Preparation method and application of fluorescent molecularly imprinted adsorption separation material

A technology for adsorption and separation materials and fluorescent molecules, which is applied in the field of preparation of fluorescent molecular imprinted adsorption and separation materials, and can solve the problems of unsatisfactory selectivity of sensors and probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

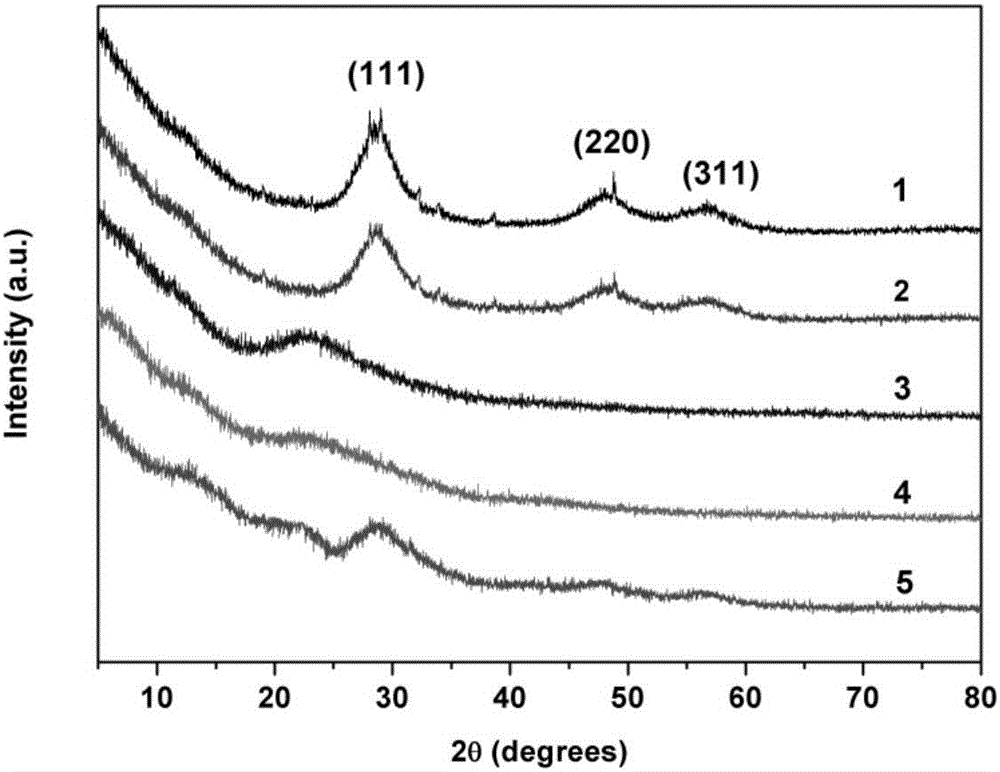

Image

Examples

Embodiment 1

[0038] Step 1. SiO 2 Synthesis of Nanoparticles and Manganese-doped ZnS Quantum Dots

[0039] SiO 2 Nanoparticles are in Method based synthesis. Briefly, 30 mL of ethanol and 20 mL of ammonia water (6% by mass) were added to 50 mL of distilled water, and magnetically stirred at room temperature. Then, 5 mL of TEOS and 20 mL of ethanol were added to the solution, and the stirring was continued for 6 h. The product was washed with ethanol and obtained by centrifuge. Finally, it was dried under vacuum at 60°C.

[0040] 1.8g ZnSO 4 ·7H 2 O, 0.1 g MnCl 2 4H 2 O, and 20mL of distilled water were added to a 50mL round-bottomed flask under N 2 Stir at room temperature for 10 min under protection to mix well. Contains 5g Na 2 S·9H 2 5 mL of aqueous solution of O was added dropwise to the above solution, and the stirring was continued for 12 h. Finally, the product was washed three times with ethanol and water, and dried under vacuum at 60 °C.

[0041] Step 2, double bon...

Embodiment 2

[0047] Step 1. SiO 2 Synthesis of Nanoparticles and Manganese-doped ZnS Quantum Dots

[0048] SiO 2 Nanoparticles are in Method based synthesis. Briefly, 30 mL of ethanol and 20 mL of ammonia water (6% by mass) were added to 50 mL of distilled water, and magnetically stirred at room temperature. Then, 5 mL of TEOS and 20 mL of ethanol were added to the solution, and the stirring was continued for 6 h. The product was washed with ethanol and obtained by centrifuge. Finally, it was dried under vacuum at 60°C.

[0049] 1.8g ZnSO 4 ·7H 2 O, 0.1 g MnCl 2 4H 2 O, and 20mL of distilled water were added to a 50mL round-bottomed flask under N 2 Stir at room temperature for 10 min under protection to mix well. Contains 5g Na 2 S·9H 2 5 mL of aqueous solution of O was added dropwise to the above solution, and the stirring was continued for 12 h. Finally, the product was washed three times with ethanol and water, and dried under vacuum at 60 °C.

[0050] Step 2, double bon...

Embodiment 3

[0056] Step 1. SiO 2 Synthesis of Nanoparticles and Manganese-doped ZnS Quantum Dots

[0057] SiO 2 Nanoparticles are in Method based synthesis. Briefly, 30 mL of ethanol and 20 mL of ammonia water (6% by mass) were added to 50 mL of distilled water, and magnetically stirred at room temperature. Then, 5 mL of TEOS and 20 mL of ethanol were added to the solution, and the stirring was continued for 6 h. The product was washed with ethanol and obtained by centrifuge. Finally, it was dried under vacuum at 60°C.

[0058] 1.8g ZnSO 4 ·7H 2 O, 0.1 g MnCl 2 4H 2 O, and 20mL of distilled water were added to a 50mL round-bottomed flask under N 2 Stir at room temperature for 10 min under protection to mix well. Contains 5g Na 2 S·9H 2 5 mL of aqueous solution of O was added dropwise to the above solution, and the stirring was continued for 12 h. Finally, the product was washed three times with ethanol and water, and dried under vacuum at 60 °C.

[0059] Step 2, double bon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com