Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Act as passivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing algae essence by using enzymatic hydrolysis method

ActiveCN101580852APlay a regulating roleAct as passivationBiocidePlant growth regulatorsEnzymatic hydrolysisColloid

The invention improves the extraction yield of algae essence by using cellulase for decomposing cellulose in algae after dry algae which is ground and desanded is soaked in water and subjected to colloid mill treatment, and then leads alginic acid with large molecular weight to be degraded to alginic acid with small molecular weight by using alginate lyase, thus leading effective compositions in algae to be less damaged and having high extraction yield.

Owner:BEIJING LEILI MARINE BIOINDUSTRY INC

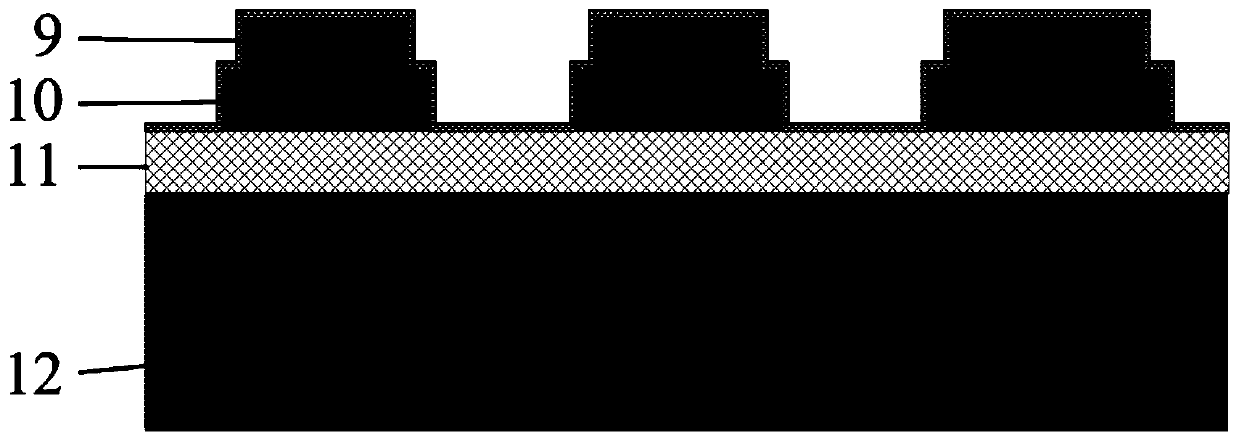

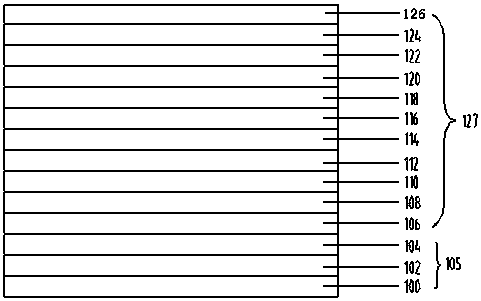

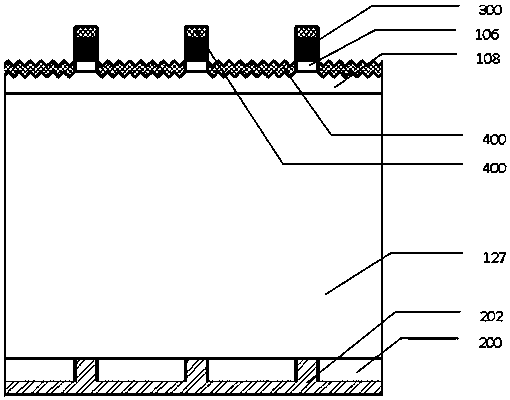

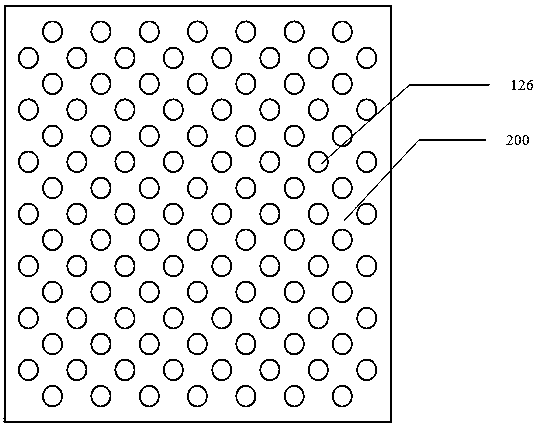

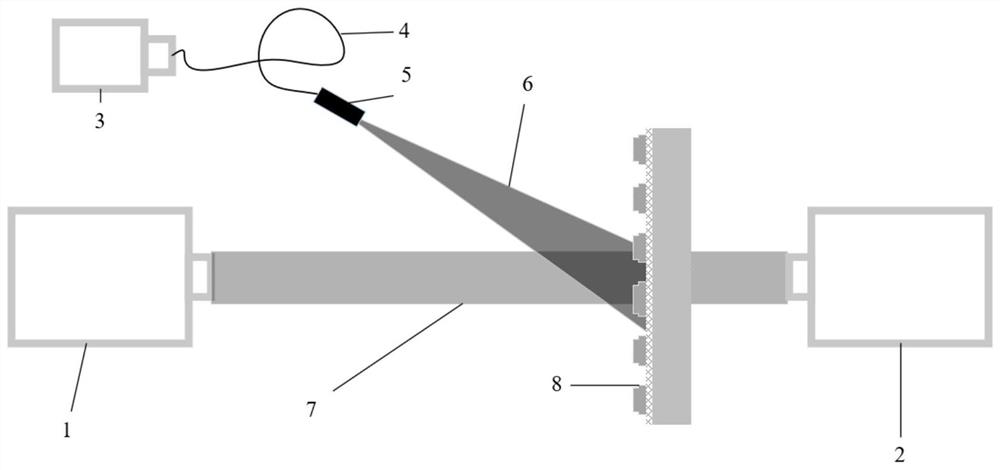

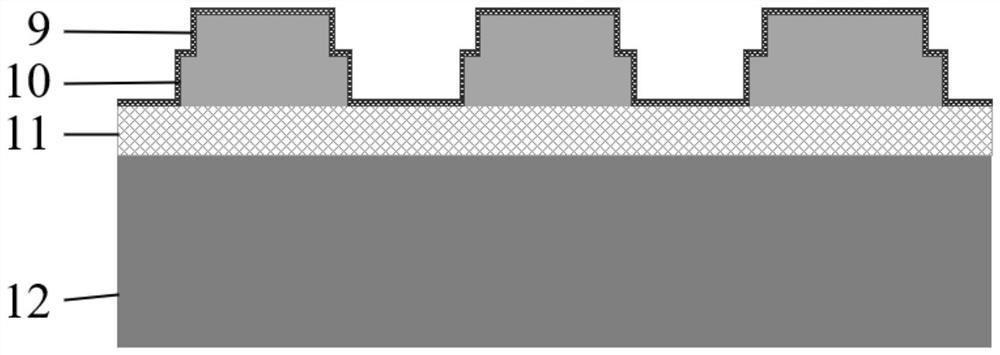

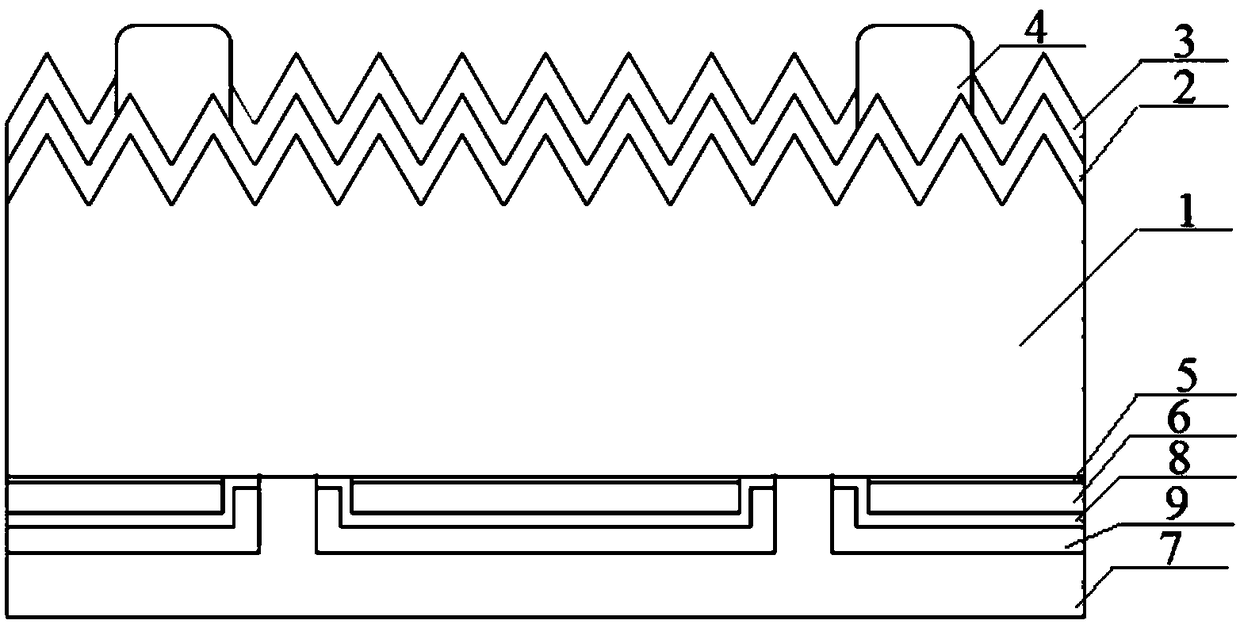

Terahertz modulator based on silicon-based microstructure on SOI, system and method

ActiveCN110095888AReduce reflectivityIncrease profitNon-linear opticsImage diffusionImage resolution

The invention provides a Terahertz modulator based on a silicon-based microstructure on SOI, a manufacturing method and a modulation system. The Terahertz modulator successively comprises an Al2O3 substrate of a bottom layer, a SiO2 isolation layer, the silicon-based microstructures, and an Al2O3 passivation layer from bottom to top. The silicon-based microstructures are periodically arranged on the SiO2 isolation layer. Each silicon-based microstructure comprises a two-layer square Si-based step structure. The modulation system comprises a semiconductor laser, a laser modulator, the Terahertzmodulator, a Terahertz radiation source, and a Terahertz detector. In the invention, a reflectivity which is lower than 22% is achieved for a Terahertz wave of 0.4 THz to 0.85 THz and a minimum of 18% can be reached at 0.82 THz so that the reflectivity of a modulation device to the Terahertz wave can be significantly reduced and a utilization rate of the Terahertz wave is improved. A 64.5% modulation depth can be achieved under 808 nm laser radiation with 1200 mw power. Compared with a traditional silicon-based Terahertz modulator, a Terahertz imaging diffusion area can effectively increase aresolution and make the resolution reach above 21.9% in an imaging system.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

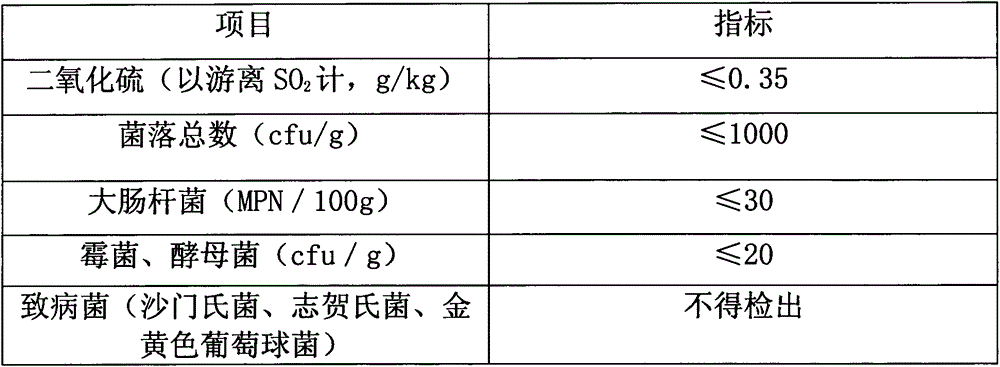

Preserved cherry tomato fruits

The invention discloses preserved cherry tomato fruits and a processing method thereof. The method comprises the following concrete steps: cleaning fresh cherry tomato fruits as a raw material, processing a plurality of holes in the cherry tomatoes fruits by a perforating machine, soaking the cherry tomato fruits in a sodium pyrosulfite solution for color-protecting, sugaring, and finally, performing processes of drying, cooling and the like to prepare the finished preserved cherry tomato fruits. According to the method, an effect of passivating phenolase is achieved while the color is protected, and the browning degree of the preserved cherry tomato fruits is lowered; the sugaring and drying processes are segmentally carried out, so that the preserved cherry tomato fruits can have the color and the flavor of original fruits and also retain the shapes of the original fruits, thus having better competitive advantages than like products.

Owner:广西田阳嘉佳食品有限公司

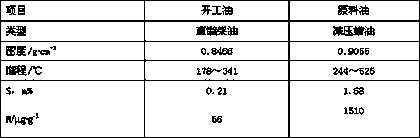

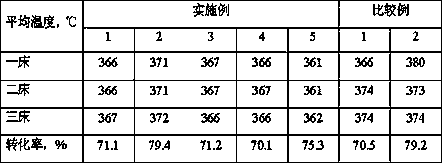

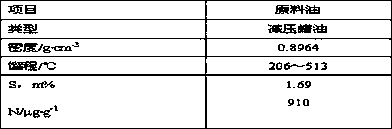

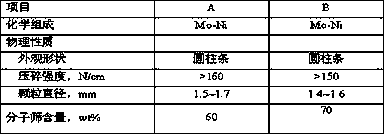

Method for improving operation safety of hydrocracking unit

ActiveCN111100687AAvoid remodeling workCatalyst activity is stableTreatment with hydrotreatment processesChemistryProcess engineering

The invention discloses a method for improving the operation safety of a hydrocracking device. The hydrocracking unit at least comprises two hydrocracking catalyst beds. The method comprises the following steps: cooling to 200-340 DEG C and switching the hydrocracking feed oil with the nitrogen content of 300 to 500 ppm when the weight percentage content of nitrogen in the hydrocracking catalyst in the first hydrocracking catalyst bed is 0.15-0.35%; switching the hydrofined oil with the nitrogen content of less than 40ppm when the nitrogen content in the hydrocracking effluent is constant at 50-80ppm; simultaneously adjusting the reaction temperature of the hydrocracking section until the mass yield of the light oil of less than 360 DEG C is finally kept constant at 35-40% and the total constant time is 48-96 hours; and then adjusting to the hydrocracking reaction condition for hydrocracking reaction. By the method, the problem that the activity of part of the hydrocracking catalyst isdamaged due to frequent startup and shutdown and then the mismatching of reaction temperatures among different catalyst beds in the reactor is influenced is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Negative electrode slurry, negative electrode plate, lithium ion soft package battery cell, lithium ion battery pack and application of lithium ion battery pack

InactiveCN112563465AAct as passivationIncrease energy densityElectrode carriers/collectorsSecondary cells servicing/maintenanceElectrochemical responseElectrolytic agent

The invention discloses negative electrode slurry, a negative electrode plate, a lithium ion soft package battery cell, a lithium ion battery pack and application thereof. The negative electrode slurry comprises a negative electrode active material, an additive and a solvent, the negative electrode active material comprises a silicon-based composite material, and the additive comprises lithium nitrate. The negative electrode active material comprising the silicon composite material is high in energy density, lithium nitrate has relatively high reduction potential and is easy to reduce and decompose, and the decomposition product can stably coat the surface of the negative electrode active material, plays a role in passivating the negative electrode active material, can effectively inhibitcontinuous side reaction between electrolyte and the negative electrode active material, such as electrochemical reactions, so that the cycle performance of the lithium ion soft package battery cell can be improved, and the cycle life is long.

Owner:GAC AION NEW ENERGY AUTOMOBILE CO LTD

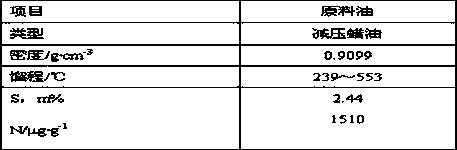

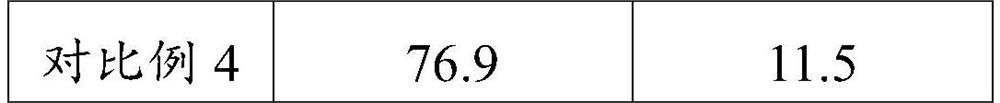

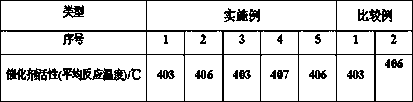

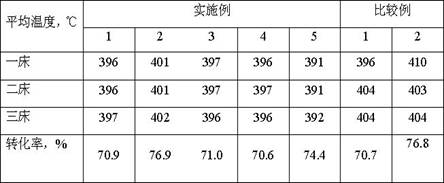

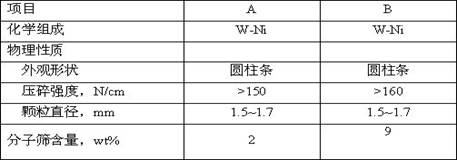

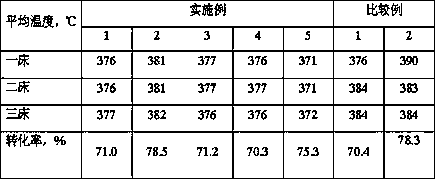

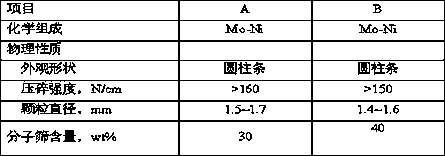

Rapid start-up method of hydrocracking catalyst

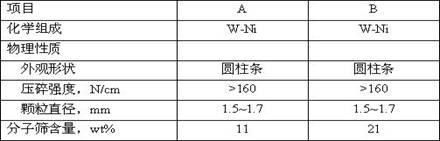

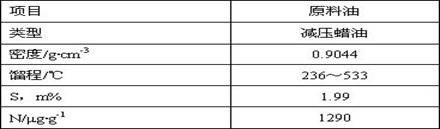

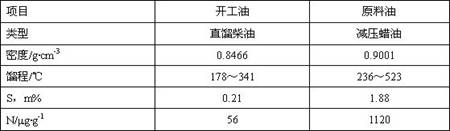

ActiveCN109777475AAvoid investingCatalyst activity is stableHydrocarbon oil crackingMolecular sieveChemistry

The invention discloses a rapid start-up method of a hydrocracking catalyst. The start-up method comprises the following steps: introducing raw material oil in the vulcanization process, after vulcanization is completed, adjusting a reaction temperature, and when the mass yield of light oil less than 360 DEG C is stabilized at 35-40%, adjusting to a hydrocracking reaction condition to carry out ahydrocracking reaction, wherein the hydrocracking catalyst comprises 0-10% of a molecular sieve by weight, and the molecular sieve comprises, but not limited, a Y type or a USY (Ultra-Stable Y Zeolite) type molecular sieve. The method is simple in start-up and raw material switching process, stable in operation and capable of avoiding consumption of a passivant in the start-up process and potential danger in the ammonia injection process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Positive electrode slurry, positive electrode sheet and electrochemical energy storage device

ActiveCN109309208BAct as passivationInhibition of sustained electrochemical oxidation reactionsCell electrodesSecondary cellsElectrolytic agentHigh temperature storage

Owner:CONTEMPORARY AMPEREX TECH CO

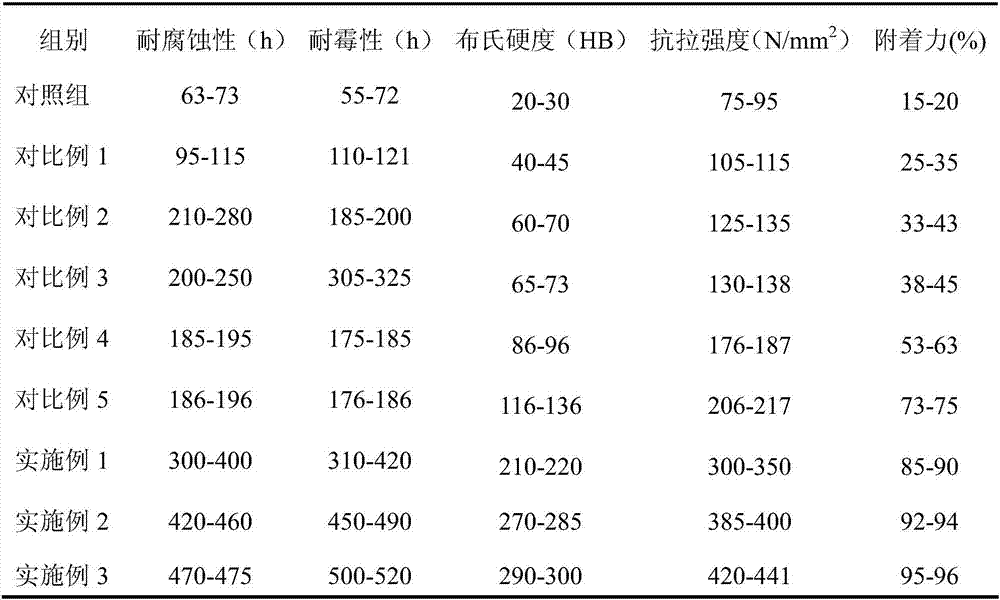

Anticorrosive aluminum product and preparation method thereof

InactiveCN107011766AImprove mechanical propertiesExtended validity periodAntifouling/underwater paintsPaints with biocidesEpoxyMethyl carbamate

The invention relates to the technical field of aluminum-based composite material, and provides an anticorrosive aluminum product and a preparation method thereof. A substrate layer is mainly prepared from the following components in parts by weight: 50 to 60 parts of aluminum powder, 20 to 30 parts of copper powder, 5 to 6 parts of nanometer zirconium dioxide, 3 to 4 parts of samarium element, 3 to 4 parts of ytterbium element and 1 to 2 parts of corrosion inhibitor. A coating layer is mainly prepared from the following components in parts by weight: 30 to 40 parts of epoxy resin, 5 to 7 parts of mesoporous SBA-15, 0.5 to 1.0 part of beta-(2,6-ditert-butyl-3-hydroxyphenyl)propionic octadecyl ester, 0.5 to 1.0 part of 2,5-ditert-butyl-3-methylphenol, 0.2 to 0.5 part of N-(fluclorolone methyl thiocarbonate)phthalimide, 0.2 to 0.5 part of benzimidazolyl methyl carbamate, 10 to 13 parts of stainless powder, and the like. The preparation method comprises the following steps of preparation of the substrate layer and the coating layer, spraying of paint and the like. The anticorrosive aluminum product has the advantages that the environment-friendly effect is realized, the comprehensive property is excellent, and the anticorrosive durability of the aluminum product is effectively improved.

Owner:玉林博飞商贸有限公司

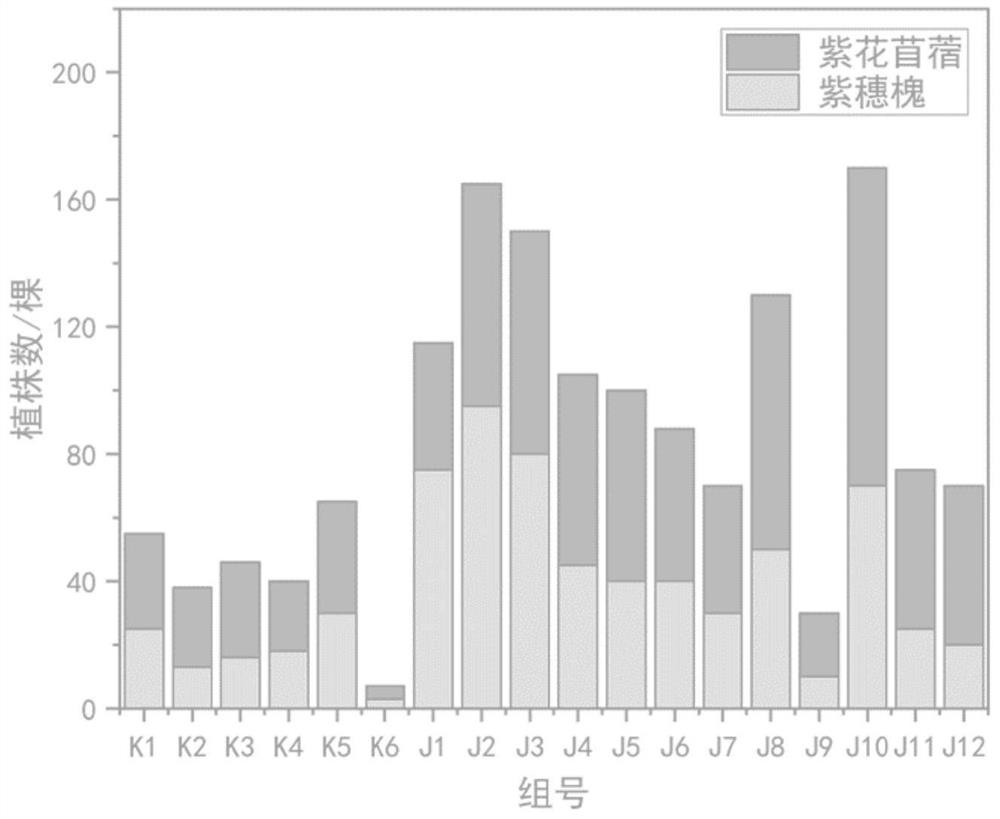

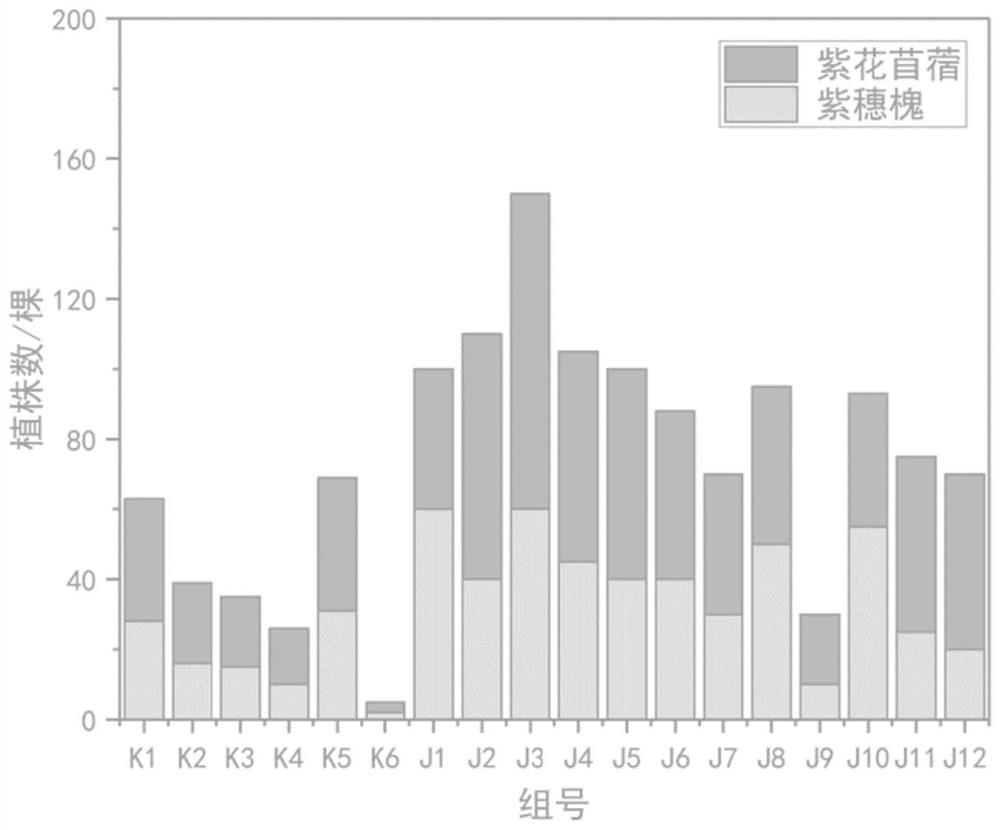

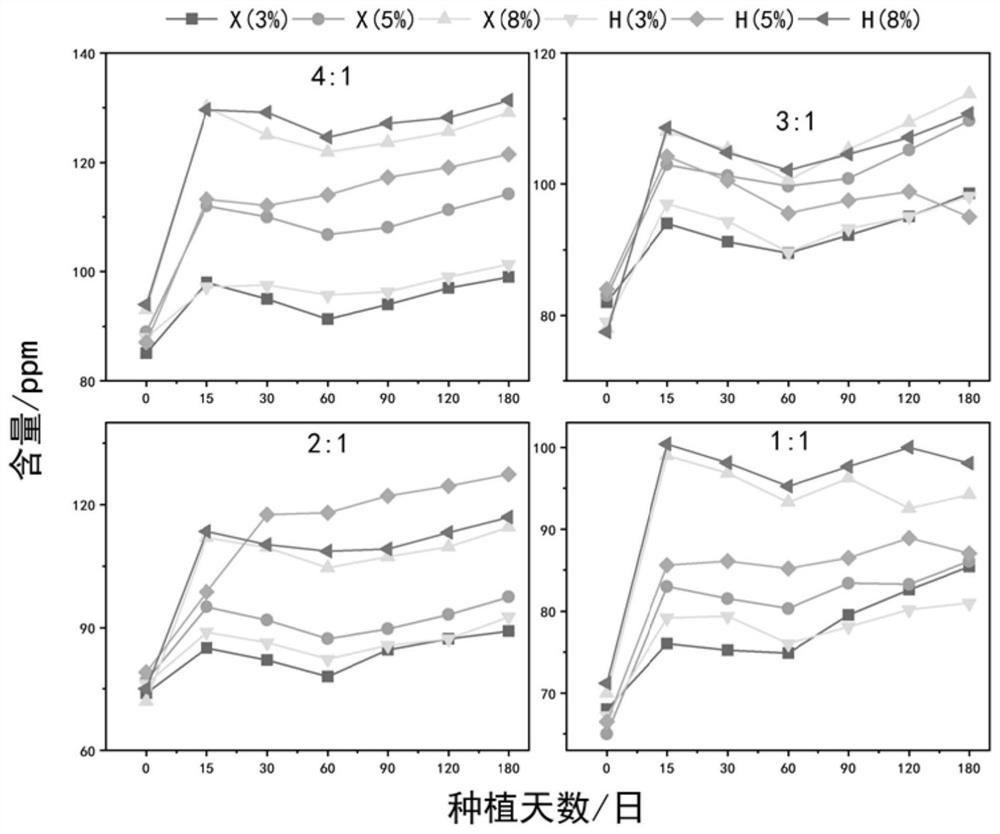

Waste residue field reclamation soil matrix as well as preparation method and application

ActiveCN112075318AImprove breathabilityImprove fertilityBio-organic fraction processingExcrement fertilisersMicroorganismSoil science

The invention provides a waste residue field reclamation soil matrix which comprises, by mass, 40%-75% of original soil, 10%-50% of engineering waste residues, 3%-8% of organic fertilizer and 3%-7% ofpine needles, and the ratio of the original soil to the engineering waste residues is 1:1-4:1. Meanwhile, the invention provides a preparation method and application thereof. According to the reclamation soil matrix, a large number of waste residues in a waste residue field can be effectively disposed, growth of plants is promoted, and the survival rate is increased. The natural soil, the engineering waste residues and the pine needles in the matrix form a loose and porous soil structure, so that air permeability and moisture transmission of soil are facilitated, formation of aggregates in the soil is facilitated, and survival and propagation of microorganisms are also facilitated. The organic fertilizer can effectively improve the fertility of the soil, improve original barren engineering waste residues and natural soil, provide nitrogen, phosphorus, potassium, organic matter and other nutrients needed by growth and development of plants, play a role in passivating heavy metal contained in municipal sludge and reduce harm possibly brought by the heavy metal in the soil. Main materials are wide in source and low in cost.

Owner:BEIJING JIAOTONG UNIV +1

Nano-nickel powder of core-shell structure

PendingCN112872349AImprove the immunityProtective natureMaterial nanotechnologyTransportation and packagingNickel sulfideCarbon dioxide content

The invention discloses a nano-nickel powder of a core-shell structure. The nano-nickel powder comprises a spherical nickel bead and a protecting layer, wherein the outer surface of the spherical nickel bead is coated with the protecting layer, and the protecting layer has the passivation function and the agglomeration-preventing function. The spherical nickel bead is of a crystal structure; the diameter of the spherical nickel bead is 10-600 nanometers; and the thickness of the protecting layer which is a nickel-sulphur-oxygen protecting layer is 0.5-6 nanometers. The nickel-sulphur-oxygen protecting layer comprises 10-25% of nickel sulfide, 50-75% of nickel oxide, 3-10% of nickel hydroxide, basic nickel carbonate, 1-3% of carbon dioxide and 0.1-0.5% of water. The degree of sphericity of the nickel powder is high; the crystal structure is complete; the dispersibility is high; the sintering temperature is high; and the shrinkage rate is low.

Owner:杭州新川新材料有限公司

Heat-insulating and anticorrosive real-stone coating

InactiveCN109704639AEnhanced interactionImprove thermal stabilityCeramicwareSludgeFunctional modification

The invention discloses heat-insulating and anticorrosive real-stone coating and belongs to the field of building materials. In the invention, phenolic resin is modified by boric acid, nano TiO2 and the like, so that internal stability is improved; by combination of inorganic stone material, anti-external erosion effect is greatly enhanced, and the heat resistance of the macromolecular paint basematerial is improved; raw materials, such as talc, mullite and mica, are subjected to high-pressure and high-temperature treatment to obtain a high-stability cordierite structure; functional modification is combined and a similar passivating treatment is supplied so as to improve the anticorrosive effect; the stone material is subjected to fermenting modification by watermelon juice and active sludge in order to generate free polar groups, aromatic rings and the like, so that internal stability is enhanced; groups are introduced through microbial crosslinking so as to improve the compatibilitywith the organic paint material, thereby improving the anticorrosive and heat-insulating effect in the tissue for a long lasting time. The invention solves the problems of poor heat-insulating and anticorrosive performance of common real-stone coatings in the prior art.

Owner:雷国平

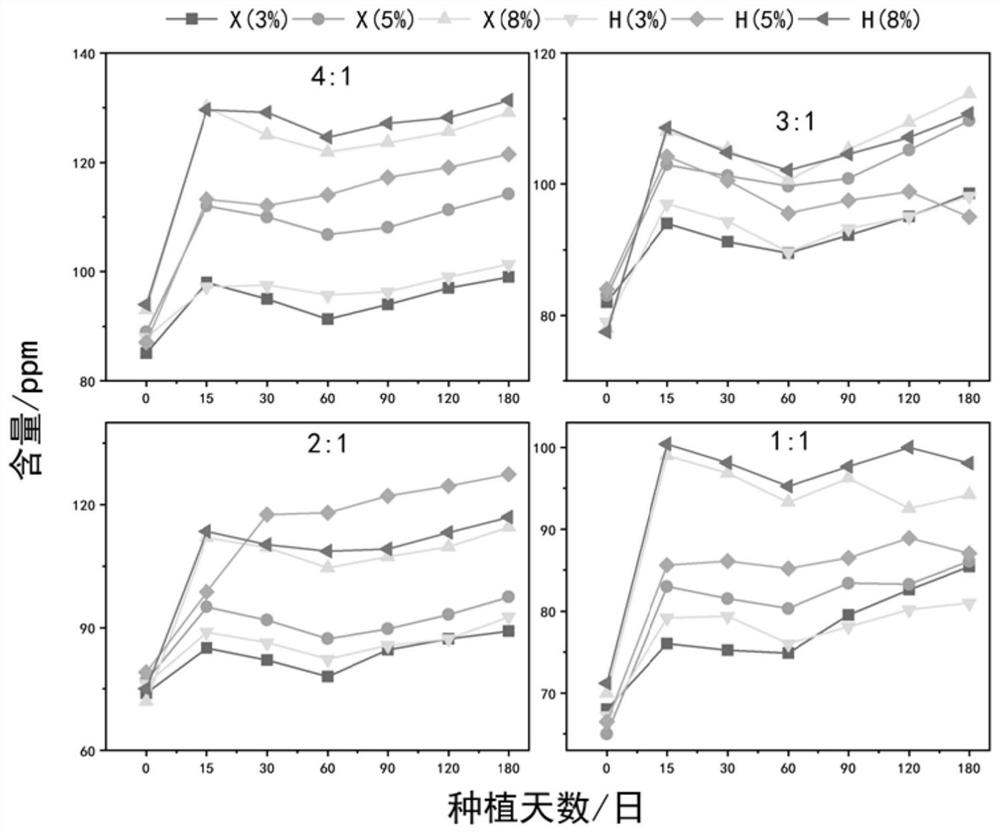

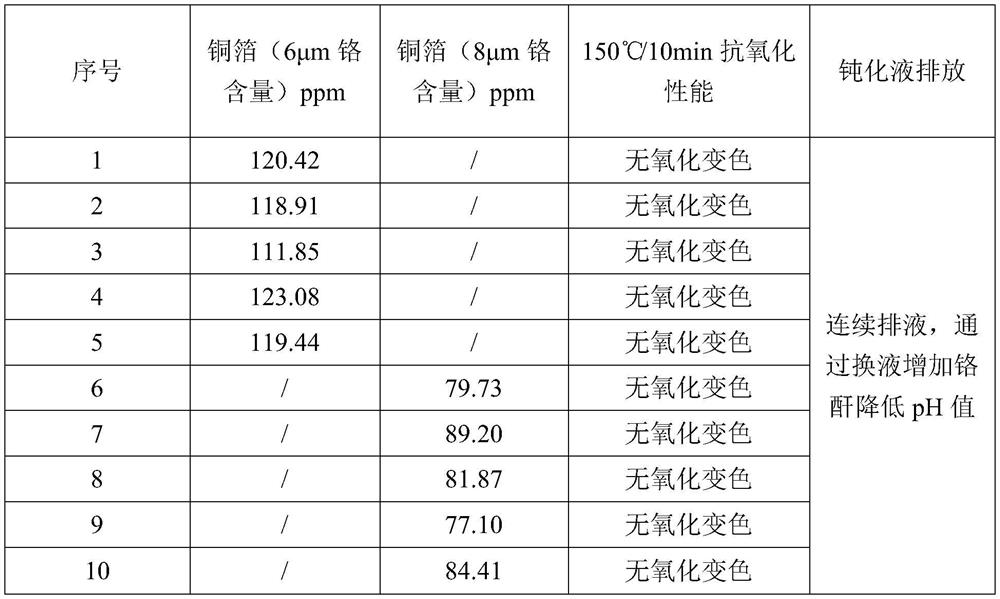

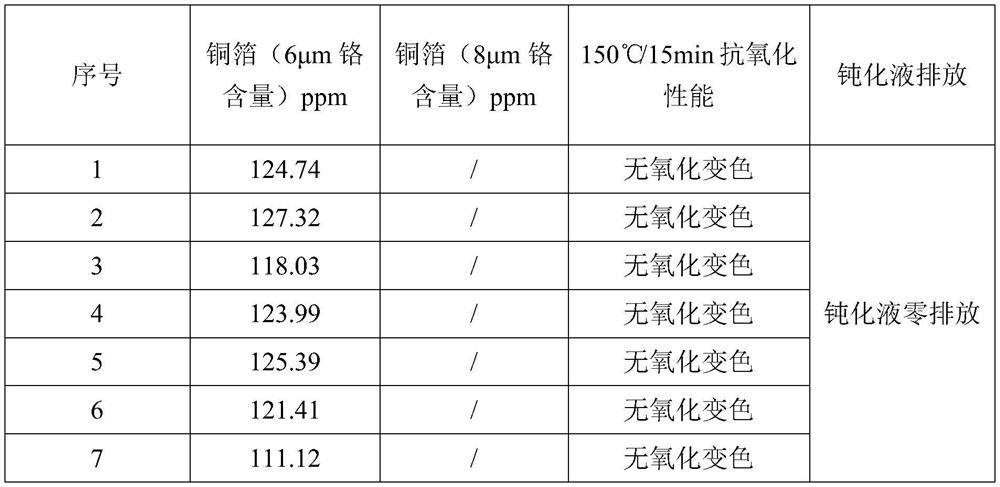

Passivation process of ultrathin double-sided light lithium battery copper foil

ActiveCN114214704AAct as passivationGood alkali resistanceChromatisationPhosphatisationCopper foilOxidation resistant

The invention relates to a passivation process of an ultrathin double-sided light lithium battery copper foil. The passivation process comprises the following steps: step S1, surface treatment; step S2, degreasing; s3, coarsening for the first time; step S4, carrying out secondary coarsening; step S5, curing; s6, passivating treatment is conducted through a passivating solution; step S7, carrying out post-treatment; the chromium content of the copper foil can be controlled by adjusting technological parameters of the anti-oxidation liquid, the chromium content of the copper foil is adjusted according to different production specifications, the chromium content of the copper foil (6 microns) is smaller than or equal to 150 ppm, and the chromium content of the copper foil (8 microns) is smaller than or equal to 100 ppm; (2) zero discharge of the anti-oxidation liquid is realized, and the anti-oxidation liquid can be recycled and continuously used; and (3) the oxidation resistance of the copper foil is improved, and the copper foil can be baked at 150 DEG C for 15 minutes without oxidation discoloration.

Owner:江西华创新材有限公司

Wear-resisting alloy steel for door handle and preparation method thereof

The invention discloses wear-resisting alloy steel for a door handle and a preparation method thereof. The method comprises the steps that (1) alloy steel is subjected to water washing and alcohol washing and then subjected to oxygen-free calcination and then is put into an activating agent to be subjected to activating treatment; (2) the alloy steel subjected to activating treatment is subjected to primary heating heat treatment and secondary heating heat treatment in sequence; and (3) the alloy steel subjected to heat treatment is subjected to quenching and heating and then is put into a sodium chloride solution to obtain the wear-resisting alloy steel for the door handle, wherein elements in the alloy steel include, by weight, 0.25-0.55% of C, 0.15-0.35% of Si, 0.20-0.30% Mn, 0.3-0.55% of Mo, 0.15-0.4% of Mg, 0.05-0.15% of Ge, and the balance Fe; and the oxygen-free calcination temperature is 230-250 DEG C, and the oxygen-free calcination time is 3-4 h. The door handle wear-resisting alloy steel manufactured through the method has excellent mechanical properties and wear-resisting property.

Owner:ANHUI KATA DOOR & WINDOW

Method for preparing algae essence by using enzymatic hydrolysis method

ActiveCN101580852BPlay a regulating roleAct as passivationBiocidePlant growth regulatorsEnzymatic hydrolysisColloid

Owner:BEIJING LEILI MARINE BIOINDUSTRY INC

High-hardness alloy steel for door frame and preparation method thereof

The invention discloses high-hardness alloy steel for a door frame and a preparation method thereof. The method comprises the steps of (1) carrying out water washing and oxygen-free calcination on the alloy steel, and then putting the alloy steel in sldium lauryl sulfate to be subjected to activating treatment; (2) carrying out thermal treatment of primary heating and secondary heating on the alloy steel; and (3) carrying out quenching, heating and cooling on the alloy steel subjected to thermal treatment, and then, putting the alloy steel into a magnesium chloride solution, so as to prepare the high-hardness alloy steel for the door frame, wherein the alloy steel comprises the following elements by weight percent: 0.65 to 0.85% of C, 0.15 to 0.35% of Si, 0.20 to 0.30% of Mn, 0.3 to 0.55% of Mo, 0.15 to 0.4% of Mg and 0.05 to 0.15% of Ge, and the balance being Fe; the primary heating comprises the steps of increasing the temperature from 20 to 25 DEG C to 520 to 540 DEG C at the temperature increase speed of 10 to 15 DEG C / min, and keeping the temperature at 520 to 540 DEG C for 110 to 130 min; and the secondary heating comprises the steps of increasing the temperature from 520 to 540 DEG C to 700 to 720 DEG C at the temperature increase speed of 20 to 25 DEG C / min, and keeping the temperature at 700 to 720 DEG C for 60 to 80 min. According to the invention, the door frame manufactured through the method has excellent mechanical properties like high strength and high hardness.

Owner:ANHUI KATA DOOR & WINDOW

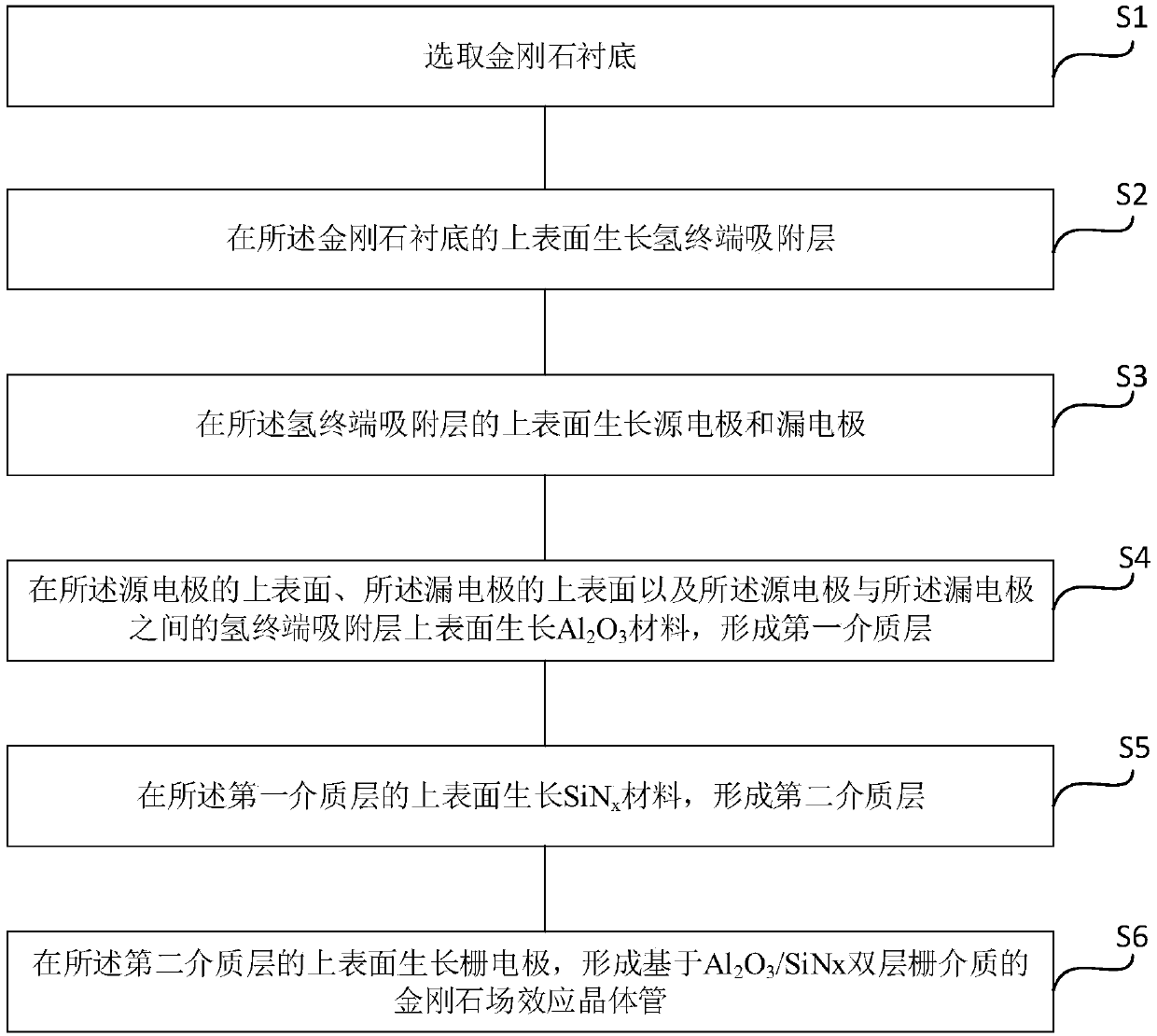

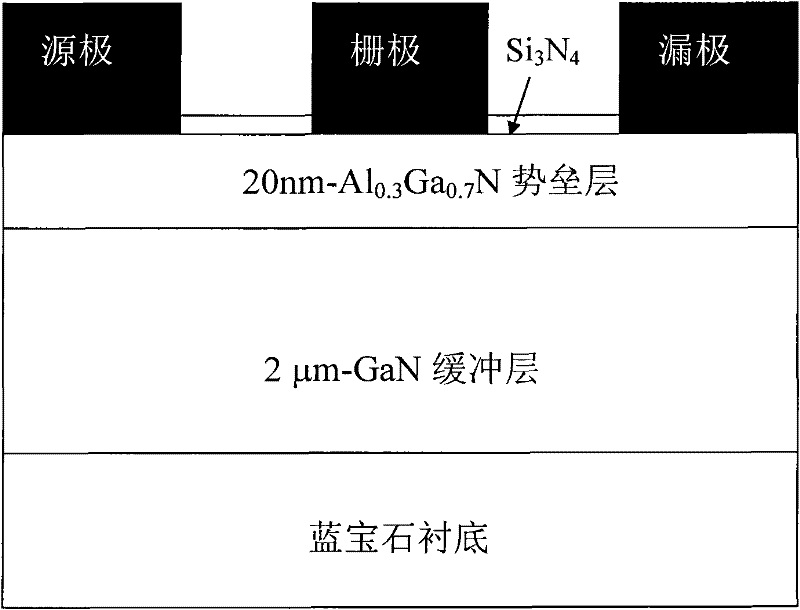

Diamond field effect transistor based on Al2O3/SiNx double-layer gate medium and preparation method of diamond field effect transistor

InactiveCN110828314AAct as passivationReduce thicknessTransistorSemiconductor/solid-state device manufacturingCapacitanceField effect

The invention relates to a diamond field effect transistor based on an Al2O3 / SiNx double-layer gate medium and a preparation method of the diamond field effect transistor. The method comprises steps of selecting a diamond substrate; growing a hydrogen terminal adsorption layer on an upper surface of the diamond substrate; growing a source electrode and a drain electrode on an upper surface of thehydrogen terminal adsorption layer; growing an Al2O3 material on an upper surface of the source electrode, an upper surface of the drain electrode and the upper surface of the hydrogen terminal adsorption layer between the source electrode and the drain electrode to form a first dielectric layer; growing a SiNx material on an upper surface of the first dielectric layer to form a second dielectriclayer; and growing a gate electrode on an upper surface of the second dielectric layer. The method is advantaged in that an Al2O3 / SiNx double-layer structure is adopted as a gate medium, a layer of SiNx medium is deposited above a thin layer of Al2O3 medium, so gate capacitance can be reduced, the frequency characteristic of the device can be improved, the passivation effect can be achieved, and stability of the device can be remarkably enhanced.

Owner:XIDIAN UNIV

Reclamation soil matrix in waste slag field and preparation method and application

ActiveCN112075318BImprove breathabilityImprove fertilityBio-organic fraction processingExcrement fertilisersSludgeEdaphic

The invention provides a soil matrix for reclamation of a waste slag field, which comprises, by mass percentage, 40-75% of original soil, 10-50% of engineering waste, 3-8% of organic fertilizer, and 3-7% of pine needles, wherein Original soil: engineering waste = 1:1‑4:1. At the same time, the preparation method and application thereof are provided. The soil matrix for reclamation of the invention can effectively dispose of a large amount of waste residue in the waste residue field, promote the growth of plants, and improve the survival rate. The natural soil, engineering waste residue and pine needles in the matrix form a loose and porous soil structure, which is conducive to soil ventilation and water transmission, the formation of aggregates in the soil, and the survival and reproduction of microorganisms. Organic fertilizer can effectively improve soil fertility, improve the originally barren engineering waste and natural soil, provide nitrogen, phosphorus, potassium, organic matter and other nutrients required for plant growth and development, and can passivate heavy metals contained in urban sludge. , reduce the possible harm caused by heavy metals in soil. The main materials are widely available and inexpensive.

Owner:BEIJING JIAOTONG UNIV +1

CMOS-TDI image sensor and forming method thereof

InactiveCN110729319AReduce generationImprove image qualitySolid-state devicesDiodeCMOSGate dielectric

The invention provides a CMOS-TDI image sensor and a forming method thereof. The forming method comprises the steps: providing a substrate; forming a photoelectric doped region in the substrate; forming a plurality of gate structures on the surface of the photoelectric doped region, wherein each gate structure includes a gate dielectric layer and a gate layer located on the gate dielectric layer;and performing the doping process at the interface between the gate dielectric layer and the substrate, wherein the doping process is used for reducing the defects between the gate dielectric layer and the substrate. According to the technical scheme, the doping process is performed at the interface between the gate dielectric layer and the substrate so that the defects formed by the substrate andthe gate dielectric layer are combined with the second ions in the doping process to realize play the passivation effect and thus the generation of dark current can be reduced and the image quality of the CMOS-TDI image sensor can be improved.

Owner:BRIGATES MICROELECTRONICS KUNSHAN

Manufacturing method of double-junction thin film solar cell module and cell module thereof

InactiveCN108666391AImprove efficiencyEasy to divideFinal product manufacturePhotovoltaic energy generationPower flowMetal electrodes

The invention discloses a method of double-junction thin film solar cell module and cell module thereof. The cell module is formed by connecting a plurality of battery units, each battery unit comprises a bottom battery and a top battery, wherein a patterned insulating layer and a back metal electrode layer electrically connected with the bottom battery are arranged on the bottom battery, and a patterned front metal electrode layer is arranged on the top battery, the bottom battery is a polycrystalline Ge bottom battery, and the top battery is a GaAs top cell, the layers of the bottom cells and the layers of the top cells are inverted and grown in an epitaxial manner, a tunnel junction N-type region and a tunnel junction P-type region are sequentially grown between the GaAs top battery andthe polycrystalline Ge bottom battery; an antireflection layer is formed on the front metal electrode layer and the top battery which is not covered by the front metal electrode layer. According to the manufacturing method of double-junction thin film solar cell module and cell module thereof, by adopting the inverted growth mode, the crystal quality is improved, and by adopting the method of one-time growth to complete the battery structure, the process can be simplified, and the yield of the product can be improved, in addition, by using Ge as the bottom battery, there is no need for a complicated battery structure and current transmission is improved.

Owner:DONGTAI HI TECH EQUIP TECH (BEIJING) CO LTD

Methods of Improving the Operational Safety of Hydrocracking Units

ActiveCN111100687BHigh activityAchieve reasonable utilizationMolecular sieve catalystsTreatment with hydrotreatment processesPtru catalystReaction temperature

The invention discloses a method for improving the operation safety of a hydrocracking unit. The hydrocracking unit contains at least two hydrocracking catalyst beds. When the nitrogen weight in the hydrocracking catalyst in the first hydrocracking catalyst bed is When the percentage content is 0.15~0.35%, cool down to 200~340°C to switch the hydrocracking feed oil with a nitrogen content of 300~500ppm, and switch the nitrogen content when the nitrogen content in the hydrocracking effluent is constant at 50~80ppm For hydrorefined oil less than 40ppm, adjust the reaction temperature of the hydrocracking section so that the mass yield of light oil <360°C is finally constant at 35~40%, and the total constant time is 48~96 hours, and then adjust to hydrocracking Reaction conditions The hydrocracking reaction is carried out. The method solves the problem that the activity of some hydrocracking catalysts is damaged due to frequent start-up and shutdown, thereby affecting the mismatch of reaction temperatures between different catalyst beds in the reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

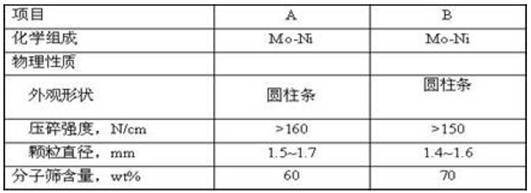

A kind of stable start-up method of hydrocracking catalyst

ActiveCN109777477BAvoid investmentHigh activityHydrotreatment operations starting-upHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a stable start-up method for a hydrocracking catalyst. In the start-up method, raw material oil is introduced during the vulcanization process, and the reaction temperature is adjusted after the vulcanization is completed so that the mass yield of light oil at <360°C is constant at 65-70%. Adjust to the hydrocracking reaction conditions to carry out the hydrocracking reaction, the hydrocracking catalyst contains 50%-70% molecular sieve by weight, and the molecular sieve includes but not limited to Y-type or USY molecular sieve. The method has the advantages of simple start-up and raw material switching process, stable operation, and avoids the consumption of passivating agent and the potential danger in the ammonia injection process during start-up.

Owner:CHINA PETROLEUM & CHEM CORP +1

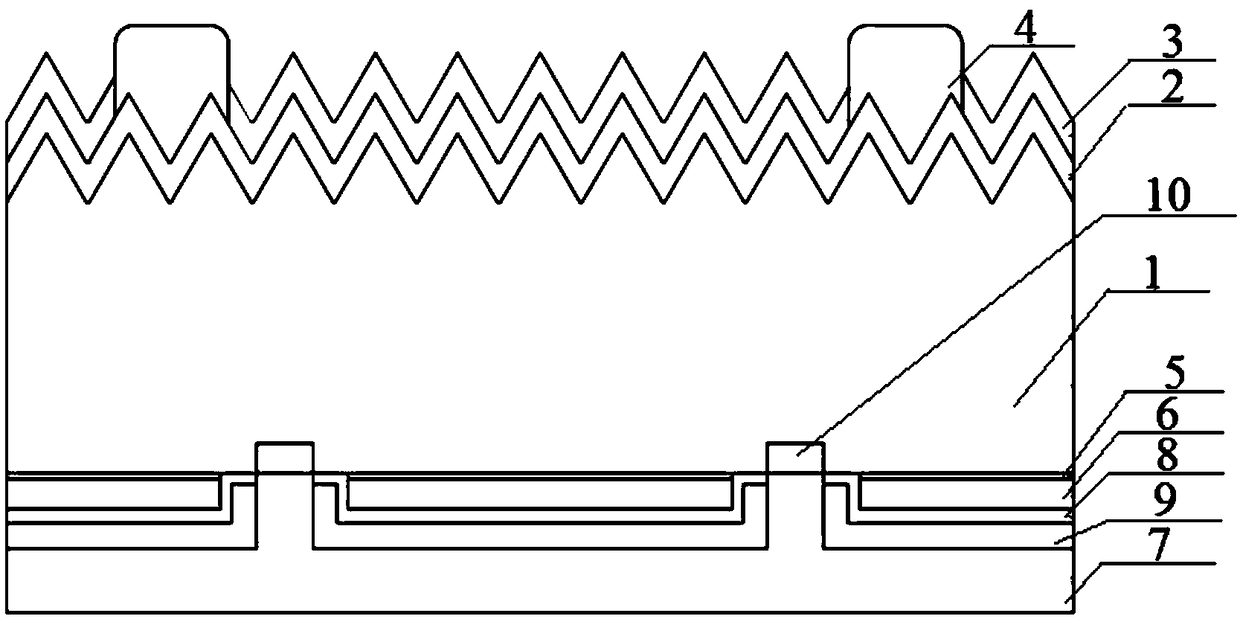

Double-heterojunction MOS-HEMT component

InactiveCN101789446BHigh resistance characteristicIncrease the bandgap widthSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionGate dielectric

The invention discloses a double-heterojunction MOS-HEMT (metal oxide semiconductor-high electron mobility transistor) component comprising a GaN nucleating layer 9, a GaN buffer layer 8, an InGaN embedding layer 7 and a GaN channel layer 6 which are sequentially formed on a sapphire substrate 10, an AlN barrier layer 5 and an Al2O3 gate dielectric layer 4, a source electrode 1 and a drain 3 formed on the AlN barrier layer 5, and a gate electrode 2 formed on the Al2O3 gate dielectric layer 4, wherein the double-heterojunction MOS-HEMT component is characterized in that an AlN material having good heat conductivity and larger band gap is used as the barrier layer, thus reducing the self-heating effect and gate leakage current of the component and reducing the threshold voltage of the component working in a depletion mode; by using the AlN material having strong polarizability, the invention can increase the electron concentration in the channel and increase the output power of the saturation current and the component; by using the Al2O3 material deposited on the basis of the atomic layer deposition process as the gate dielectric layer, the invention can greatly reduce the gate leakage current and increase the breakdown voltage of the component; and by using the reverse polarization of the InGaN material, the invention can increase the conduction band energy of the buffer layer and reduce the current collapse effect of the component.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

A Method of Improving the Operation Safety of Hydrocracking Unit

ActiveCN111100689BHigh activityAchieve reasonable utilizationMolecular sieve catalystsTreatment with hydrotreatment processesPtru catalystReaction temperature

The invention discloses a method for improving the operation safety of a hydrocracking unit. The hydrocracking unit contains at least two hydrocracking catalyst beds. When the nitrogen weight in the hydrocracking catalyst in the first hydrocracking catalyst bed is When the percentage content is 0.15~0.4%, lower the temperature to 200~340℃ and switch the hydrocracking feed oil with nitrogen content of 300~500ppm, and switch the nitrogen content when the nitrogen content in the hydrocracking effluent is constant at 50~80ppm For hydrorefined oil less than 30ppm, adjust the reaction temperature of the hydrocracking section so that the mass yield of light oil <360°C is finally constant at 45~50%, and the total constant time is 24~48 hours, and then adjust to hydrocracking Reaction conditions The hydrocracking reaction is carried out. The method solves the problem that the activity of some hydrocracking catalysts is damaged due to frequent start-up and shutdown, thereby affecting the mismatch of reaction temperatures between different catalyst beds in the reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

A safe start-up method for hydrocracking catalyst

The invention discloses a safe start-up method for a hydrocracking catalyst. In the start-up method, raw material oil is introduced during the vulcanization process, and the reaction temperature is adjusted after the vulcanization is completed, so that the mass yield of light oil at <360°C is constant at 55-60%. Adjust to the hydrocracking reaction conditions to carry out the hydrocracking reaction, the hydrocracking catalyst contains 30% to 50% molecular sieve by weight, and the molecular sieve includes but not limited to Y type or USY type. The method has the advantages of simple start-up and raw material switching process, stable operation, and avoids the consumption of passivating agent and the potential danger in the ammonia injection process during start-up.

Owner:CHINA PETROLEUM & CHEM CORP +1

Terahertz modulator, system and method based on silicon-based microstructure on soi

The present invention provides a terahertz modulator based on a silicon-based microstructure on SOI and its preparation method and modulation system. The terahertz modulator includes from bottom to top: the underlying Al 2 o 3 Substrate, SiO 2 Isolation layer, silicon-based microstructure, Al 2 o 3 passivation layer, silicon-based microstructure in SiO 2 Periodically arranged on the isolation layer, each silicon-based microstructure includes two layers of square Si-based step structures, and the modulation system includes: a semiconductor laser, a laser modulator, a terahertz modulator, a terahertz radiation source, and a terahertz detector. The present invention For terahertz waves from 0.4THz to 0.85THz, the reflectivity is below 22%, reaching the lowest 18% at 0.82THz, which can significantly reduce the reflectivity of modulation devices to terahertz waves and improve the utilization of terahertz waves; in power Under the irradiation of 1200mw 808nm laser, the modulation depth reaches 64.5%. Compared with the traditional silicon-based terahertz modulator, the terahertz imaging diffusion area effectively improves the resolution in the imaging system to more than 21.9%.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for improving stable operation of hydrocracking unit

ActiveCN111100688AHigh activityAchieve reasonable utilizationTreatment with hydrotreatment processesThermodynamicsPtru catalyst

The invention discloses a method for improving stable operation of a hydrocracking unit. The hydrocracking unit at least comprises two hydrocracking catalyst beds. The method comprises the following steps: cooling to 200-340 DEG C and switching the hydrocracking feed oil with the nitrogen content of 300 to 500 ppm when the weight percentage content of nitrogen in the hydrocracking catalyst in thefirst hydrocracking catalyst bed is 0.25-0.5%; switching the hydrofined oil with the nitrogen content of less than 10ppm when the nitrogen content in the hydrocracking effluent is constant at 50-80ppm; simultaneously adjusting the reaction temperature of the hydrocracking section until the mass yield of the light oil of less than 360 DEG C is finally kept constant at 65-70% and the total constanttime is 24-48 hours; and then adjusting to the hydrocracking reaction conditions to carry out a hydrocracking reaction. By the method, the problem that the activity of part of the hydrocracking catalyst is damaged due to frequent startup and shutdown and the mismatching of reaction temperatures among different catalyst beds in the reactor is influenced is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving stable operation of hydrocracking unit

ActiveCN111100686AHigh activityAchieve reasonable utilizationTreatment with hydrotreatment processesThermodynamicsPtru catalyst

The invention discloses a method for improving stable operation of a hydrocracking unit. The hydrocracking unit at least involves two hydrocracking catalyst beds. The method comprises the following steps: cooling to 200-340 DEG C and switching the hydrocracking feed oil with the nitrogen content of 300 to 500 ppm when the weight percentage content of nitrogen in a hydrocracking catalyst in the first hydrocracking catalyst bed is 0.2-0.45%; switching the hydrofined oil with the nitrogen content of less than 20ppm when the nitrogen content in the hydrocracking effluent is constant at 50-80ppm; simultaneously adjusting the reaction temperature of the hydrocracking section until the mass yield of the light oil of less than 360 DEG C is finally kept constant at 55-60% and the constant time is 24-48 hours; and then adjusting to the hydrocracking reaction condition for hydrocracking reaction. By the method, the problem that the activity of part of the hydrocracking catalyst is damaged due tofrequent startup and shutdown and then the mismatching of reaction temperatures among different catalyst beds in the reactor is influenced is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of rapid start-up method of hydrocracking catalyst

The invention relates to a rapid start-up method for a hydrocracking catalyst. In the start-up method, raw material oil is introduced during the vulcanization process, and the reaction temperature is adjusted after the vulcanization is completed so that the mass yield of light oil at <360°C is constant at 35-40%. The hydrocracking reaction is carried out under the conditions of the hydrocracking reaction, and the hydrocracking catalyst contains 0% to 10% molecular sieve by weight, and the molecular sieve includes but not limited to Y type or USY type. The method has the advantages of simple start-up and raw material switching process, stable operation, and avoids the consumption of passivating agent and the potential danger in the ammonia injection process during start-up.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-strength alloy steel for door frame and preparing method thereof

InactiveCN106399828AHigh strengthImprove qualityQuenching agentsActive agentFatty acid glycerol esters

The invention discloses high-strength alloy steel for a door frame and a preparing method thereof. The method comprises: (1) performing water washing on alloy steel, then performing anaerobic calcinating, and then placing in an active agent for activation processing; (2) performing thermal processing for the first time and thermal processing for the second time on the activated alloy steel in sequence; (3) quenching, heating and cooling the thermally processed alloy steel, and then placing in a magnesium chloride solution to prepare the high-strength steel for a door frame, wherein the alloy steel contains respective elements in parts by weight: 0.65-0.85% of C, 0.15-0.35% of Si, 0.20-0.30% of Mn, 0.3-0.55% of Mo, 0.15-0.4% of Mg, 0.05-0.15% of Ge and the balance of Fe, the active agent is one of sodium dodecyl benzene sulfonate, fatty glyceride and sodium glycocholate, a quenching agent used in step (3) is PAG quenching agent, and in step (3), a heating temperature is 500-520 DEG C, and time is 100-120min. The high-strength alloy steel for a door frame prepared by the method has excellent mechanical properties such as large strength and large hardness.

Owner:ANHUI KATA DOOR & WINDOW

Passivation-contact-based floating-junction back-passivation crystalline silicon battery and preparation method thereof

PendingCN109494274APrevent leakageReduce the impactFinal product manufacturePhotovoltaic energy generationOptoelectronicsP type silicon

The invention discloses a passivation-contact-based floating-junction back-passivation crystalline silicon battery and a preparation method thereof. The crystalline silicon battery comprises a p typesilicon substrate, a tunneling oxide layer form on the back surface of the p type silicon substrate, and an n type polysilicon layer formed on the back surface of the tunneling oxide layer. The tunneling oxide layer and the n type polysilicon layer form a floating junction; and an open hole is formed in a preset position of the floating junction. In addition, the crystalline silicon battery also includes a metal electrode that is formed on the back surface of the n type polysilicon layer and is in contact with the exposed p type silicon substrate through the open hole and a first dielectric layer that is arranged between the n type polysilicon layer and the metal electrode in the open hole. According to the invention, since the tunneling oxide layer and the n type polysilicon layer can beresistant to the high temperature in metal electrode preparation without any change and can be protected from being damaged by the high temperature, the influence on the floating junction by the high-temperature sintering process is eliminated, so that the passivation effect on the crystalline silicon battery by the floating junction is improved.

Owner:SUZHOU TALESUN SOLAR TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com