Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

414 results about "Zinc sulphide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc sulfide (or zinc sulphide) is an inorganic compound with the chemical formula of ZnS. This is the main form of zinc found in nature, where it mainly occurs as the mineral sphalerite. Although this mineral is usually black because of various impurities, the pure material is white, and it is widely used as a pigment.

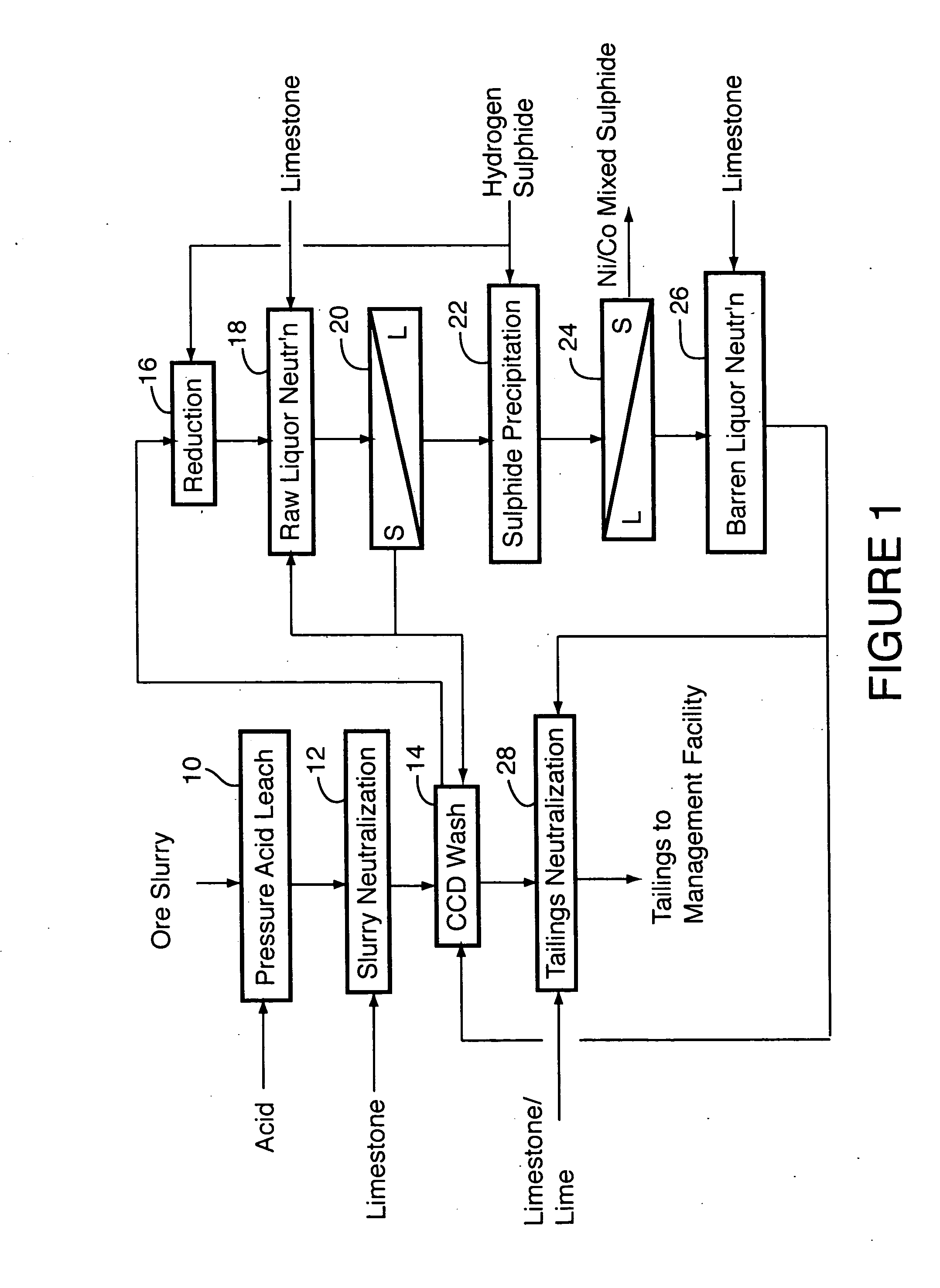

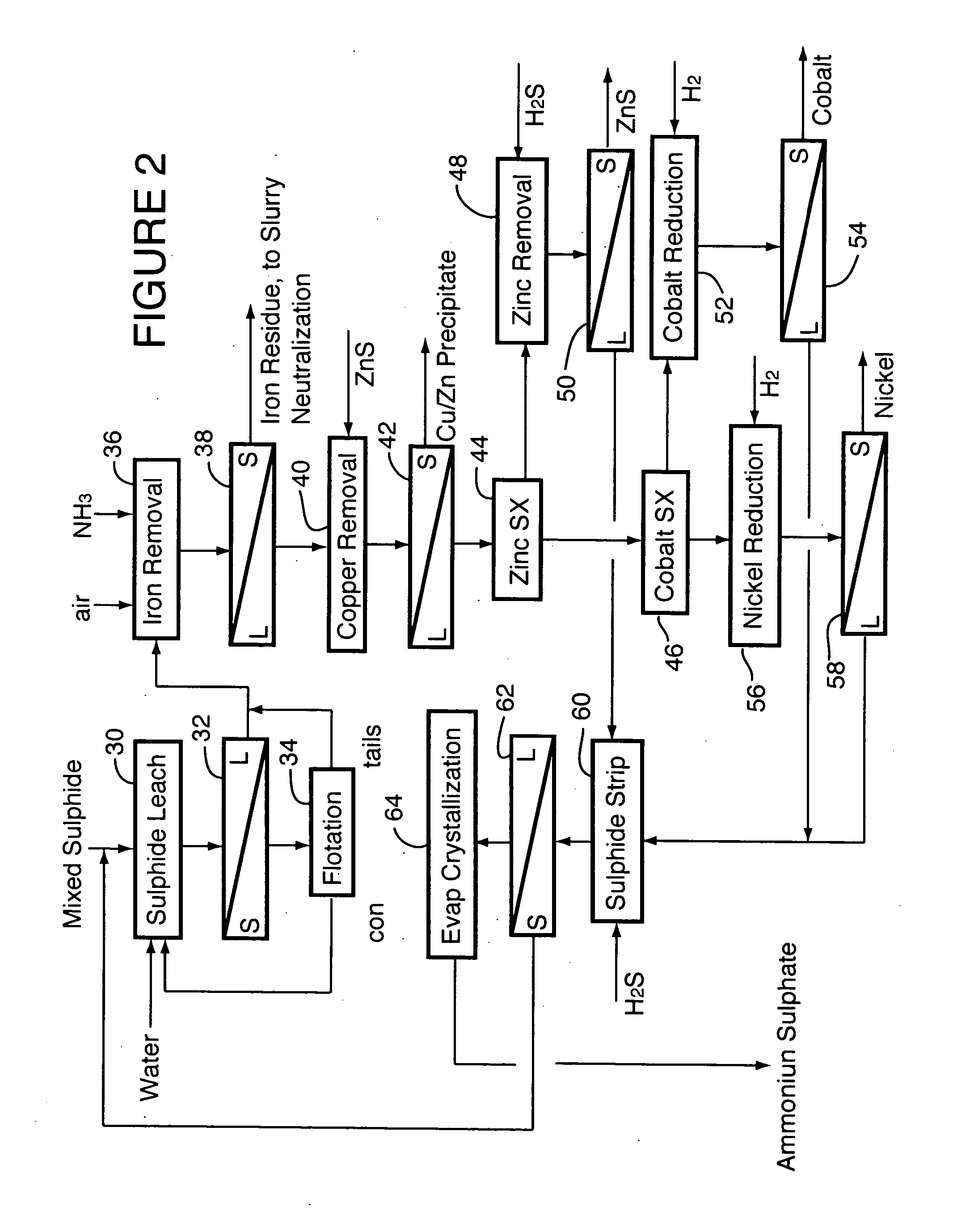

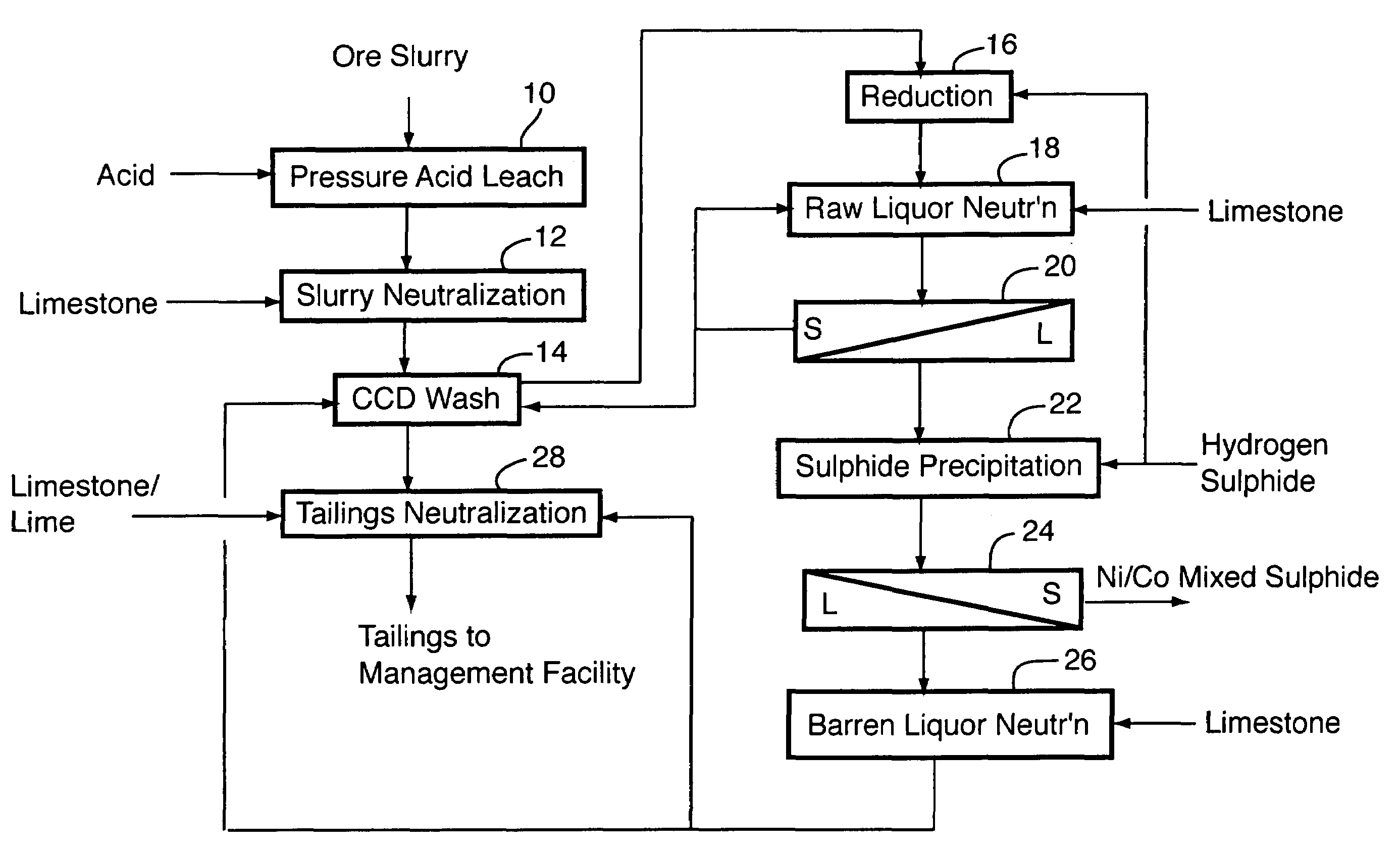

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

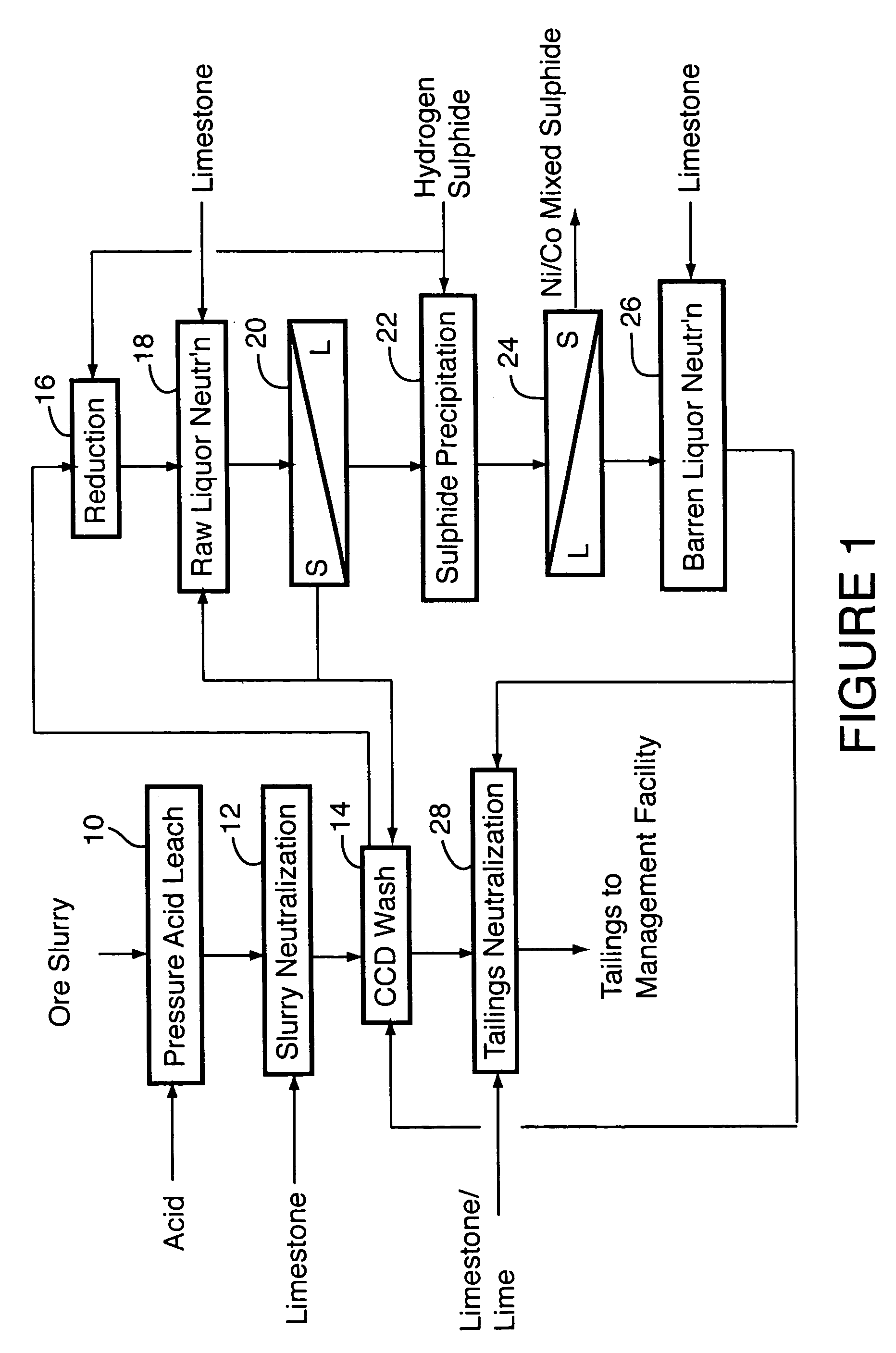

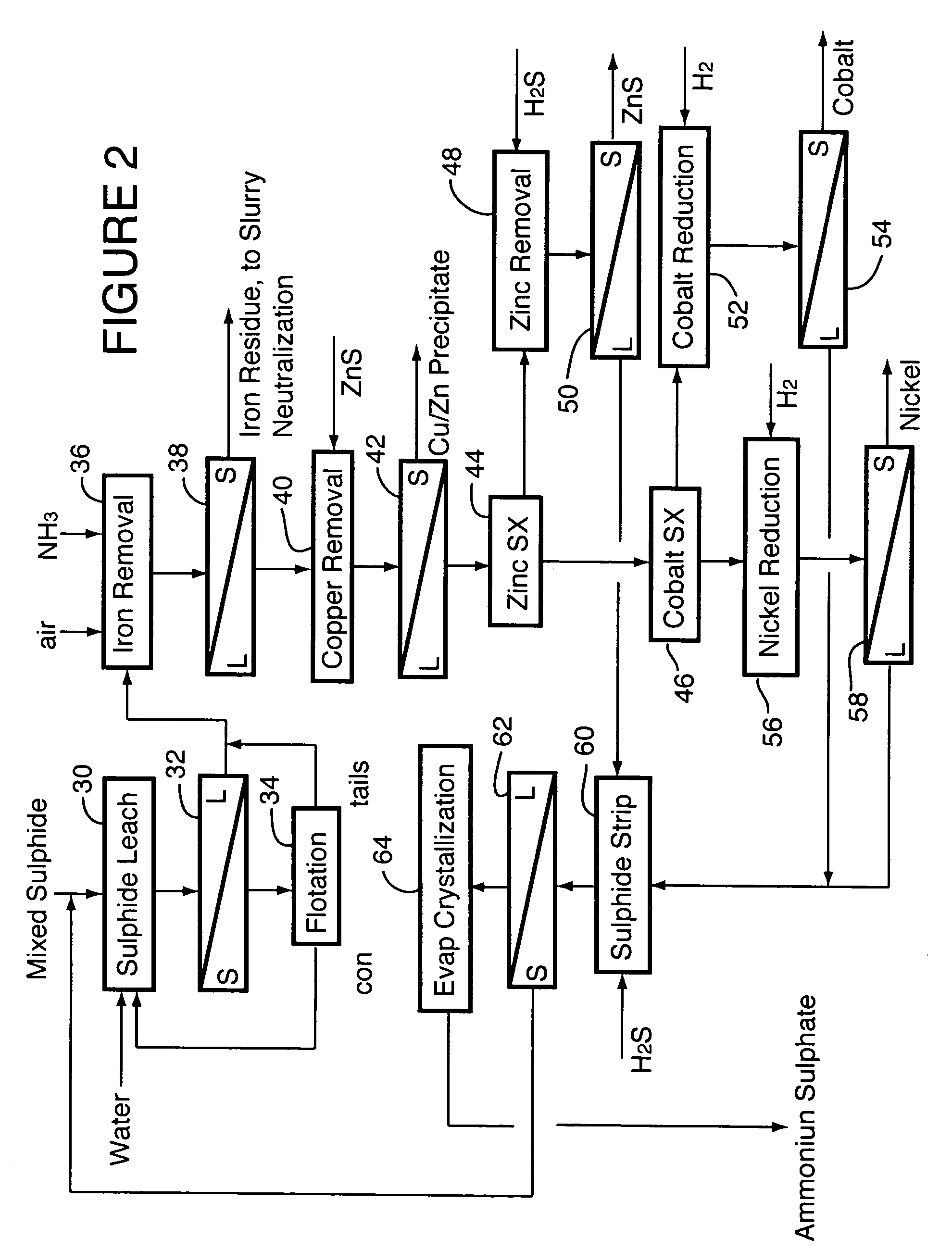

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

Heat curable thermosetting luminescent resins

InactiveUS6905634B2Improve luminous performanceImprove propertiesLuminescent paintsElectroluminescent light sourcesSodium BentoniteAlkaline earth metal

Luminescent polymers are prepared from thermosetting unsaturated polyesters, suspending fillers and phosphorescent pigments and utilized to make gel coated articles and molded, cast and fiberglass reinforced plastic (FRP) articles. The luminescent polymers show bright and long-lasting photoluminescent afterglow, strong thermostimulation of afterglow by heat and electroluminescent properties. The preferred thermosetting unsaturated polyester resins are prepared by condensing mixtures of ethylenically unsaturated and aromatic dicarboxylic acids and anhydrides with dihydric alcohols and a polymerizable vinylidene monomer. Preferred suspending fillers and thixotropic modifiers include silica, microspheres, glass fibers and other short fibers, nepheline syenite, feldspar, mica, pumice, magnesium sulfate, calcium carbonate, bentonite and the various clays and thixotropic modifiers and mixtures thereof. Preferred phosphorescent pigments include alkaline earth aluminate phosphors, zinc sulfide phosphors and mixtures of these phosphors.

Owner:BURNELL JONES PETER

Fluorescigenic pavement reflecting adhesive tape and manufacturing method thereof

ActiveCN101875823ANight driving safetyLuminescent paintsFilm/foil adhesivesRare earth ionsFluorescence

The invention relates to a fluorescigenic pavement reflecting adhesive tape and a manufacturing method thereof. The fluorescigenic pavement reflecting adhesive tape is manufactured by adding a reflecting coating or adding various flourescent materials (such as rare earth ion-activated zinc sulfide fluorescence powder) in an amount which is 0.1 to 5 weight percent based on the total amount of the reflecting coating and a substrate into the reflecting coating or the reflecting coating and substrate of any of various conventional pavement reflecting adhesive tapes. The pavement reflecting adhesive tap is comprised of the fluorescigenic reflecting coating, the substrate and a pressure sensitive adhesive, wherein the fluorescigenic reflecting coating is coated on the front side (upper side) ofthe substrate; and the pressure sensitive adhesive is applied on the back side (down side) of the substrate. The novel pavement reflecting adhesive tape retains the various kinds of performance of the conventional pavement reflecting adhesive tapes, particularly retroreflection (namely reflection) performance. The novel pavement reflecting adhesive tape can also emit fluorescence of certain intensity. When used as pavement traffic marking lines or other marks, the novel pavement reflecting adhesive tape is more striking and can be clearly seen easily by drivers, so that the drivers can drive more safely at night.

Owner:亮线上海新材料科技有限公司

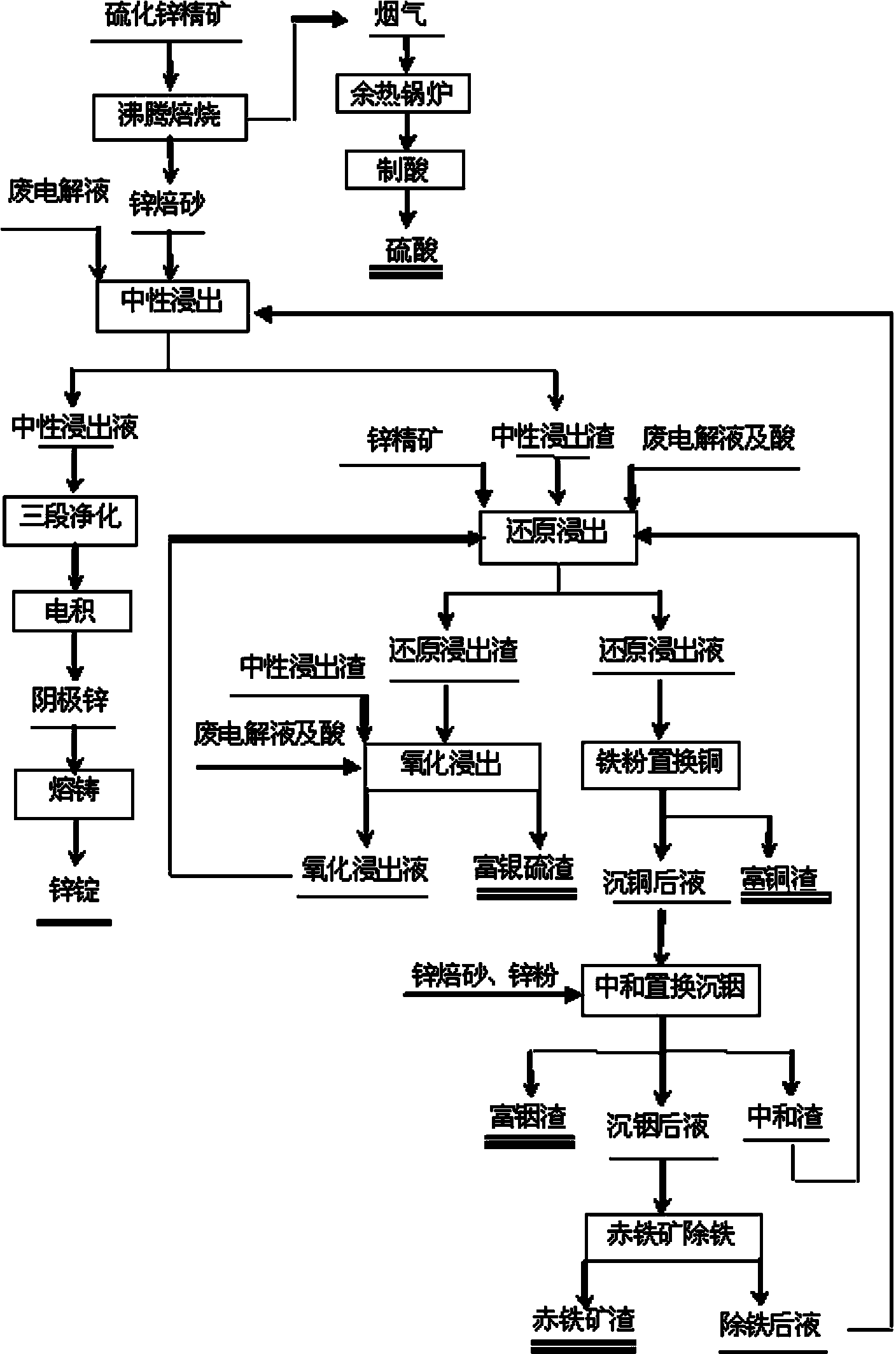

Method for individually processing high-iron zinc sulfide concentrate

ActiveCN103409622AThe process is highly targetedHigh enrichment ratioProcess efficiency improvementIndiumHydrometallurgy

The invention belongs to the technical field of hydrometallurgy, and particularly relates to a method for individually processing high-iron zinc sulfide concentrate. The method comprises a step of subjecting the high-iron zinc sulfide concentrate to calcination in a fluidized bed combustion boiler to obtain zinc calcine; a step of subjecting the zinc calcine to neutral leaching to produce neutral leaching solution and neutral leaching residue; a step of, after the neutral leaching residue and the high-iron zinc sulfide concentrate are mixed, successively performing reduction leaching and oxidation leaching, and circulating oxidation leaching solution to the reduction leaching to produce reduction leaching solution and silver-rich sulfur residue; a step of replacing the reduction leaching solution by using iron powder to precipitate copper and to produce copper-rich slag and solution after copper precipitation; a step of subjecting the solution after copper precipitation to pre-neutralization by using the zinc calcine, and then replacing by using zinc powder to precipitate indium and to produce indium-rich slag and solution after indium precipitation; and a step of bubbling oxygen into the solution after indium precipitation, heating and removing iron to obtain iron removal solution and hematite slag. The hematite slag can be utilized as a raw material for ironmaking. The method has strong pertinence, short technological process and high metal recovery yield, and the method is clean, efficient, energy-saving and environmental friendly. Separation and comprehensive utilization of zinc, indium, copper and iron are achieved.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

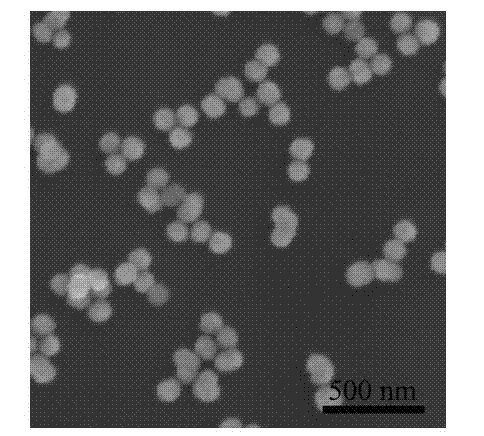

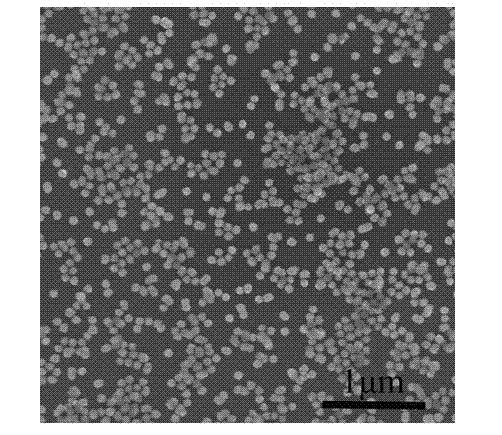

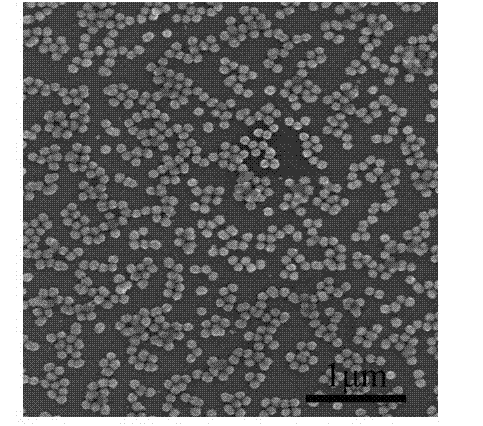

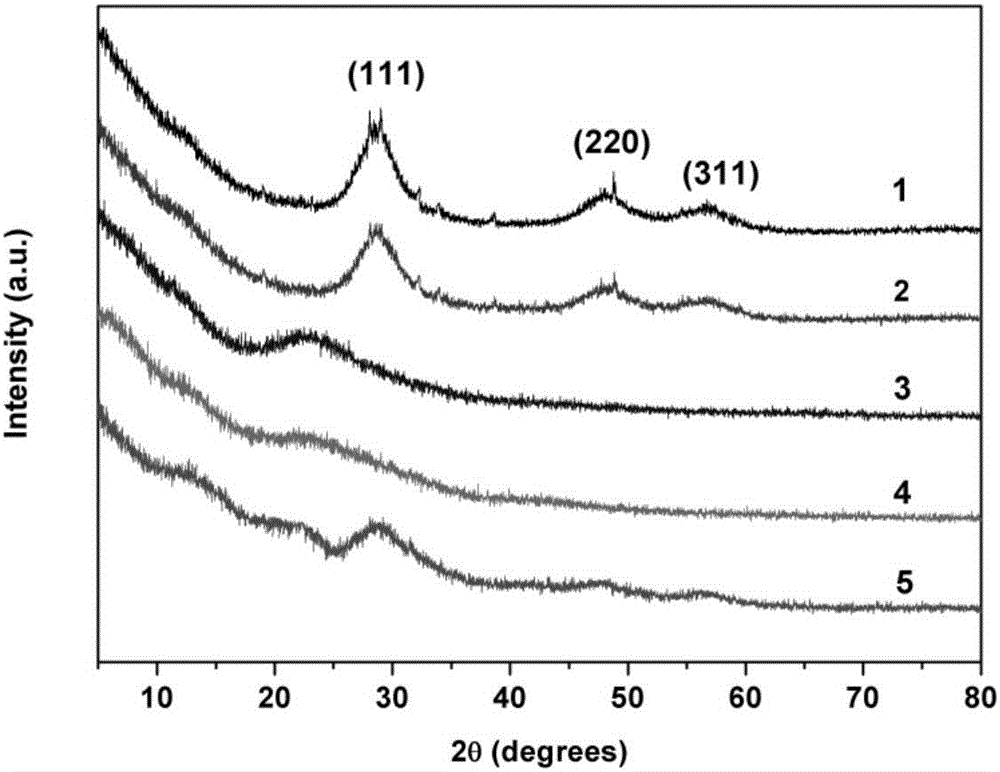

Method for preparing zinc sulfide nanospheres

The invention discloses a method for preparing zinc sulfide nanospheres, which comprises the following steps: 1) preparing a solution A by dissolving zinc acetate and a surfactant in deionized water, and preparing a solution B by dissolving thioacetamide in deionized water; and 2) mixing the solution A and the solution B to obtain a reaction solution, reacting the reaction solution in a water bath and obtaining zinc sulfide nanospheres, wherein the particle size of the zinc sulfide nanospheres can be kept between 90 and 120 nanometers by controlling reaction conditions. The method has the characteristics of readily available raw material, simple equipment, easy operation, high efficiency, high speed and the like; and the prepared zinc sulfide nanospheres with regular form, high dispersity, controllable size, high yield and high stability are suitable for mass industrial production. The zinc sulfide nano material prepared by the method has a great application prospect in fields of fluorescent lamps, field emission flat-panel displays, light-emitting diodes, electroluminescent devices, solar cells and the like.

Owner:SOUTHWEST UNIVERSITY

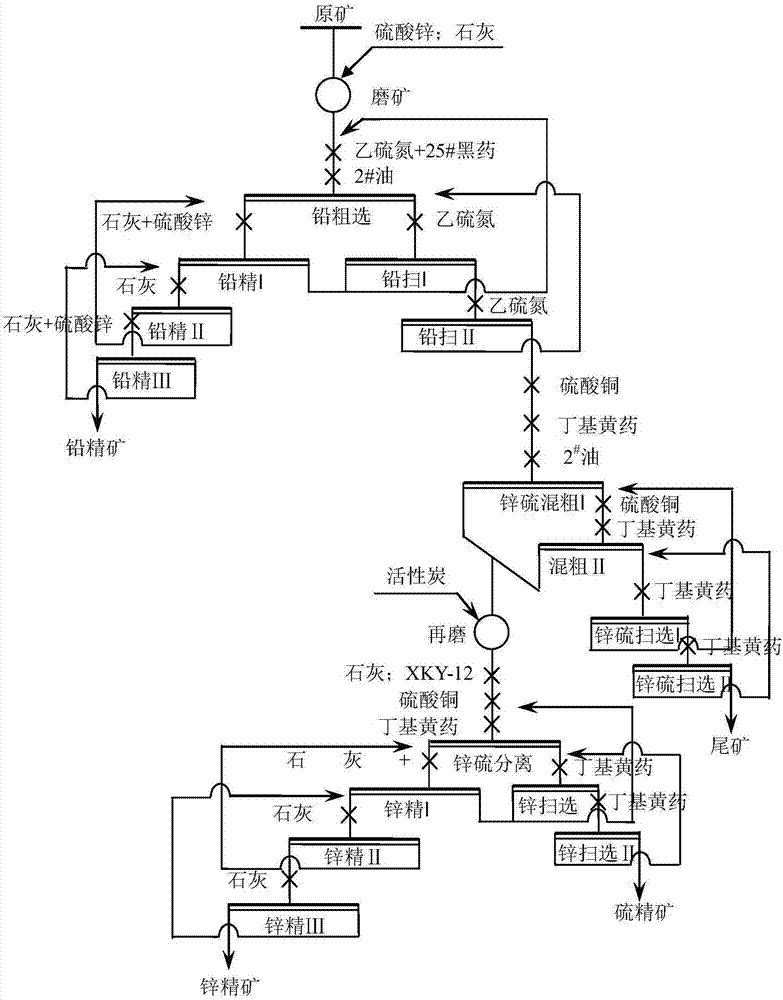

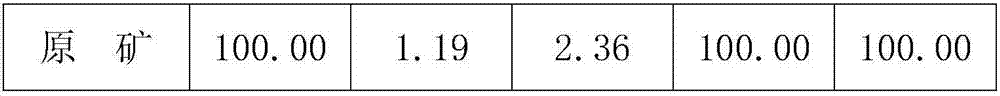

Beneficiation method of micro-fine particle dissemination type lead-zinc sulphide ore containing marmatite and pyrrhotite

ActiveCN107252731ASolve efficiency problemsSolve the accuracy problemFlotationWet separationActivated carbonSeparation technology

The invention discloses a beneficiation method of micro-fine particle dissemination type lead-zinc sulphide ore containing marmatite and pyrrhotite. For the complicated nature of micro-fine particle dissemination type lead-zinc sulphide ore containing marmatite and pyrrhotite, the zinc-sulphide two-stage bulk flotation-zinc-sulphide mixed rough concentrate regrinding and separation technology is adopted, easy-floating zinc-sulphide minerals are preferentially floated during zinc-sulphide mixed first-stage flotation, difficult-floating marmatite flotation is reinforced in the second stage, two-stage mixed rough concentrate is reground so as to promote sufficient monomer separation of zinc-sulphide intergrowth minerals, activated carbon is added in the regrinding process to enhance mineral surface reagent removal, during separation floatation, XKY-12 is added to form deep restraining of pyrrhotite, and efficient separation of marmatite and pyrrhotite is enhanced; according to the method, the good ore dressing recovery rate is ensured, and qualified and high-quality zinc concentrate is obtained; meanwhile, the efficient pyrrhotite inhibitor XKY-12 is adopted, and the problems that the marmatite and pyrrhotite separation efficiency is low and the separation precision is poor are solved.

Owner:WESTERN MINING CO LTD +3

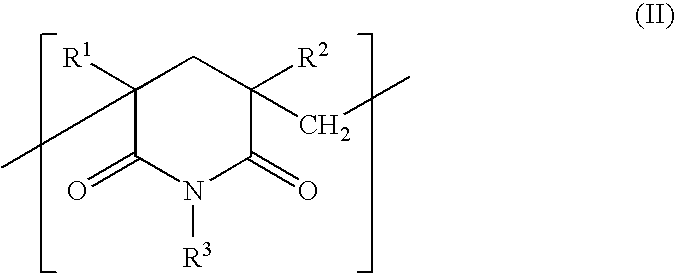

Polymethacrylimide plastic foam materials with reduced inflammability in addition to a method for the production thereof

InactiveUS20050090568A1Reduce flammabilityReduce the amount requiredNon-magnetic metal hullsWatercraft hull designFlammabilityZinc sulphide

The present invention relates to compositions for producing poly(meth)acrylimide foams having reduced flammability which comprise ammonium polyphosphate and / or zinc sulphide. Furthermore, the present invention also provides poly(meth)acrylimide moulding compositions and also poly(meth)acrylimide foams obtainable from the abovementioned compositions and moulding compositions. The present invention further relates to processes for producing poly(meth)acrylimide foams having reduced flammability.

Owner:ROEHM GMBH & CO KG

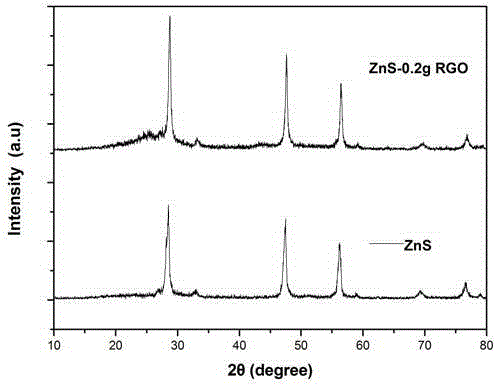

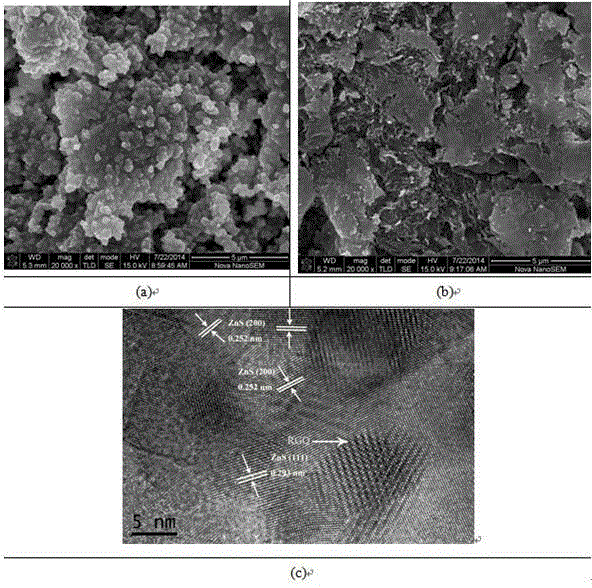

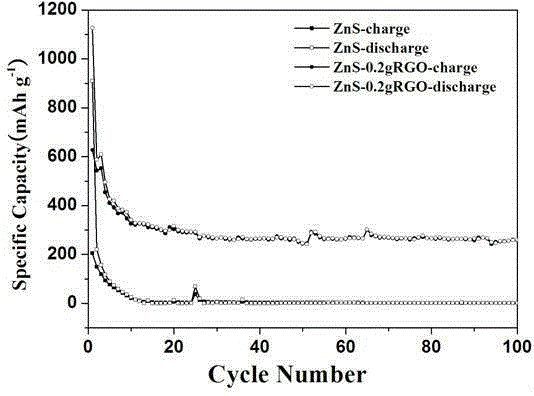

Preparing method for zinc sulfide-graphene composite material for lithium ion battery negative electrode and application

InactiveCN105355890AIncreased initial charge and discharge capacityImprove cycle stabilityNegative electrodesSecondary cellsGraphiteGraphene

The invention discloses a preparing method for a zinc sulfide-graphene composite material for a lithium ion battery negative electrode and application. The preparing method includes the step that the ZnS-RGO composite material is obtained through in-situ synthesis, centrifugation and drying to serve as the lithium ion battery negative electrode. A button type lithium ion battery is assembled, a charging and discharging performance test is carried out on the ZnS-RGO composite sample electrode under the current density of 40 mA / g, and the charging and discharging performance of the ZnS-RGO composite sample electrode is compared with that of a pure ZnS electrode. The result indicates that the first-time charging and discharging specific capacity and the circulation stability of the ZnS-RGO composite sample electrode are improved. After circulation for 25 weeks, the reversible discharging capacity of the ZnS-RGO composite sample electrode can reach 135.9 times that of the pure ZnS electrode. The discharging specific capacity and the circulation stability of the ZnS-RGO composite sample electrode are improved.

Owner:TIANJIN NORMAL UNIVERSITY

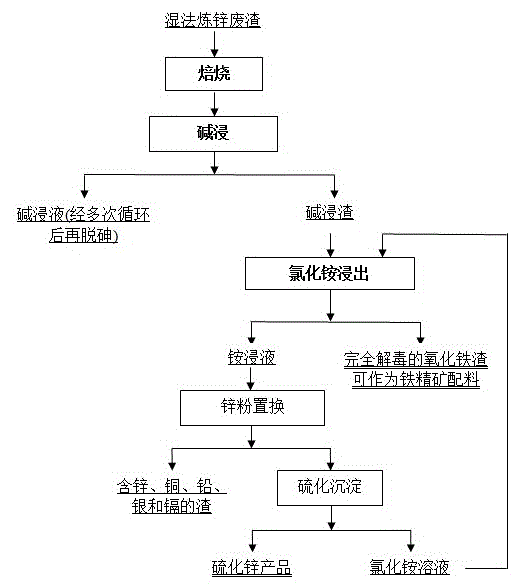

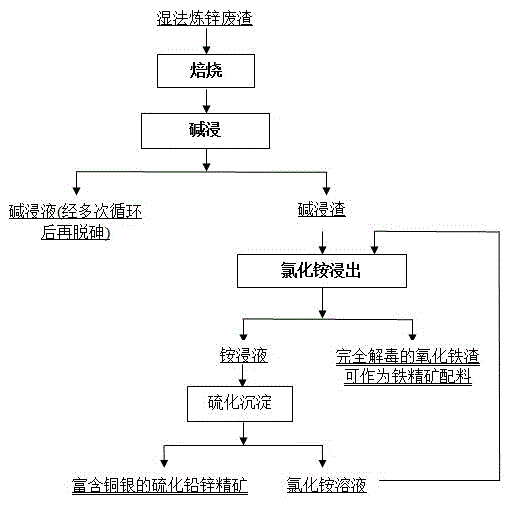

Method for treating zinc hydrometallurgy waste residue by using alkali ammonium sulfur coupling method

The present invention discloses a method for treating zinc hydrometallurgy waste residue by using an alkali ammonium sulfur coupling method, relates to a method for comprehensive utilization of lead silver residue and iron alum residue in zinc hydrometallurgy waste residue by using a alkali ammonium sulfur coupling clean metallurgical method, and belongs to the field of metallurgical hazardous solid reside treatment, wherein the method can further be used to treat other complex waste containing lead and zinc. According to the method, a medium temperature calcination method is performed on zinc hydrometallurgy residue; then an alkali leaching treatment is performed; then the leached alkali residue is leached with ammonium chloride; the resulting alkali leaching liquid is replaced by zinc powder to obtain residues containing zinc, copper, lead, silver and cadmium, and a solution; the solution is subjected to precipitation by using a sulfide to obtain a zinc sulfide product and an ammonium chloride solution; or after the ammonium chloride is leached, the resulting leaching liquid is directly treated by using a precipitating agent, and then is filtered to obtain a lead-zinc sulfide concentrate containing copper and silver and an ammonium chloride solution. With the method of the present invention, valuable metal resources in zinc hydrometallurgy residue can be subjected to effective comprehensive recovery, harmlessness and resource of the final residue are achieved, and good environmental benefits and economic benefits can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of copper-zinc sulfide ore flotation separation inhibitor and application thereof

The invention provides a preparation method of a copper-zinc sulfide ore flotation separation inhibitor, comprising the following steps: adding 200-300ml of sulfuric acid solution the volume percentage content of which is 40-50% and 120-150g of pyrite smelting slag containing 40-50wt% of ferrum to a 500ml of three-neck flask at room temperature, stirring the obtained mixed solution with the speed of 60RPM for reacting for 4-6 hours, and filtering while being hot to obtain acid leaching liquid; and placing 200ml of the acid leaching liquid in a 500ml of three-neck flask, adding 50-60g of ferrous powder as a reducing agent, carrying out heating reflux reaction at the temperature of 75-85 DEG C for 1-2 hours, filtering the unreacted ferrous powder while being hot, transferring the obtained filtrate to an evaporation pan, evaporating and concentrating the filtrate into crystal at the constant temperature of 75-80 DEG C, filtering and drying while being hot to obtain white powder, that is, the zinc sulfide ore inhibitor. The preparation method has good inhibition effect on zinc ore so that copper-zinc associated ore can be effectively separated to obtain copper concentrate with higher quality; and the method adopts a small amount of agents, thus being nontoxic and pollution-free.

Owner:GUANGXI UNIV

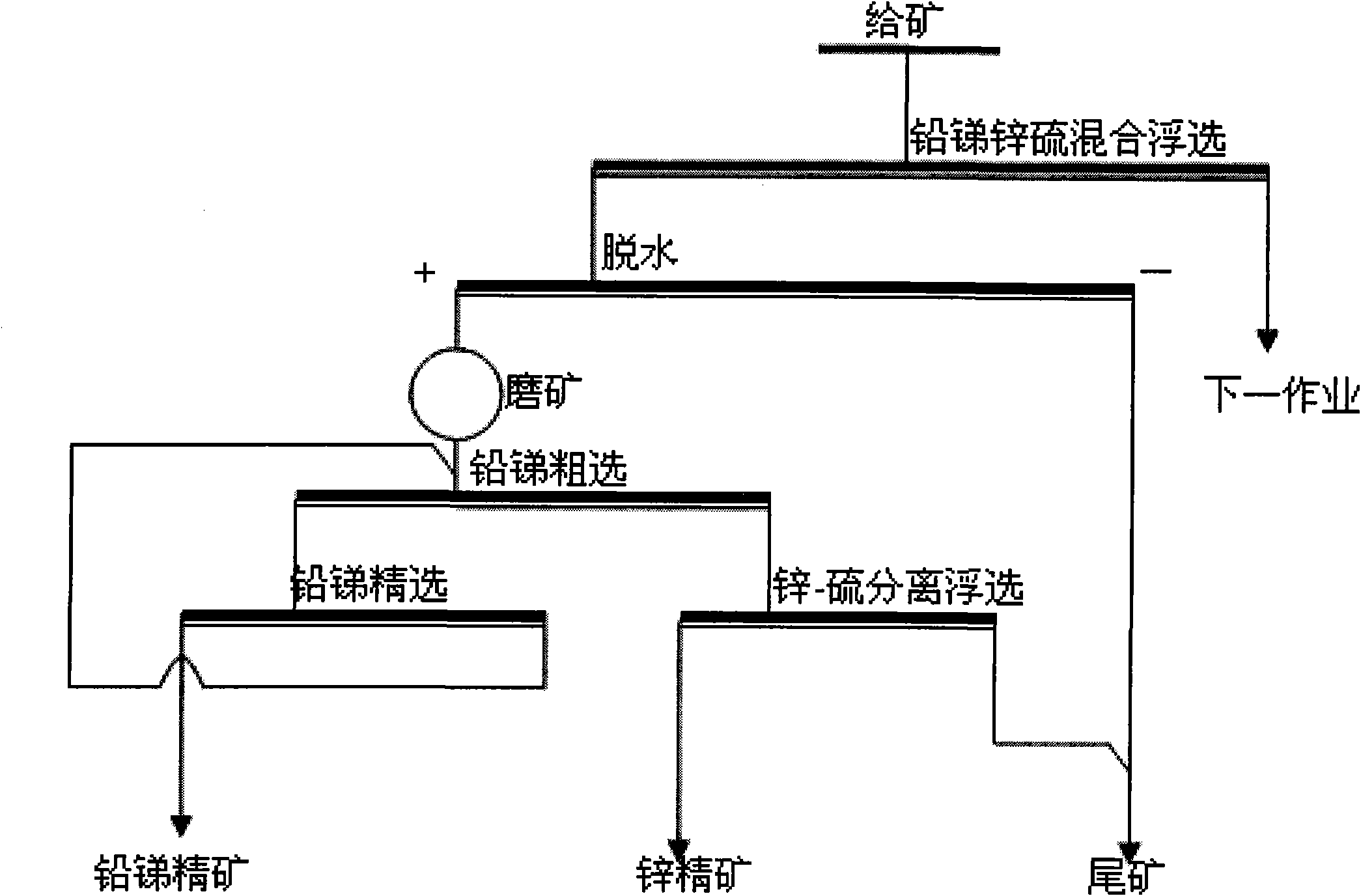

Separating flotation method of low-grade complex lead-antimony-zinc

ActiveCN102029220AImprove work efficiencyAvoid interferenceFlotationWet separationMineral SourcesResource utilization

The invention relates to a novel flotation method of lead-antimony-zinc sulphide ores, particularly for selecting low-grade complex refractory lead-antimony-zinc sulphide ores. A method of ore selecting and washing is adopted, which combines washing and selection and eliminates interference of unfavorable factors such as harmful ions, drugs, slurry and the like on the selection of the low-grade lead-antimony-zinc so as to effectively improve the ore selection technical economical indexes of low-grade lead-antimony-zinc sulphide ores. The method has great significance on the improvement of utilization rate of ore resources and effective recovery of old, incomplete and waste ore resources and secondary resources, imposes important influence on the ore selection area suffering increasing insufficiency of ore resources, and is suitable for floating recovery of low-grade non-ferrous metals such as lead, non-ferrous metal, zinc and molybdenum.

Owner:广西华锡矿业有限公司铜坑矿业分公司 +1

Recovery of nickel, cobalt, iron, silica, zinc and copper from laterite ore by sulfuric acid leaching

ActiveUS7387767B2Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INC

Method for recovering sulfur element from zinc sulphide concentrate direct leaching residues

InactiveCN101734626ASimple processPromote environmental protectionSulfur compoundsNatural resourceNatural source

The invention relates to a method for recovering sulfur element from zinc sulphide concentrate direct leaching residues. The method comprises the following steps of: (1) carrying out floatation separation on zinc sulphide concentrate direct leached residues to obtain sulfur concentrate and floatation tailings, and stacking floatation tailings after pressure filtration; (2) carrying out filtration, heat fusing and heat filtration on the sulfur concentrate in step (1) to obtain a sulfur element solution; and 3) keeping the temperature of the sulfur element solution in step (2), and delivering into a sulfur granulator for granulating. The invention can recover sulfur element from zinc concentrate direct leached residues, and obtain industrial sulfur through granulation, thereby reducing the filtration stacking amount of oxygen pressure leached residues, and enabling the sulfur in natural sources to be utilized and not wasted.

Owner:CINF ENG CO LTD

Method for developing latent finger prints using zinc sulphide and zinc oxide nanoparticles

The invention belongs to the technical field of detection, and in particular relates to a method for applying ZnS, ZnO and functionalized nano granules thereof in revealing latent fingerprints on different surfaces. The invention provides a method for revealing latent fingerprints on surfaces including glass, plastics, metal, clad plate (lacquer wood), paper and the like by means of ZnS, ZnO and functionalized nano granules thereof, wherein ZnS is prepared by two methods of a grinding method and a solution method, while ZnO nano powder is prepared by a sol-gel method; during revealing, the method for revealing the latent fingerprints on different object surfaces is realized by means of a dry powder brushing revealing method and a wet revealing method. The method has the advantages of simplicity, quickness, easy operation, no toxic and side effects on an operator and visualized result.

Owner:NORTHEAST NORMAL UNIVERSITY

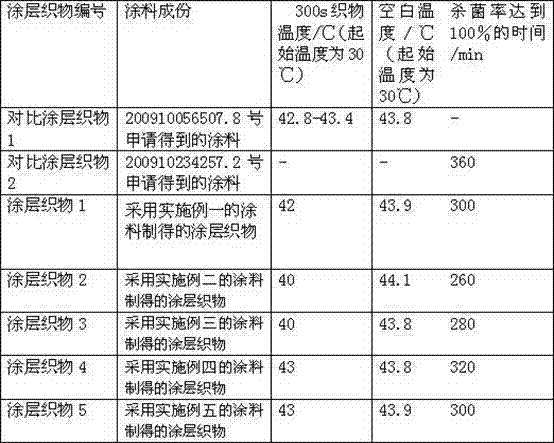

Antimicrobial thermal-insulation coating for fabrics and preparation method thereof

ActiveCN102733196ATo achieve the purpose of antibacterialGood heat insulationVegetal fibresThermal insulationPolyvinyl alcohol

The invention provides an antimicrobial thermal-insulation coating for fabrics and a preparation method thereof. The fabric coating has favorable thermal insulation property and is harmless to human bodies. The preparation method has the advantages of simple technique and low production cost, and is suitable for industrial production. The fabric with the composite coating is applicable to the fields of outdoor supplies, clothing, construction, military affairs and the like, and is widely applied to the occasions in need of heat preservation and thermal insulation. The coating comprises the following components in percentage by weight: 20-30% of ethanol, 5-10% of dioctyl phthalate, 0.6-0.9% of polyvinyl formal, 15-20% of zinc sulfide / magniferous aluminum oxide composite material, 5-12% of polyethyleneglycol and the balance of polyurethane.

Owner:NANTONG ABLE OUTDOOR PROD COMPANY

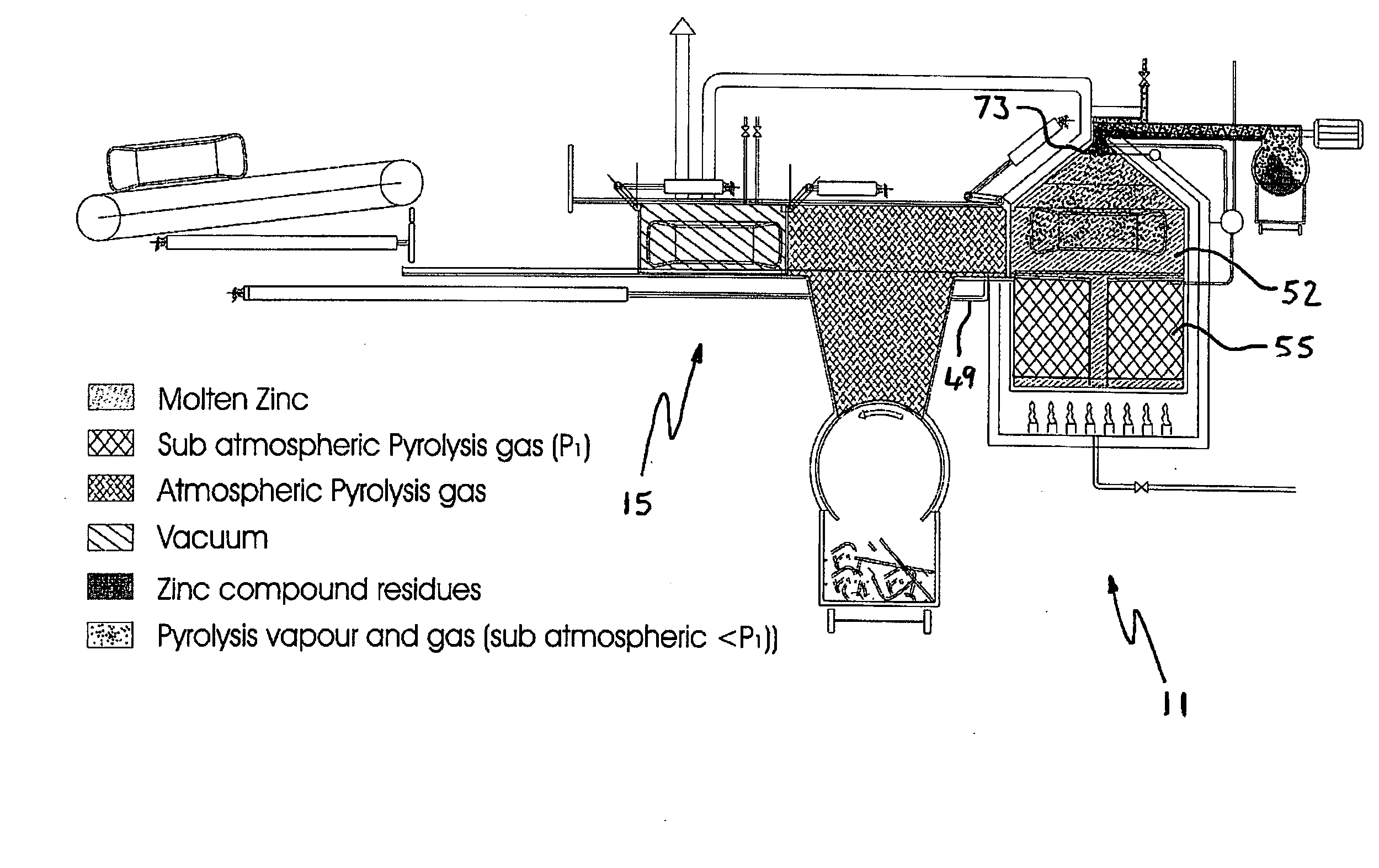

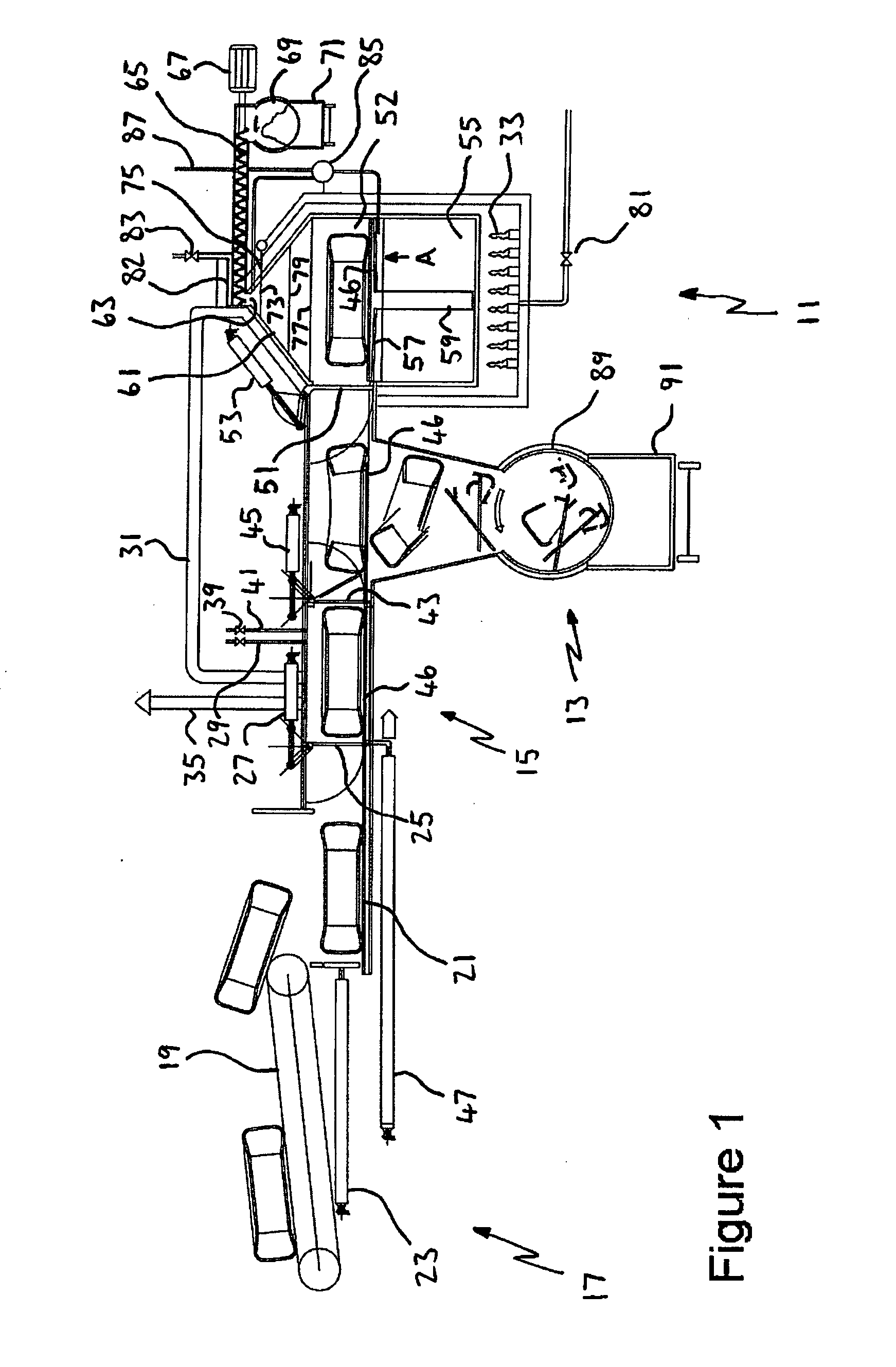

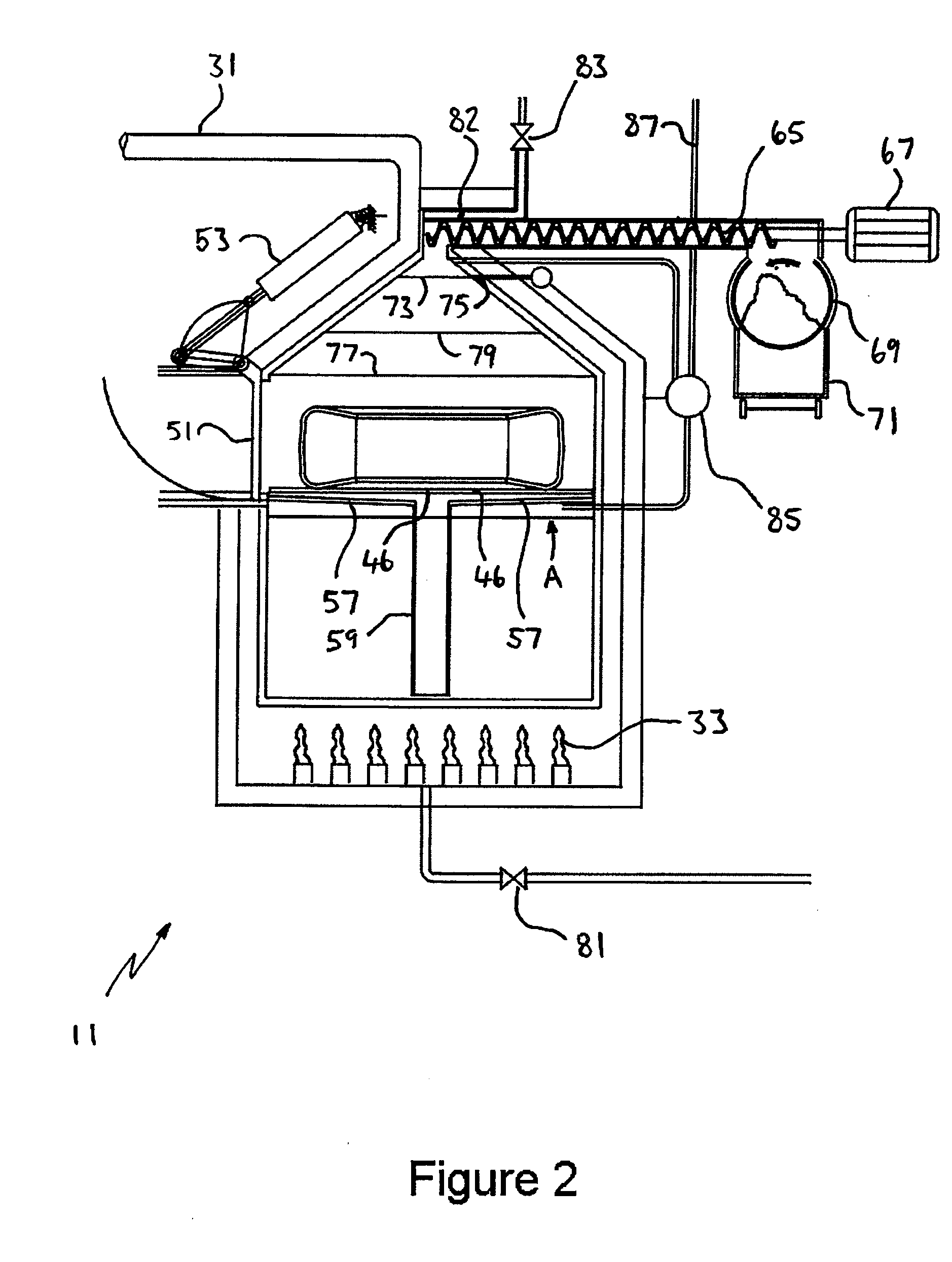

Process and apparatus for decomposition of polymer products including those containing sulphur such as vulcanised rubber tyres and recovery of resources therefrom

A method and apparatus for pyrolytic destruction of polymer products including whole vehicle vulcanised rubber tyres is disclosed. The apparatus 111 has a reaction chamber 153 into which a tyre can be placed, and immersed for pyrolytic decomposition in a molten alloy of zinc with a minor proportion of aluminium. The apparatus 111 has a heated reservoir 155 in which the alloy is maintained in a molten state, and from where it can be transferred to the reaction chamber 153 to immerse the tyre. Fluid hydrocarbon byproducts are drawn off for condensation and recovery, and solid zinc sulphides are also recovered. Where steel belted tyres are processed, carbon and steel residues are also recovered.

Owner:SHAW MICHAEL JOHN

Synergistic leaching-copper arsenate removing method for leaching residues in high-iron zinc calcine and high-iron zinc sulfide concentrate

InactiveCN103789544AHigh recovery rateEfficient reductionProcess efficiency improvementHydrometallurgyCopper sulfate

The invention belongs to the field of wet metallurgy of zinc, and particularly relates to a synergistic leaching-copper arsenate removing method for leaching residues in high-iron zinc calcine and high-iron zinc sulfide concentrate. The method comprises the following steps: mixing the leaching residues in the high-iron zinc calcine with the high-iron zinc sulfide concentrate; mixing zinc electrowinning waste liquor and a part of sulfuric acid-containing solution prepared from concentrated sulfuric acid and synergistically leaching; adding a reaction dosage of industrial iron powder into a synergistically-leached copper arsenate-removing primary solution; replenishing a proper amount of copper sulfate as required; reacting; performing liquid-solid separation on reaction ore pulp to obtain cuprous arsenide precipitate serving as a copper-leaching raw material and a copper arsenate-removing secondary solution; returning the copper arsenate-removing secondary solution to a zinc hydrometallurgy process to further recover valuable metals therein. The method is clean and efficient, efficient leaching of copper and efficient reduction of Fe<3+> can be realized, the solution treatment amount is small, the comprehensive recovery rate of valuable metals in a zinc hydrometallurgy process is increased comprehensively, and the smelting flow is simplified.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT +1

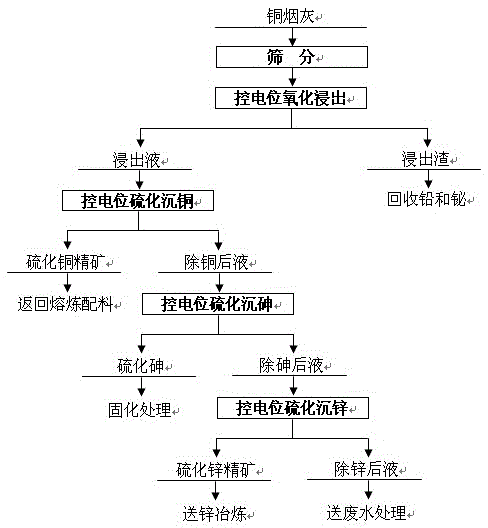

Method for potential controlled selection separation of copper refinery ash

InactiveCN105567984AIncrease sedimentation rateEasy to separateProcess efficiency improvementSlurryCopper sulfide

The invention relates to a method for potential controlled selection separation of copper refinery ash. The copper refinery ash is screened and then subjected to oxidizing leaching in a sulfuric acid system. An oxidizing agent is added to control the metal ion mixed potential of slurry, copper, arsenic, zinc and other metal are dissolved into a solution, and lead, bismuth and other metal precipitate and enter leaching residues. The metal ion mixed potential and the pH value of a leachate are simultaneously controlled, so that copper sulfide concentrate is produced through precipitation. The metal ion mixed potential and the pH value of copper-removed liquid are simultaneously controlled, so that arsenic sulfide products are produced through precipitation. The metal ion mixed potential and the pH value of arsenic-removed liquid are simultaneously controlled, so that zinc sulfide concentrate is produced through precipitation. Zinc-removed liquid is subjected to wastewater treatment and then discharged after reaching the standard. According to the method, the potential controlled oxidizing leaching and potential controlled sulfide precipitation ways are simultaneously adopted for recovering valuable metal step by step, the selection separation effect, which cannot be achieved by independently using the ways, of the valuable metal in the copper refinery ash is achieved, and the leaching rates of copper, arsenic and zinc are larger than 98.0%.

Owner:CENT SOUTH UNIV

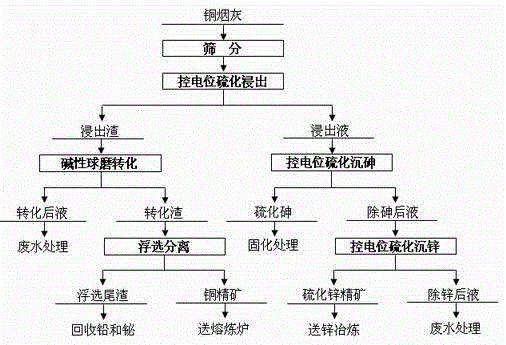

Copper soot smelting and separation combined treatment method

InactiveCN105624412AEasy to separateEasy to controlProcess efficiency improvementArsenic compoundsSlagFiltration

The invention discloses a copper soot smelting and separation combined treatment method. Copper soot is leached in water solution after ball milling to a requested particle size; sodium sulfide is added to control the metal ion mixed potential of whole pulp at a requested numerical value; meanwhile, sulfuric acid is added to adjust the pH value of the pulp to keep at a requested numerical value; after the solution potential is stabilized, and the stirring is continued by a period of time, the filtration is performed; the leaching liquid controls the metal ion mixed potential and the pH value; arsenic sulfide and zinc sulfide precipitates are respectively prepared to send to waste water for treatment; and leaching slag directly performs flotation to prepare copper concentrate and flotation tailing after alkaline ball milling conversion. The method recovers valuable metal step by step by using a control potential vulcanization leaching and beneficiation combined method; the processes are tightly associated; and single process cannot achieve the desired effect of selection and separation of the valuable metal in copper soot. The leaching rates of arsenic and zinc both reach above 95.0%; and the direct recovery rate of copper reaches above 98.0%.

Owner:CENT SOUTH UNIV

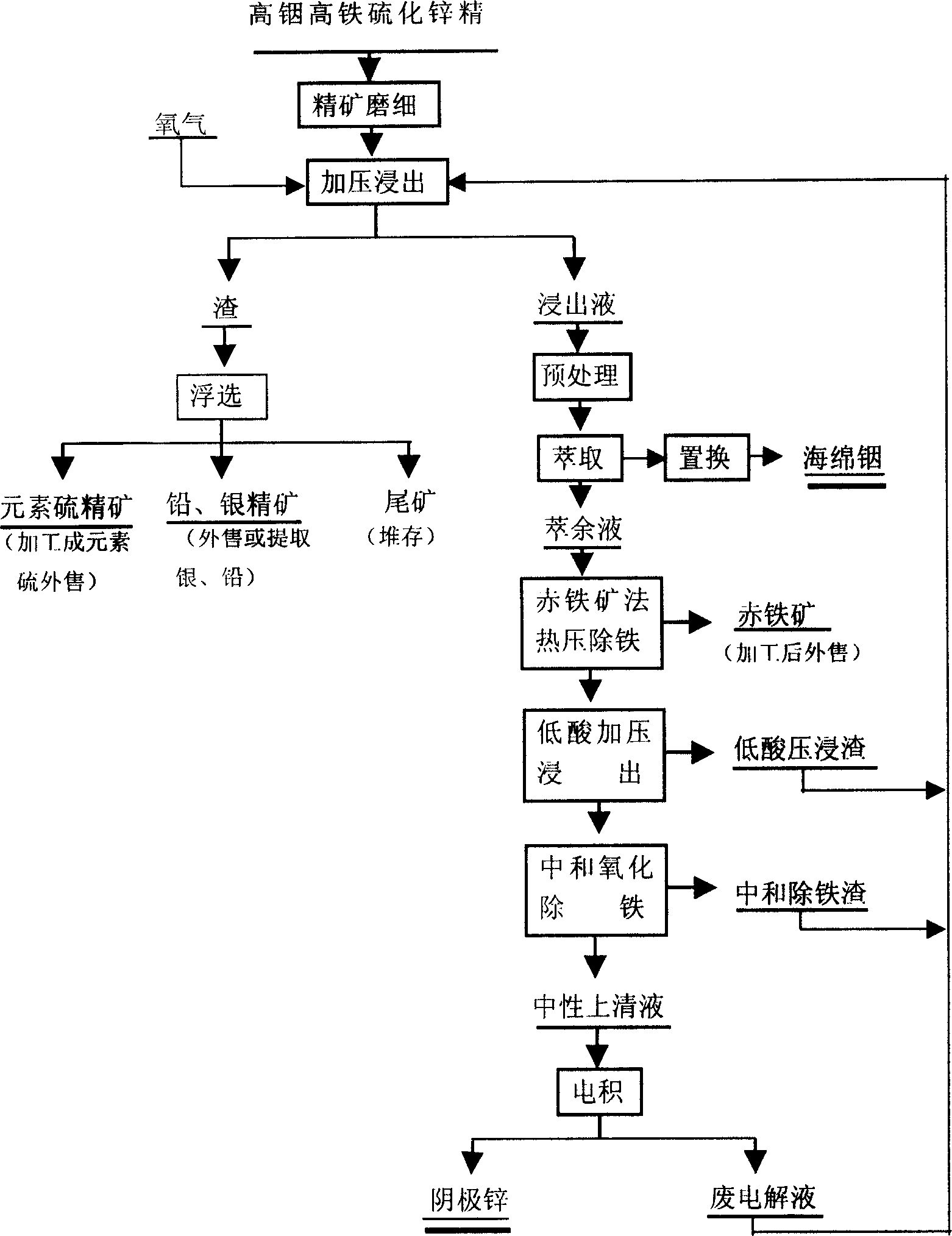

Method for extracting indium from high-indium high-iron zinc sulphide concentrates by pressure acid leach and solvent extraction

InactiveCN1664131AEfficient leachingHigh recovery rateProcess efficiency improvementPregnant leach solutionIndium

The invention relates to an indium extraction method by acid dipping and solvent extraction under high pressure from zine sulfide clean ore with high component of indium and iron. After jevigating process of zine sulfide clean ore with high component of indium and iron, pasting the powder with zinc electrodeposition discard solution, sending the mixture to pressure pan to do acid dipping directly, in which zinc leaching ratio approaches to 99% or higher while indium leaching ratio approaches to 96% or higher, extracting more than 95% of indium in leachate by solvent, so recovery ratio of sponge indium from zine clean ore approaches to 85% or more, processing leachate, from which indium is extracted, to produce sine by wet zinc smelting technology such as deironing, extraction in neutral condition, solution purification, electrodeposition and fusion casting. This invention has the properties of simplifying process, high recovery ratio of indium and zine and high-activity processing of complex zinc clean ore with high component of indium.

Owner:YUNNAN METALLURGICAL GROUP

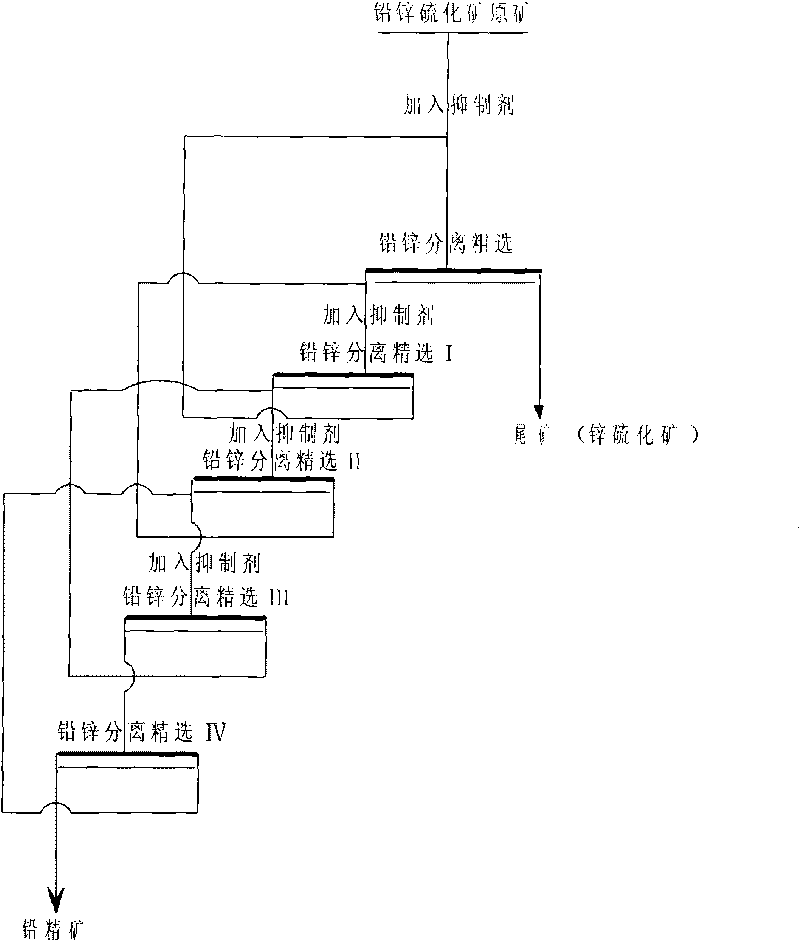

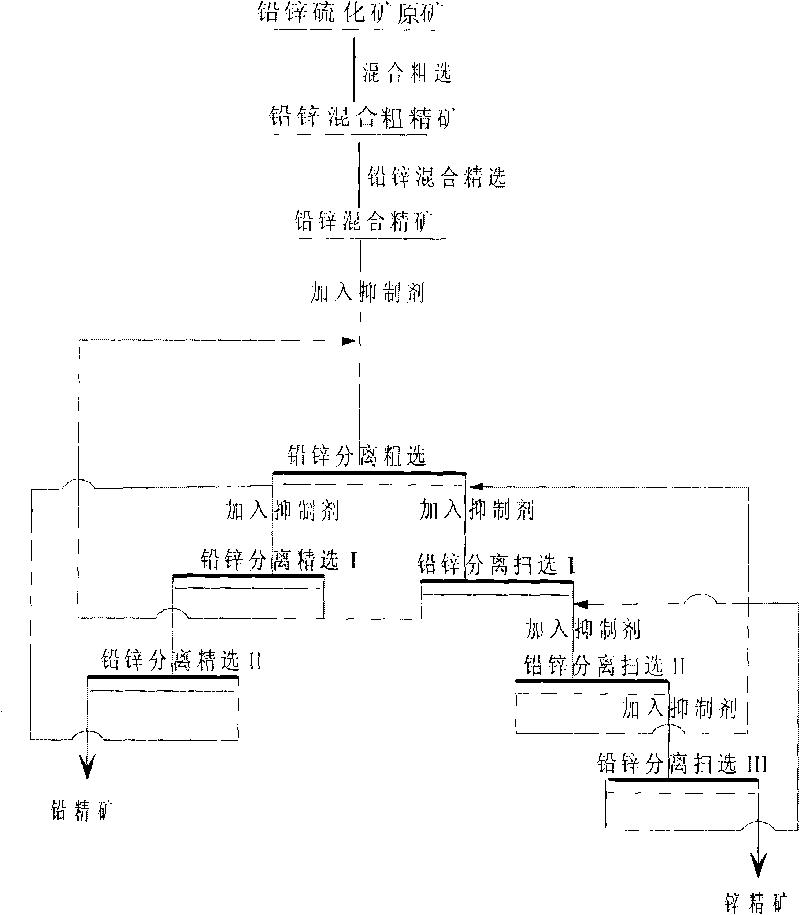

Separation method of lead-zinc sulphide minerals

The invention discloses a separation method of lead-zinc sulphide minerals, which belongs to the technical field of mineral dressing. The separation method utilizes crude ore of the lead-zinc sulphide minerals as raw materials and includes steps of performing flotation separation for the crude ore of the lead-zinc sulphide minerals to obtain lead concentrates or obtain lead concentrates and zinc concentrates, and water-soluble thiol acetate or thioglycolic acid is added to be utilized as an inhibitor of the zinc sulphide minerals in separation minerals. Because the water-soluble thiol acetate or thioglycolic acid which is utilized as the inhibitor of the lead-zinc sulphide minerals has advantages of fine selectivity, strong inhibition capacity, low usage, convenient adding and the like, the water-soluble thiol acetate or thioglycolic acid not only can inhibit the zinc sulphide minerals well, but also can achieve better flotation effect. Simultaneously, the water-soluble thiol acetate or thioglycolic acid is low in environment influence and does not pollute environments, thereby improving production conditions well and overcoming the shortage that high common agent usage pollutes and damages the environment.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Preparation method and application of fluorescent molecularly imprinted adsorption separation material

InactiveCN106380619AQuick checkGood removal effectOther chemical processesWater/sewage treatment by sorptionMaterials preparationQuantum dot

The invention provides a preparation method and application of a fluorescent molecularly imprinted adsorption separation material. The method includes the steps of: 1. preparation of SiO2 nano particles; 2. synthesis of manganese doped zinc sulfide quantum dots; 3. preparation of double bond modified SiO2 nano particles; 4. preparation of double bond modified and manganese doped zinc sulfide quantum dots; and 5. preparation of the fluorescent molecularly imprinted adsorption separation material. The preparation method of the surface molecularly imprinted composite photocatalytic material provided by the invention belongs to the technical field of environmental material preparation. The fluorescent molecularly imprinted polymer combines the selectivity of molecularly imprinted polymers and the fluorescence properties of quantum dots, and can realize rapid detection of target molecules through change of the fluorescence intensity.

Owner:JIANGSU UNIV

Method for preparing acid from high-concentration SO2 smelting flue gas

InactiveCN107892280AInhibition reaction temperatureLow running costSulfur compoundsMetallic sulfideCopper sulfide

The invention discloses a method for preparing acid from high-concentration SO2 smelting flue gas. The acid preparing method comprises the purification process, the dry suction process, the conversionprocess and the finished product obtaining process. In the metallurgical industry, most smelting raw materials are metal sulfide such as zinc sulfide and copper sulfide, a large amount of sulfur dioxide smoke is generated in the smelting process, and pollution to the environment is severe; when the concentration of SO2 in the flue gas reaches a certain degree, the method for preparing the acid from the smelting flue gas can be used, waste is changed into wealth, sulfuric acid is produced, and the purposes of pollutant emission reduction and comprehensive utilization of waste gas are also achieved. According to the method, the reversibility of a sulfur dioxide conversion reaction is utilized, before the high-concentration SO2 smelting flue gas enters a reactor, part of the flue gas is usedfor reacting with diluent air and pure oxygen to generate a small amount of sulfur trioxide, and the one-layer reaction temperature of a converter is inhibited. The pure oxygen is supplemented, so that the amount of the diluent air is reduced, the size of equipment is reduced, and the operating cost of an acid preparing device is reduced.

Owner:广西金川有色金属有限公司

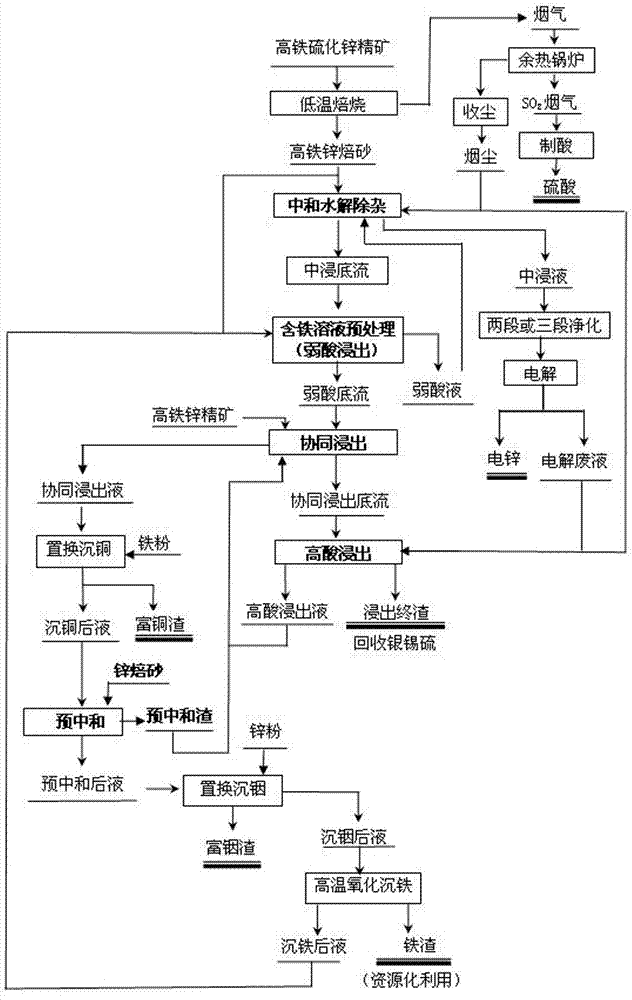

Treatment technique of copper-containing high-indium high-iron zinc sulfide concentrate

ActiveCN104745810AHigh recovery rateHigh enrichment ratioPhotography auxillary processesProcess efficiency improvementPregnant leach solutionIndium

The invention provides a treatment technique of a copper-containing high-indium high-iron zinc sulfide concentrate, relating to a slag / ore synergic leaching-combined iron precipitation technique of a copper-containing high-indium high-iron zinc sulfide concentrate. The technique comprises the following steps: (1) roasting the high-iron zinc sulfide concentrate in a fluidized bed furnace to obtain high-iron zinc calcine; (2) carrying out neutralizing hydrolysis on the high-iron zinc calcine and a zinc-hydrometallurgy electrolysis waste liquid for impurity removal to generate a medium immersion liquid and medium immersion slag; (3) mixing the medium immersion slag with high-iron zinc calcine and a weak acid solution to generate a weak acid solution and weak acid slag; (4) mixing the weak acid slag with the high-iron zinc sulfide concentrate and a strong acid solution to perform slag-ore synergic leaching to generate a synergic leach solution and synergic leach slag; (5) carrying out strong acid leaching on the synergic leach slag to generate a strong acid solution and strong acid slag; (6) separating and recovering copper and indium from the synergic leach solution by a two-stage continuous replacement technique to generate copper-rich slag, indium-rich slag and an indium precipitation solution; and (7) carrying out high-temperature oxygen-pressure hydrothermal iron precipitation on the indium precipitation solution to obtain an iron precipitation solution and recoverable iron slag. The technique has high metal recovery rate, and solves the problem of zinc-iron separation.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT +1

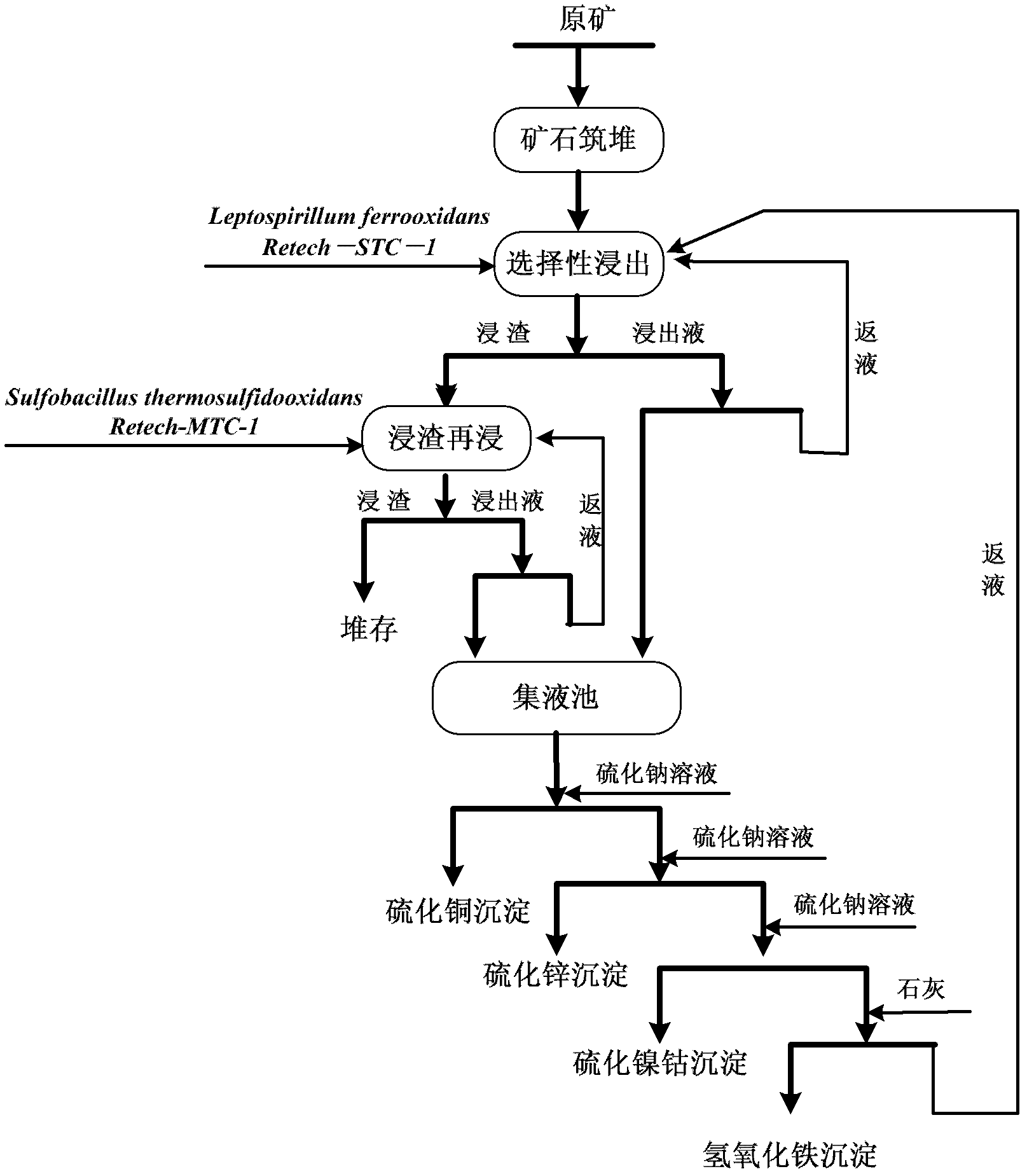

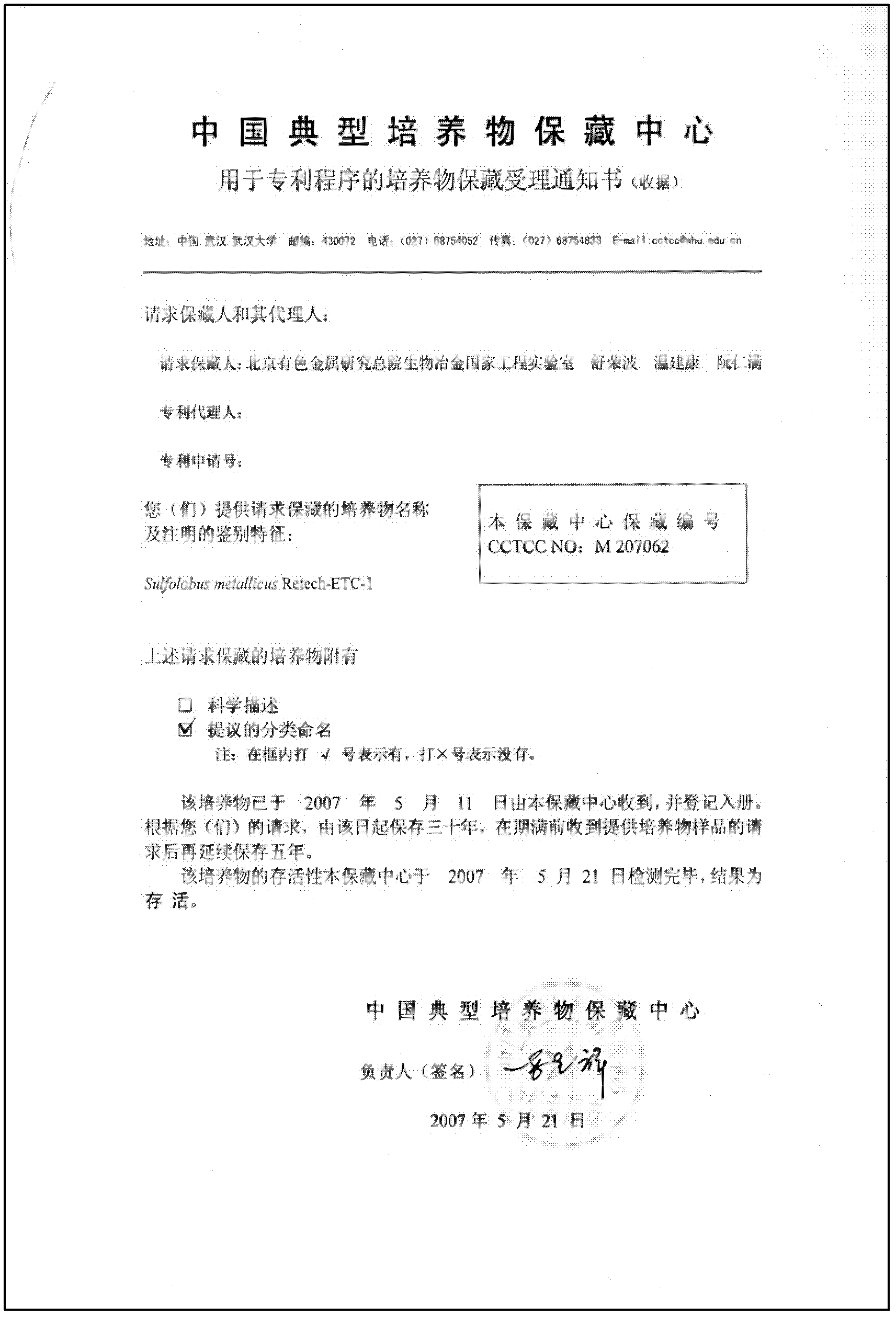

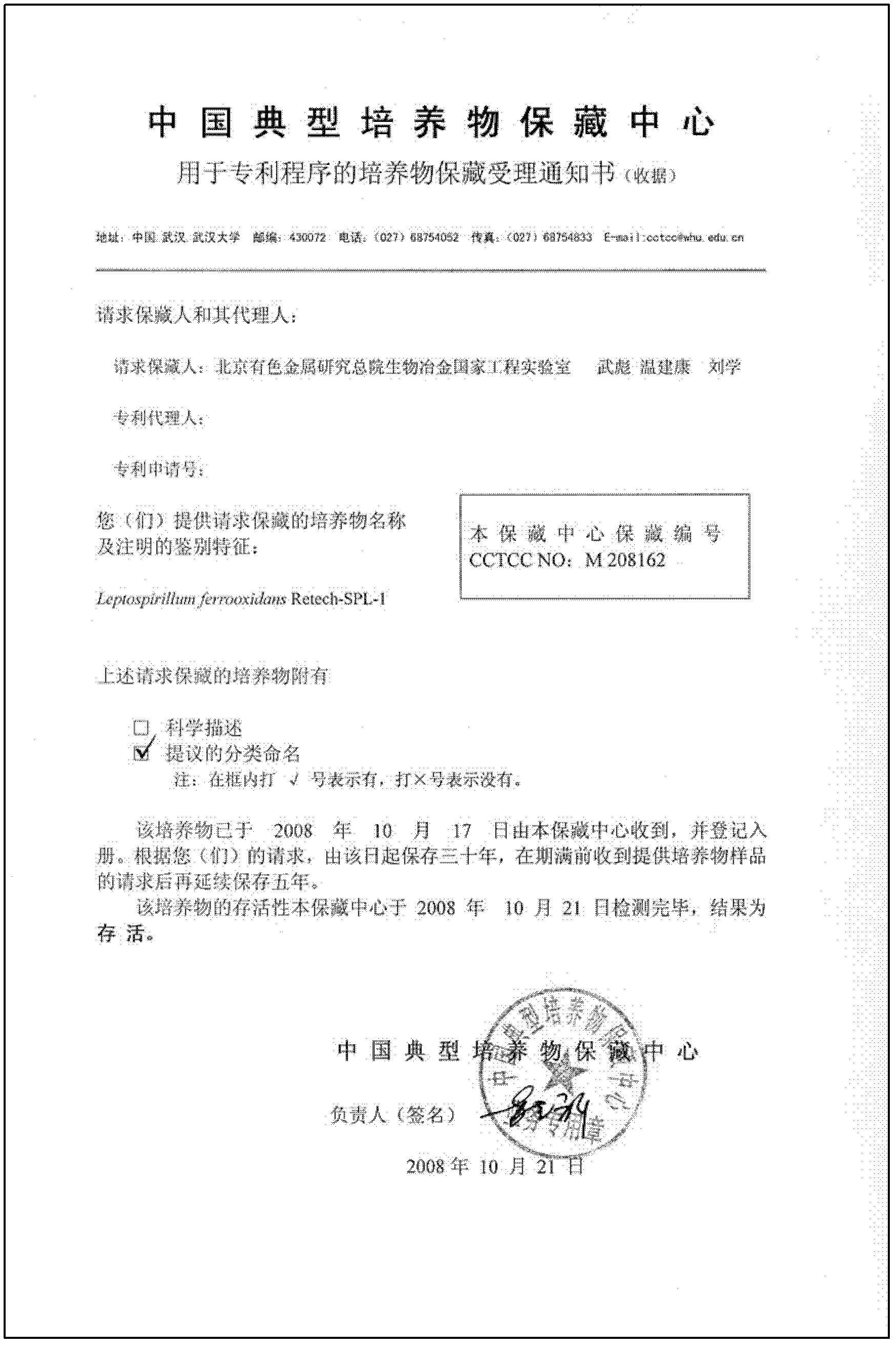

Low-grade multi-metal sulfide mineral selective bioleaching technology

ActiveCN103184335ALow impurity contentReduce the amount of sedimentProcess efficiency improvementSulfide mineralsContamination

The invention provides a low-grade multi-metal sulfide mineral selective bioleaching technology. The process is as follows: pile building is performed on the raw mineral materials, dilute acid solution is adopted for presoaking, and efficient mineral leaching bacteria are led in for leaching after the acidity of the mineral pile is basically stable; pile unloading is performed when the leaching of nickel reaches more than 80 wt%, then pile building is performed again on the leaching residue, and thermophilic bacteria are led in for leaching; and when the concentration of nickel in the leaching agent is more than 2.0 g / L, open-cycle is performed on the partial leaching agent, sodium sulfide is added into the leaching agent for fractional precipitation, so as to obtain copper sulphide, zinc sulphide and nickel and cobalt sulphide products, after precipitation is completed, lime is added into the leaching agent for neutralization, wherein concentration of iron in the neutralized leaching agent is less than 1.0 g / L, and the neutralized leaching agent can be reused at the leaching stage. According to the invention, technological process is short, equipment is simple, investment conservation and zero contamination are realized, cost is low, recovery rate of valuable metal is improved, the purpose of comprehensively utilizing low-grade multi-metal sulfide mineral resources is realized, and greater economic benefits can be achieved.

Owner:有研资源环境技术研究院(北京)有限公司

Wire and cable insulation

InactiveCN1496570AReduce or eliminate the needImprove convenienceRubber insulatorsPlastic/resin/waxes insulatorsPolypropyleneZinc sulphide

Wire or cable insulation comprising at least 30 %, preferably at least 40 %, of polypropylene homo- and / or co-polymer, and comprising at least 2 %, preferably at least 4 % zinc sulphide and / or at least 5 %, preferably at least 10 %, zinc oxide, percentages being by weight based on the whole insulation composition. Preferably, the insulation contains little or substantially zero hydrated flame-retardant fillers and substantially zero mercaptobenzimidazole, and a majority by weight or substantially all of any propylene copolymers present are copolymers of propylene with halogen-free co-monomers.

Owner:TYCO ELECTRONICS (UK) LTD

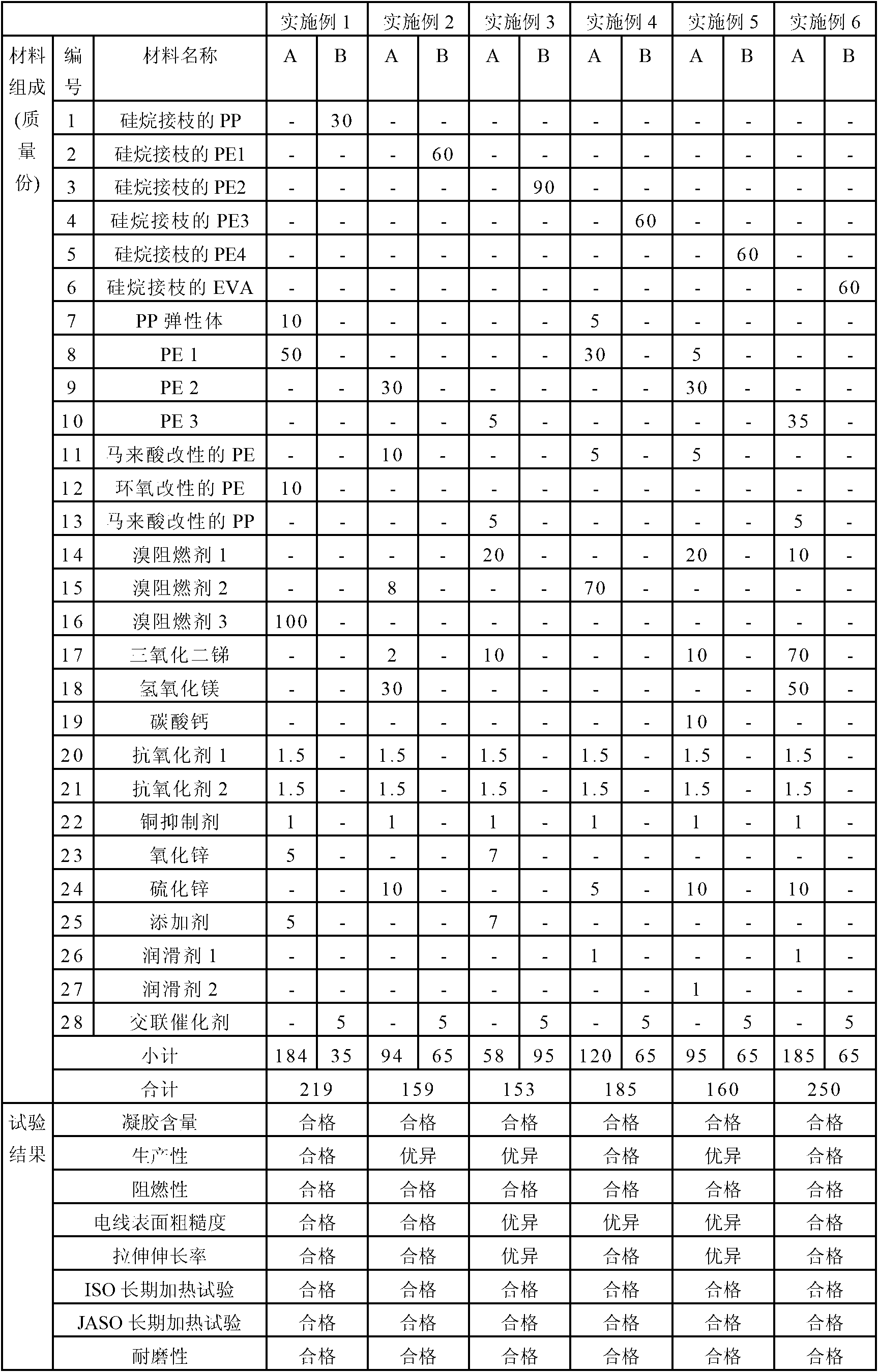

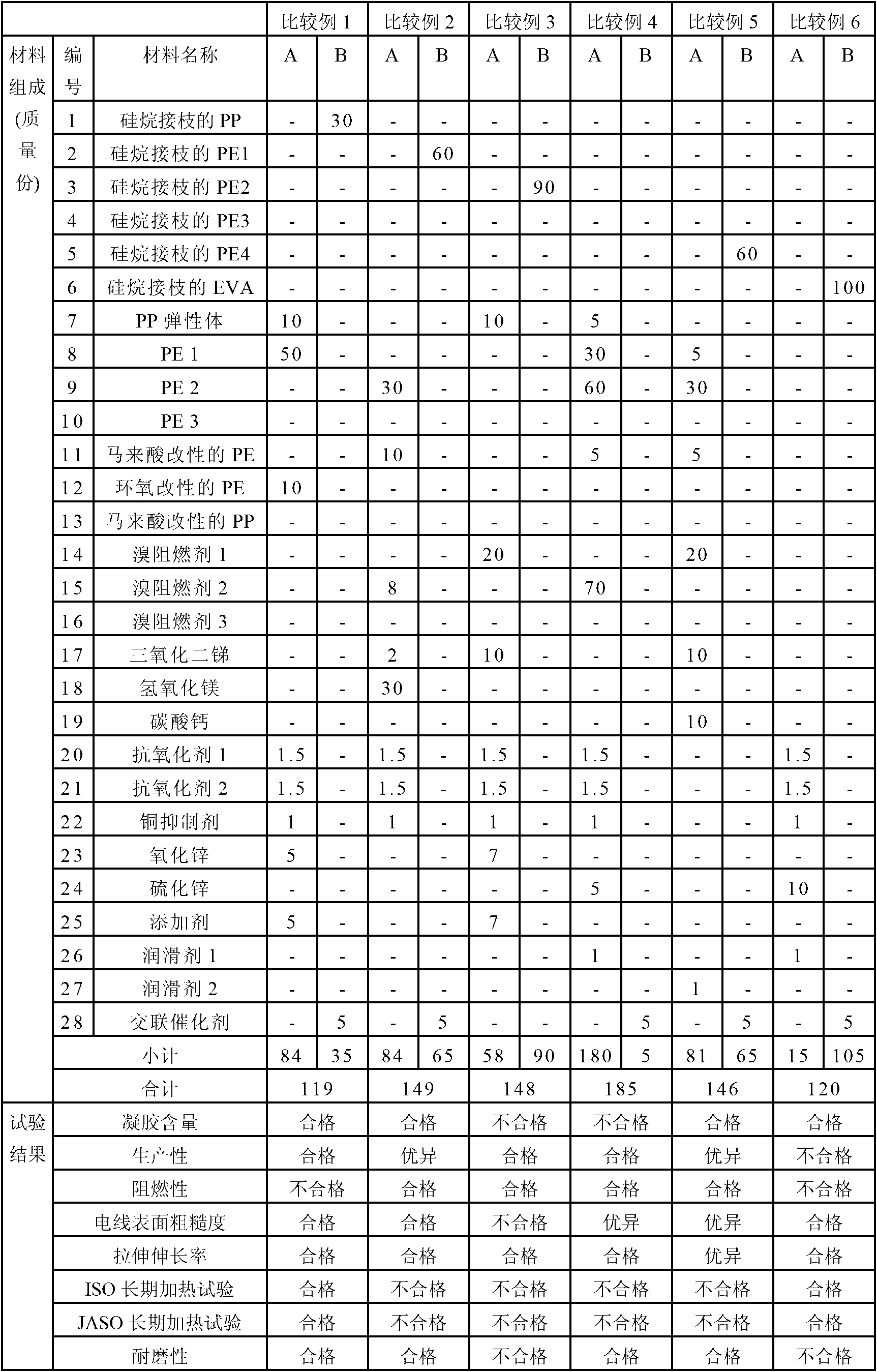

Composition for use in wire coating material, insulated wire and wire harness

ActiveCN102762650AImpossible to reduce heat resistanceImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesPolyolefinElectrical conductor

Disclosed are a composition for use in a wire coating material, an insulated wire and a wire harness. The disclosed composition achieves excellent heat resistance, good productivity, and flame resistance without using electron beam crosslinking. After the composition for use in a wire coating material is extrusion molded around a conductor to form the coating material, and water crosslinking is performed to create the insulated wire. The composition for wire coating material contains (A) water crosslinked polyolefins formed by modifying a polyolefin with a silane coupling agent, (B) unmodified polyolefins, (C) modified polyolefins modified with functional groups, (D1) a brominated flame retardant, (E) a crosslinking catalyst, (F) a phenolic antioxidant, and (G) (G1) a zinc sulphide or (G2) a zinc oxide-imidazole compound.

Owner:AUTONETWORKS TECH LTD +2

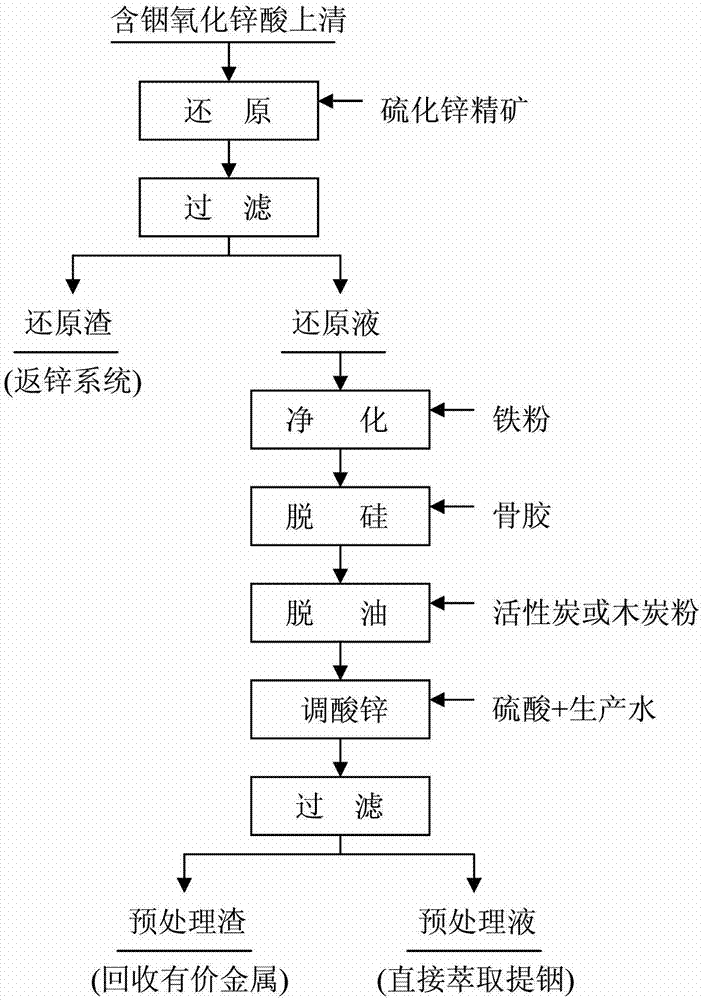

Method for pretreating indium-containing zinc oxide acid supernatant

The invention provides a method for pretreating indium-containing zinc oxide acid supernatant. The method comprises the following steps of: A, reducing, to be specific, adding ball-milled zinc sulfide concentrate into the indium-containing zinc oxide acid supernatant, reacting and then filtering to obtain a reducing solution; B, purifying, to be specific, adding iron powder in the reducing solution, qualitatively detecting until the content of Fe<3+> in the reducing solution is qualified, thus obtaining a purifying solution; C, carrying out desilicication, to be specific, adding bone glue in the purifying solution to obtain a desilicication solution; D, deoiling, to be specific, adding a deoiling agent into the desilicication solution to obtain a deoiling solution; and E, regulating acidicity and the zinc ion concentration and filtering, to be specific, adding sulfuric acid and water in the deoiling solution until the system acidicity and the zinc ion concentration reach the extraction requirements, then filtering to obtain a pretreating solution and pretreating slag. According to the method for pretreating the indium-containing zinc oxide acid supernatant, impurities in the indium-containing zinc oxide acid supernatant, which influence the indium extraction, can be removed so that a pre-extraction feed liquid suitable for direct extraction of indium is obtained; and meanwhile, valuable metals such as bismuth, copper and tin are enriched.

Owner:ZHUZHOU SMELTER GRP

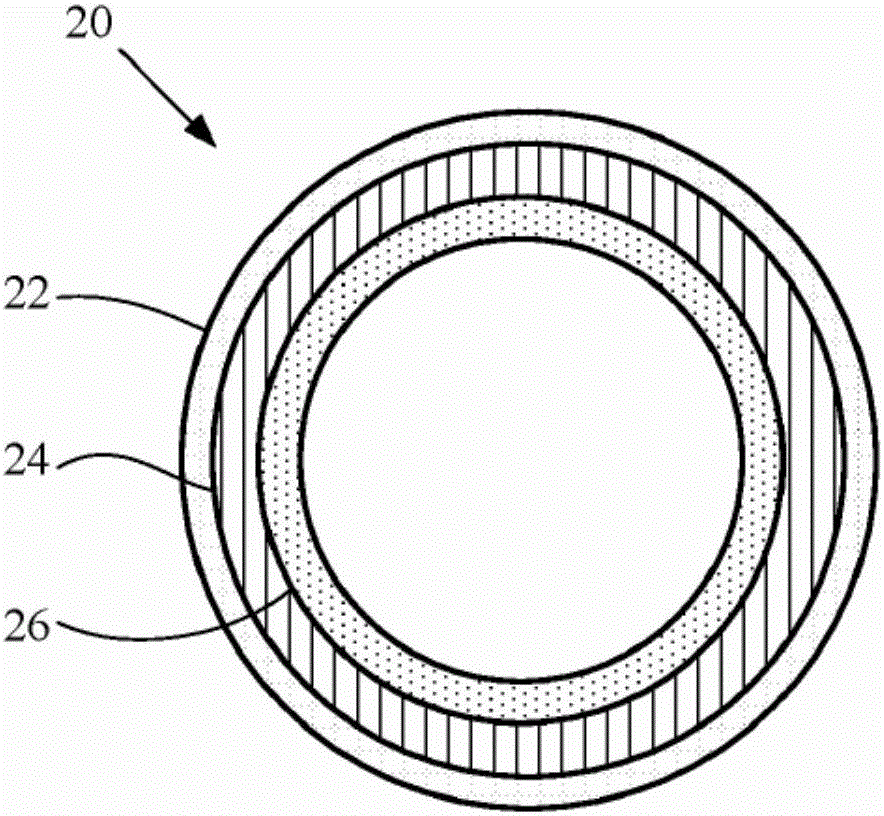

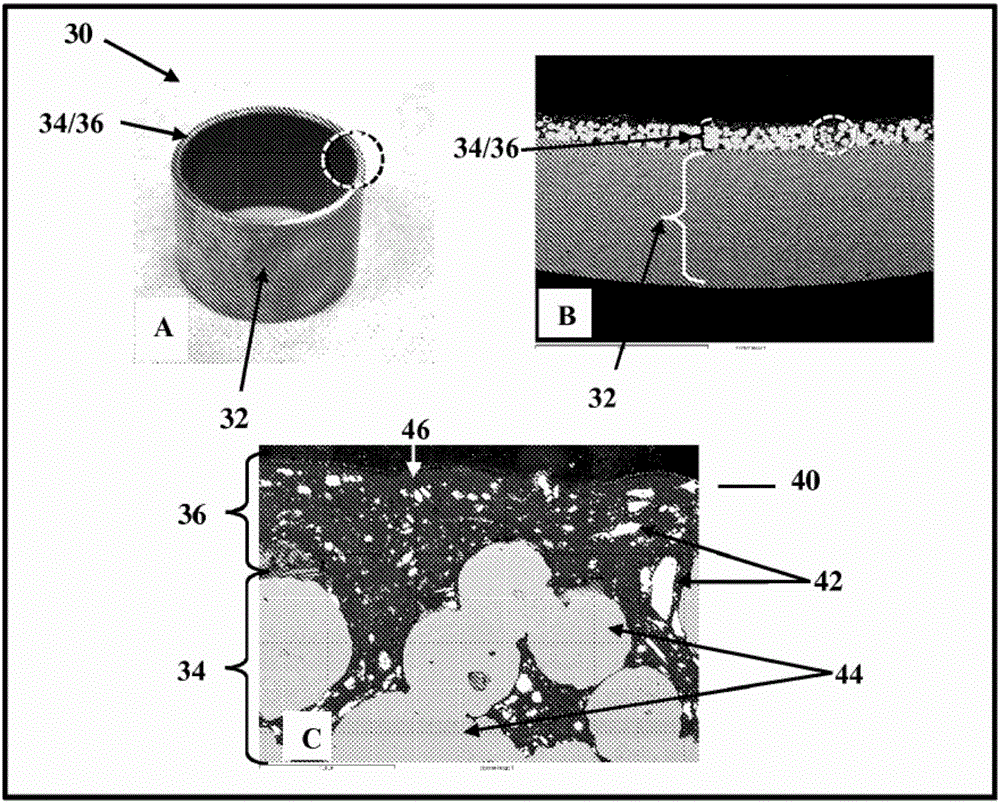

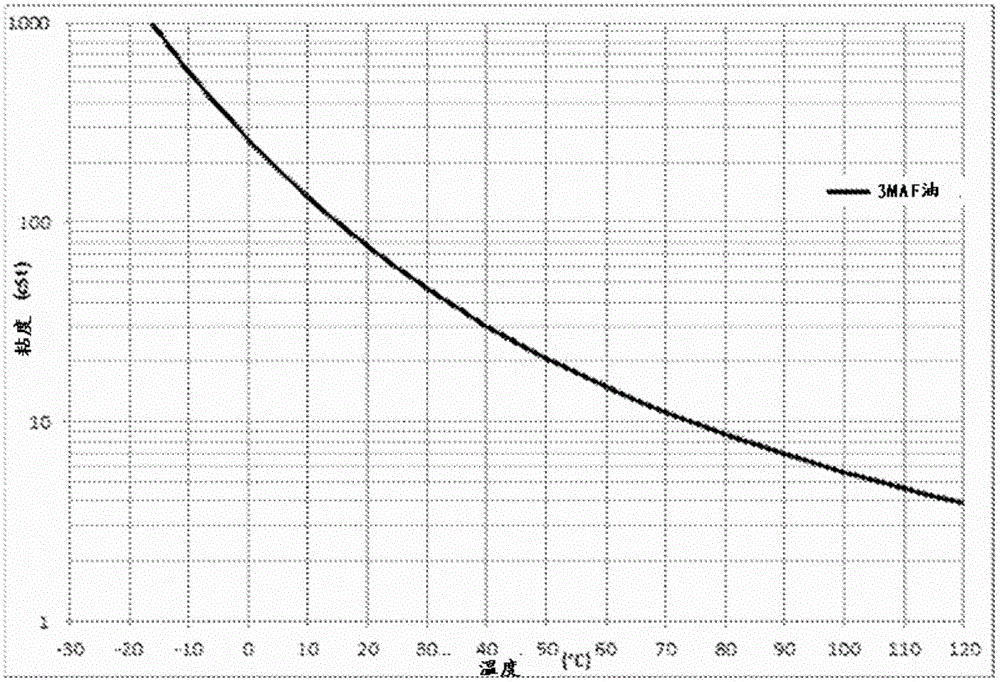

Bearing performance for compressors using high energy refrigerants with sulfur-based oil additives

Methods for improving bearing performance in compressors, especially for those that use high energy refrigerants or that have a high-side design, are provided. The compressor comprises a bearing that is substantially free of lead. The bearing comprises copper and at least one lubricant particle type selected from a group consisting of: molybdenum disulfide (MoS2), calcium fluoride (CaF2), tungsten disulfide (WS2), zinc sulfide (ZnS), hexagonal boron nitride, polytetrafluoroethylene (PTFE), carbon fiber, graphite, graphene, carbon nanotubes, carbon particles, thermoset polyimide, and combinations thereof. The compressor processes a high energy refrigerant and a lubricant oil comprising a sulfur-based additive. The sulfur-based additive reacts with the copper in the bearing to enhance lubricity and improve performance of the bearing in the compressor machine. Compressors having such features and improved bearing performance are also contemplated.

Owner:EMERSON CLIMATE TECH INC

Combined leaching method for high-iron zinc sulfide concentrate and high-iron zinc calcine leaching slag

InactiveCN103409621AImprove solubilityImprove leaching rateProcess efficiency improvementPregnant leach solutionMetal leaching

The invention belongs to the technical field of zinc hydrometallurgy, and particularly relates to a combined leaching method for high-iron zinc sulfide concentrate and high-iron zinc calcine leaching slag. The method comprises a step of mixing the high-iron zinc sulfide concentrate and the high-iron zinc calcine leaching slag according to a mass ratio of 0.15:1-0.35:1; a step of adopting a solution containing 160-190 g / L of sulfur acid as a leaching agent; a step of adding 1-3 kg sodium lignosulphonate per ton zinc concentrate allowing that the liquid-solid ratio is 6-8 mL / g; and a step of reacting at 85-95 DEG C for 2-4 h under stirring to leach out valuable metals comprising zinc, indium and copper and to reduce Fe<3+> to Fe<2+>. According to the method, a hot-acid leaching technology of zinc leaching slag and a high-iron leaching solution reduction technology are combined to be completed in a process, thereby improving the leaching rate of the valuable metals, achieving efficient reduction of the Fe<3+>, and contributing to subsequent extraction of the zinc, the copper and the indium. The method is characterized by being short in technology process, clean, efficient, energy-saving, and the like.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com