Anticorrosive aluminum product and preparation method thereof

An aluminum product and durable technology, applied in the field of anti-corrosion and durable aluminum products and its preparation, can solve the problems of unsatisfactory durability, gloss, hardness and anti-corrosion performance, consumption of precious metal resources, poor anti-corrosion performance, etc. Mold, promote effective bonding, delay corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

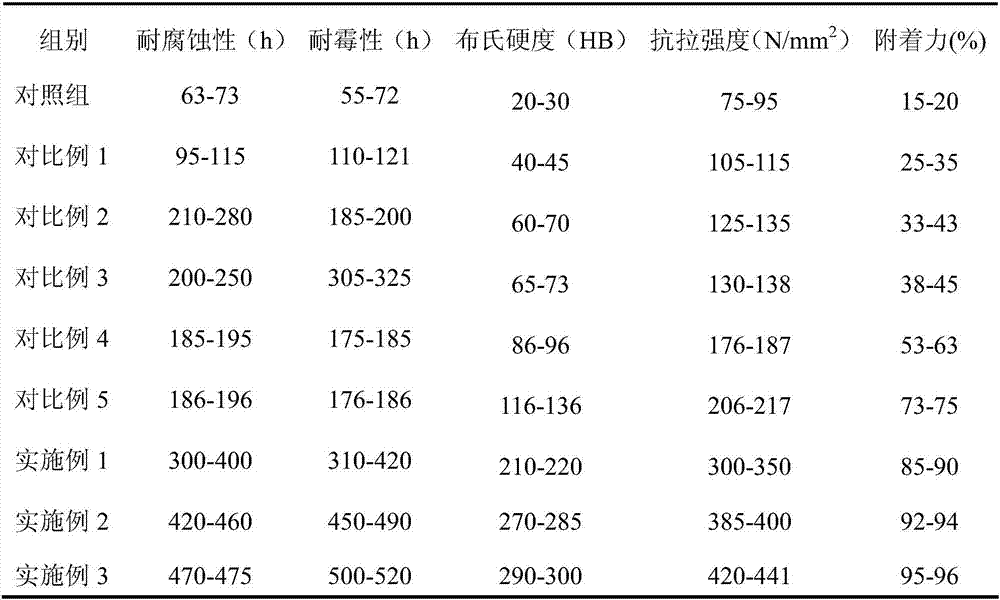

Examples

Embodiment 1

[0032] An anti-corrosion and durable aluminum product, including a substrate layer and a coating, wherein the substrate layer is mainly made of the following parts by weight: 50 parts of aluminum powder, 20 parts of copper powder, 5 parts of nano-zirconia, 3 parts of samarium element 3 parts of ytterbium element and 1 part of corrosion inhibitor mixed with equal mass of potassium dichromate and copper silicate; the coating is mainly made of the following parts by weight: 30 parts of epoxy resin, 30 parts of mesoporous SBA-15 (Particle size 7nm) 5 parts, β-(2,6-di-tert-butyl-3-hydroxyphenyl) octadecyl propionate 0.5 parts, 2,5-di-tert-butyl-3-methylphenol 0.5 parts, 0.2 parts of N-(fluorodichloromethylthio)phthalimide, 0.2 parts of methyl benzimidazole carbamate, 10 parts of nitrocellulose, 10 parts of stainless steel powder, 10 parts of kaolin, silicon 10 parts of limestone, 10 parts of n-butanol, 10 parts of styrene, 5 parts of defoamer, 10 parts of T31 curing agent and 10 pa...

Embodiment 2

[0047] An anti-corrosion and durable aluminum product, including a substrate layer and a coating, wherein the substrate layer is mainly made of the following parts by weight: 55 parts of aluminum powder, 25 parts of copper powder, 5.5 parts of nano-zirconia, 3.5 parts of samarium element 3.5 parts of ytterbium element and 1.5 parts of corrosion inhibitor mixed with potassium dichromate and copper silicate of equal mass; the coating is mainly made of the following parts by weight: 35 parts of epoxy resin, 35 parts of mesoporous SBA -15 (particle size 8.5nm) 6 parts, β-(2,6-di-tert-butyl-3-hydroxyphenyl) octadecyl propionate 0.7 parts, 2,5-di-tert-butyl-3- 0.7 parts of methylphenol, 0.3 parts of N-(fluorodichloromethylthio)phthalimide, 0.3 parts of methyl benzimidazole carbamate, 13 parts of nitrocellulose, 12 parts of stainless steel powder, 12 parts of kaolin 12 parts, 12 parts of wollastonite, 13 parts of n-butanol, 13 parts of styrene, 7 parts of defoamer, 13 parts of T31 cu...

Embodiment 3

[0062] An anti-corrosion and durable aluminum product, including a substrate layer and a coating, wherein the substrate layer is mainly made of the following parts by weight: 60 parts of aluminum powder, 30 parts of copper powder, 6 parts of nano-zirconia, 4 parts of samarium element 4 parts of ytterbium element and 2 parts of corrosion inhibitor mixed with equal mass of potassium dichromate and copper silicate; the coating is mainly made of the following parts by weight: 40 parts of epoxy resin, 40 parts of mesoporous SBA-15 (Particle size 10nm) 7 parts, β-(2,6-di-tert-butyl-3-hydroxyphenyl) octadecyl propionate 1.0 parts, 2,5-di-tert-butyl-3-methylphenol 1.0 parts, 0.5 parts of N-(fluorodichloromethylthio)phthalimide, 0.5 parts of methyl benzimidazole carbamate, 15 parts of nitrocellulose, 13 parts of stainless steel powder, 13 parts of kaolin, silicon 13 parts of limestone, 15 parts of n-butanol, 15 parts of styrene, 10 parts of defoamer, 15 parts of T31 curing agent and 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com