Method for treating zinc hydrometallurgy waste residue by using alkali ammonium sulfur coupling method

A technology of hydrometallurgy and waste slag, which is applied in the direction of improving process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

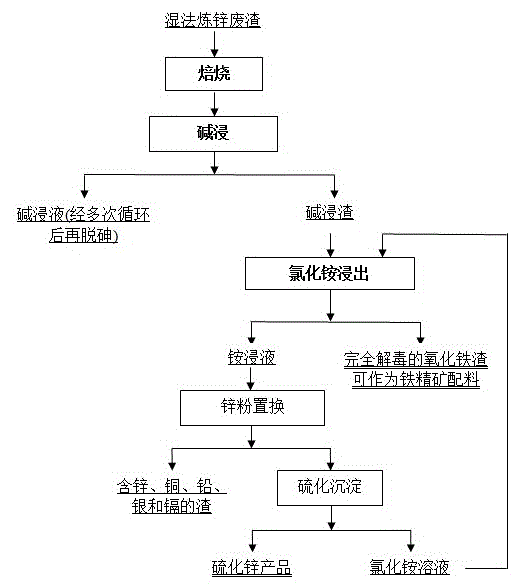

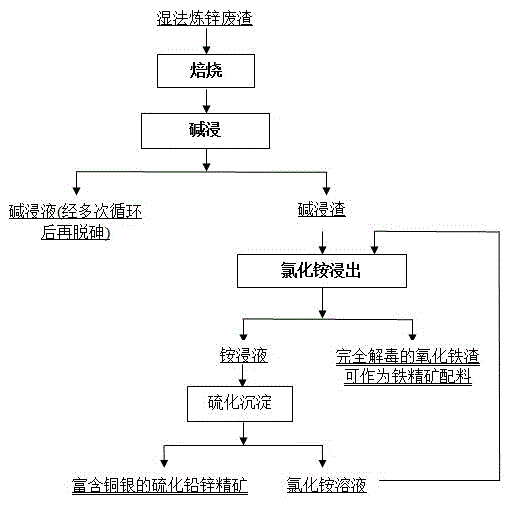

Method used

Image

Examples

Embodiment 1

[0045]

[0046] (1) Boil the yellow potassium iron residue for 1 hour at a temperature of 650 ° C, so that the alum or iron saccinogenic phase in the residue is converted into zinc sulfate, lead sulfate, and iron oxide.2 The first line shown in the first line.

[0047]

[0048] Note: The "^" in the table indicates that the unit is G / T (solid phase) or PPM (liquid phase) "-" indicates that the detected amount is extremely low, and "*" indicates that it is not detected (mainly SO in the solution. 4 2- The content is unbelievable).

[0049] (2) Press the sodium hydroxide solution with a concentration of 50 g / L with a concentration of 50 g / L. The roast residue obtained in the steps at 100 ° C (1) The solid liquid is separated by the solid fluidThe liquid and alkaline immersion return cycle utilization; the ingredients of the obtained immersion slag are shown in Table 2.The slag rate is 85%, and the immersion rate of arsenic reaches 72%.

[0050] When the alkaline immersion is...

Embodiment 2

[0056] Zn PB FE AG^ CU AS CD SIO 2 So 4 2- Before roasting % 8.46 3.00 24.88 60 0.18 0.1 0.08 13.34 37.29

[0057] Note:^Indicates that the data unit is G / T.

[0058] (1) Boil the lead silver residue for 1.5 hours at 550 ° C, and convert the iron or iron of zinc in the residue into zinc sulfate, lead sulfate, and iron oxide.The first line shown.

[0059]

[0060] Note: The "^" in the table indicates that the unit is G / T (solid phase) or PPM (liquid phase) "-" indicates that the detected amount is extremely low, and "*" indicates that it is not detected (mainly SO in the solution. 4 2- The content is unbelievable).

[0061] (2) Press the sodium hydroxide solution with a concentration of 30 g / L with a concentration of 30 g / L. The roast residue obtained in the step of immersed in 160 ° C is 1.2 hours.The liquid and alkaline immersion return cycle utilization; the ingredients of the obtained immersion slag are shown in Table 4.The slag rate i...

Embodiment 3

[0066] (2) According to the solid fluid ratio 1:10, the concentration of 100 g / L sodium hydroxide solution is immersed in steps at 30 ° C (1) The roasting residue obtained in the roasting residue is 0.5 hours, and the solid fluid is separated from the alkali dip and the alkaline immersion fluid.The alkaline immersion liquid returns cyclic use; when the alkaline immersion is used, when the concentration is less than 100 g / L, the recycling of sodium hydroxide adjustment to 100g / L is added before recycling.

[0067] (3) Step (2) the obtained alkaline dipping residue according to the solid fluid ratio 1:10 in the mixture of 90 ° C (100g / L) and ammonia (ammonia water concentration 1g / L) in a mixed solution(Moore ratio of ammonium ions and chloride ions in the mixed solution is 2: 1), and after filtering, the ammonium chloride is immersed and immersed;

[0068] (4) The total Moore of copper, lead, cadmium, and silver in the ammonium chloride out exfoliating solution is 0.5 times the zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com