Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148 results about "Tellurium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tellurium oxide may refer to either of these: Tellurium monoxide, TeO Tellurium dioxide, TeO₂ Tellurium trioxide, TeO₃

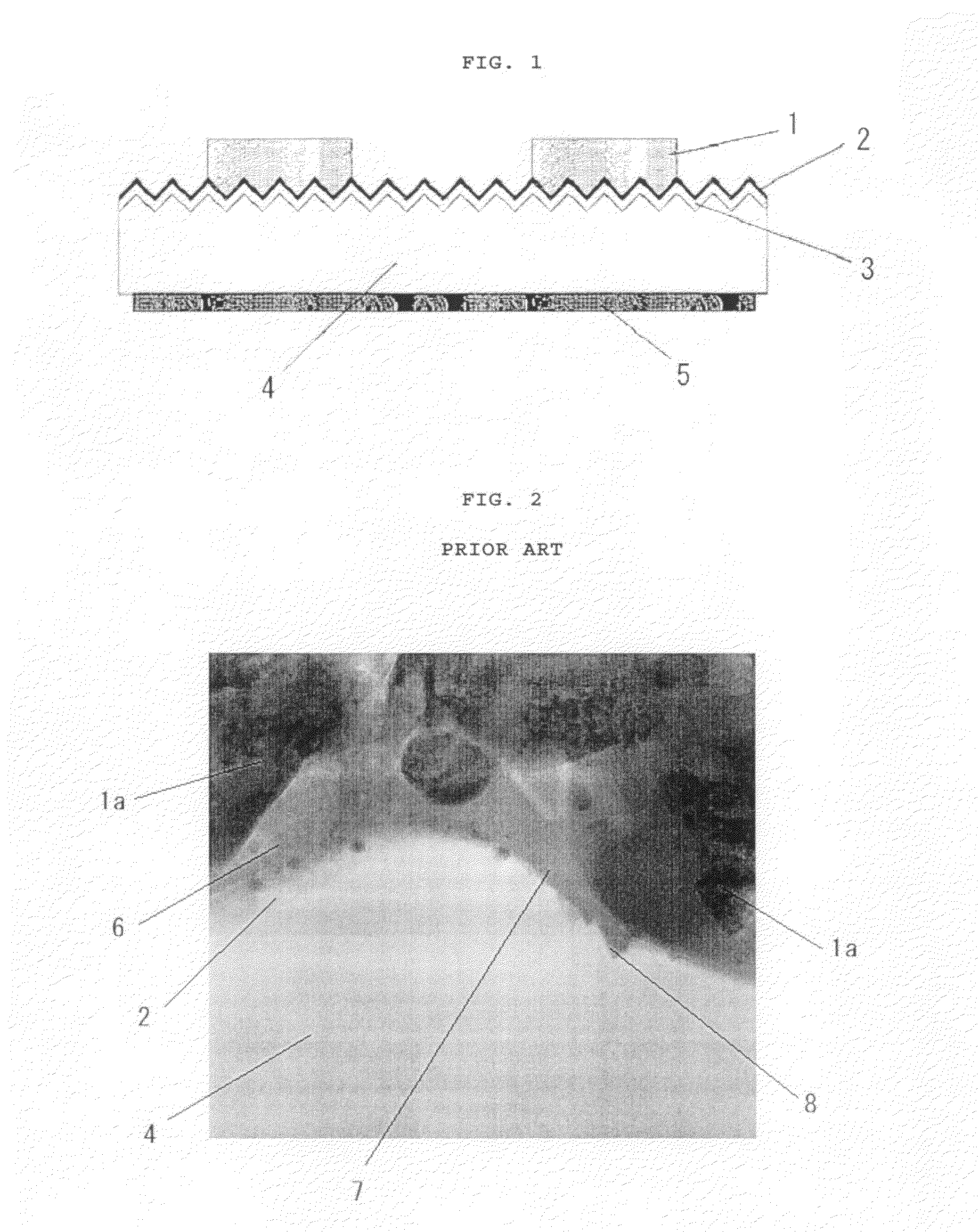

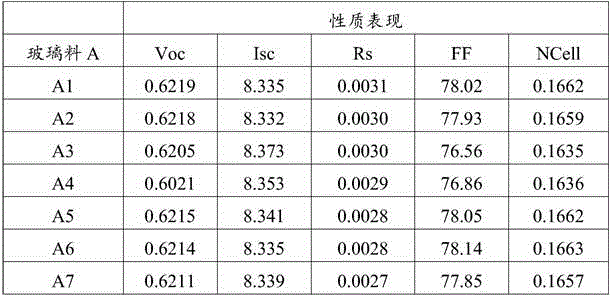

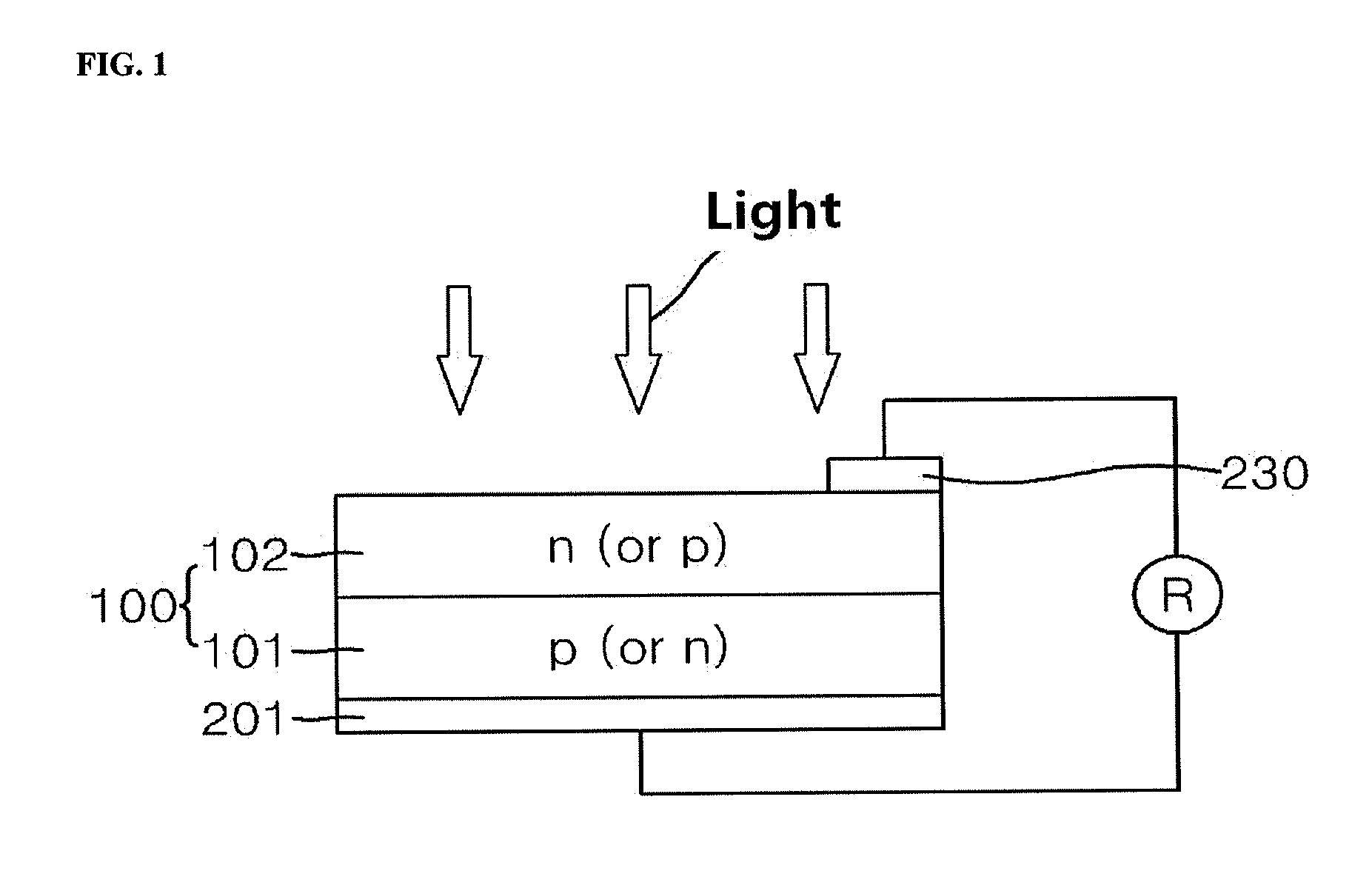

Conductive paste for forming a solar cell electrode

ActiveUS20110095240A1Good solar cell characteristicConductive materialNon-conductive material with dispersed conductive materialConductive pasteFrit

A conductive paste for forming a solar cell electrode, including: a conductive powder comprising silver as a main component; glass frit; and an organic vehicle, wherein the glass frit contains tellurium glass frit having tellurium oxide as a network-forming component. The conductive paste of the present invention makes it possible to form a solar cell electrode having a low dependence on firing temperature without causing problems due to fire-through into the substrate, and to thereby obtain a solar cell having good solar cell characteristics.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD +1

Thick-film pastes containing lead- and tellurium-oxides, and their use in the manufacture of semiconductor devices

ActiveUS20110308595A1Transportation and packagingSemiconductor/solid-state device detailsTe elementOrganic media

Owner:SOLAR PASTE LLC

Glass powder and its preparation method and conductive paste for solar cell

ActiveCN102476919AConvenient sourceImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialSemiconductor devicesEngineeringSelenium Oxide

The invention provides glass powder, which comprises bismuth oxide 30wt%-70wt%, titanium oxide 1wt%-20wt%, zinc oxide 5wt%-40wt%, antimony oxide 5wt%-30wt% optional tellurium oxide 0wt%-30wt%, optional molybdenum oxide 0wt%-10wt% and selenium oxide 0wt%-15wt%. The invention also relates to a preparation method of the glass powder and conductive paste for solar cell prepared from the glass powder. The inventive glass powder contains no lead and boron, does no harm to the environment and can be used for preparing conductive paste for solar cell with high photoelectric conversion efficiency.

Owner:BYD CO LTD

Conductive paste for forming a solar cell electrode

ActiveUS8551368B2Good solar cell characteristicConductive materialNon-conductive material with dispersed conductive materialConductive pasteFrit

A conductive paste for forming a solar cell electrode, including: a conductive powder containing silver as a main component; glass frit; and an organic vehicle, wherein the glass frit contains tellurium glass frit having tellurium oxide as a network-forming component. The conductive paste of the present invention makes it possible to form a solar cell electrode having a low dependence on firing temperature without causing problems due to fire-through into the substrate, and to thereby obtain a solar cell having good solar cell characteristics.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD +1

Conductive paste and method for manufacturing same

ActiveCN104575661ATo achieve the effect of energy savingImprove conversion efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilicon oxideSilicon dioxide

Owner:GIGA SOLAR MATERIALS

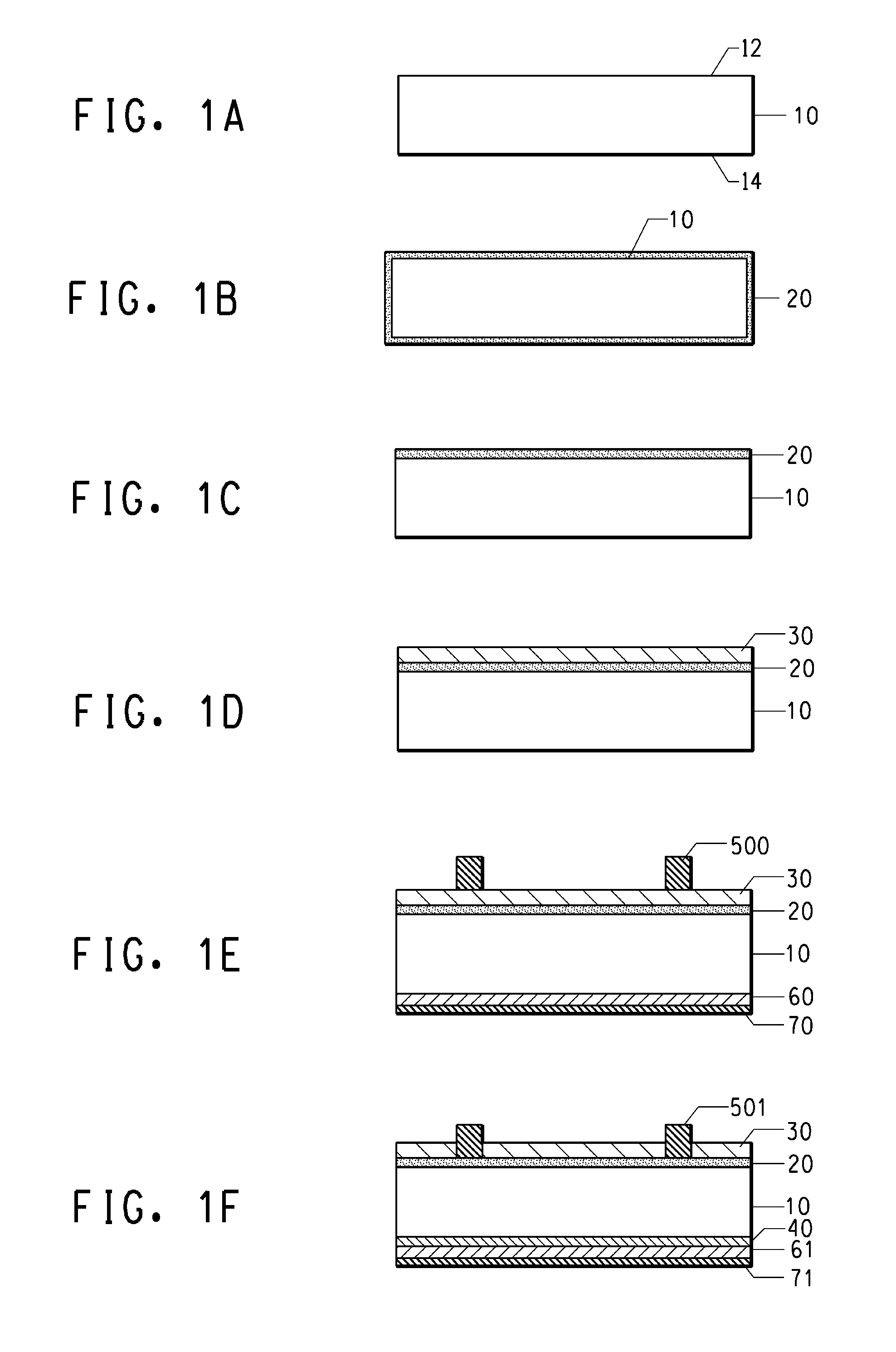

Conductive Paste for Solar Cell and the Method Thereof

InactiveUS20150115207A1Enhance performance of conversion efficiencyImprove conversion efficiencyConductive materialNon-conductive material with dispersed conductive materialSilicon oxideTellurium dioxide

The present invention discloses a conductive paste for solar cell, including the following composition: silver particle and two glass frits. A glass frit (I) comprises bismuth oxide, tellurium oxide, tungsten oxide, silicon oxide, and zinc oxide; and a glass frit (II) comprises lead oxide, tellurium oxide, and zinc oxide. The conductive paste is utilized to form the electrode of the substrate for solar cell to enhance the performance of Ohmic contact, fill factor and conversion efficiency of the solar cell, after sintering.

Owner:GIGA SOLAR MATERIALS

Method for preparing tellurium dioxide from tellurium slag

InactiveCN102390819AMain grade improvedSave resourcesBinary selenium/tellurium compoundsPregnant leach solutionSlag

The invention relates to a method for preparing tellurium dioxide from tellurium slag. According to the technical scheme, the method comprises the following steps of: adding tellurium slag to sulfuric acid solution, stirring at normal temperature, adding 10% oxydol at the temperature of 30-40 DEG C, and then heating to 80-90 DEG C, and leaching under normal pressure; adding copper powder to leachate, carrying out replacement reaction at the temperature of 90-95 DEG C for 2 hours, and carrying out solid-liquid separation to obtain copper telluride slag; adding copper telluride slag to sulfuricacid solution, adding 10% oxydol, stirring at the temperature of 90 DEG C for 1 hour, and filtering; adding sodium carbonate to filtrate for neutralizing the filtrate till pH of the filtrate is 3, and filtering; adding NaOH to filter residue, carrying out alkali leaching and stirring at the temperature of 85-95 DEG C for 1 hour, and filtering; and adding H2SO4 to filtrate for neutralizing the filtrate till pH of the filtrate is 6-7, filtering, washing and drying to obtain a product. The method has the characteristics that: low-grade tellurium-containing material discarded by a copper anode mud production enterprise is used as a raw material to produce high-purity tellurium dioxide, the process is reasonable and pollution-free, and the recovery rate of tellurium is high.

Owner:LIAONING UNIVERSITY

Hot pressed sintering high-purity zirconia composite ceramic and preparation method thereof

The invention provides a zirconia composite tough material with adjustable toughness and low price. The tough ceramic is prepared by complex powder of high-purity zirconia doped with at least one of hafnium oxide, yttrium oxide, cerium oxide, calcium oxide, magnesium oxide, aluminum oxide, titanium oxide, silicon oxide, cobalt oxide, iron oxide, scandium oxide, vanadium oxide, manganese oxide, nickel oxide, copper oxide, zinc oxide, niobium oxide, molybdenum oxide, indium oxide, stannic oxide, barium oxide, tantalum oxide, tungsten oxide, lanthanum oxide, praseodymium oxide, neodymium oxide, tellurium oxide, terbium oxide, europium oxide and erbium oxide. The preparation method comprises the following steps: dispersing the zirconia composite powder by using a high energy ball milling method, and adding the dispersed powder into a graphite mold for performing hot pressed sintering treatment, thereby obtaining the high-purity zirconia composite ceramic.

Owner:南京金鲤新材料有限公司

Method for comprehensively recovering valuable metal from copper tellurium slag

InactiveCN102994766AReduce the impactReduce pollutionProcess efficiency improvementBinary selenium/tellurium compoundsFractional PrecipitationSlag

The invention discloses a method for comprehensively recovering valuable metal from copper tellurium slag. The copper tellurium slag is dissolved by using nitric acid, so that silver, copper and bismuth in the copper tellurium slag are basically dissolved in a solution; tellurium is oxidized into tellurium oxide, thereby entering undissolved slag. Silver, copper and bismuth are separated and recovered via fractional precipitation of the solution; and tellurium is separated and recovered via alkaline leaching of the undissolved slag. The method solves the problems that cost of a conventional process is high, copper recovery rate and tellurium recovery rate are not high, and that silver and bismuth cannot be recovered in the conventional process; influences on the environment of the production process are reduced; a whole process is simple; and pollutions toward the environment is small. The method is simple in the whole production process, low in cost and small pollutions toward the environment, has high comprehensive recovery rate, and realizes complete separation of silver, copper, bismuth and tellurium. The obtained products have high purity; and the recovery rate of silver, copper, bismuth and tellurium is higher than 99%.

Owner:SIHUI CITY HONGMING PRECIOUS METALS

Conductive Paste And Method For Producing Solar Cell By Using The Same

ActiveCN106098138AImprove conversion efficiencyImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialPhotovoltaic energy generationConductive pasteFrit

The present invention relates to a conductive paste and a method for producing solar cell by using the same. The conductive paste comprises at least silver powders and a composite glass frit comprising a first type of glass frit containing lead oxides and silicon oxides and a second type of glass frit containing tellurium oxides and zinc oxides wherein the first type of glass frit and the second type of glass frit are in a weight ratio of 93:7 to 44:56.

Owner:GIGA SOLAR MATERIALS

Conductive Thick Film Paste For Solar Cell Contacts

The present invention relates to an inorganic reaction system used in the manufacture of electroconductive pastes. The inorganic reaction system comprises a lead containing matrix forming composition and a tellurium oxide additive. Preferably the lead containing matrix forming composition is between 5-95 wt. % of the inorganic reaction system, and the tellurium oxide additive is between 5-95 wt. % of the inorganic reaction system. The lead containing matrix forming composition may be a glass frit, and may comprise lead oxide. Another aspect of the present invention relates to an electroconductive paste composition that comprises metallic particles, an inorganic reaction system as previously disclosed, and an organic vehicle. Another aspect of the present invention relates to an organic vehicle that comprises one or more of a binder, a surfactant, a solvent, and a thixatropic agent. Another aspect of the present invention relates to a solar cell printed with an electroconductive paste composition as disclosed, as well as an assembled solar cell module. Another aspect of the present invention relates to a method of producing a solar cell.

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

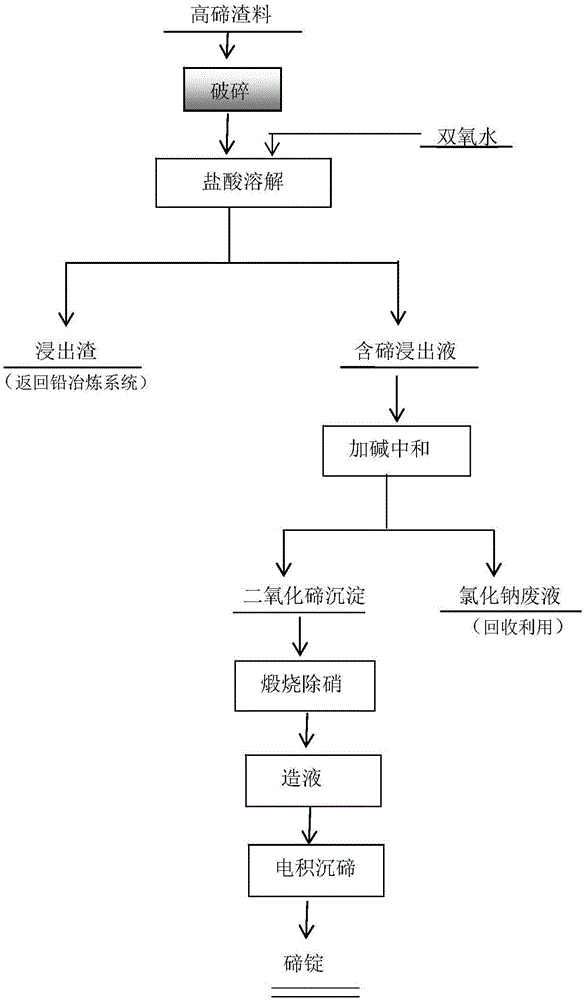

Method for recovering tellurium from high-tellurium residues

ActiveCN106381399AEfficient recyclingReduce consumptionElectrolysis componentsProcess efficiency improvementPregnant leach solutionLead smelting

The invention discloses a method for recovering tellurium from high-tellurium residues in an efficient and environment-friendly mode. The method includes the steps of breaking the high-tellurium residues, slowly adding hydrochloric acid and hydrogen peroxide into the high-tellurium residues, controlling the temperature and continuously stirring to carry out oxidizing leaching; carrying out liquid-solid separation after the residues are completely dissolved, wherein tellurium oxide as the major element enters leaching solutions, valuable metal such as Pb and Ag enters leaching residues in the mode of chloride salt, and lead and silver residues return to a lead smelting system to recover the valuable metal; and adjusting the pH value of the tellurium-containing leaching solutions to be 5.0-6.0 through sodium hydroxide solutions, obtaining TeO2 sediments, carrying out liquid preparation after TeO2 is roasted and nitrate is removed and returning to the electrodeposition process to directly recover the tellurium. According to the method, the high-tellurium residues is directly leached to recover the tellurium through the hydrochloric acid and the hydrogen peroxide, the direct recovery rate of the tellurium can reach above 95%, so that efficient recovery of the tellurium is realized, the recovery rate of silver can reach above 99.0%, and the recovery rate of lead can reach above 97.6%. The method has the advantages that the technological processes are simple, needed equipment is reduced, the production cost is low, the environment friendliness is high and the comprehensive recovery degree is high, thereby having wide application prospects.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

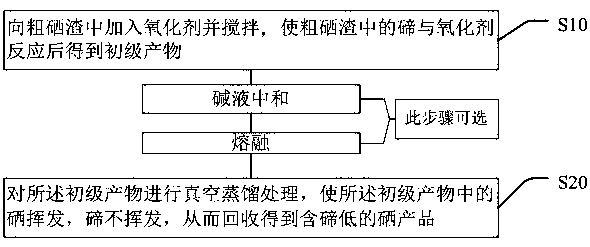

Method for removing tellurium from crude selenium slag

The invention discloses a method for removing tellurium from crude selenium slag. The method comprises the following steps: an oxidizing agent is added to the crude selenium slag and stirred, a primary product is obtained after tellurium in the crude selenium slag is subjected to a reaction with the oxidizing agent, vacuum distillation is performed on the primary product to enable selenium in theselenium slag to be volatilized while tellurium is not volatilized, and a selenium product with low tellurium content is obtained by recovery. The oxidizing agent is added to the crude selenium slag and subjected to an oxidation reaction with tellurium in the crude selenium slag, and accordingly, form of tellurium is changed; based on the property difference between tellurium oxide in the changedform and selenium in a vacuum state, tellurium is removed from selenium by vacuum distillation, content of tellurium in selenium is reduced, and the selenium product with purity higher than 99.9% is obtained.

Owner:KUNMING DIBOO TECH

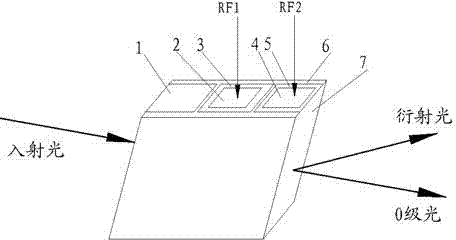

Transverse wave acousto-optic devices using tellurium oxide as the acousto-optic medium

The invention discloses a transverse wave acousto-optic device using tellurium oxide as the acousto-optic medium, comprising a surface electrode, a transducer, a bonding layer and an acousto-optic medium, the transducer is bonded to the surface of the acousto-optic medium through the bonding layer, The surface electrode is plated on the surface of the transducer; the acousto-optic medium is tellurium oxide crystal, the transducer is lithium niobate, and the included angle θ between the thickness direction of lithium niobate and the Y axis is 163±5°. Under the same process conditions, the present invention respectively uses X-cut lithium niobate and 163±5°Y-cut lithium niobate to make transverse wave acousto-optic devices on tellurium oxide crystals. Under the same temperature range, 163±5°Y-cut lithium niobate The cracks produced by lithium are about one-fifth of that of X-cut lithium niobate, which greatly improves the reliability of tellurium oxide transverse wave acousto-optic devices.

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

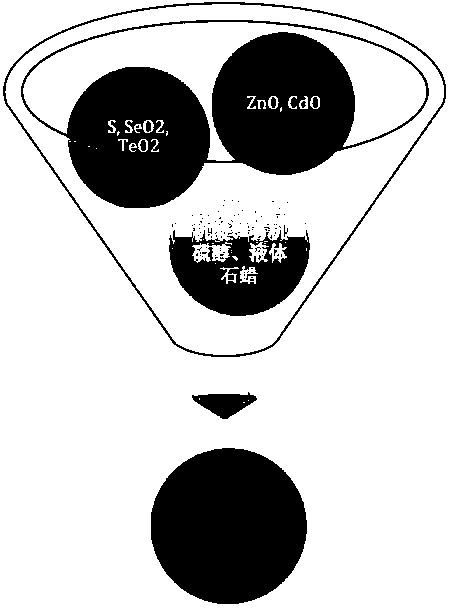

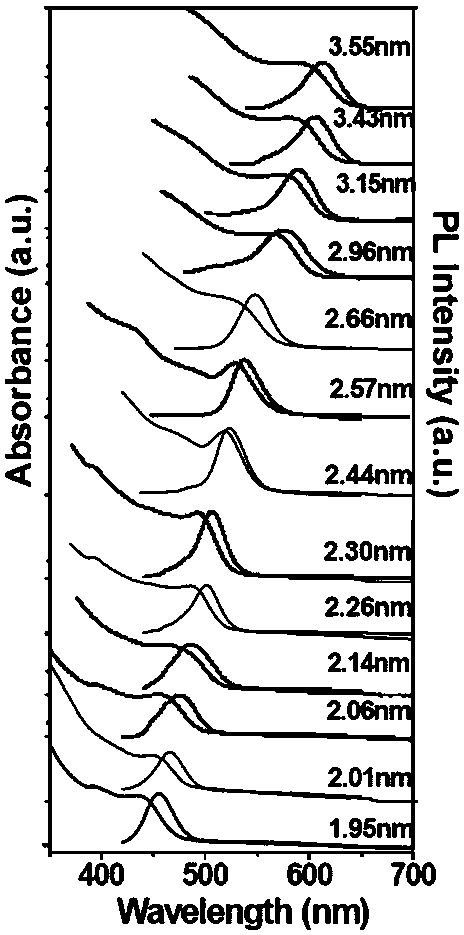

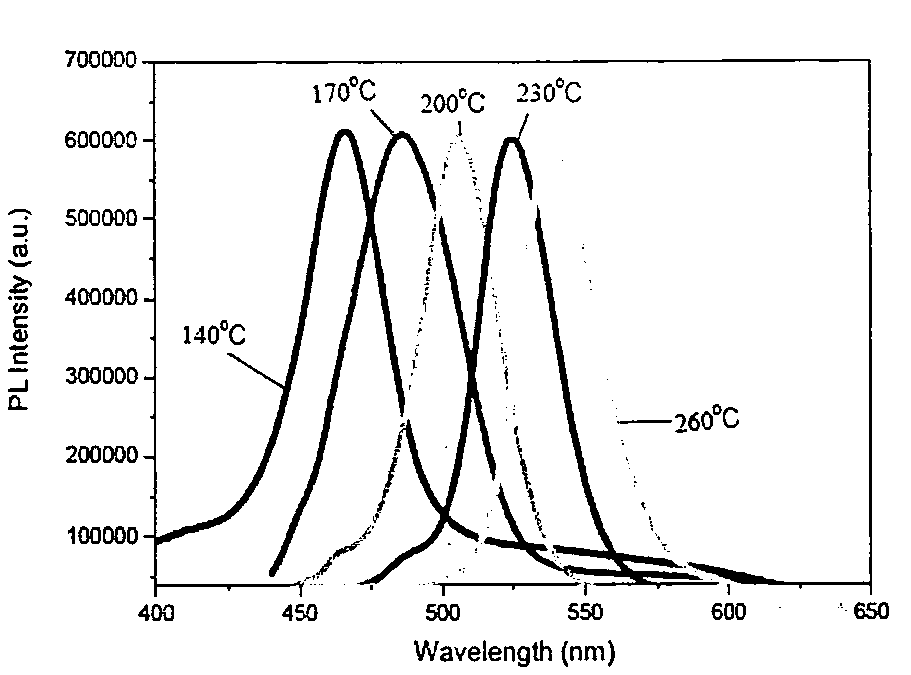

Efficient light-emitting sulfur selenium tellurium zinc cadmium/zinc sulfide quinary alloy core-shell structure quantum dot material and preparation method

ActiveCN107794044ALow priceStable chemical structureMaterial nanotechnologyNanoopticsQuantum yieldTe element

The invention discloses an efficient light-emitting sulfur selenium tellurium zinc cadmium / zinc sulfide quinary alloy core-shell structure quantum dot material and a preparation method. Liquid paraffin serves as a solvent, powdered sulfur serves as a sulfur source, selenium oxide powder serves as a selenium source, tellurium oxide serves as a tellurium powder source, zinc oxide serves as a zinc source, cadmium oxide serves as a cadmium source, liquid organic amine, liquid organic acid and liquid mercaptan serve as stabilizers, and heating reaction is performed in inert gas atmosphere to prepare an inner core of a sulfur selenium zinc cadmium telluride quinary alloy core. The liquid organic amine serves as a solvent, alkyl sulfhydryl serves as a sulfur source, zinc fatty acid serves as a zinc source, and heating reaction is performed in the inert gas atmosphere to grow a zinc sulfide shell. ZnCdSSeTe / ZnS quinary alloy core-shell structure quantum dots with adjustable light-emitting peakpositions, uniform shapes and sizes and high fluorescence quantum yield are controllably prepared by low-cost reaction raw materials and reaction solvents.

Owner:苏州帝格欣新材料科技有限公司

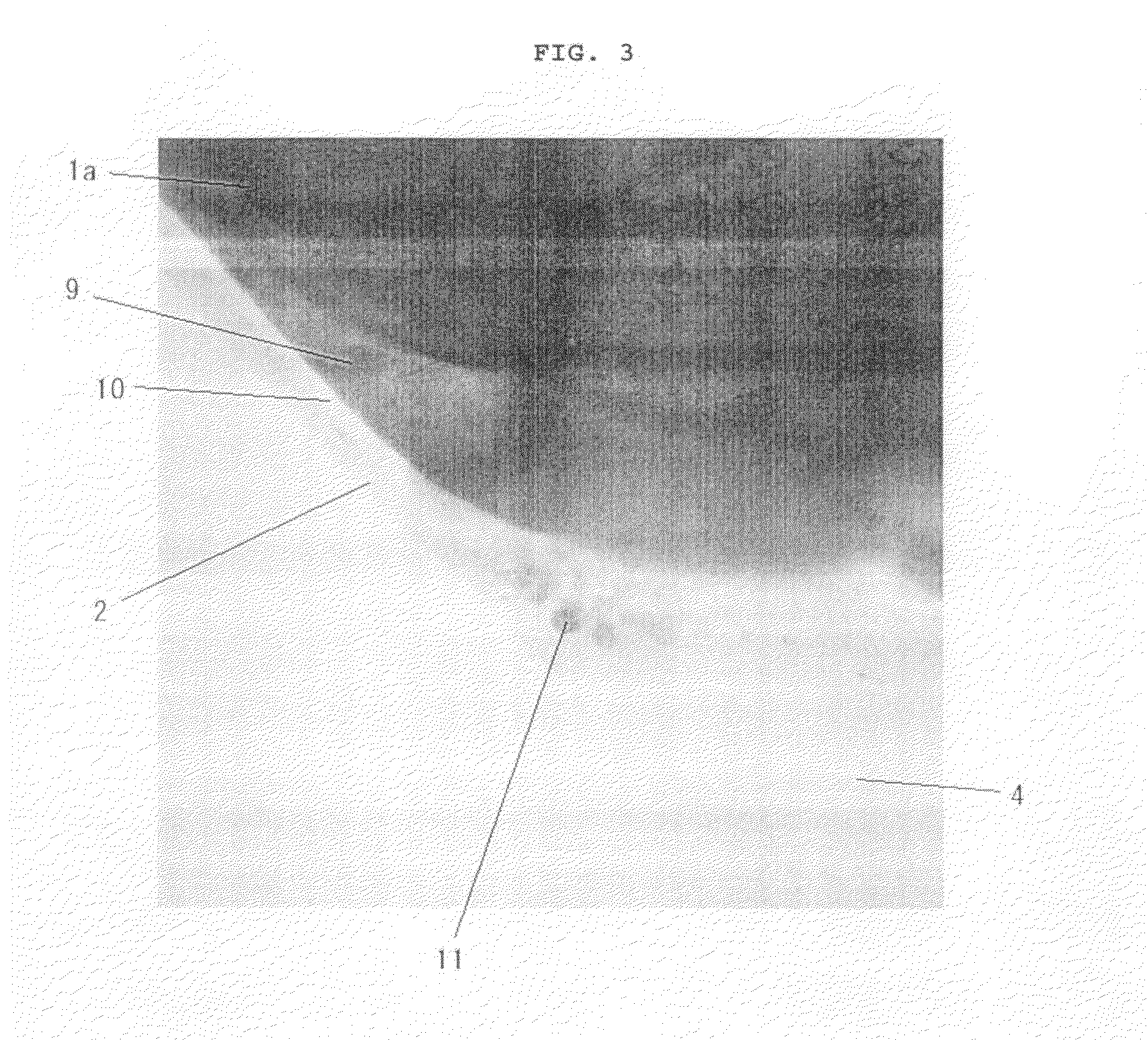

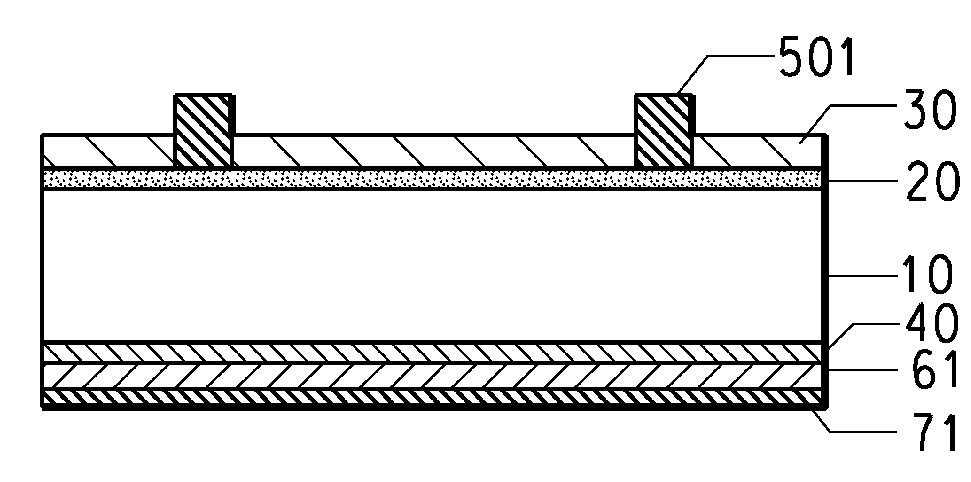

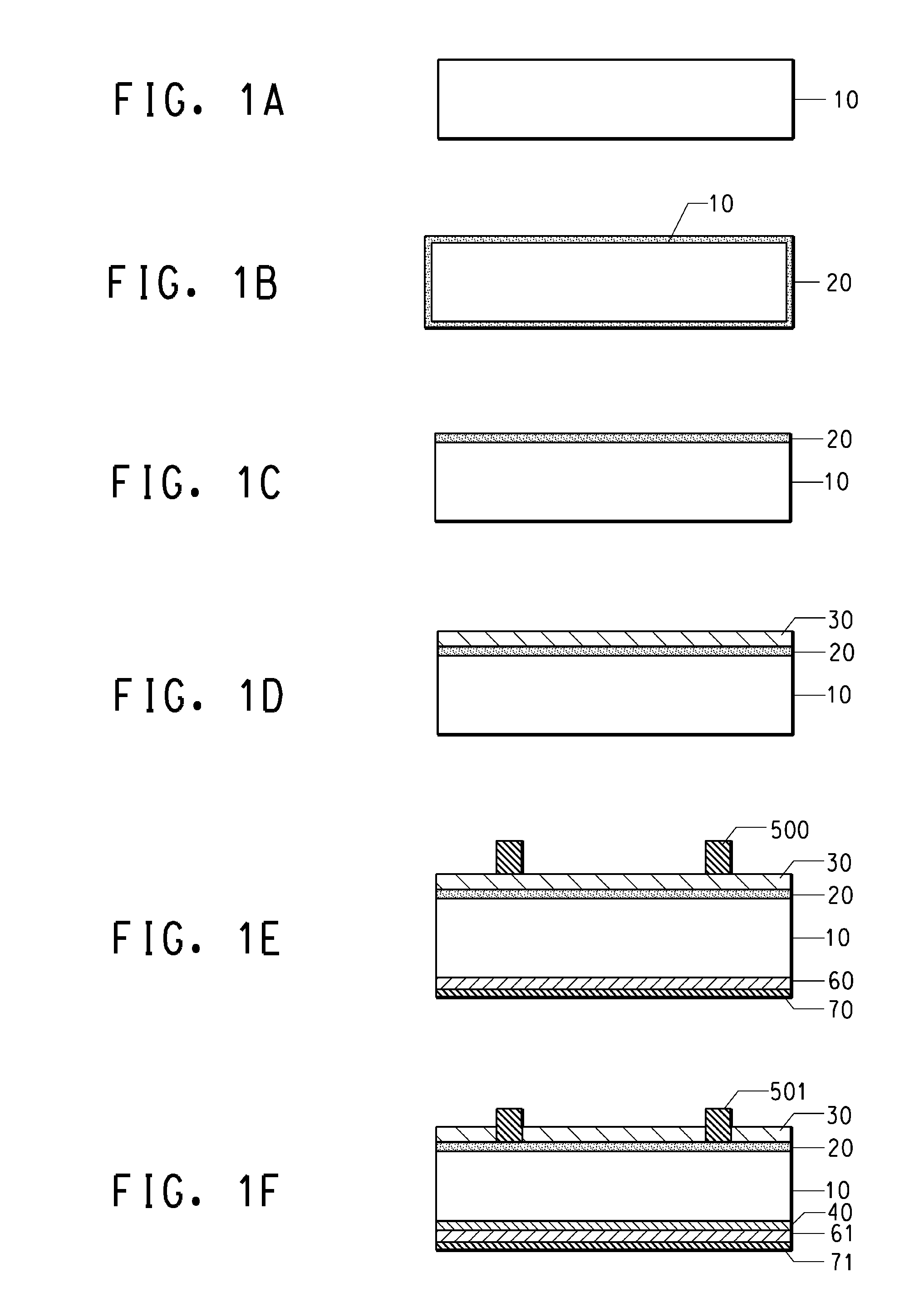

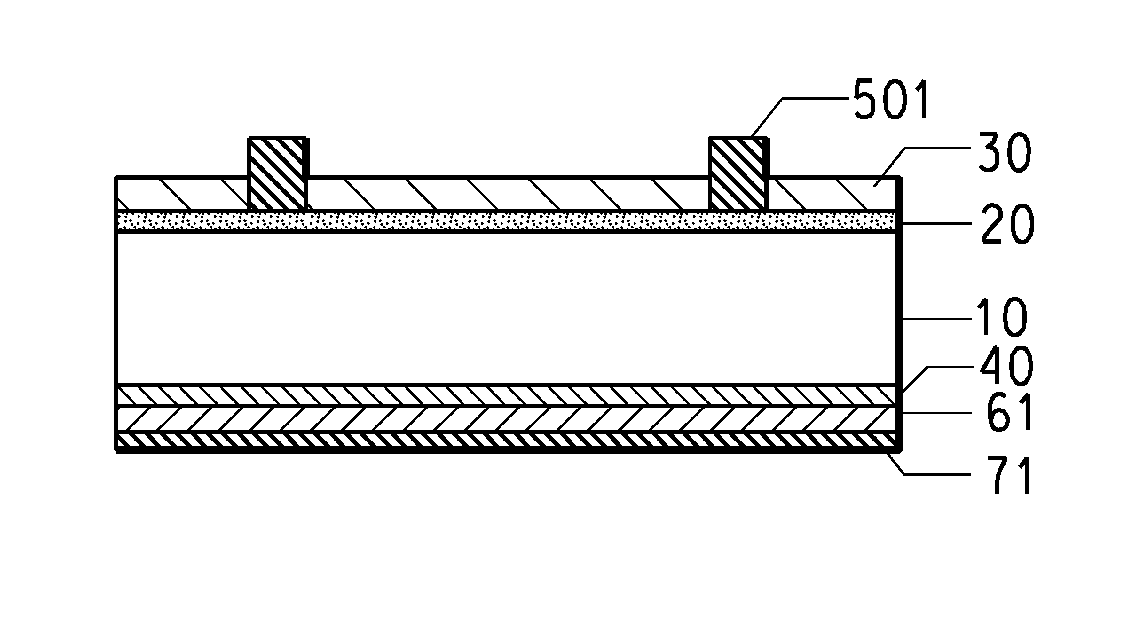

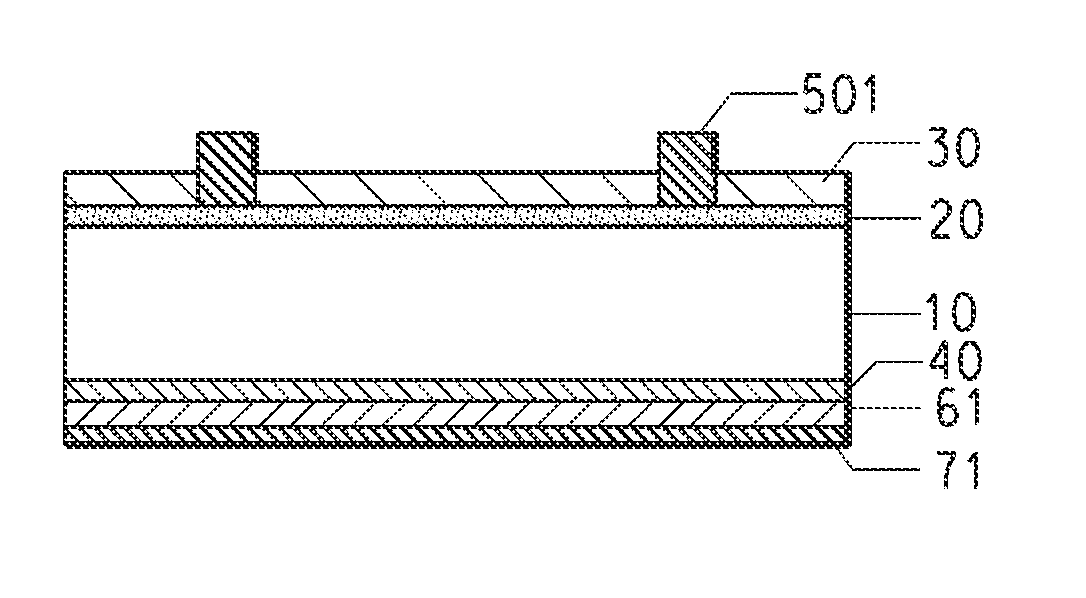

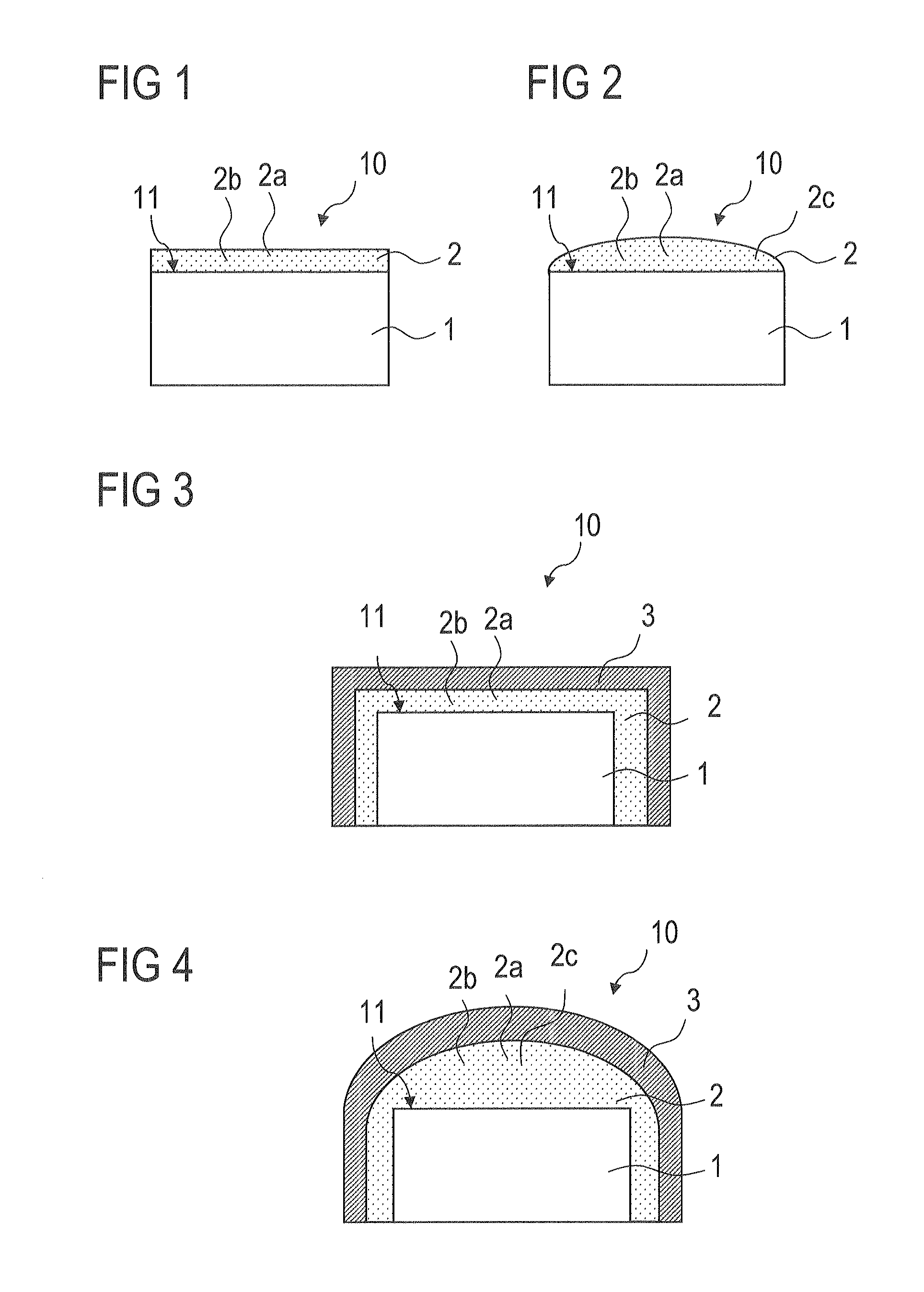

Electronic Component, Method for Producing Same, and Sealing Material Paste Used in Same

ActiveUS20150187510A1Reduce heat damageImprove reliabilityNon-macromolecular adhesive additivesNatural resin coatingsPhosphoric acidSolvent

An electronic component has an organic member between two transparent substrates, in which outer peripheral portions of the two transparent substrates are bonded by a sealing material containing to melting glass. The low melting glass contains vanadium oxide, tellurium oxide, iron oxide and phosphoric acid, and satisfies the following relations (1) and (2) in terms of oxides. The sealing material is formed of a sealing material paste which contains the low melting glass, a resin binder and a solvent, the low melting glass containing vanadium oxide, tellurium oxide, iron oxide and phosphoric acid, and satisfies the following relations (1) and (2) in terms of the oxides. Thereby, thermal damages to an organic element or an organic material contained in the electronic component can be reduced and an electronic component having a glass bonding layer of high reliability can be produced efficiently.V2O5+TeO2+Fe2O+P2O5≧90(mass %) (1)V2O5>TeO2>Fe2O3>P2O5(mass %) (2)

Owner:RESONAC CORP

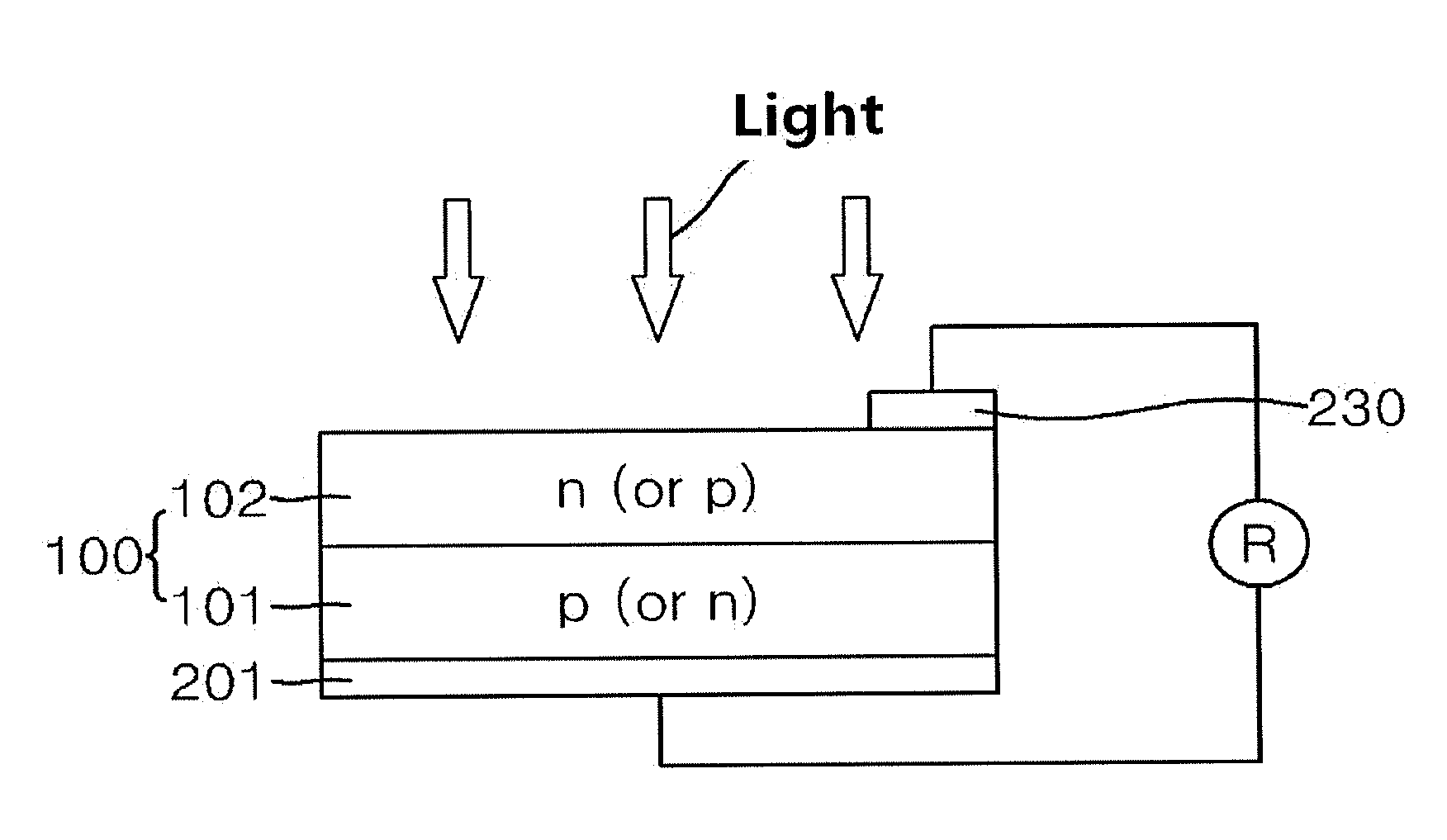

Conductive paste composition and semiconductor devices made therewith

A conductive paste composition contains a source of an electrically conductive metal, an alkaline-earth-metal boron tellurium oxide, and an organic vehicle. An article such as a high-efficiency photovoltaic cell is formed by a process of deposition of the paste composition on a semiconductor device substrate (e.g., by screen printing) and firing the paste to remove the organic vehicle and sinter the metal and establish electrical contact between it and the device.

Owner:SOLAR PASTE LLC

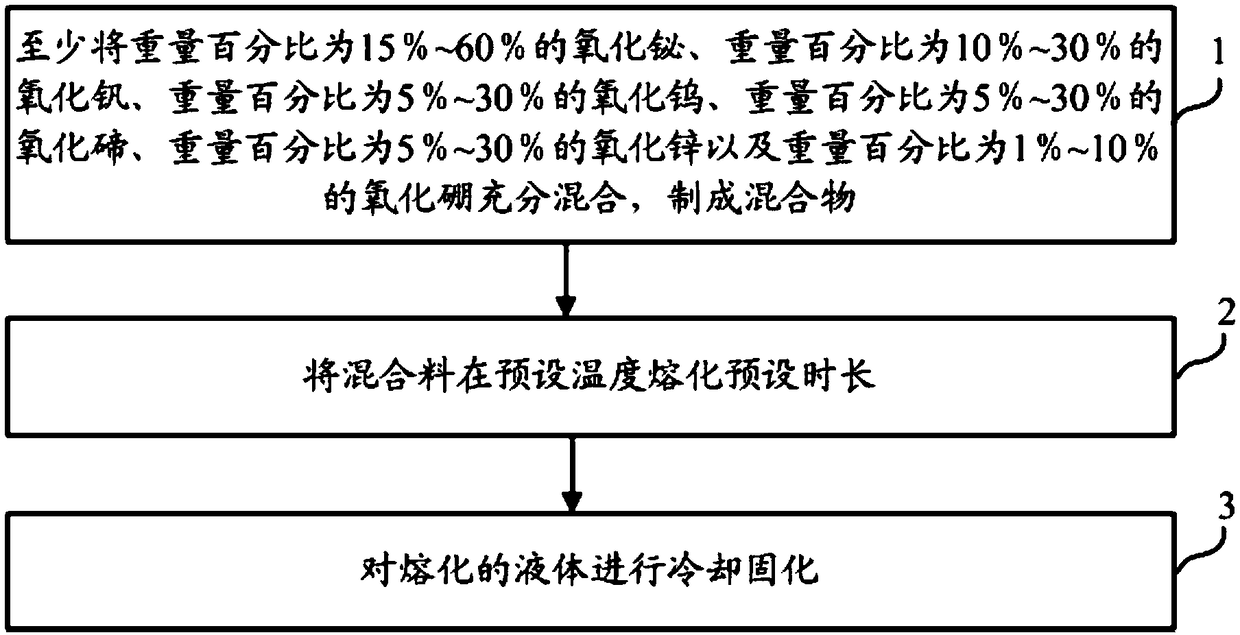

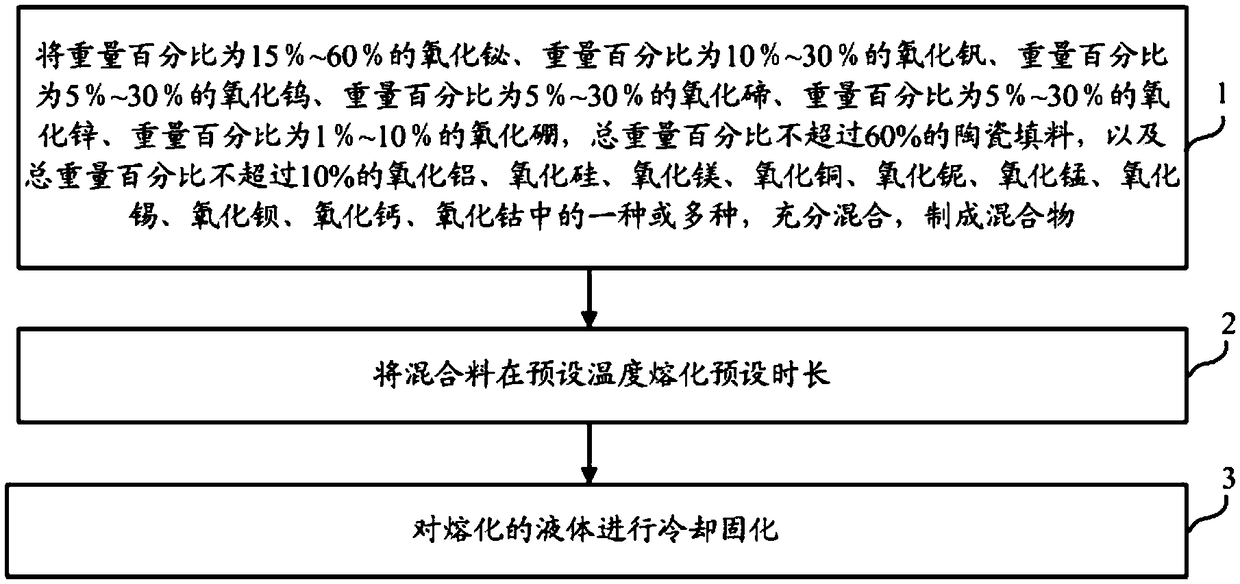

Lead-free sealing glass, sealing device and production method of lead-free sealing glass

The invention discloses lead-free sealing glass, a sealing device and a production method of the lead-free sealing glass and aims to provide sealing glass which contains no lead and has lower expansion coefficient. The lead-free sealing glass is at least prepared from, in percentage by weight, 15%-60% of bismuth oxide, 10%-30% of vanadium oxide, 5%-30% of tungsten oxide, 5%-30% of tellurium oxide,5%-30% of zinc oxide and 1%-10% of boron oxide through mixing and melting.

Owner:BEIJNG ASAHI ELECTRONICS MATERIAL CO LTD

Composition for forming electrode of solar cell and electrode formed thereof

ActiveUS20160013331A1Reduced series resistanceIncrease the open circuit voltageConductive materialNon-conductive material with dispersed conductive materialLithium oxideFrit

Disclosed herein is a composition for solar cell electrodes. The composition includes a conductive powder, a glass frit, and an organic vehicle, wherein the glass frit is a bismuth oxide-tellurium oxide-zinc oxide-lithium oxide-based glass frit comprising: 5 wt % to 20 wt % of bismuth oxide; 55 wt % to 80 wt % of tellurium oxide; 0.1 wt % to 15 wt % of zinc oxide; and 0.1 wt % to 10 wt % of lithium oxide. Solar cell electrodes formed of the composition have low serial resistance (Rs) and high open voltage (Voc), thus providing high conversion efficiency and good adhesive strength with respect to a ribbon.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD

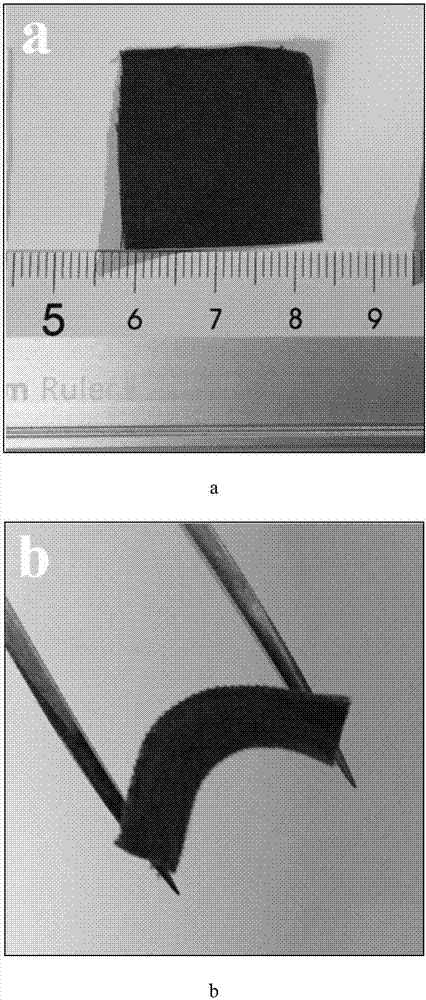

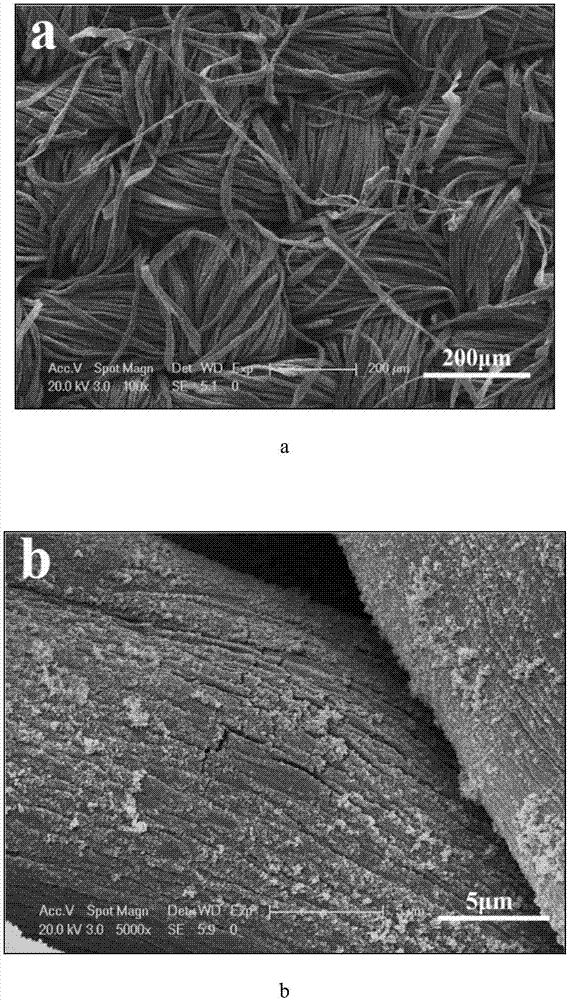

Preparation method for flexible fabric composite thermoelectric material

ActiveCN107039576ASignificant technological progressImprove thermoelectric performanceMaterial nanotechnologyThermoelectric device manufacture/treatmentWater bathsThermoelectric materials

The present invention belongs to the field of material science and provides a preparation method for flexible Bi2Te3 / PEDOT: PSS / fabric composite thermoelectric material. The preparation method comprises the following steps: weighing tartrate, bismuth nitrate pentahydrate, tellurium dioxide, potassium hydroxide and deionized water according to the material ratio, and adding the same to a container to form a mixed solution; then putting the fabric into the solution, performing stirring, adding potassium borohydride, performing continuous stirring for a period of time, stopping stirring and placing and heating the container in a thermostatic waterbath for reaction; after the reaction is completed, repeatedly washing the obtained Bi2Te3 / fabric composite material with deionized water and ethanol and then subjecting the obtained material to vacuum drying, and placing a dried product in dimethyl sulfoxide doping PEDOT: PSS mixed solution for processing; and finally performing vacuum drying to obtain Bi2Te3 / PEDOT: PSS / fabric composite thermoelectric material. The flexible fabric thermoelectric material prepared by the method has a broad application prospect in the field of wearable electronics, and has huge market potential.

Owner:SHANGHAI INST OF TECH

Method for extracting high-purity tellurium oxides from copper anode mud

ActiveCN102502532AEasy to separateHigh purityBinary selenium/tellurium compoundsFiltrationSodium hydroxide

The invention discloses a method for extracting high-purity tellurium oxides from copper anode mud. The method comprises the steps as follows: firstly, sulfuric acid is added in the copper anode mud at first, sodium chlorate is then added in the copper anode mud, the mixture is heated, silver and lead are precipitated in residues and are separated out, and gold, copper, bismuth, tellurium and selenium enter leach liquor; secondly, common salt is added in leach liquor that is processed in the first step, the mixture is mixed and resolved, then gaseous SO2 is pumped in mixed liquor for 1 hour, and gold, tellurium and selenium are reduced and deposited and then are processed through pressure filtration; thirdly, in step A, sulfuric acid is added in deposited residues of the gold, tellurium and selenium, then catalytic agents are added in the mixture, then sodium chlorate is added in the mixture until the color of the deposited residues is transformed into the color of tellurium oxides, and pressure filtration is carried out; in step B, sodium hydroxide is added in the deposited residues that are processed in the step A, the mixture is processed through pressure filtration, and then sodium tellurite and sodium selenite solution are obtained; and fourthly, sulfuric acid is added in sodium tellurite and sodium selenite solution which are obtained in the third step, sodium selenite remains in liquid, and tellurium dioxide is precipitated and separated out.

Owner:湖南省金润碲业有限公司

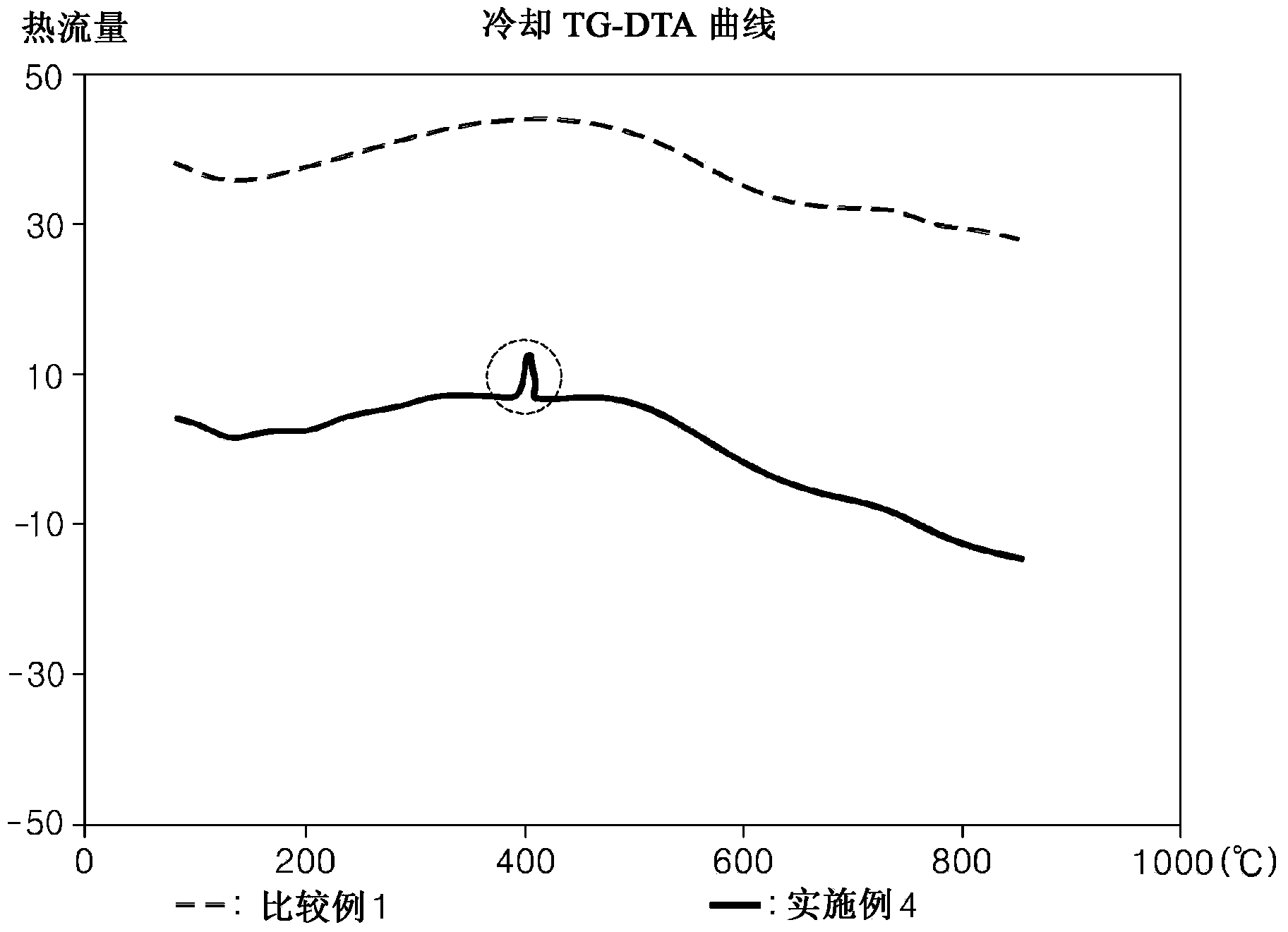

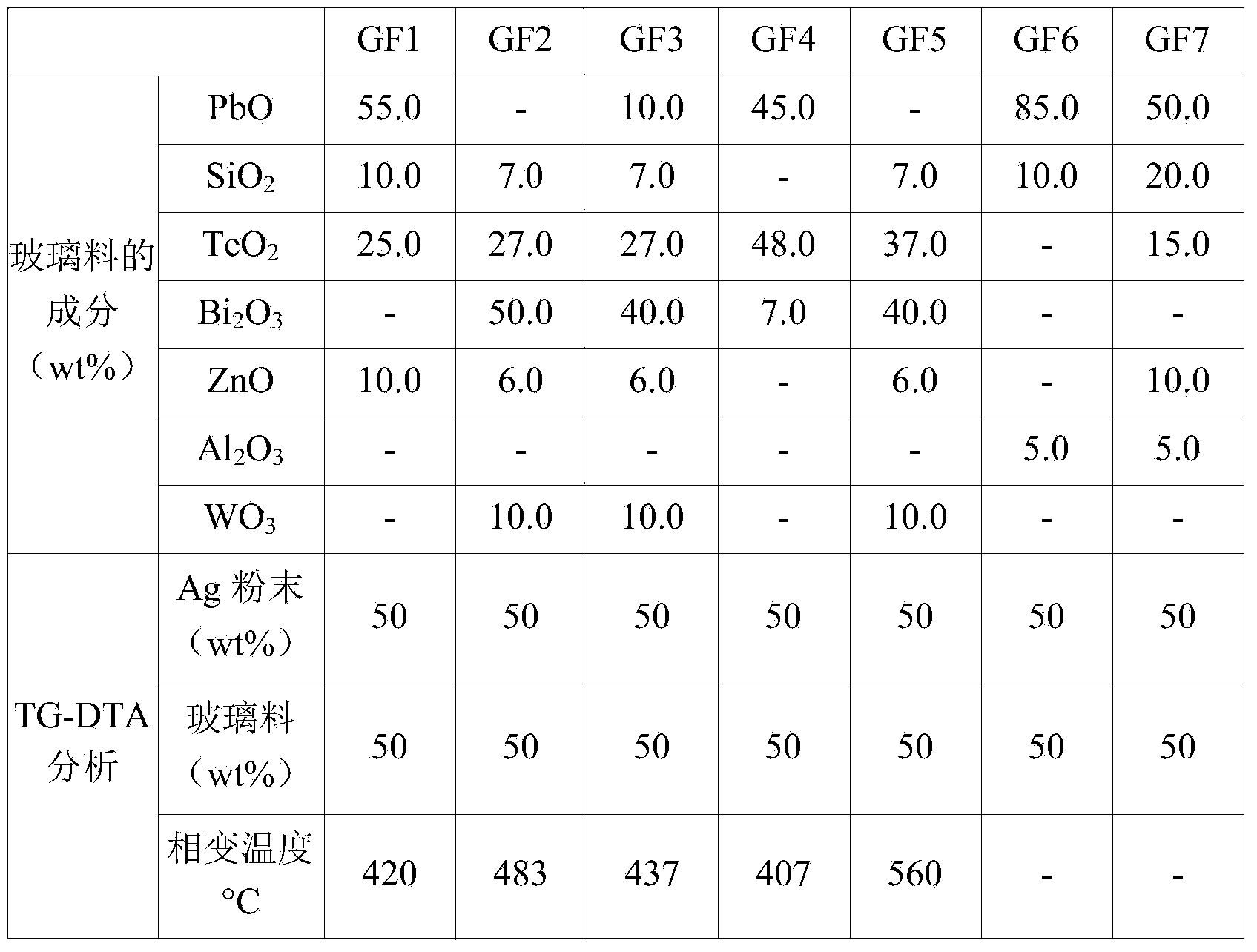

Glass frit, composition for solar cell electrodes including the same, and electrode fabricated using the same

InactiveCN103880291ANon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilicon oxideSolar cell

The invention relates to a glass frit, a composition for solar cell electrodes including the same, and an electrode fabricated using the same. The glass frit includes at least three metal oxides selected from the group of lead oxide, silicon oxide, tellurium oxide, bismuth oxide, zinc oxide, and tungsten oxide, wherein the glass frit exhibits a phase transition peak in the range of about 300 DEG C. to about 600 DEG C. on a cooling curve obtained via an TG-DTA analysis while a mixture of the glass frit and silver powder, obtained by mixing the glass frit with the silver powder in a weight ratio of 1:1, is cooled at a cooling rate of 10 DEG C. / min, after heating the mixture to 850 DEG C. at a heating rate of 20 DEG C. / min and held there for a wait-time of 10 minutes.

Owner:CHEIL IND INC

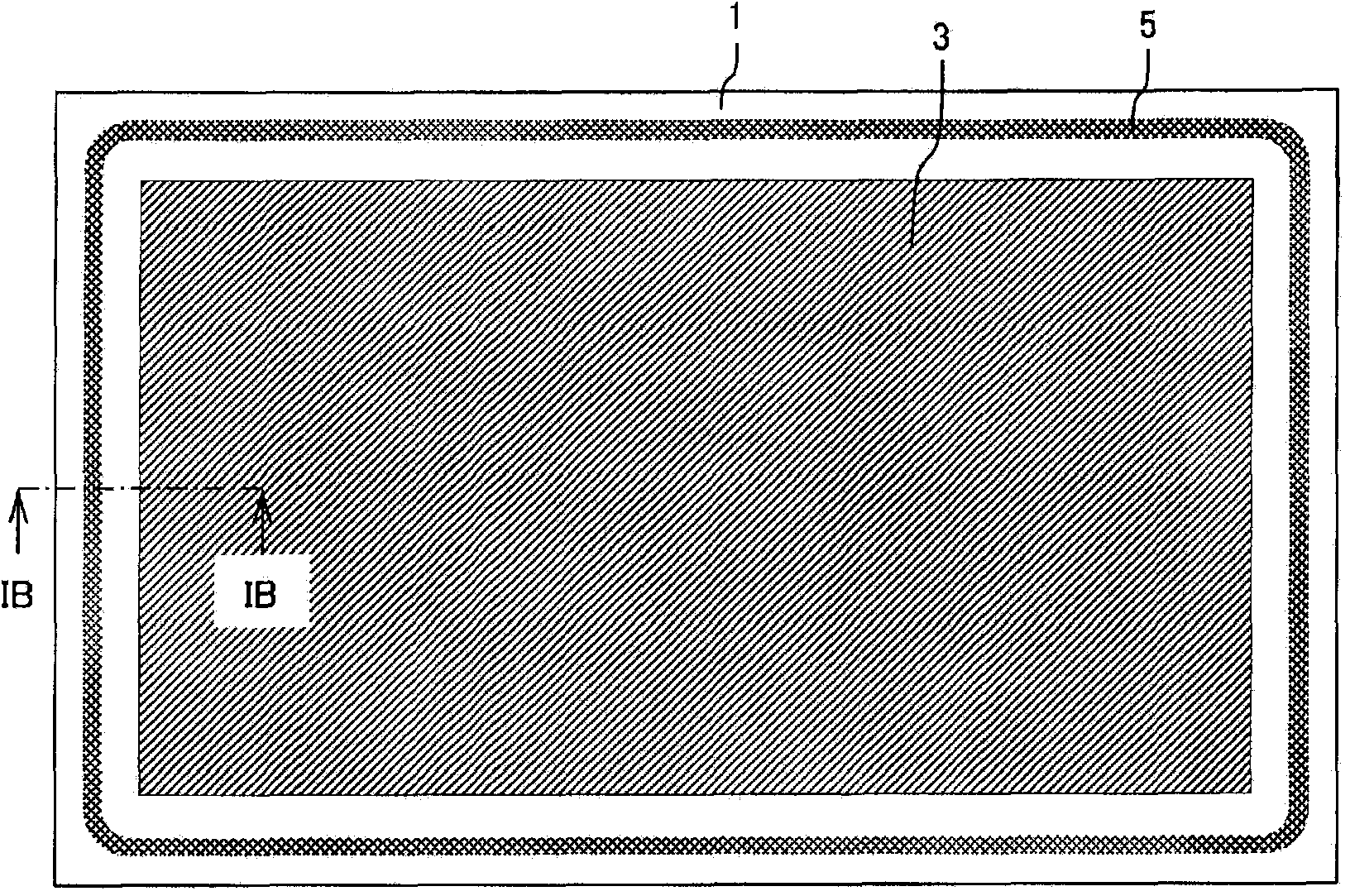

Electronic component, production method therefor, and sealing material paste used therein

InactiveCN104081877AReduce heat damageReduce devitrificationFinal product manufactureElectroluminescent light sourcesElectronic componentVanadium oxide

The invention relates to an electronic component, production method therefor, and sealing material paste used therein. The electronic component has an organic member (3) between two transparent substrates (1, 2). The outer peripheral sections of the two transparent substrates (1, 2) are bonded using a sealing material (5) that comprises low-melting-point glass. The low-melting-point glass comprises vanadium oxide (V2O5), tellurium oxide (TeO2), phosphorus oxide (P2O5), and iron oxide (Fe2O3), and in terms of oxide content, corresponds to the following: V2O5+TeO2+P2O5+Fe2O3>=75 mass%, and V2O5>TeO2>P2O5>Fe2O3 (in mass%).

Owner:HITACHI CHEM CO LTD

Conductive paste composition and semiconductor devices made therewith

ActiveUS20150155069A1Conductive materialSemiconductor/solid-state device manufacturingConductive pasteLithium

A conductive paste composition contains a source of an electrically conductive metal, a boron lithium tellurium oxide, and an organic vehicle. An article such as a high-efficiency photovoltaic cell is formed by a process of deposition of the paste composition on a semiconductor device substrate (e.g., by screen printing) and firing the paste to remove the organic vehicle and sinter the metal and establish electrical contact between it and the substrate.

Owner:SOLAR PASTE LLC

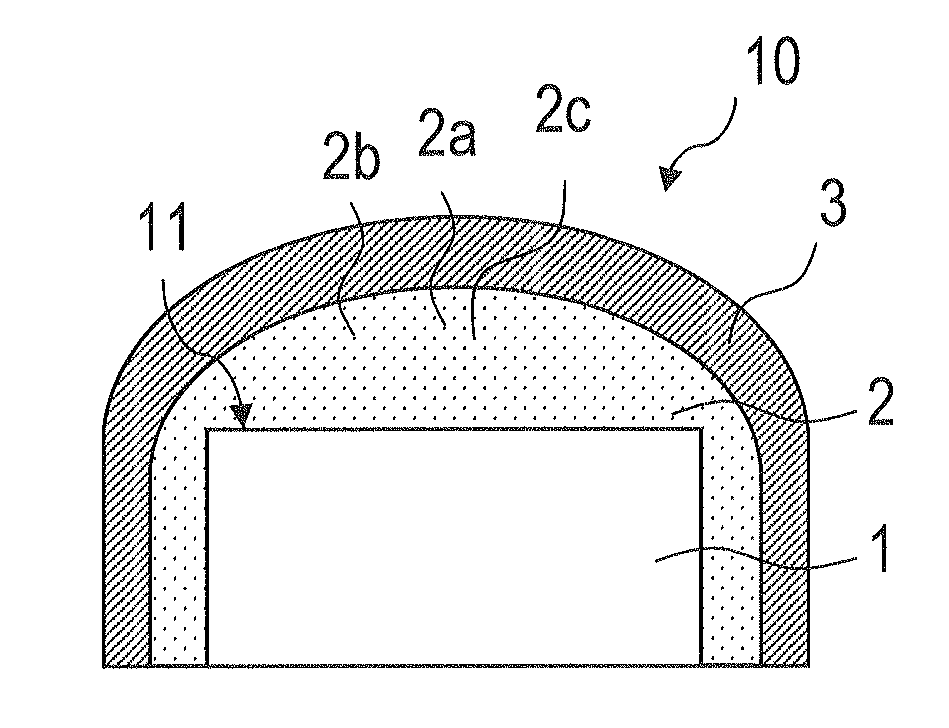

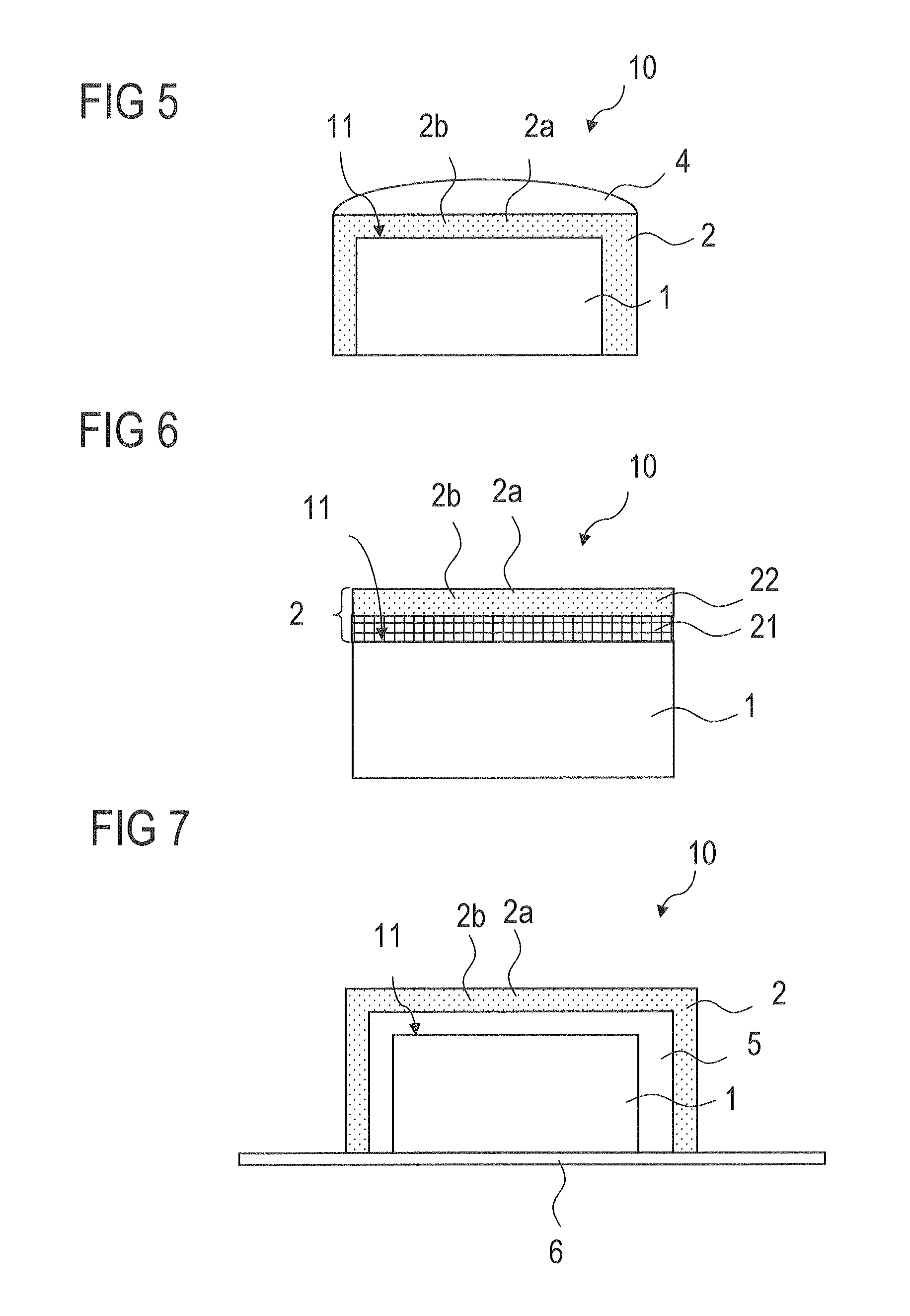

Radiation-Emitting Component with a Semiconductor Chip and a Conversion Element and Method for the Production Thereof

InactiveUS20130056725A1Improve cooling effectHigh refractive indexSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipBoron trioxide

A radiation-emitting component includes a semiconductor chip and a conversion element. The semiconductor chip includes an active layer suitable for generating electromagnetic radiation and a radiation exit face. The conversion element includes a matrix material and a luminescent material. The conversion element is arranged downstream of the radiation exit face of the semiconductor chip. The matrix material comprises at least 40 wt. % tellurium oxide and is free of boron trioxide and / or germanium oxide. A method for producing such a radiation-emitting component is furthermore stated.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG +1

Glass powder, preparation method thereof and application of glass powder in TOPCon battery

ActiveCN112592068AModerate corrosionImprove conversion efficiencySemiconductor devicesSilver pasteMischmetal

The invention discloses glass powder, and relates to the field of silver electrode slurry. The glass powder comprises the following components in parts by weight: 25-50 parts of lead oxide, 25-45 parts of tellurium oxide, 10-30 parts of bismuth oxide, 2-10 parts of molybdenum oxide, 0-6 parts of silicon dioxide, 0-6 parts of boron oxide, 0-4 parts of alkaline earth metal oxide, 0-6 parts of alkalimetal oxide and 0-3 parts of rare earth metal oxide. The invention further provides TOPCon battery silver paste containing the glass powder, the contact performance of the TOPCon battery silver pasteon thin Poly (60-100 nm) and metal compounding can be balanced, and the efficiency of a client is improved by 0.1% or above.

Owner:GUANGZHOU RUXING TECH DEV +1

Insulator-coated soft magnetic powder, method for producing insulator-coated soft magnetic powder, powder magnetic core, magnetic element, electronic device, and vehicle

An insulator-coated soft magnetic powder includes core particles each of which includes a base portion containing a soft magnetic material and an oxide film provided on the surface of the base portion and containing an oxide of an element contained in the soft magnetic material, ceramic particles which are provided on the surface of each of the core particles and have an insulating property, and a glass material which is provided on the surface of each of the core particles, has an insulating property, and contains at least one type of phosphorus oxide, bismuth oxide, zinc oxide, boron oxide, tellurium oxide, and silicon oxide as a main component, wherein the ceramic particles are included in a proportion of 100 vol % or more and 500 vol % or less of the glass material.

Owner:SEIKO EPSON CORP

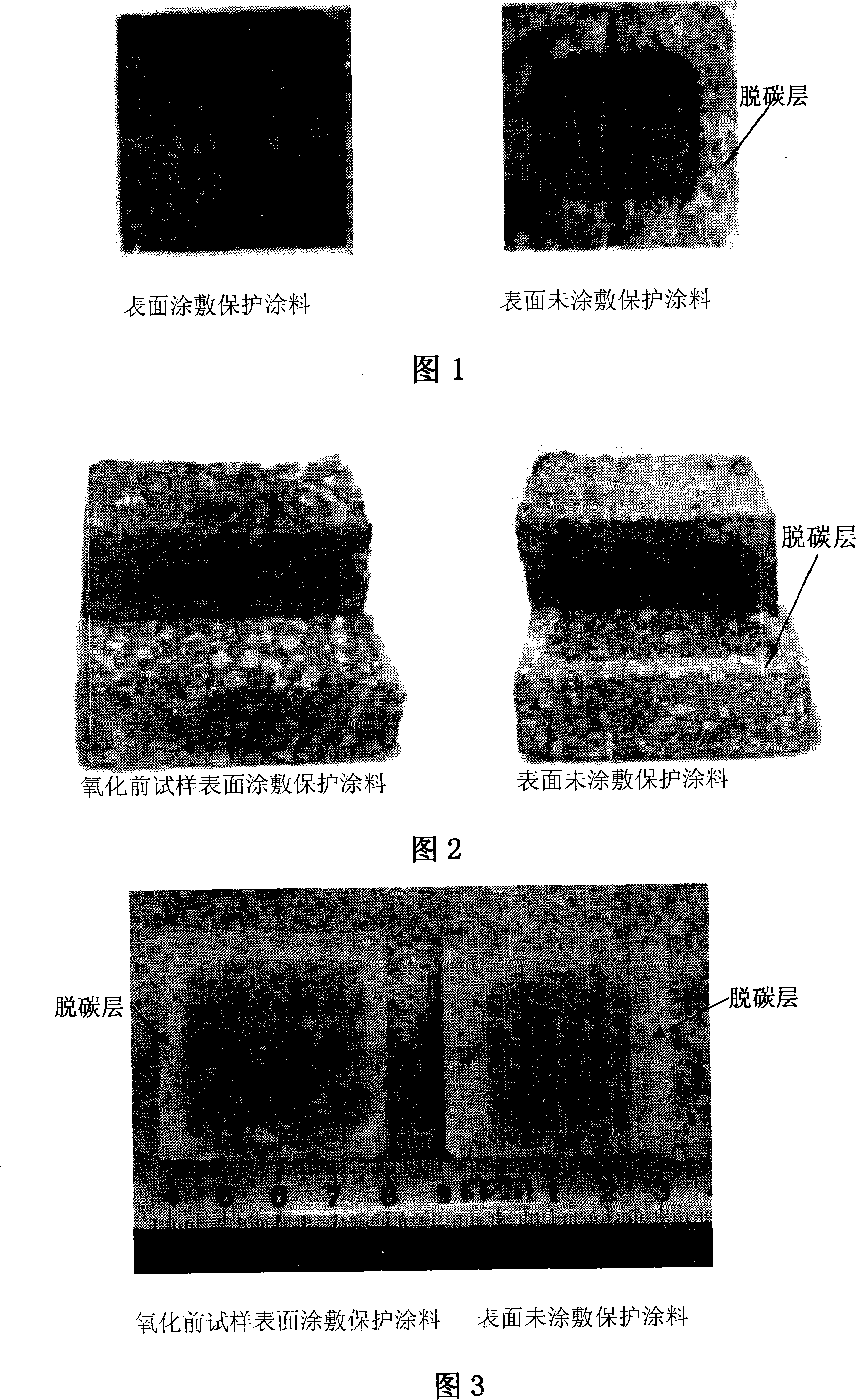

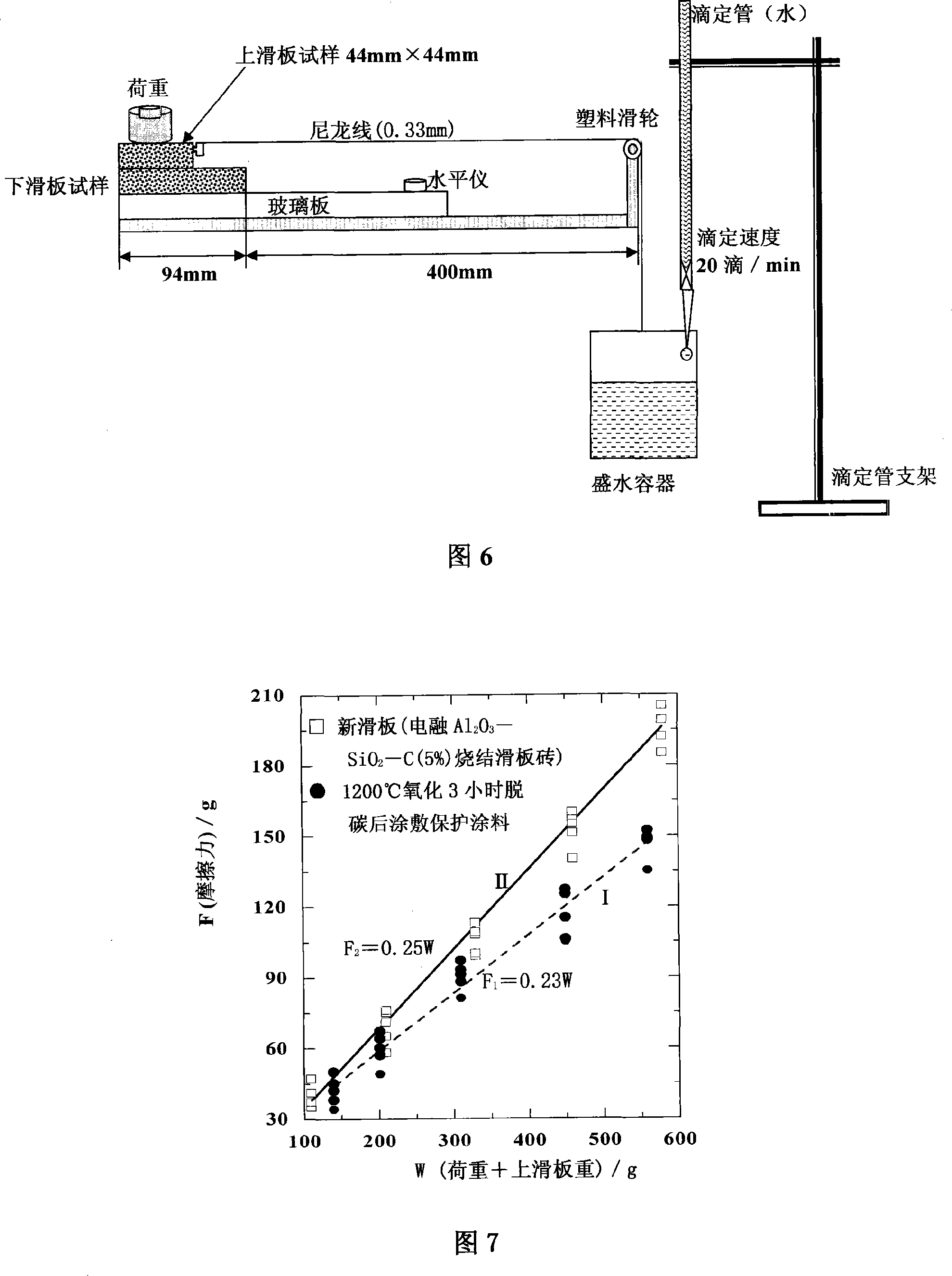

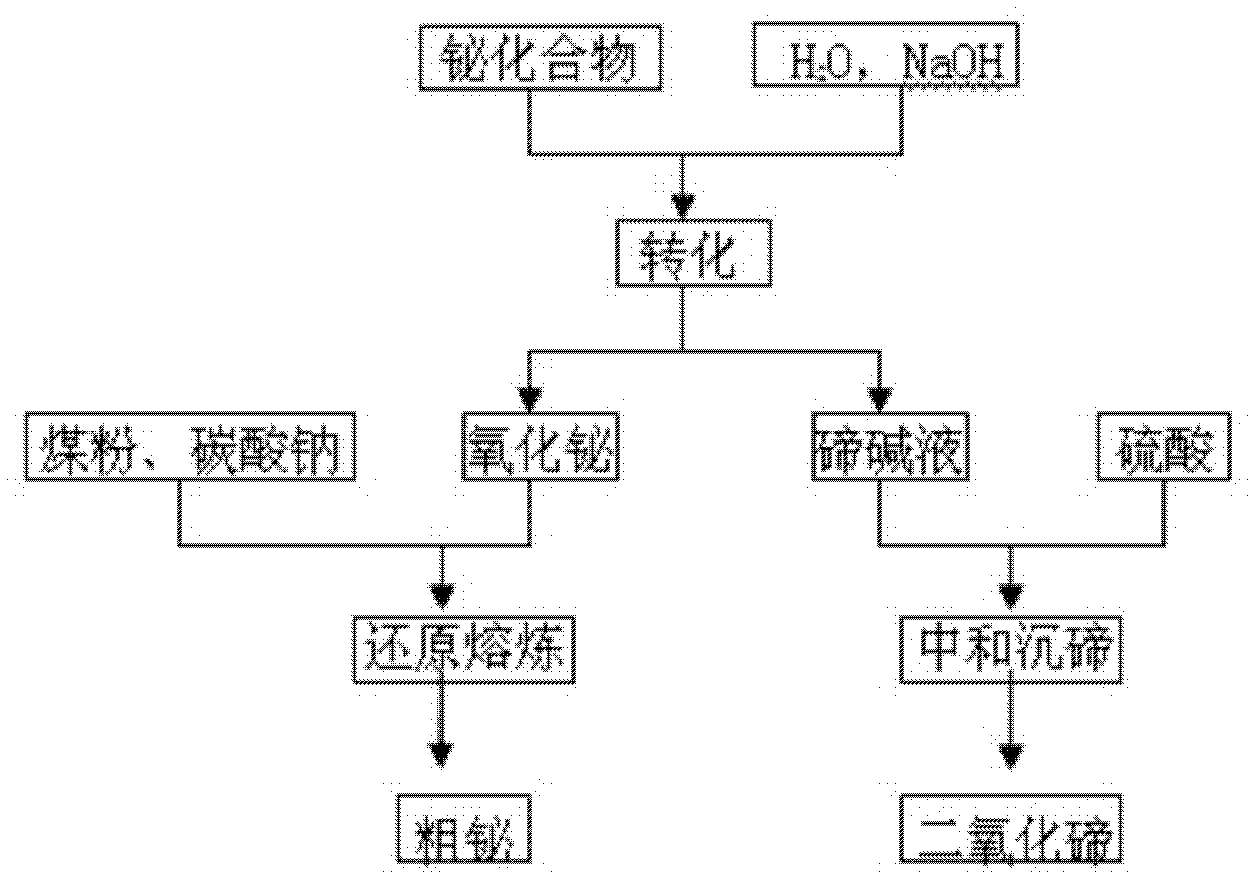

Carbonaceous sliding gate slide board protection coating material

InactiveCN101134677AImprove antioxidant capacityImprove the lubrication effectCelluloseALUMINUM PHOSPHATE

The present invention is one kind of paint for protecting carbon-containing slide board of sliding gate, and belongs to the field of paint for ferrous metallurgy. The paint consists of water solution 65-75 wt%, micro powder 25-35 wt% and small amount of cellulose dispersant and viscosity regulator, and the micro powder dispersed homogeneously inside the water solution to form suspension consists of flake graphite 50-80 wt%, alumina 5-22 wt% boron nitride 1-15 wt%, aluminum phosphate 10-22 wt%, zirconium silicate 2-5 wt%, tellurium oxide 0.1-1 wt% and small amount of impurity. The paint is coated to the surface of hot or cold slide board to form protecting film to raise the antioxidizing performance, lubricating performance and use performance of the slide board, and to increase its service life.

Owner:马鞍山方圆机电科技有限公司

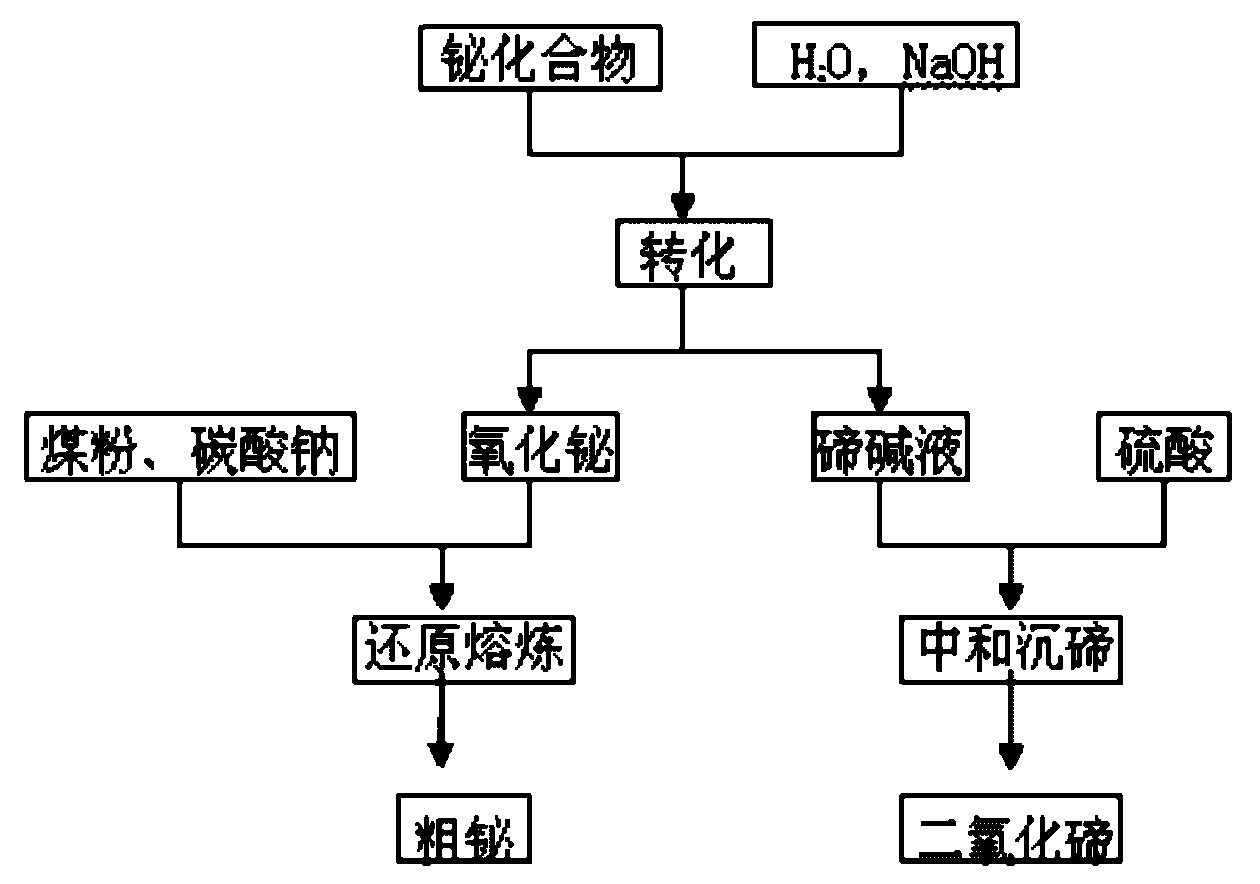

Novel bismuth smelting separation method

InactiveCN102534257AReduce moistureSolve the problem of high volume and high moistureElemental selenium/telluriumTe elementSlurry

The invention discloses a novel bismuth smelting separation method. According to the method, bismuth compounds and water are mixed and stirred to a slurry state according to a mass ratio being 1:(1-2) to form a slurry mixture, then, sodium hydroxide is added into the slurry mixture according to the bismuth to sodium hydroxide mass ratio being 1:(0.5-0.8), the temperature is controlled to be 90 to 95 DEG C, the materials are stirred for reaction for 1 to 2 hours so that the bismuth is converted into bismuth tellurium oxides to be dissolved into aqueous alkali, then, the filtering is carried out so that bismuth oxides and tellurium-containing solution are separated to respectively obtain bismuth oxides and tellurium lye, the bismuth oxides are washed by water, and the bismuth oxides are reduced and smelted to produce bismuth metal. The novel bismuth smelting separation method has the advantages that the bismuth compounds are converted into the bismuth oxides though alkaline addition, the bismuth oxides have small size, low moisture content and high bismuth content, the smelting energy consumption is reduced, only the bismuth oxides are produced, negative ions such as nitrate radicals, chlorine radicals and carbonic acid radicals are eliminated, poisonous gas generated in the smelting process is eliminated, the bismuth oxides are thoroughly separated from tellurium, nitrate radicals and the like after being filtered and washed, the impurity tellurium is eliminated, the bismuth purity is improved, the bismuth metal is produced through reduction and smelting, and the recovery rate of the bismuth reaches 99 percent.

Owner:SIHUI CITY HONGMING PRECIOUS METALS +1

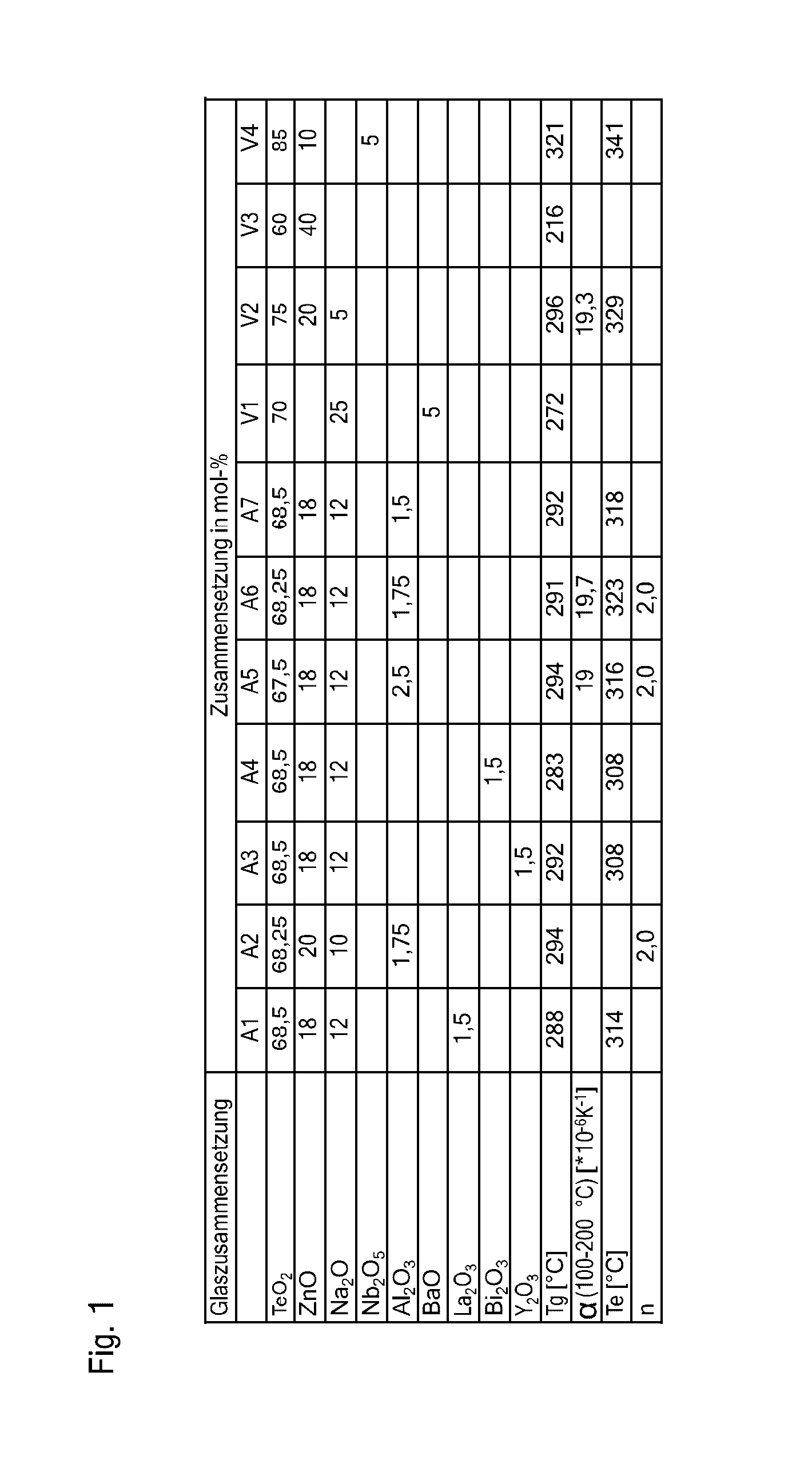

Glass Composition, Component, and Method for Producing a Component

ActiveUS20160304391A1Improved chemicalGood physical propertiesSolid-state devicesSemiconductor devicesMaterials scienceTellurium oxide

A glass composition, a device and a method for producing the device are disclosed. In an embodiment, the glass composition includes a tellurium oxide in a proportion of at least 65 mol. % and at most 90 mol. %, R1O in a proportion between 0 mol. % and 20 mol. %, wherein R1 is selected from Mg, Ca, Sr, Ba, Zn, Mn and combinations thereof and at least one M12O in a proportion between 5 mol. % and 25 mol. %, wherein M1 is selected from Li, Na, K and combinations thereof. The glass component further includes at least one R22O3 in a proportion between 1 mol. % and 3 mol. %, wherein R2 is selected from Al, Ga, In, Bi, Sc, Y, La, rare earths and combinations thereof, and M2O2 in a proportion between 0 mol. % and 2 mol. %, wherein M2 is selected from Ti, Zr, Hf and combinations thereof.

Owner:OSRAM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com