A kind of ncm/lmo composite material based on microwave synthesis, preparation method and application thereof

A composite material and microwave synthesis technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of easy decomposition and release, aggravate the decomposition of positive electrode materials, and large-scale application restrictions, so as to change thermal stability and improve Thermal stability, improving the effect of the contact interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The NCM811 ternary precursor material ((Ni 8 co 1 mn 1 )(OH) 2 ) and 200mL of water were placed in a round-bottomed flask, and mechanically stirred for several hours; and NCM811 ternary precursor material according to the molar ratio of 5:1, weighed 6.32g of KMnO4 powder, placed in a round-bottomed flask and continued to stir until uniform; the round-bottomed flask Put it in a microwave reactor with 500W power to react for 30s, take it out and cool it, repeat the above operation 3 times, wash and filter after cooling, put the collected powder in a vacuum oven for several hours in vacuum drying, and obtain the NCM811 / LMO precursor (after ICP test get (Ni 0.8 co 0.1 mn 0.1 )(OH) 2 with MnO 2 The ratio is about 9:1). Weigh 10g of the NCM811 / LMO precursor, add lithium salt (Li 2 CO 3 ) 2.4g was pre-fired in an oxygen atmosphere furnace at 550°C for 4h, then heated to 800°C for 20h, and finally NCM811 / LMO composite was obtained after cooling.

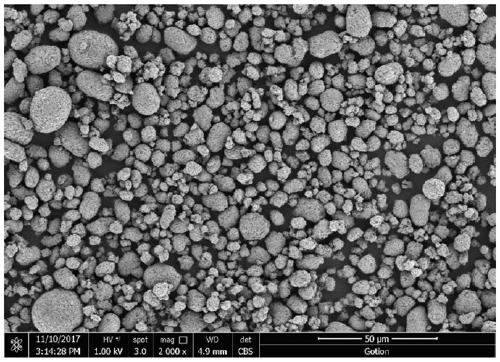

[0035] Such as fig...

Embodiment 2

[0042] The NCM532 ternary precursor material ((Ni 5 co 3 mn 2 )(OH) 2 ) and 200mL of water were placed in a round bottom flask, and mechanically stirred for several hours; and the NCM811 ternary precursor material was weighed according to the molar ratio of 5:1 KMnO4 powder 12.64g was placed in a round bottom flask and continued to stir until uniform; the round bottom flask Put it in a microwave reactor with 500W power to react for 90s, take it out and cool it down, repeat the above operation 3 times, wash and filter after cooling, put the collected powder in a vacuum oven and dry it in vacuum for several hours to obtain the NCM532 / LMO precursor (after ICP test get (Ni 0.8 co 0.1 mn 0.1 )(OH) 2 with MnO 2 The ratio is about 9:2). Weigh 10g of the NCM532 / LMO precursor, add lithium salt (Li 2 CO 3 ) 2.75g was pre-fired in an oxygen atmosphere furnace at 550°C for 4h, then heated to 800°C for 20h, and finally NCM811 / LMO material was obtained after cooling.

[0043] Acc...

Embodiment 3

[0052] A method for synthesizing NCM / LMO composites based on microwaves, comprising the following steps:

[0053] (1) The NCM ternary precursor material (Ni 4 co 3 mn 3 )(OH) 2 Add water and stir, then add KMnO 4 The powder continues to stir; where (Ni 4 co 3 mn 3 )(OH) 2 with KMnO 4 The molar ratio is 10:1.

[0054] (2) Put the product of step (1) in a microwave reactor with a power of 100W to react for 180s;

[0055] (3) Take it out and cool it, then place it in a microwave reactor for 180s, repeat the above operation twice;

[0056] (4) washing and filtering after cooling, and drying the collected powder to obtain a composite material precursor;

[0057] (5) Add the composite material precursor to LiNO at a molar ratio of 1:1 3 and placed in an oxygen or air atmosphere furnace, pre-fired at 500°C for 12h, then heated to 850°C for 36h, and then cooled to obtain NCM / LMO composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com