Method for extracting indium from high-indium high-iron zinc sulphide concentrates by pressure acid leach and solvent extraction

A technology for zinc sulfide concentrate and high-speed iron, which is applied in the direction of improving process efficiency, can solve the problems of long processing flow, low indium recovery rate, difficult to handle economically, and achieves high indium recovery rate, high leaching temperature, and process intensification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

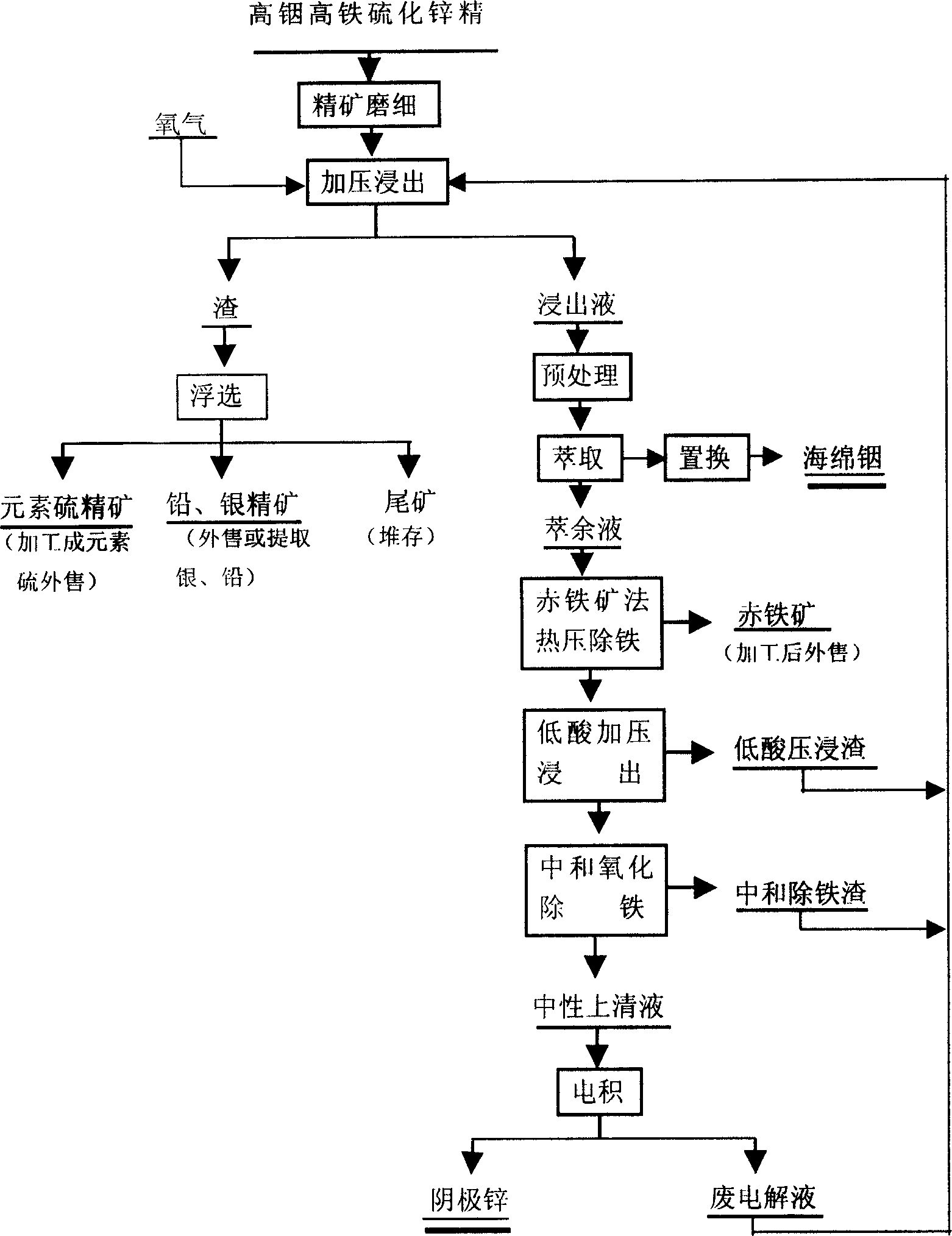

Image

Examples

Embodiment 1

[0009] Example 1. The high-indium and high-iron zinc sulfide concentrate has an iron content of 15%, an indium content of 0.03%, and a zinc content of 42.45%.

[0010] The finely ground high-indium and high-iron zinc sulfide concentrate is slurried with the electrolytic zinc waste electrolyte, and put into an acid-resistant pressure kettle made of titanium with a volume of 4L for continuous oxygen leaching.

[0011] The zinc leaching rate is 99.28%, the indium leaching rate is 97.43%, and the sulfur conversion rate is 82.38%. The leaching solution contains 138g / L of zinc and 45.78mg / L of indium. The leaching slag contains 0.67% zinc and 53.88% elemental sulfur.

[0012] Leaching solution plus 3 # 0.3g / L, gelatin 0.15g / L, stand at 65°C for 6 hours, after pretreatment, use 20% P204+80% kerosene solution, use 5-stage countercurrent extraction of indium, the extraction rate of indium is 96.58%.

[0013] The solution after indium extraction adopts the low-pollution jarosite metho...

Embodiment 2

[0014] Example 2. The high-indium and high-iron zinc sulfide concentrate has an iron content of 18%, an indium content of 0.09%, and a zinc content of 40%.

[0015] The finely ground high-indium and high-iron zinc sulfide concentrate is slurried with electrolytic zinc waste electrolyte, and added to a 4L titanium autoclave for continuous oxygen leaching.

[0016] The zinc leaching rate is 99.79%, the indium leaching rate is 98.02%, and the sulfur conversion rate is 81.98%. The leaching solution contains 132g / L of zinc and 62.44mg / L of high indium. The leaching slag contains 0.87% zinc and 55.23% elemental sulfur.

[0017] Leaching solution plus 3 # 0.3g / L, gelatin 0.1g / L, stand at 55°C for 6 hours, after pretreatment, use 20% P204 + 80% kerosene solution, use 5-stage countercurrent extraction of indium, the extraction rate of indium is 95.89%.

[0018] The liquid after indium extraction adopts the hematite method to remove iron, and the iron slag contains 0.81% zinc.

Embodiment 3

[0019] Example 3, the iron content of the high indium and high iron zinc sulfide concentrate is 25%, the indium content is 0.042%, the zinc 48% concentrate is ground, and 96% passes through a 0.043mm sieve.

[0020] The finely ground high-indium and high-iron zinc sulfide concentrate is slurried with the electrolytic zinc waste electrolyte, and put into an acid-resistant pressure kettle made of titanium with a volume of 4L for continuous oxygen leaching.

[0021] The zinc leaching rate is 99.48%, the indium leaching rate is 98.21%, and the sulfur conversion rate is 83.62%. The leaching solution contains 141g / L of zinc and 55.63mg / L of high indium. The leaching slag contains 1.02% zinc and 54.42% elemental sulfur.

[0022] Leaching solution plus 3 # 0.3g / L, gelatin 0.2g / L, stand at room temperature for 10 hours, after pretreatment, use 20% P204 + 80% kerosene solution to extract indium with 5-stage countercurrent, and the extraction rate of indium is 97.13%.

[0023] The solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com