Composition for use in wire coating material, insulated wire and wire harness

A technology for coating components and insulated wires, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve the problems of increased production costs, expensive equipment required for electron beam crosslinking, etc., to achieve cost savings, prevent poor dispersion, and excellent Effect of heat resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

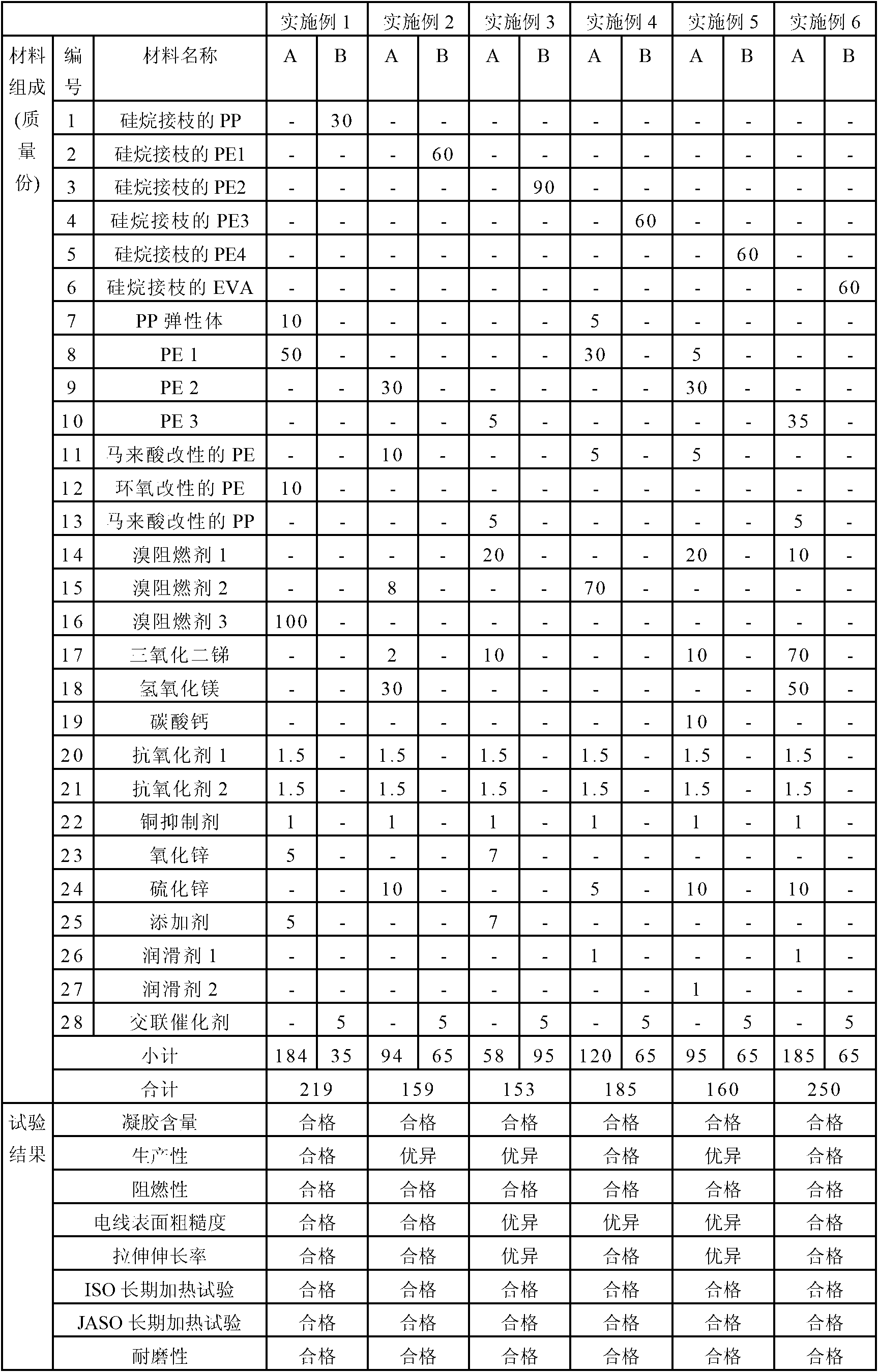

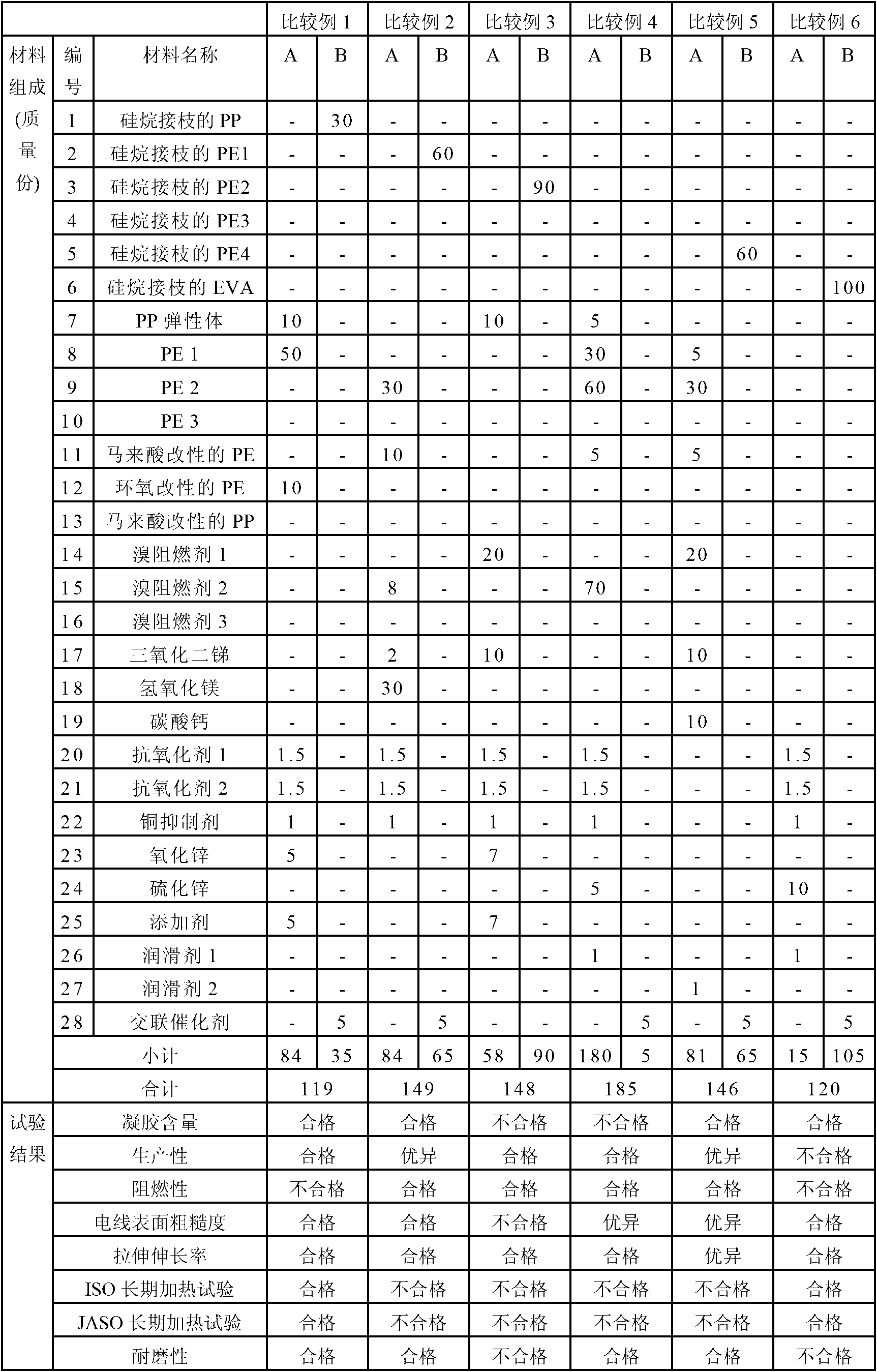

[0091] The description of the present invention will now be specifically provided with reference to Examples and Comparative Examples. However, the present invention is not limited to this.

[0092] (Materials used, manufacturers and other information)

[0093] The materials used in the examples and comparative examples, as well as their manufacturers and trade names are provided below.

[0094] [1] Silane grafted PP [Manufacturer: MITSUBISHI CHEMICAL CORPORATION, trade name: LINKLON XPM800HM]

[0095] [2] Silane grafted PE1 [Manufacturer: Mitsubishi Chemical Corporation, trade name: LINKLON XLE815N (LLDPE)]

[0096] [3] Silane grafted PE2 [Manufacturer: Mitsubishi Chemical Corporation, trade name: "LINKLON XCF710N" (LDPE)]

[0097] [4] Silane grafted PE3 [Manufacturer: Mitsubishi Chemical Corporation, trade name: "LINKLON QS241HZ" (HDPE)]

[0098] [5] Silane grafted PE4 [Manufacturer: Mitsubishi Chemical Corporation, trade name: "LINKLON SH700N" (VLDPE)]

[0099] [6] Silane grafted EVA [...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com