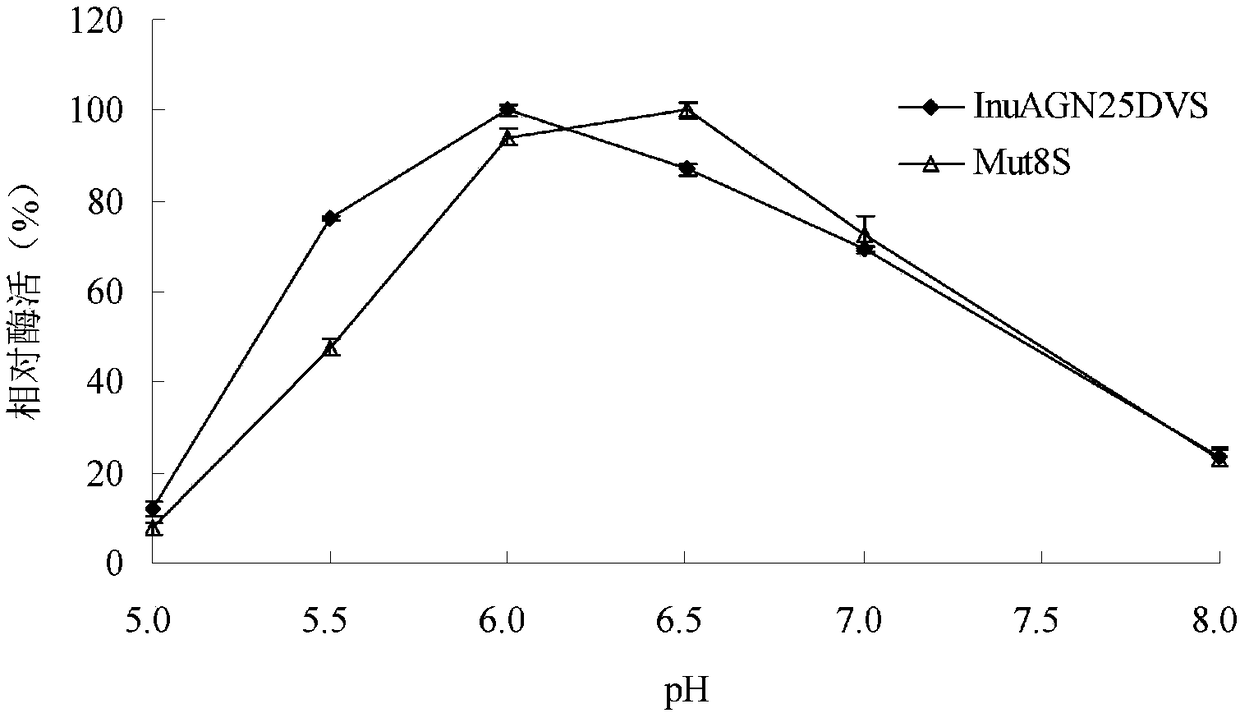

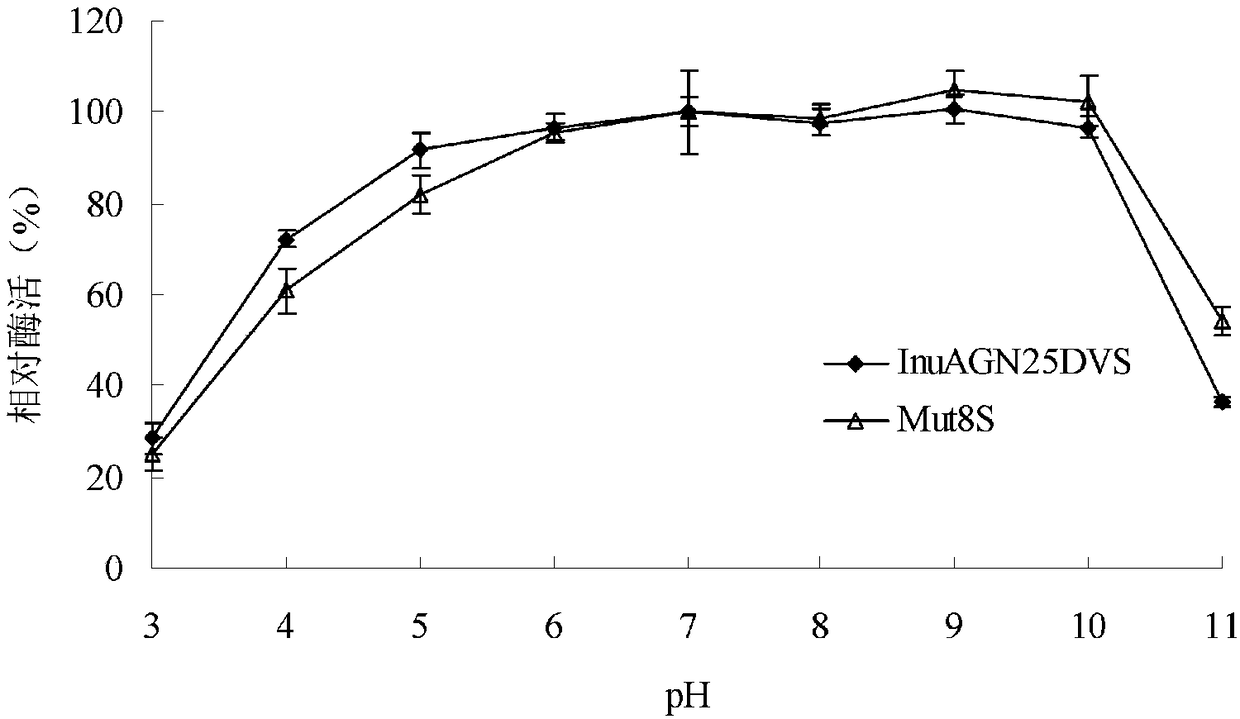

Low-temperature exoinulinase mutant Mut8S with improved heat stability

ActiveCN108504644AChange thermal stabilityIncreased thermal activityFermentationGlycosylasesBiotechnologyGenetically engineered

The invention relates to the technical fields of genetic engineering and protein modification and particularly relates to a low-temperature exoinulinase mutant Mut8S with the improved heat stability.The amino acid sequence of the mutant Mut8S is represented by SEQ ID NO.1. The optimal pH value of the Mut8S is 6.5; the optimal temperature of the Mut8S is 40 DEG C, and the Mut8S respectively has the enzyme activities of 16%, 27%, 51%, 76% and 78% at the temperatures of 0 DEG C, 10 DEG C, 20 DEG C, 30 DEGC and 50 DEG C; and after being processed at 50 DEG C for 60 minutes, the Mut8S still preserves 100% of the enzyme activity; and the enzyme can be used for hydrolyzing inulin so as to generate fructose. The low-temperature exoinulinase mutant Mut8S with the improved heat stability can be applied to the industries of foods, wine brewing, biological energy sources and the like.

Owner:YUNNAN NORMAL UNIV

Application of carbon nano tube in polyethylene fiber composite weftless fabric

InactiveCN101016678AImprove mechanical propertiesChange thermal stabilityNon-macromolecular adhesive additivesNon-woven fabricsCarbon nanotubeMicrometer

The invention relates to an application of carbon nanometer tube in polythene fiber composite weft-free cloth, wherein the nanometer particles are two-dimension nanometer carbon tube, as seamless hollow tube surrounded by hexagon carbon atom grid, whose two ends are covered by hemi-spherical large Furehee molecules, while the diameter is from zero-point nanometer to tens nanometers and the length is from several micrometers to hundreds micrometers. And the production comprises that (1) pretreatment of carbon nanometer tube as purifying and organic treatment that refluxing 1-4g carbon nanometer tube / ml and 0.01-0.04g / ml titanic acid coupler in organic solvent for 1-3h, (2) mixing carbon nanometer tube and adhesive for 1-2h at 60-80Deg. C, and defoaming at vacuum, (3) uniformly laying strengthener UHMWPE fiber on a coiler, (4) plating adhesive for 1-2 times and drying at 40-70Deg. C, (5) drying at 60+-3Deg. C for 10-20min. The invention can increase the application temperature of polythene fiber composite weft-free cloth as 10Deg. C, and improve 20% of impact resistance, with better thermal resistance, strength and creep resistance, or the like.

Owner:DONGHUA UNIV

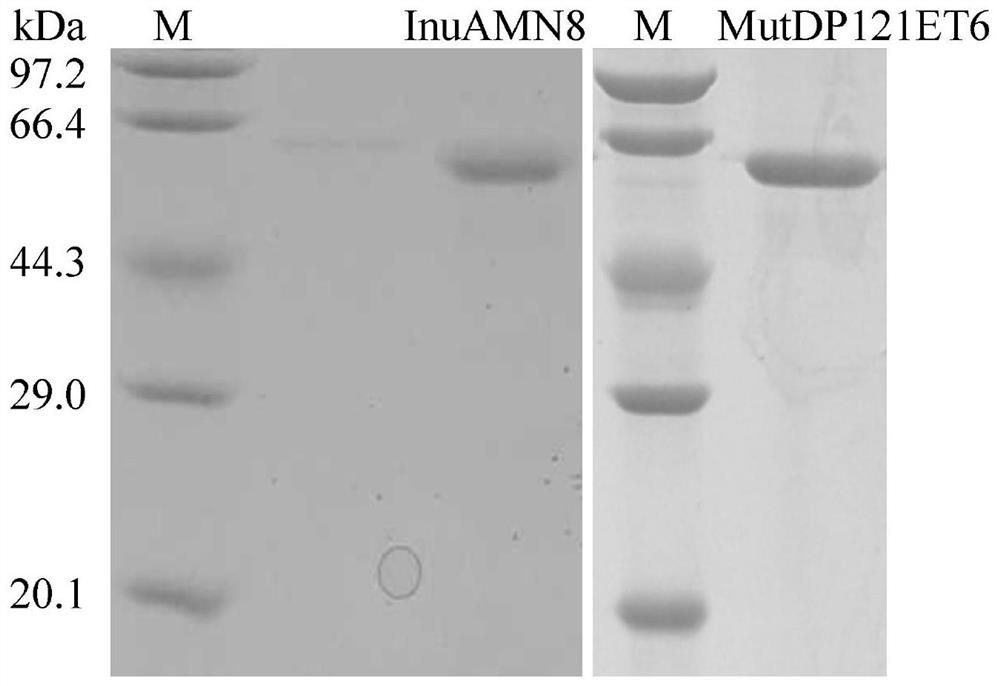

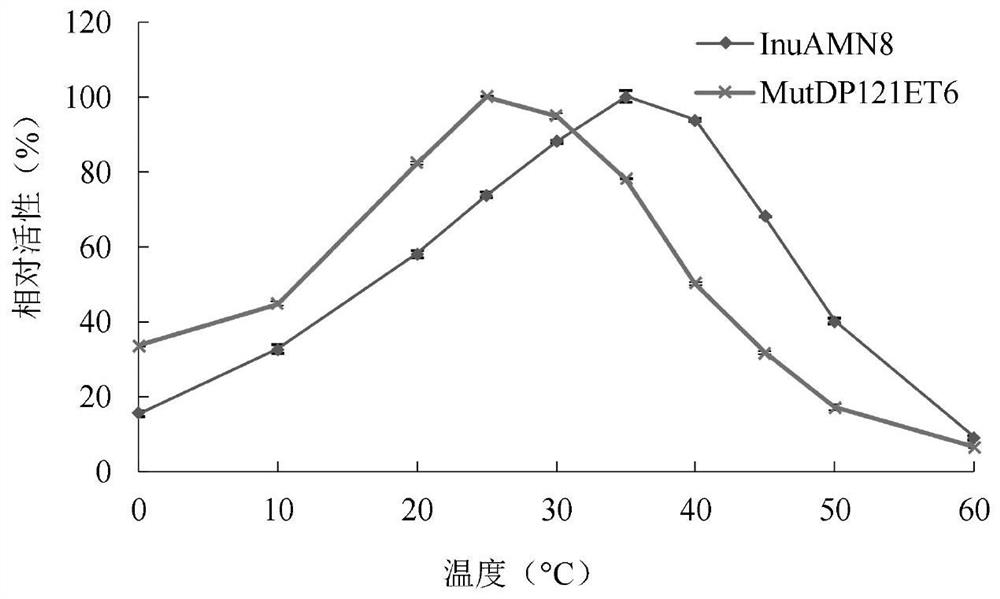

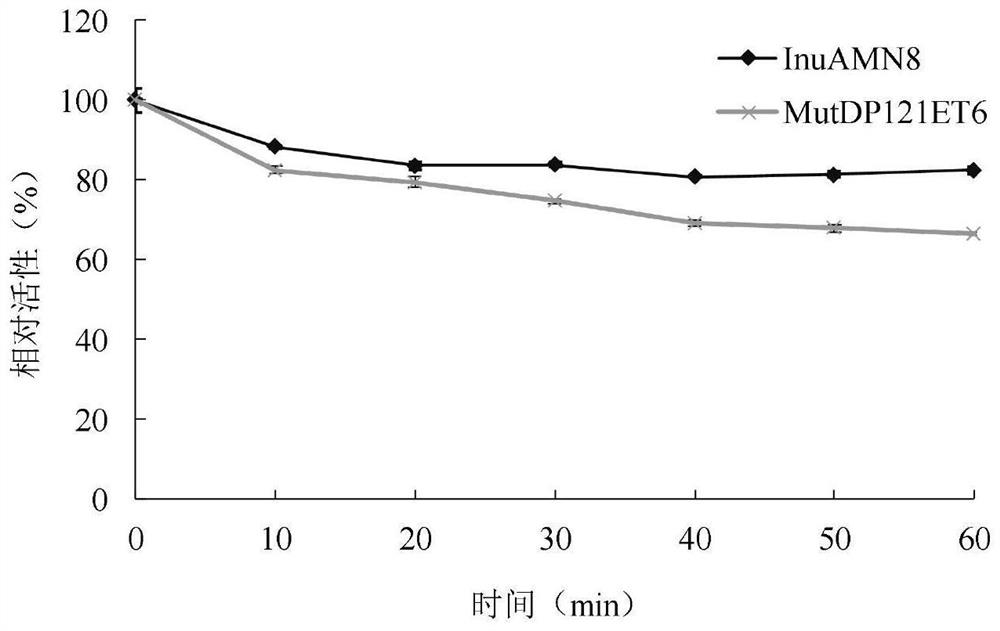

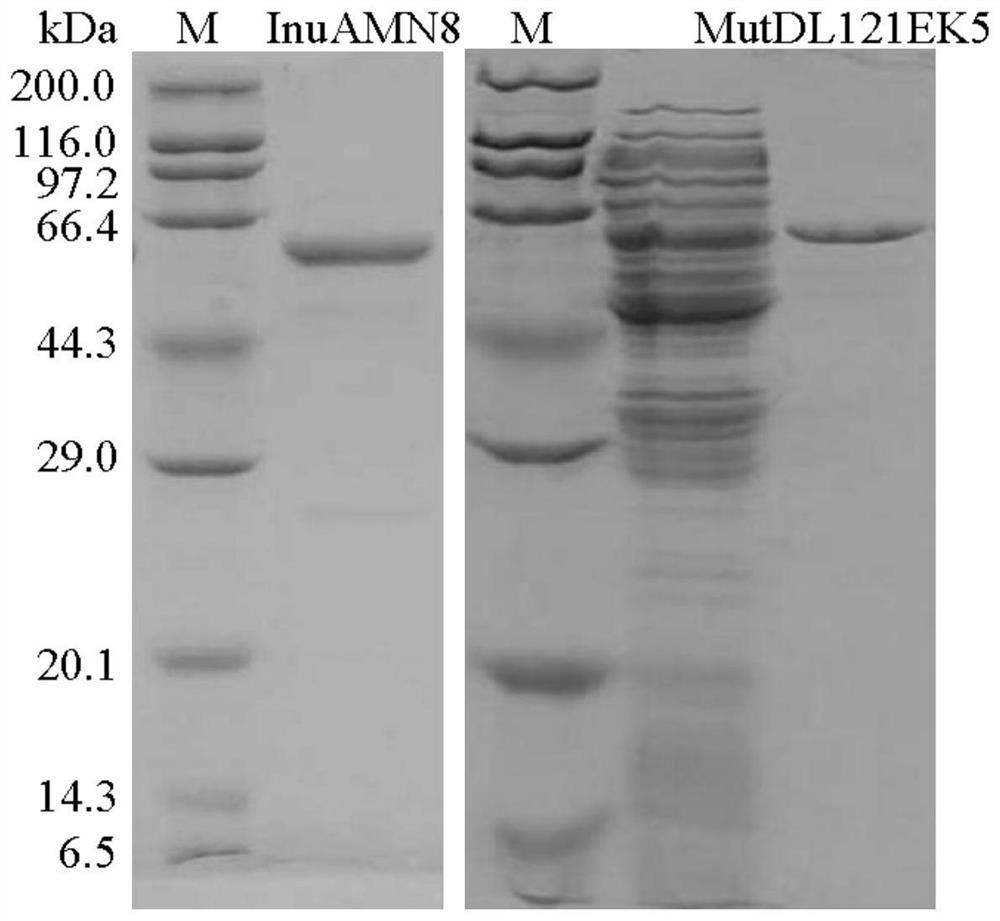

Exo-inulinase mutant MutDP121ET6 with improved low-temperature activity

ActiveCN112813052AReduce dosageChange thermal stabilityBacteriaMicrobiological testing/measurementMolecular biologyAmino acid

The invention discloses an exo-inulinase mutant MutDP121ET6 with improved low-temperature activity. The mutant MutDP121ET6 has an amino acid sequence as shown in SEQ ID NO. 1. Compared with a wild enzyme InuAMN8, the thermal activity and the thermal stability of the mutant enzyme MutDP121ET6 are changed, the mutant enzyme MutDP121ET6 has higher activity at low temperature, reduction of the thermal stability and improvement of the low-temperature activity are beneficial to reduction of the use amount of the enzyme or shortening of the reaction time during low-temperature reaction, and deterioration of the thermal stability is beneficial to control of the reaction process of the enzyme through thermal treatment. After treatment at 55 DEG C, the enzyme activity of the wild enzyme InuAMN8 is reduced from 70% to 17%, and the enzyme activity of the mutant enzyme MutDP121ET6 is reduced from 74% to 8%. The low-temperature exo-inulinase mutant MutDP121ET6 disclosed by the invention can be applied to the industries of food, wine brewing, washing and the like.

Owner:YUNNAN NORMAL UNIV

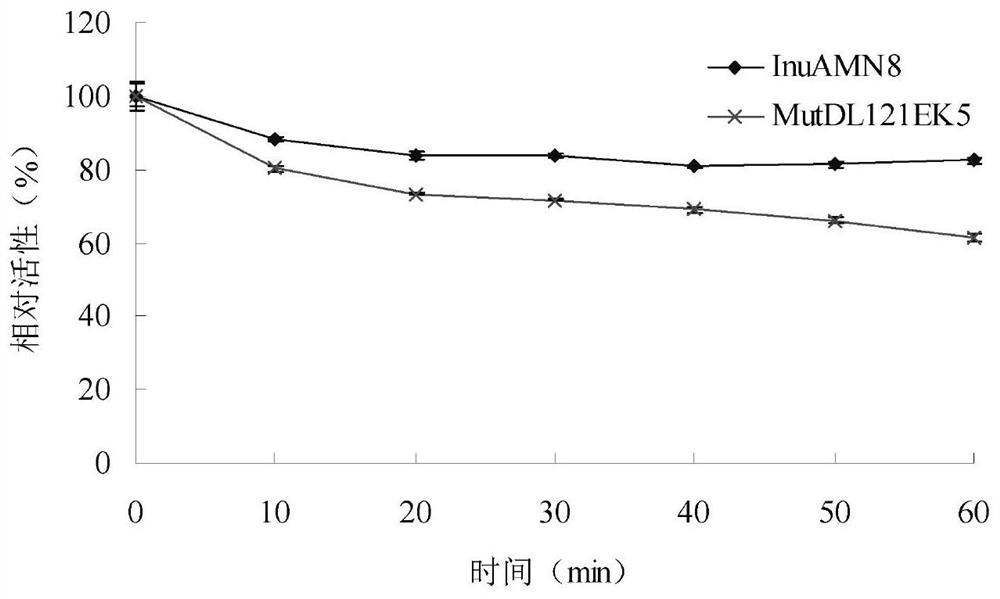

Exo-inulinase mutant MutDR121EH9 with improved low-temperature activity

The invention discloses an exo-inulinase mutant MutDR121EH9 with improved low-temperature activity, which has an amino acid sequence as shown in SEQ ID NO.1; the thermal activity and the thermal stability of the mutant MutDR121EH9 are changed, so that the mutant MutDR121EH9 has higher activity at low temperature, the thermal stability is reduced and the low-temperature activity is increased, and the use amount of enzyme is reduced or the reaction time is shortened during a low-temperature reaction; meanwhile, the degraded thermal stability makes the enzyme reaction process to be controlled through thermal treatment, wherein optimal temperature of the wild enzyme InuAMN8 is 35 DEG C, and the optimal temperature of the mutant enzyme MutDR121EH9 is 20 DEG C; after treatment at 50 DEG C, the enzyme activity of the wild enzyme InuAMN8 keeps 81% or above, and the enzyme activity of the mutant enzyme MutDR121EH9 is reduced from 32% to 14%. The mutant MutDR121EH9 disclosed by the invention can be applied to the industries of food, wine brewing, washing and the like.

Owner:YUNNAN NORMAL UNIV

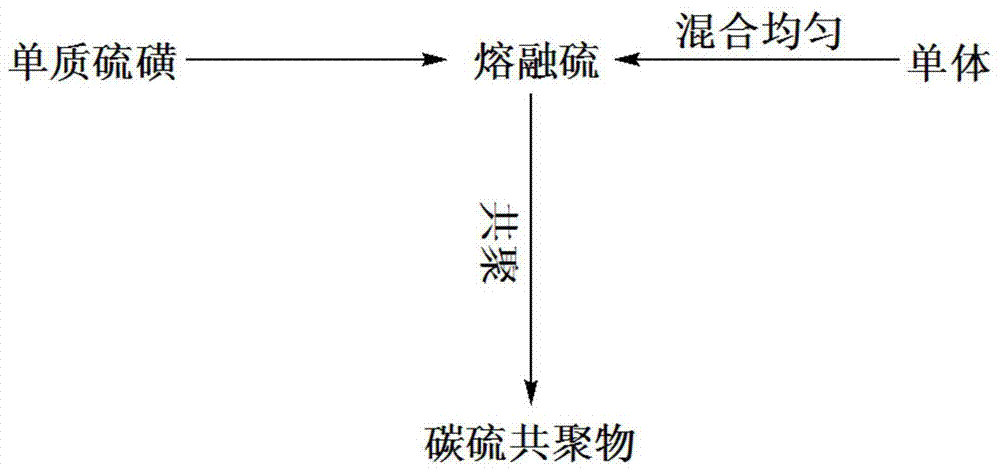

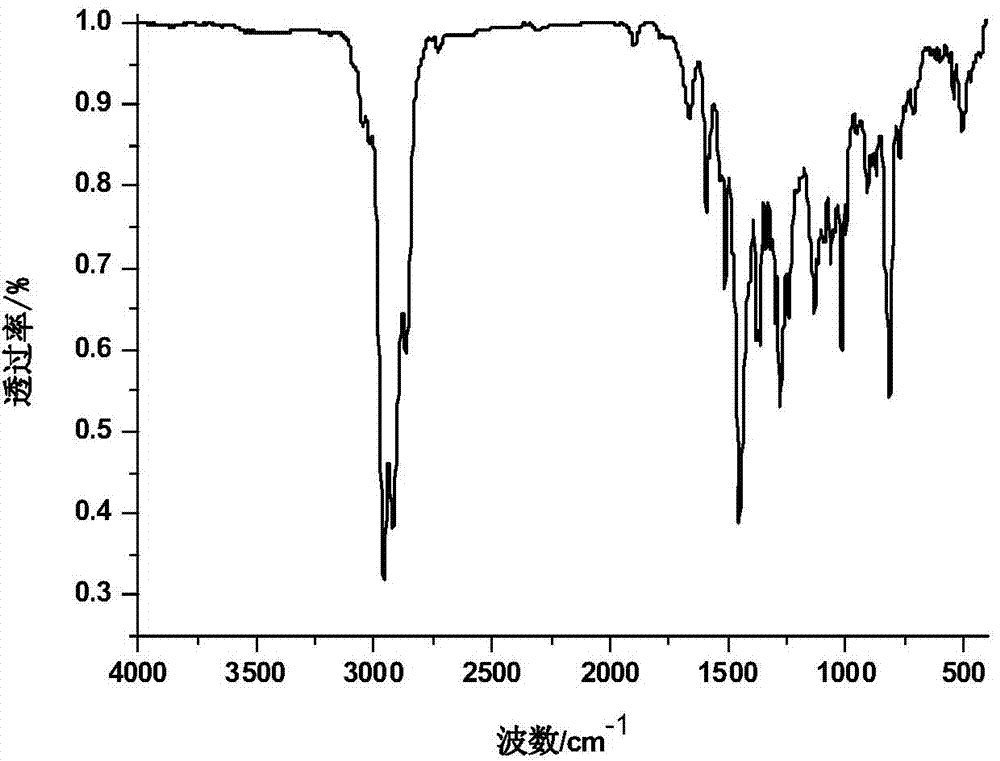

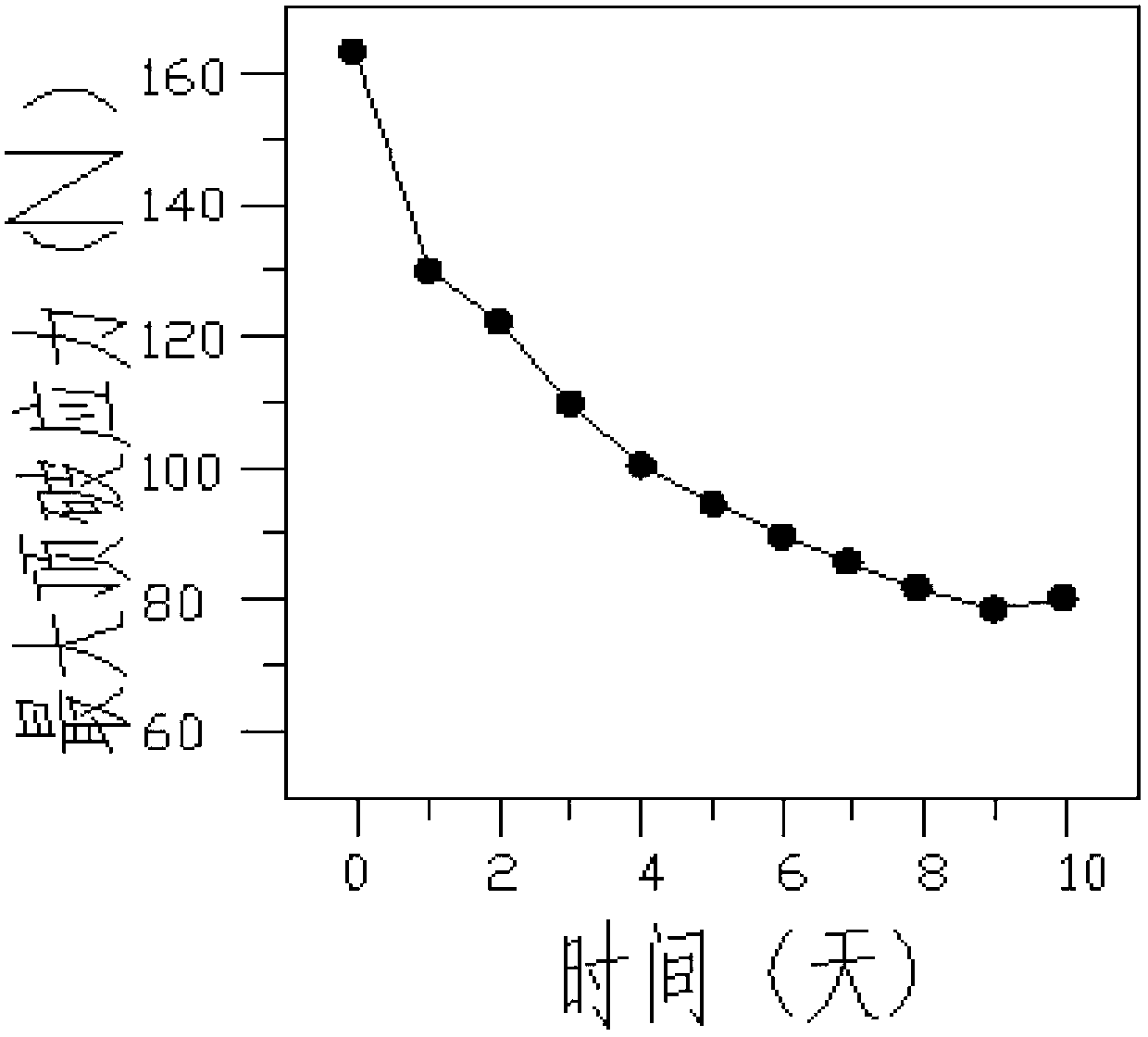

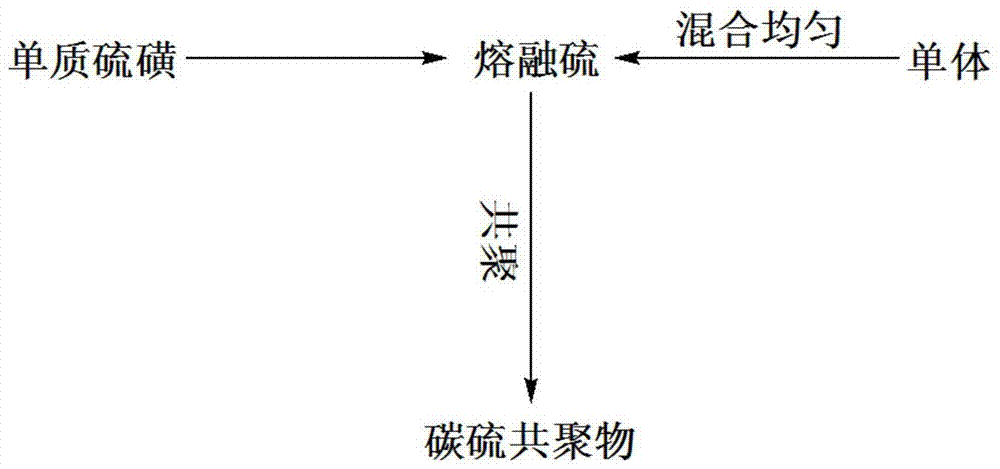

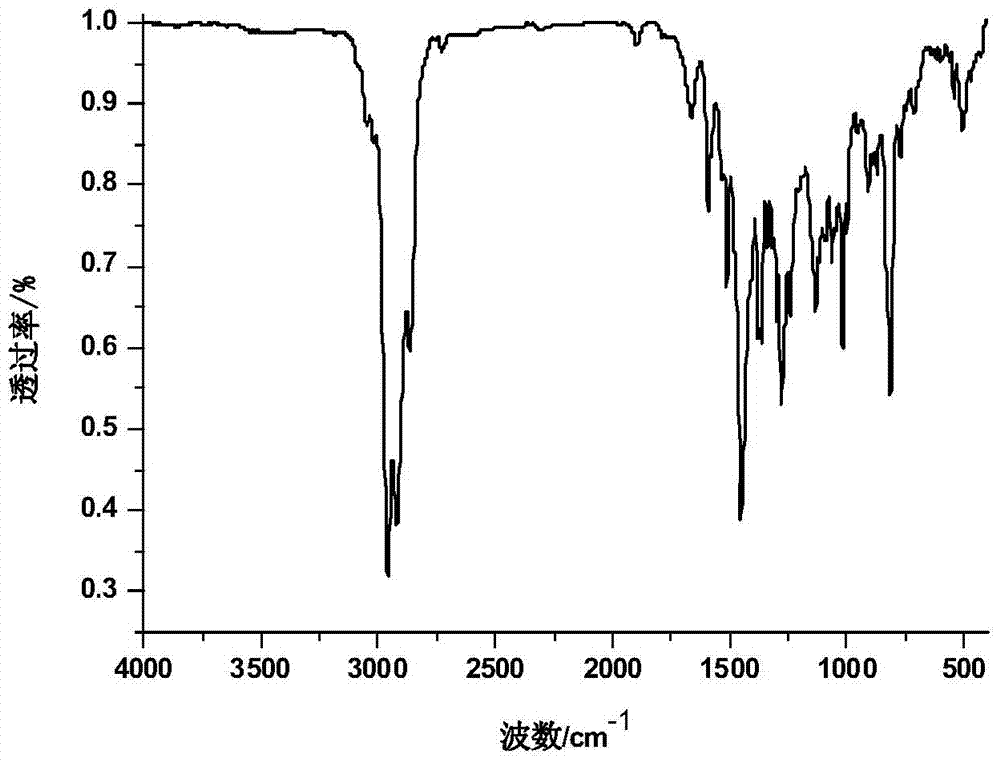

Soluble elemental sulfur and alicyclic olefin copolymer and preparation method thereof

ActiveCN104844772AEliminate sulfur free radicalsActs as a chemical cross-linking pointSulfur preparation/purificationChemical synthesisSulfur

The invention belongs to the chemical synthesis field and particularly relates to a soluble elemental sulfur and alicyclic olefin copolymer and a preparation method thereof. Elemental sulfur is heated in the nitrogen atmosphere under the condition that a catalyst exists or does not exist until the temperature of a reaction system is above a melting point of the elemental sulfur and below the transformation temperature, an alicyclic olefin monomer is added to be stirred and uniformly mixed after the elemental sulfur is completely molten, a polymerization reaction is performed, and the soluble elemental sulfur and alicyclic olefin copolymer is obtained. According to the soluble elemental sulfur and alicyclic olefin copolymer, a carbon chain is introduced into a sulfur chain and accordingly sulfur free radicals are eliminated, the effect of a chemical crosslinking point can be achieved due to the fact that unsaturated olefin comprises more than one double-bond, and accordingly the effect of the sulfur chain stabilization can be achieved.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

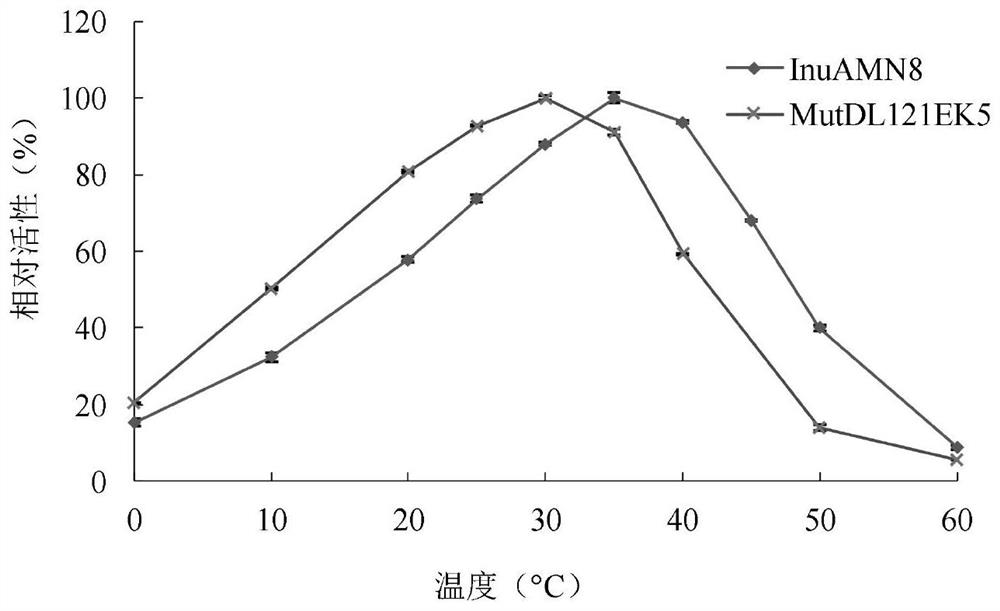

Low-temperature exoinulinase mutant MutDL121EK5 with improved low-temperature adaptability and application thereof

ActiveCN112852782AChange thermal stabilityHigh activityBacteriaMicroorganism based processesBiotechnologyThermal denaturation

The invention relates to the technical field of gene engineering and protein modification, and discloses a low-temperature exoinulinase mutant MutDL121EK5 with improved low-temperature adaptability and application thereof, the amino acid sequence of the mutant MutDL121EK5 is obtained by replacing DAAPL from the 121st site to the 125th site of wild exoinulinase InuAMN8 with five amino acids EEDRK, and the sequence of the MutDL121EK5 is shown as SEQ ID NO.1. Compared with a wild enzyme InuAMN8, the mutant enzyme MutDL121EK5 has the advantages that the low-temperature activity is improved, the mutant enzyme MutDL121EK5 is more easily subjected to thermal denaturation, the improvement of the low-temperature activity is beneficial to reducing the dosage of the enzyme or shortening the reaction time during low-temperature reaction, and the easy thermal denaturation is beneficial to controlling the reaction process of the enzyme through thermal treatment. The low-temperature exoinulinase mutant MutDL121EK5 disclosed by the invention can be applied to the industries of food, wine brewing, washing and the like.

Owner:YUNNAN NORMAL UNIV

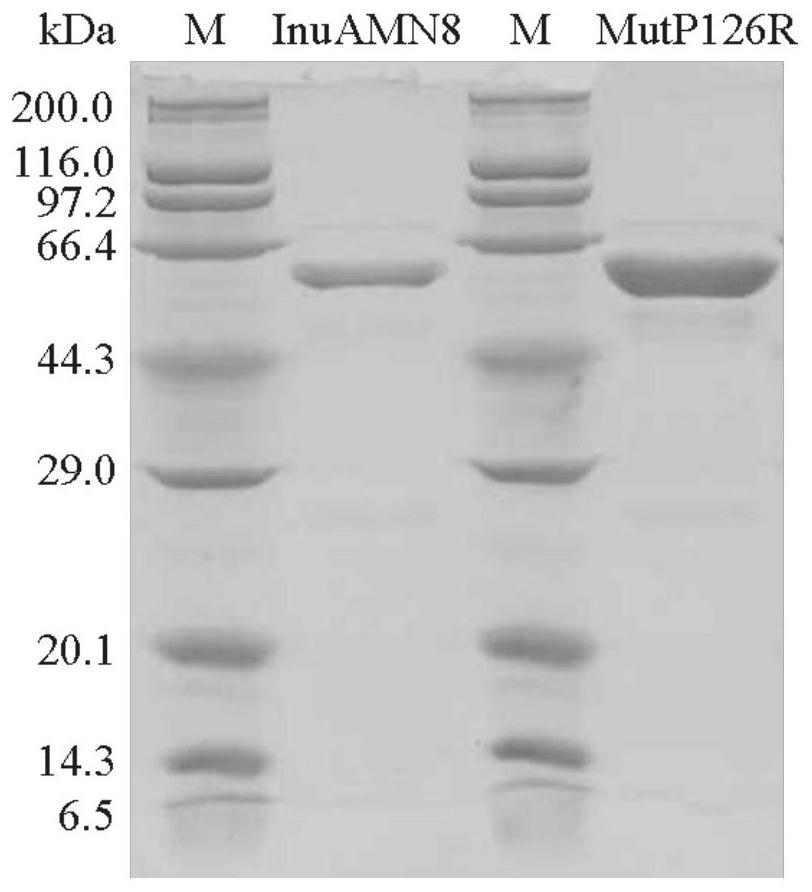

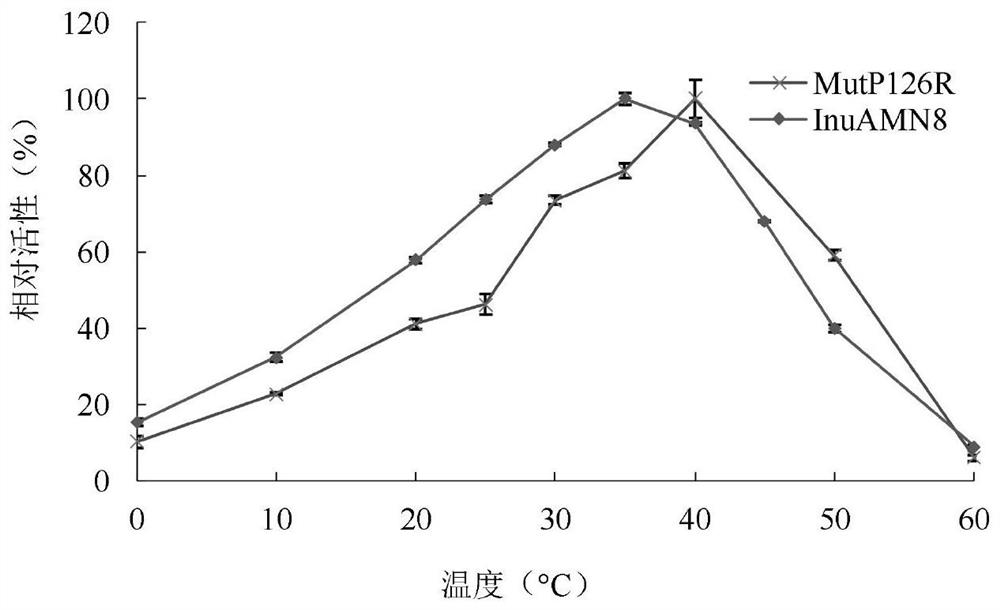

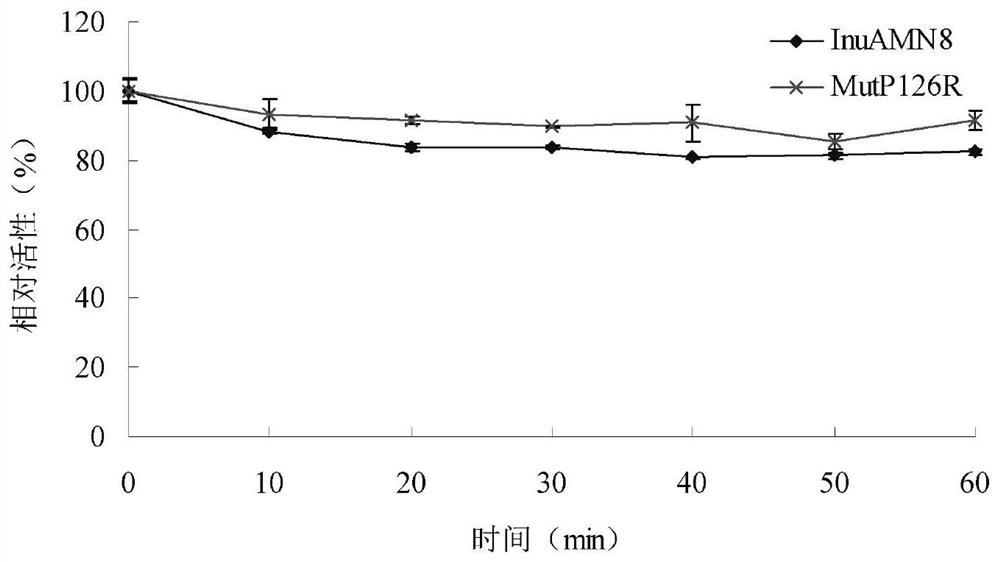

Low-temperature excision inulase mutant MutP126R stable at medium temperature

ActiveCN112725309AEasy to produceEasy to storeBacteriaMicroorganism based processesMutant enzymeAmino acid

The invention discloses a low-temperature exoinulinase mutant MutP126R stable at medium temperature, the mutant MutP126R has an amino acid sequence as shown in SEQ ID NO.1, the thermal activity and thermal stability of the mutant MutP126R are changed, the optimal temperature is increased, the thermal stability is better, and the mutant MutP126R is beneficial to production, storage, transportation and the like of enzymes. The optimum temperature of the purified wild enzyme InuAMN8 is 35 DEG C, and the optimum temperature of the mutant enzyme MutP126R is 40 DEG C; after the wild enzyme InuAMN8 is treated at 55 DEG C for 10-60 minutes, the enzyme activity of the wild enzyme InuAMN8 is reduced from 70% to 17%, and the enzyme activity of the mutant enzyme MutP126R is reduced from 70% to 26%. The low-temperature excision inulase mutant MutP126R disclosed by the invention can be applied to the industries of food, wine brewing, biological energy and the like.

Owner:YUNNAN NORMAL UNIV

Photosensitive quartz tube preparation method

ActiveCN104986947APromote degradationChange thermal stabilityGlass shaping apparatusMetal/metal-oxides/metal-hydroxide catalystsWater useUltraviolet lights

The invention relates to a photosensitive quartz tube preparation method, and belongs to the field of chemistry and chemical engineering. According to the preparation method, Al2O3 and bismuth silicate are taken as a doping material to obtain a novel quartz glass tube according to a certain ratio, and the heat stability and the light transmittance of the quartz glass tube are changed, so as to obtain a peculiar high photosensitivity. The photosensitive quartz tube has efficient photocatalytic activity within a wavelength range of 185 to 500, is capable of catalyzing, oxidizing and degrading organic compounds in an ultraviolet light waveband and a visible light waveband, can be widely applied in household water-consumption equipment, independent type air purifiers, wall-mounted air purifying equipment, pipeline air handling units, urban water treatment systems and air handling equipment, is capable of reducing energy consumption, and is a new environmental and cleaning material.

Owner:JIANGSU SHENGDA QUARTZ PROD CO LTD

Preparation method of white carbon black enhanced UHMWPE (ultrahigh molecular weight polyethylene) fiber composite non-weft fabric

ActiveCN103015041AImproved impact and heat resistanceImproved stab and ballistic resistanceNon-macromolecular adhesive additivesNon-woven fabricsPolymer chemistryAdhesive

The invention belongs to the field of bulletproof protective products and relates to a preparation method of white carbon black enhanced UHMWPE (ultrahigh molecular weight polyethylene) fiber composite non-weft fabric. The preparation method includes: pretreating white carbon black; further functionally modifying the pretreated white carbon black to allow the white carbon black to be dispersed evenly in matrix adhesives; well mixing the functionally modified white carbon black with the adhesives; sizing the UHMWPE fiber; and drying. By adding gas phase white carbon black, energy caused bullet impact on fibers can be absorbed more, bulletproof performance is improved, and overall heat resistance is improved. Live ammunition tests applied to a certain layers of the composite non-weft fabric according to the GA141-2001 standard shows the composite non-weft fabric completely accords to the requirements of the standard, use temperature is increased by 5 DEG C, and impact resistance is increased by about 20%.

Owner:JIANGSU LINRY NEW MSTAR TECH

Photosensitive quartz tube

ActiveCN105036554AChange thermal stabilityMeet vision requirementsOptical radiationUltraviolet lights

The invention provides a photosensitive quartz tube. The photosensitive quartz tube comprises the following components: quartz sand, aluminum oxide and bismuth silicate, wherein by taking the weight of the quartz sand as a basic part by weight, the aluminum oxide accounts for 0.0076% and the bismuth silicate accounts for 0.0114%. The quartz tube provided by the invention changes the thermal stability and the light transmittance of a common quartz glass tube, and has high photosensitivity. The photosensitive quartz tube has efficient photocatalytic activity within a wavelength range of 185-500, and can carry out photocatalytic oxidation degradation on an organic compound under radiation of visible light or ultraviolet light. The photosensitive quartz tube can be widely applied to household water-consumption equipment, independent type air purifiers, wall-mounted type air purification equipment, pipeline air treatment units, urban water treatment systems and air treatment equipment, and is capable of reducing energy consumption. Therefore, the photosensitive quartz tube is a novel environmentally-friendly clean material.

Owner:JIANGSU SHENGDA QUARTZ PROD CO LTD

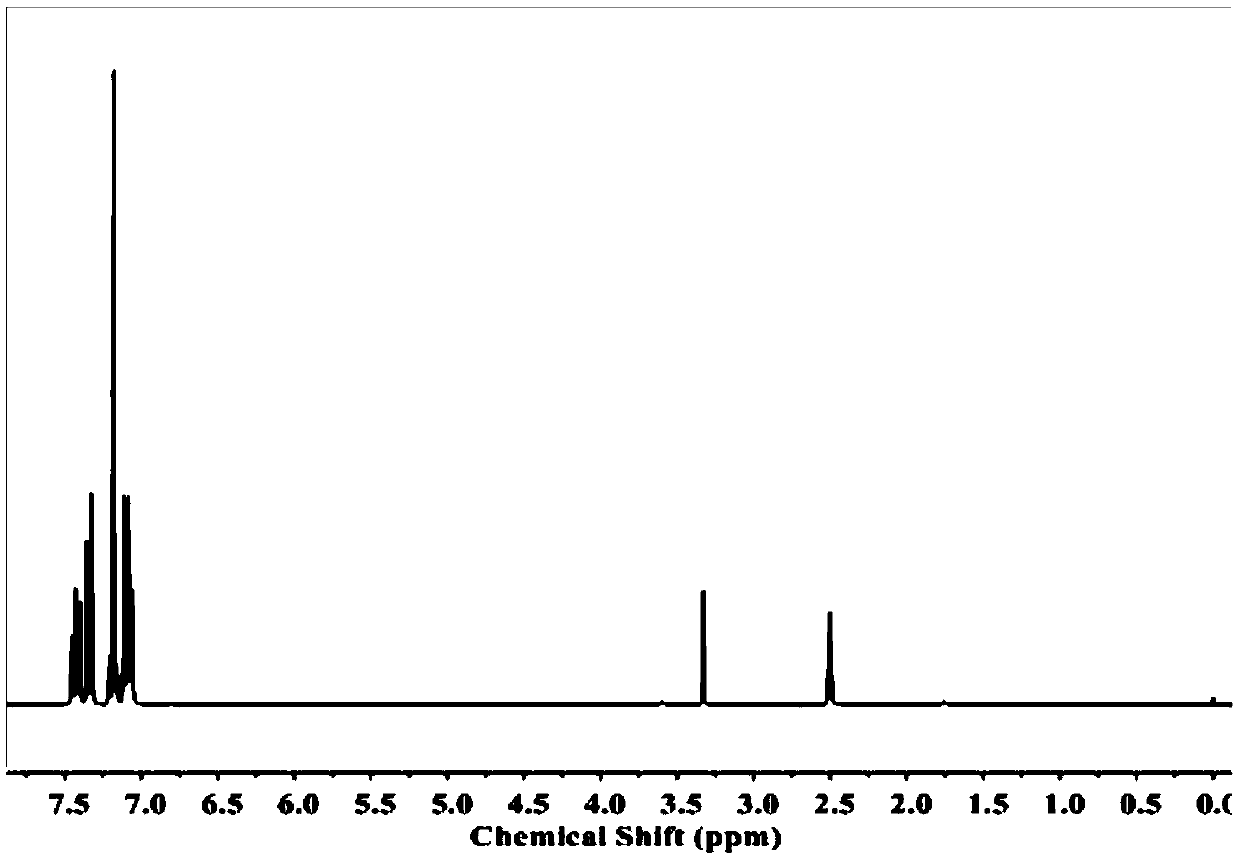

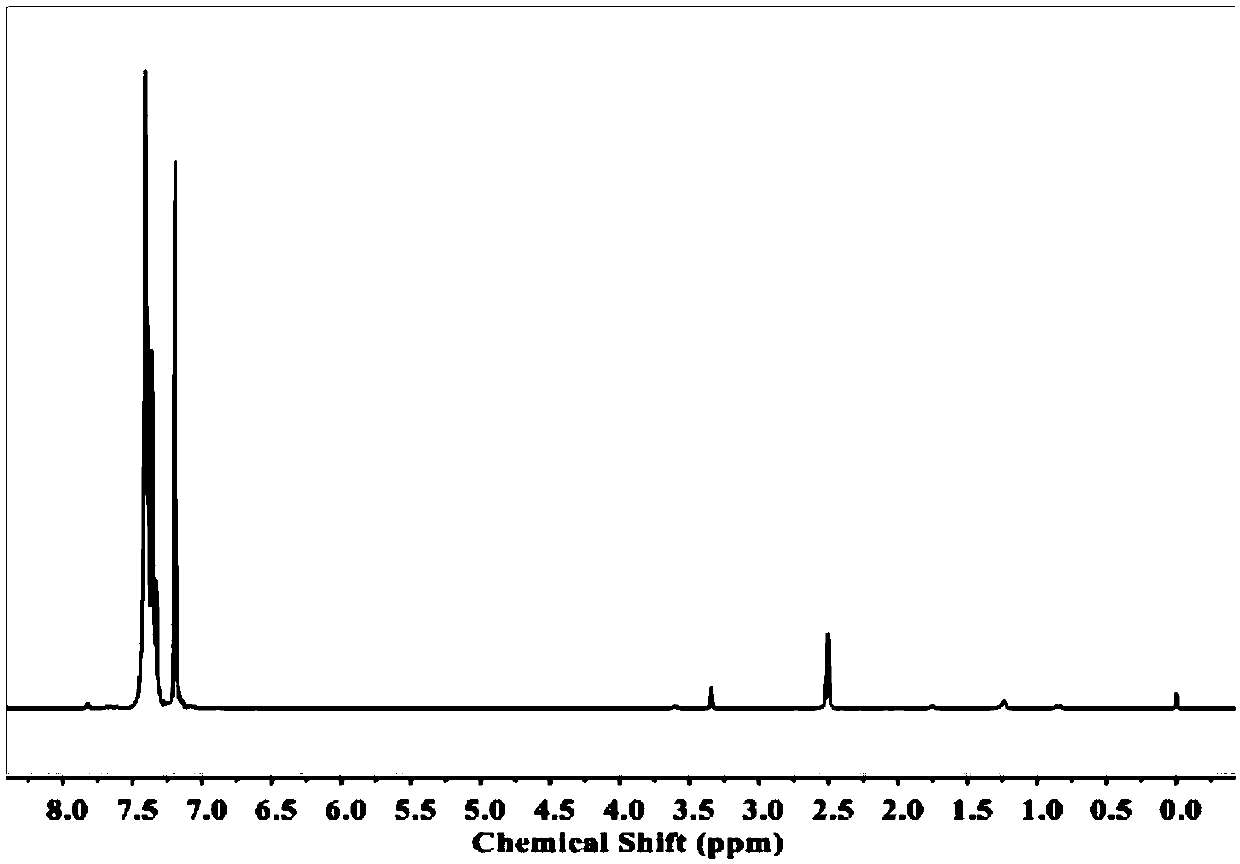

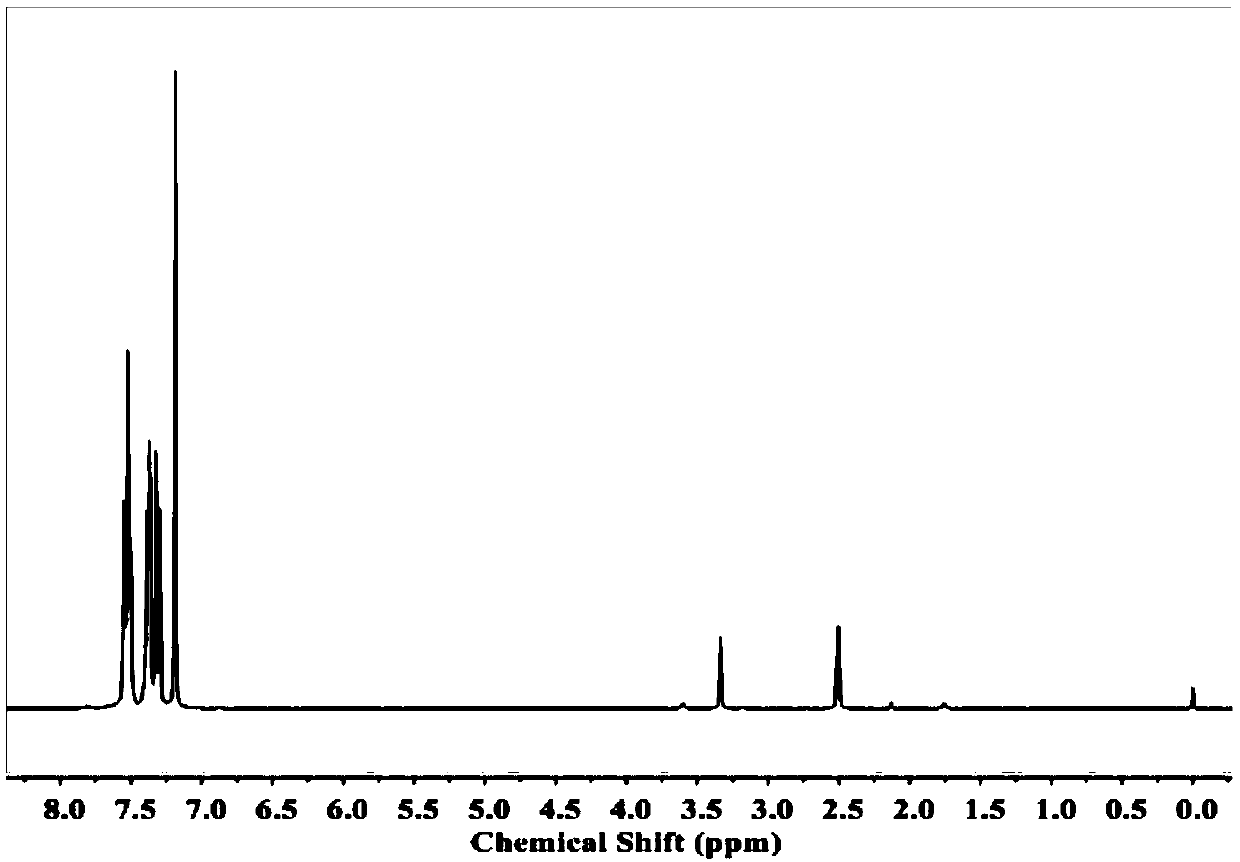

Selenium-containing maleimide polymer as well as preparation method and application thereof

ActiveCN109593154AHigh refractive indexImprove the defect of low refractive indexPolymer scienceRefractive index

The invention discloses a selenium-containing maleimide polymer as well as a preparation method and application thereof and belongs to the technical field of polymer materials. The selenium-containingmaleimide polymer with various refractive indexes is obtained through carrying out active free radical polymerization on a synthesized selenium-containing maleimide monomer with a novel structure anda styrene monomer at different mol ratios; and the refractive index is the greatest when the mol ratio of the two monomers is 1 to 1 and the refractive index value is 1.69 when the wavelength is 633nm. Compared with oxygen and sulfur substituted polymers with the same structure, the refractive index is remarkably improved. Furthermore, the styrene monomer is changed into a synthesized novel selenium-containing vinyl monomer and then the synthesized novel selenium-containing vinyl monomer is copolymerized with selenium-containing maleimide, so that the refractive index value of the obtained polymer is further improved on the basis of 1.69 and reaches 1.87 when the wavelength is 633nm. By adopting the selenium-containing maleimide polymer, the defects that the thermal stability is poor andthe molecular weight cannot be controlled are overcome; and the refractive index is controllably adjusted so that the application of the selenium-containing maleimide polymer in the optical field is expanded.

Owner:SUZHOU UNIV

A kind of selenium-containing maleimide polymer and its preparation method and application

ActiveCN109593154BHigh refractive indexImprove the defect of low refractive indexImideRefractive index

The invention discloses a selenium-containing maleimide polymer as well as a preparation method and application thereof and belongs to the technical field of polymer materials. The selenium-containingmaleimide polymer with various refractive indexes is obtained through carrying out active free radical polymerization on a synthesized selenium-containing maleimide monomer with a novel structure anda styrene monomer at different mol ratios; and the refractive index is the greatest when the mol ratio of the two monomers is 1 to 1 and the refractive index value is 1.69 when the wavelength is 633nm. Compared with oxygen and sulfur substituted polymers with the same structure, the refractive index is remarkably improved. Furthermore, the styrene monomer is changed into a synthesized novel selenium-containing vinyl monomer and then the synthesized novel selenium-containing vinyl monomer is copolymerized with selenium-containing maleimide, so that the refractive index value of the obtained polymer is further improved on the basis of 1.69 and reaches 1.87 when the wavelength is 633nm. By adopting the selenium-containing maleimide polymer, the defects that the thermal stability is poor andthe molecular weight cannot be controlled are overcome; and the refractive index is controllably adjusted so that the application of the selenium-containing maleimide polymer in the optical field is expanded.

Owner:SUZHOU UNIV

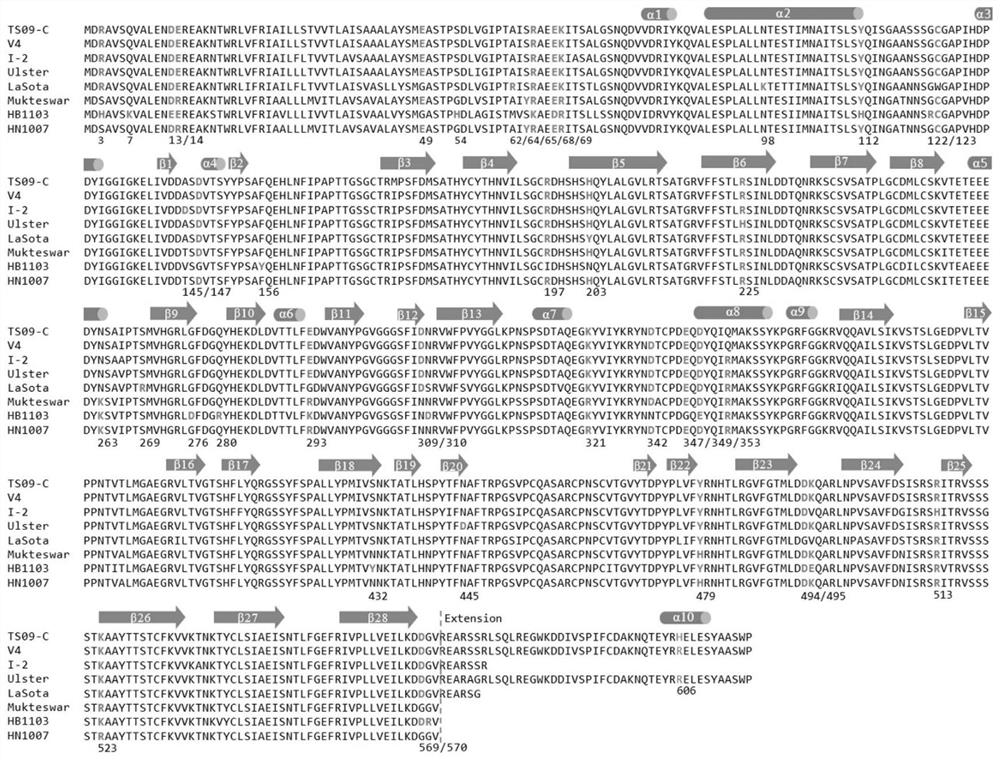

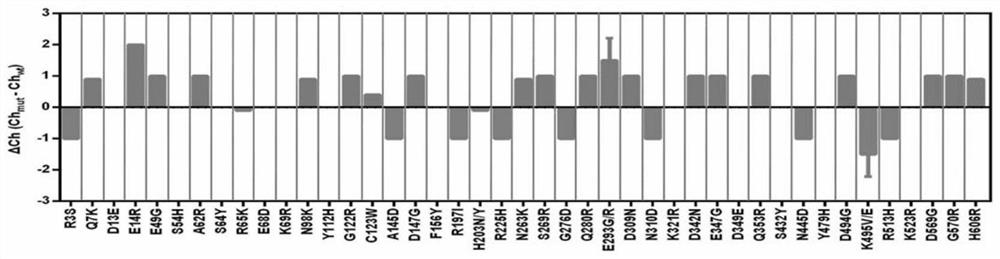

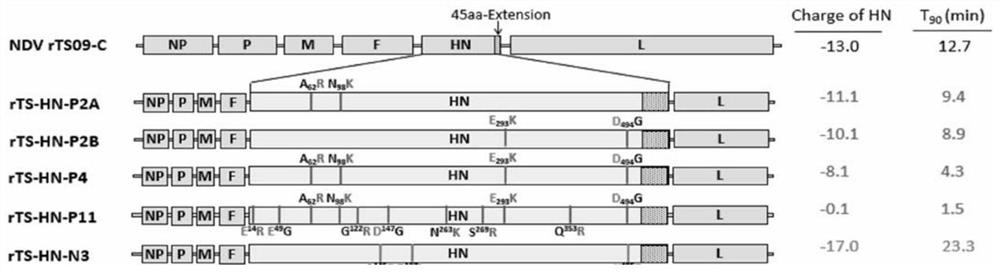

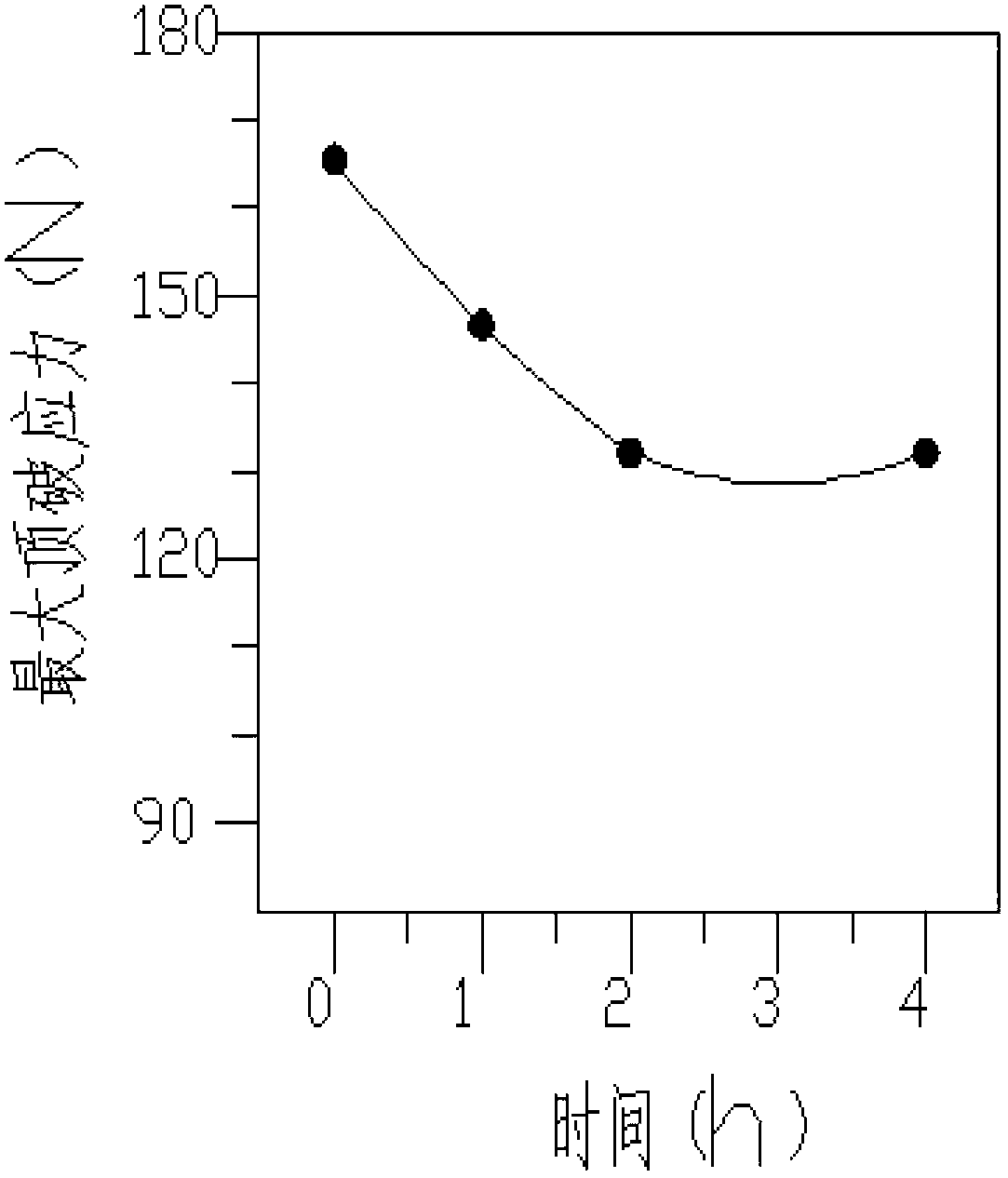

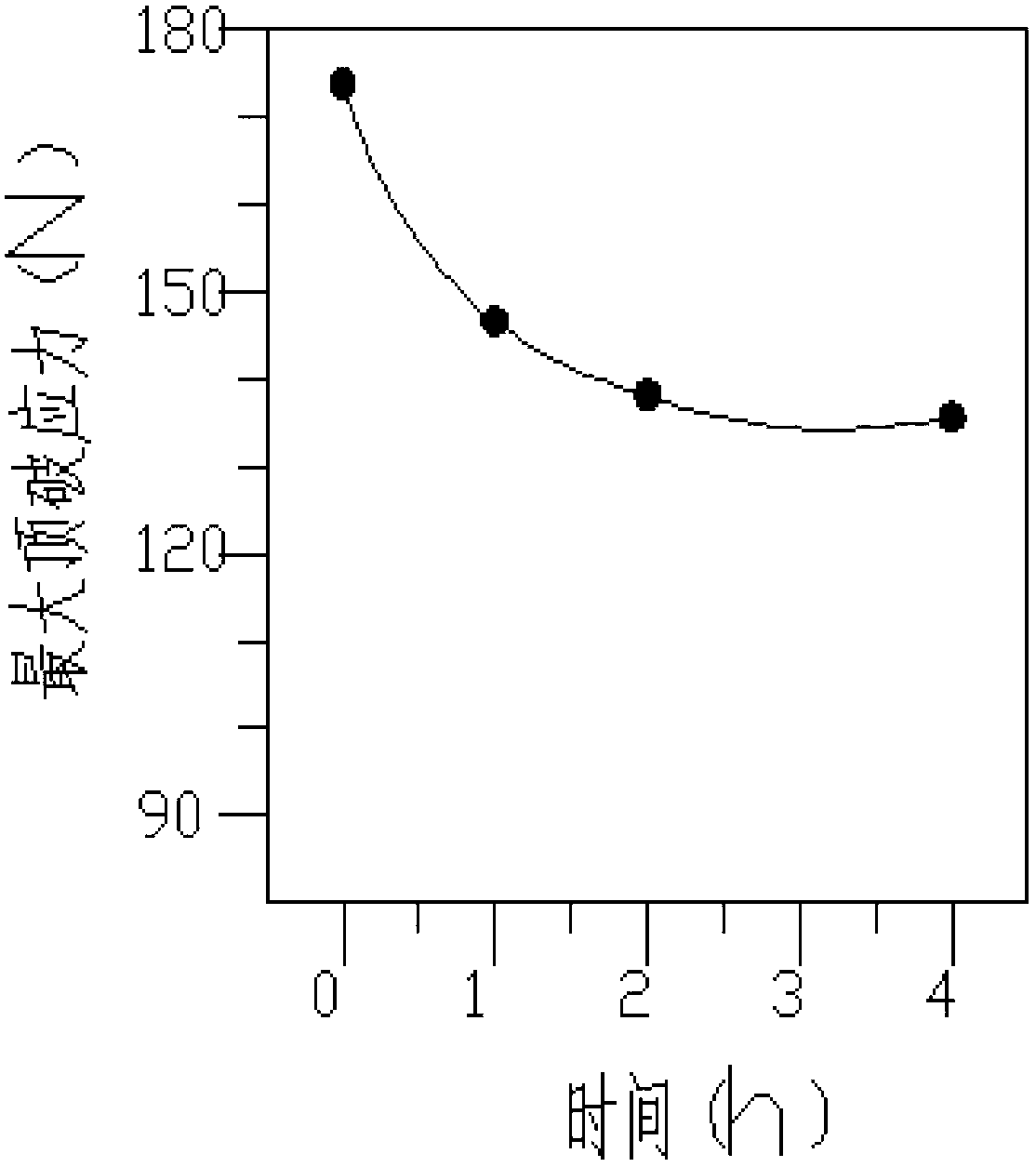

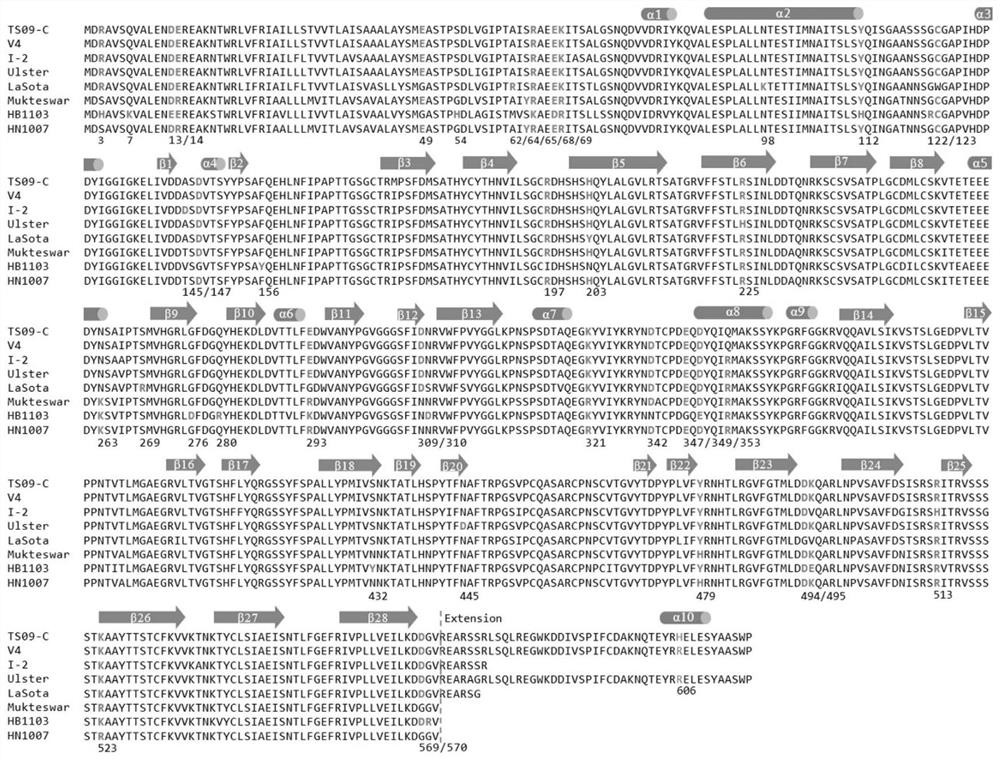

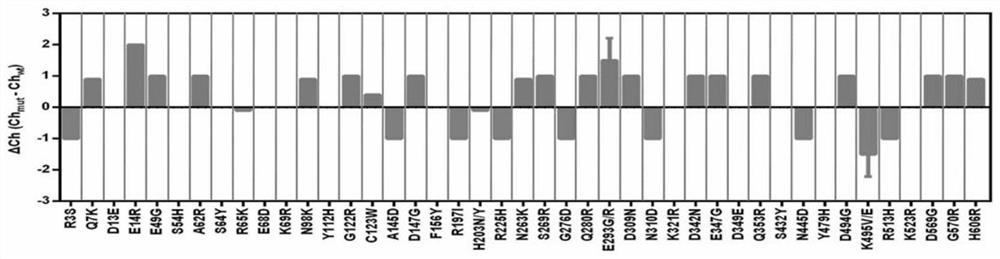

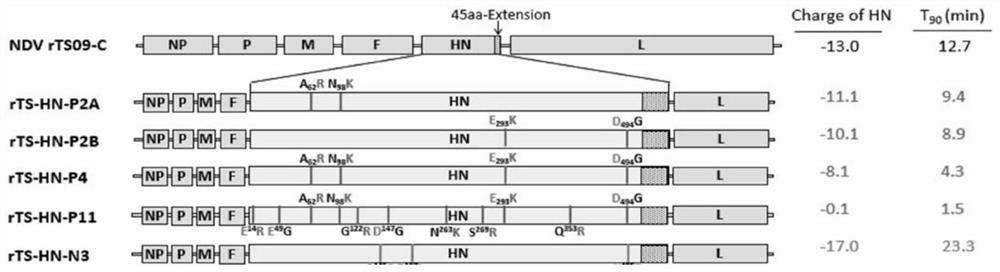

Genetic modification method for changing thermal stability of envelope virus, recombinant virus and application of recombinant virus

ActiveCN113005100AChange thermal stabilityHigh heat resistanceSsRNA viruses negative-senseVirus peptidesEngineeringTGE VACCINE

The invention provides a genetic modification method for changing thermal stability of an envelope virus, a recombinant virus and an application of the recombinant virus. The method comprises the following steps: comparing multiple sequences of enveloped viruses to obtain amino acid mutation which obviously influences an adsorptive protein charge value of a virus strain to be modified; analyzing the change value of the amino acid mutation to the adsorbed protein charge, and screening an amino acid mutation combination capable of remarkably increasing or reducing the adsorbed protein charge; applying the genetic manipulation technology of the virus, performing mutation modification on the envelope virus at the transcription plasmid level, and saving and obtaining the recombinant envelope virus subjected to heat-resistant modification. According to the invention, the heat-resistant characteristic of the envelope virus is obviously changed in an artificial mutation mode for the first time. The method can be widely applied to heat-resistant transformation of envelope virus vaccine strains, and has a wide application prospect in the aspect of research and development of heat-resistant, safe and efficient envelope virus vaccines.

Owner:INST OF ANIMAL SCI & VETERINARY HUBEI ACADEMY OF AGRI SCI

Curing agent reinforcement aramid fiber composite no-woven cloth and preparation method and applications of the same

ActiveCN103122556AImprove low temperature performanceBursting Force GuaranteePersonal protection gearNon-woven fabricsPolymer scienceAcrylate ester

The invention belongs to the field of bulletproof protective articles, and discloses curing agent reinforcement aramid fiber composite no-woven cloth and a preparation method and applications of the curing agent reinforcement aramid fiber composite no-woven cloth. The curing agent reinforcement aramid fiber composite no-woven cloth is made after silk is spread, aramid fiber is evenly, parallelly and straightly arranged, glued and dried, wherein curing agent is contained in an adhesion agent used in the process of gluing. The curing agent is trimethylolpropane triacrylate. The quantity of the added curing agent accounts 0.8-1.6% of the weight of the adhesion agent. The curing agent reinforcement aramid fiber composite no-woven cloth can overcome defects existing in the prior art to a large extent, not only changes heat stability of materials, improves anti-impact, bulletproof and anti-pricking performance of the aramid fiber composite no-woven cloth, but also can improve high-low-temperature performance of the aramid fiber composite no-woven cloth, and production efficiency.

Owner:JIANGSU LINRY NEW MSTAR TECH

Preparation of shell micro-powder reinforced super-high molecular weight polyethylene fibre composite non woven cloth

InactiveCN101082182BImprove impact resistanceChange thermal stabilityMacromolecular adhesive additivesTextiles and paperFiberPolymer science

The present invention relates to superfine shell powder reinforced composite weftless fabric of ultrahigh molecular weight polyethylene (UHMWPE) and its making process. Adding superfine shell powder into the laminated material can raise bullet-proof performance via making the fiber absorb even more impact energy of bullet and raise the heat resistance. The making process of the reinforced composite weftless fabric includes the following steps: 1. pre-treating shell powder to make its surface contain functional group; 2. modifying the pre-treated shell powder for homogeneous dispersing in the base adhesive; 3. mixing the modified shell powder and adhesive; 4. spreading UHMWPE; 5. spreading adhesive onto UHMWPE; and 6. stoving. Test shows that the superfine shell powder reinforced compositeweftless fabric of UHMWPE has 5 deg.c raised use temperature and about 20 % raised impact resistance.

Owner:DONGHUA UNIV

A kind of soluble elemental sulfur/alicyclic olefin copolymer and preparation method thereof

ActiveCN104844772BEliminate sulfur free radicalsActs as a chemical cross-linking pointSulfur preparation/purificationChemical synthesisSolubility

The invention belongs to the field of chemical synthesis, and in particular relates to a soluble elemental sulfur / alicyclic olefin copolymer and a preparation method thereof. In the present invention, the elemental sulfur is heated in the N2 atmosphere under the condition of catalyst presence or absence until the temperature of the reaction system is above the melting point of the elemental sulfur and below the transition temperature. After the elemental sulfur is completely melted, the alicyclic olefin monomer is added and stirred. Mix evenly; then perform polymerization reaction to obtain soluble elemental sulfur / alicyclic olefin copolymer; the copolymer introduces carbon chains in the sulfur chain, which not only eliminates sulfur free radicals, but also because the unsaturated olefin used contains more than one The double bond can act as a chemical cross-linking point, which in turn can stabilize the sulfur chain.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Novel production process of plastic woven bag

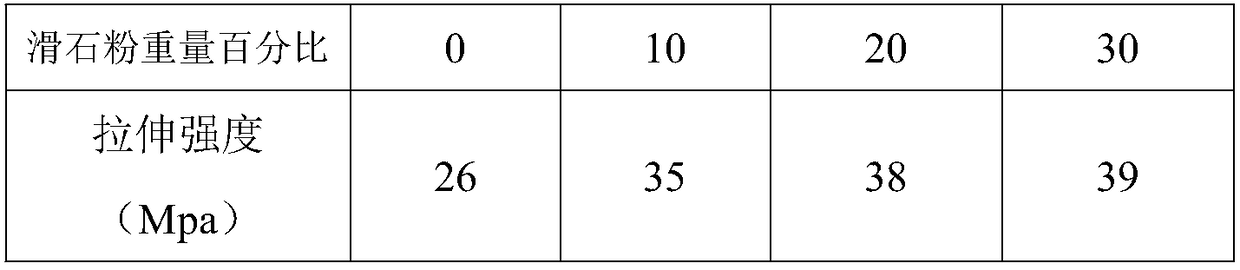

The invention relates to a novel production process of plastic woven bag. The production process comprises the following steps of: mixing preparation of raw materials including a component A that comprises the raw materials of polypropylene, maleic anhydride, styrene, xylene and dicumyl peroxide with a weight ratio of the polypropylene to the maleic anhydride to the styrene being 25:1:1, and a component B that comprises the raw materials of polypropylene, polyethylene, talcum powder, a dispersing agent and a light stabilizer, wherein the component A and the component B are sent into a drying stirrer according to a weight ratio of 1:20, the drying temperature is 30-35 DEG C, and the drying time is 15-20min; extrusion of the raw materials: placing the above raw materials in a melting machineat 240-250 DEG C for melting treatment, feeding the melt into an extruder, and cooling an extruded plastic film into water at 30-35 DEG C to form a solid film; and carrying out drawing, weaving and sewing. The novel production process of the plastic woven bag, provided by the invention, has the advantages of little pollution and good product performance.

Owner:TIANJIN HUAQING BAISHENG PLASTIC INDAL

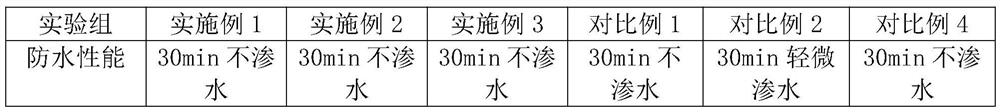

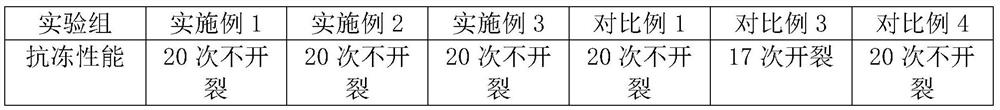

High-temperature-resistant waterproof epoxy asphalt and preparation method thereof

PendingCN112920614AChange the adhesionChange tensile strengthBuilding insulationsPolymer scienceAcrylonitrile

The invention discloses high-temperature-resistant waterproof epoxy asphalt and a preparation method thereof. The high-temperature-resistant waterproof epoxy asphalt is prepared from the following raw materials in parts by weight: 40-50 parts of asphalt, 5-10 parts of concrete, 20-30 parts of bisphenol A epoxy resin, 5-7 parts of higher aliphatic amine, 1-2 parts of acrylonitrile, 0.2-0.4 part of epoxy chloropropane, 3-4 parts of hyper-branched polyester, 1-2 parts of an antioxidant, 2-3 parts of a filler and 0.1-0.2 part of a dispersing agent, wherein the filler is a mixture of talcum powder, diatomite and mica powder, and the higher aliphatic amine is one or more of octadecyl amine and dodecyl amine. The bisphenol A epoxy resin and the asphalt are mixed, a three-dimensional interpenetrating network structure polymer can be formed, the adhesive force, the tensile strength and the thermal stability of the product can be fundamentally changed, hyper-branched polyester is added, the asphalt is subjected to toughening modification, the problem of poor compatibility can be avoided, and the tensile strength of the product at low temperature can be improved.

Owner:金闻闻

Composite material of modified micro plant fiber powder and natural rubber and its prepn process and application

InactiveCN100432134CAchieve refinementGood dispersionMale contraceptivesSolesUrinary catheterVulcanization

The present invention discloses one kind of composite material of modified micro plant fiber powder and natural rubber and its preparation process and application. The composite material includes natural rubber or latex 100 weight portions, modified micro plant fiber powder 1-60 weight portions, sulfur 0.5-3.3 weight portions, promoter 1.2-4.3 weight portions, antiager 1-3 weight portions and other assistant. The preparation process includes mixing, forming, vulcanizing and other steps. The composite material has high tensile strength, high tearing strength, high ageing resistance, high virus permeation resistance, etc. and may be used widely in making urinary catheter, blood transfusion tube, condom, medical gloves and other products.

Owner:JINAN UNIVERSITY

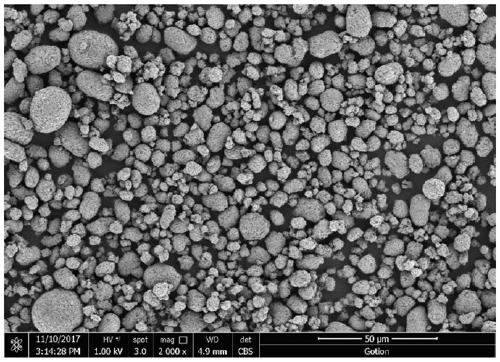

A kind of ncm/lmo composite material based on microwave synthesis, preparation method and application thereof

ActiveCN109301206BImprove thermal stabilityIncrease contact interfaceCell electrodesAir atmospherePhysical chemistry

The invention provides a NCM / LMO composite material based on microwave synthesis, and a preparation method and an application thereof. The method includes: adding an NCM ternary precursor material towater with stirring, and adding KMnO4 powder and continuously stirring the solution; performing a reaction in a microwave reactor; moving out and cooling a product, and performing a reaction in the microwave reactor again, the operations hereinabove being repeated for 2-10 times; adding the product in lithium salt, and calcining the mixture in an oxygen or air atmosphere furnace; and cooling the calcined material to obtain the NCM / LMO composite material. Because the LMO uniformly grows on the surface of the NCM to form a stable LMO layer, compared with blending of the two components, the composite material improves the contact interface of the two components during composition and is effectively improved in thermal stability, thereby improving the security of a lithium ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A genetic modification method for changing the thermal stability of enveloped virus, recombinant virus and its application

ActiveCN113005100BChange thermal stabilityHigh heat resistanceSsRNA viruses negative-senseVirus peptidesEngineeringTGE VACCINE

The invention provides a genetic modification method for changing the heat stability of enveloped virus, recombinant virus and application thereof. The method comprises the following steps: comparing multiple sequences of enveloped viruses to obtain amino acid mutations that significantly affect the charge value of the adsorbed protein of the virus strain to be transformed; analyzing the change value of the amino acid mutation to the charge of the adsorbed protein, and screening which can significantly increase or Combination of amino acid mutations that reduce the negative charge of the adsorbed protein; use the genetic manipulation technology of viruses to mutate enveloped viruses at the level of transcription plasmids, rescue and obtain heat-resistant recombinant enveloped viruses. The invention significantly changes the heat-resistant property of the enveloped virus by means of artificial mutation for the first time. The invention can be widely applied to the heat-resistant transformation of enveloped virus vaccine strains, and has broad application prospects in the research and development of heat-resistant, safe and efficient enveloped virus vaccines.

Owner:INST OF ANIMAL SCI & VETERINARY HUBEI ACADEMY OF AGRI SCI

Preparation method of tin and silver composite plating layer with high reflectivity

The invention relates to a preparation method of a tin and silver composite plating layer with high reflectivity, and belongs to the technical field of semiconductor illumination. The preparation method comprises the following steps of (1) electrically depositing a tin plating layer onto the surface of a copper substrate by tin sulfate and concentrated sulfuric acid; (2) electrically depositing asilver plating layer onto the surface of the tin plating layer by a nicotinic acid system; (3) annealing the obtained tin and silver composite plating layer, and enabling tin and silver atoms to disperse in a tin and silver solid-solid interface, so as to obtain an Ag3Sn thin film with high reflectivity. The preparation method has the advantages that after annealing, the plating layer is uniformlydistributed; the bonding strength between the plating layers is improved; the Ag3Sn thin film is formed at the surface of the plating layer, so that an HRBE (high reflective back electrode) with highreflectivity and excellent antioxidation property and sulfurizing property is obtained.

Owner:DALIAN UNIV OF TECH

A kind of preparation method of photosensitive quartz tube

The invention provides a method for preparing a photosensitive quartz tube. The components of the photosensitive quartz tube include quartz sand, alumina, and bismuth silicate. The weight of the quartz sand is used as the basic unit, and the mass ratio of the dopant to the quartz sand is : Aluminum oxide 0.076‰, bismuth silicate 0.114‰. The quartz tube provided by the invention changes the thermal stability and light transmittance of the ordinary quartz glass tube, so that it has unique high photosensitivity. The photosensitive quartz tube has high-efficiency photocatalytic activity in the 185-500 wavelength range, and can photocatalytically oxidize and degrade organic compounds under visible light or ultraviolet light radiation. It can be widely used in residential water equipment, independent air purifiers, wall-mounted air purification equipment, pipeline air treatment units, urban water treatment systems, air treatment equipment, and reduce energy consumption. It is an environmentally friendly and clean new material.

Owner:JIANGSU SHENGDA QUARTZ PROD CO LTD

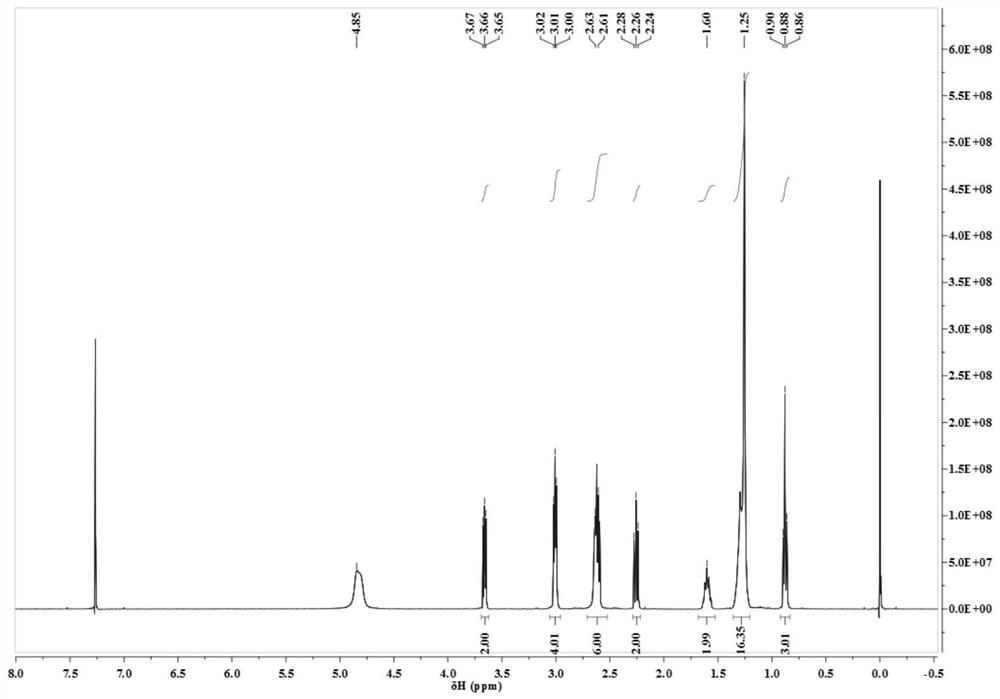

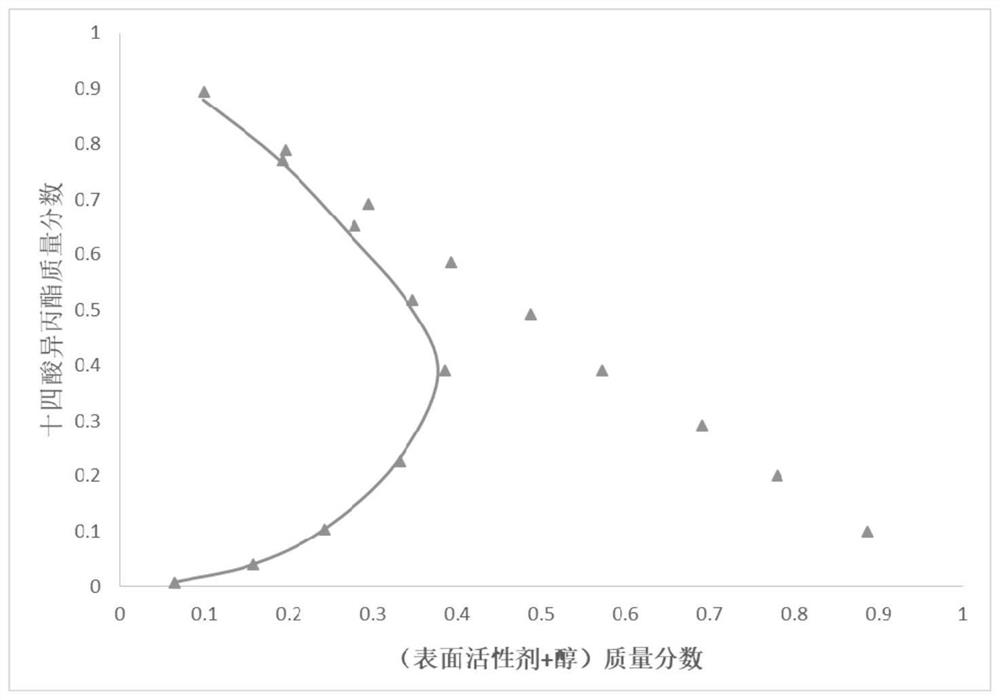

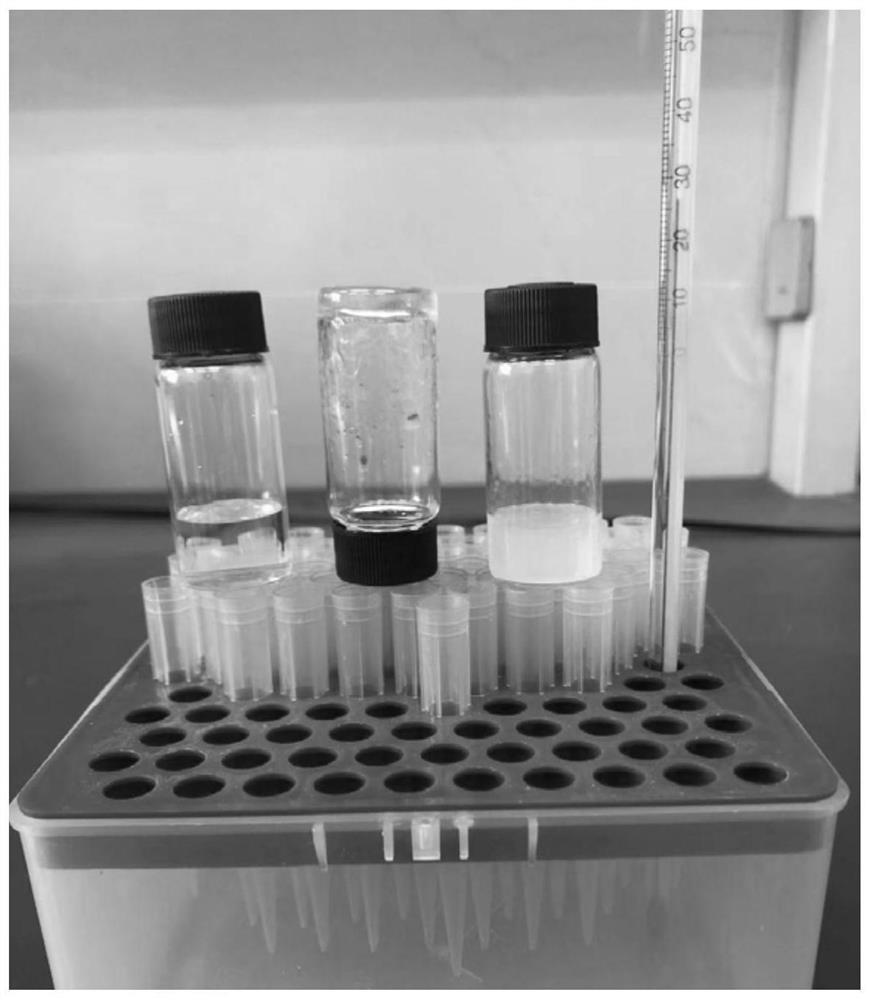

Piperazinyl ionic liquid surfactant as well as synthesis method and application thereof

ActiveCN112707875AEasy to manufactureLow costOrganic compound preparationTransportation and packagingIsopropylActive agent

The invention discloses a piperazinyl ionic liquid surfactant, which has a chemical structural general formula shown in the specification, wherein R1 is methyl, ethyl, n-propyl, isopropyl, n-butyl, isobutyl, tert-butyl, hydroxyethyl, hydroxypropyl, formyl or phenyl, and R2 is a straight-chain alkyl group of C9-C17. The invention further discloses a synthetic method of the piperazinyl ionic liquid surfactant, the process is simple, the period is short, and the product purity can reach 97% or above. The invention also discloses application of the piperazinyl ionic liquid surfactant as a microemulsion component and a microemulsion gel component.

Owner:GUANGDONG PHARMA UNIV

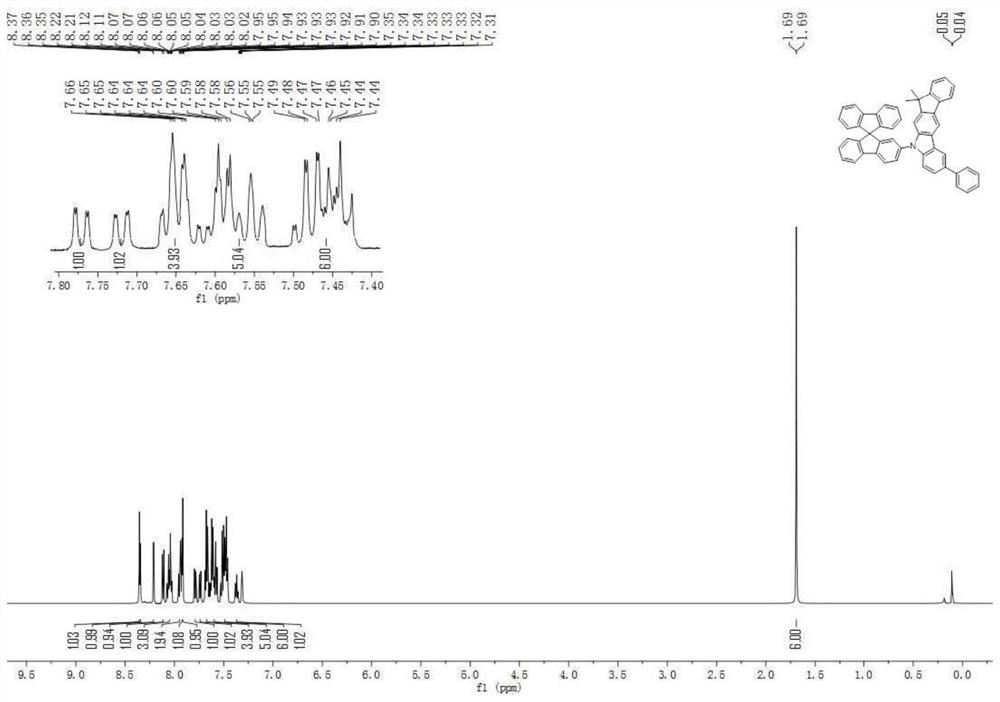

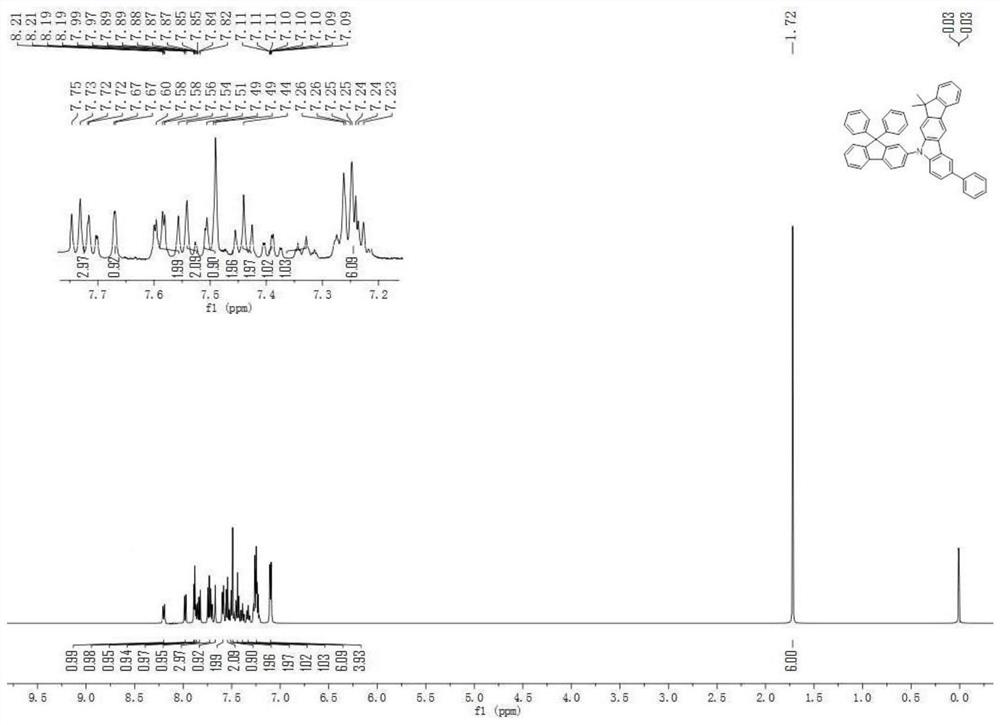

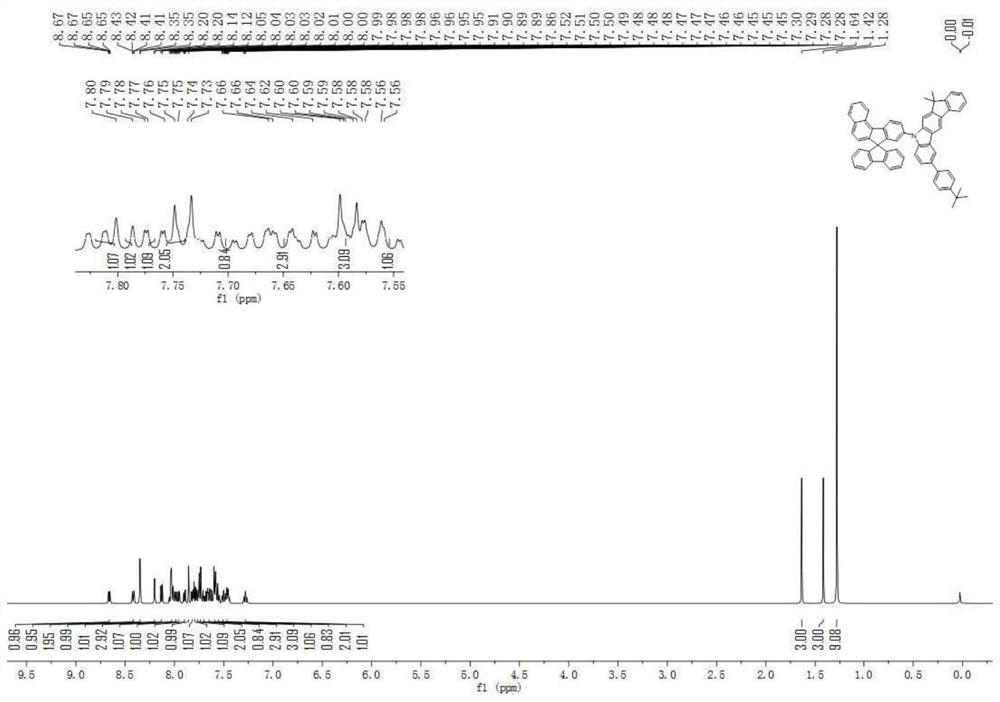

An organic electroluminescent device comprising fluorene derivatives

ActiveCN111969120BAsymmetricalImprove stabilityOrganic chemistrySolid-state devicesCarbazoleOrganic electroluminescence

The invention provides an organic electroluminescent device containing fluorene derivatives, and relates to the field of organic photoelectric technology. The organic electroluminescent device of the present invention comprises a fluorene derivative, and carbazole / indenocarbazole and its derivative groups are introduced into the fluorene derivative, thereby obtaining a series of compounds with higher glass transition temperature, so it has good thermal stability, and the organic electroluminescent device containing this type of compound also has good stability, so it has the advantage of long service life; at the same time, the compound provided by the invention has better hole mobility , a suitable HOMO energy level, and a higher triplet state energy level are conducive to hole transport and can effectively block the dissipation of excitons, which can significantly improve the luminous efficiency of the device.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com