Preparation method for flexible fabric composite thermoelectric material

A technology of thermoelectric materials and fabrics, applied in the field of materials science, can solve the problems of less research and achieve the effects of huge market potential, stable thermoelectric performance, broad application prospects and market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Bi 2 Te 3 / PEDOT:PSS / Fabric Flexible Composite Thermoelectric Material

[0027] (1) Ingredients: firstly mix 0.025 mol C 4 h 4 Na 2 o 6 , 0.005 mol Bi(NO 3 ) 3 ·5H 2 O, 0.0075 molTeO 2 , 0.1 mol KOH, put into a beaker containing 100mL deionized water, stir until dissolved, put a cotton fabric with a size of 2cm*2cm into the solution and continue to stir for 1h. Add 0.05 mol KBH 4 After that, stirring was continued for 1 h. After stopping stirring, control water-bath temperature is 75 DEG C, reacts 24h;

[0028] (2) Washing: Alternately wash with deionized water and absolute ethanol 3 times each;

[0029] (3) Drying: Bi 2 Te 3 / The fabric is vacuum dried at 70°C for 12 hours;

[0030] (4) Treatment: use DMSO-doped PEDOT:PSS solution (the mass ratio of DMSO and PEDOT:PSS is 1:19) to Bi 2 Te 3 / The fabric is soaked for 0.5h;

[0031] (5) Drying: Bi 2 Te 3 / PEDOT:PSS / The fabric was vacuum dried at 130°C for 0.5h.

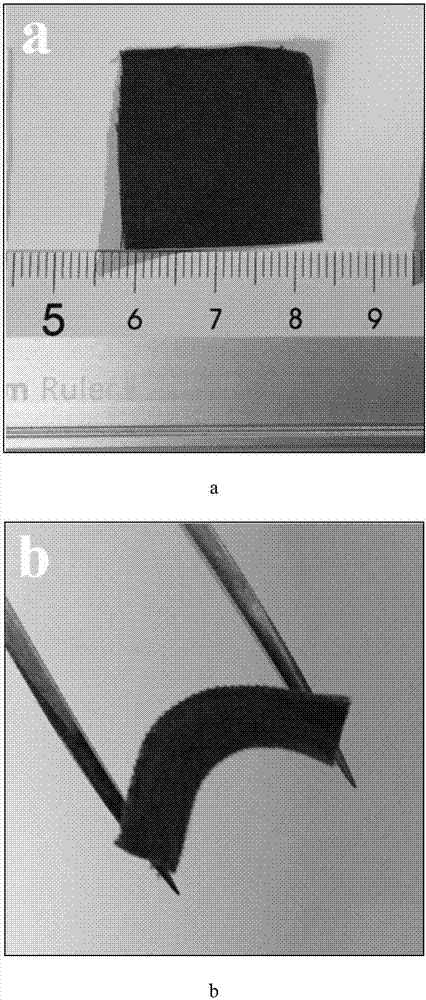

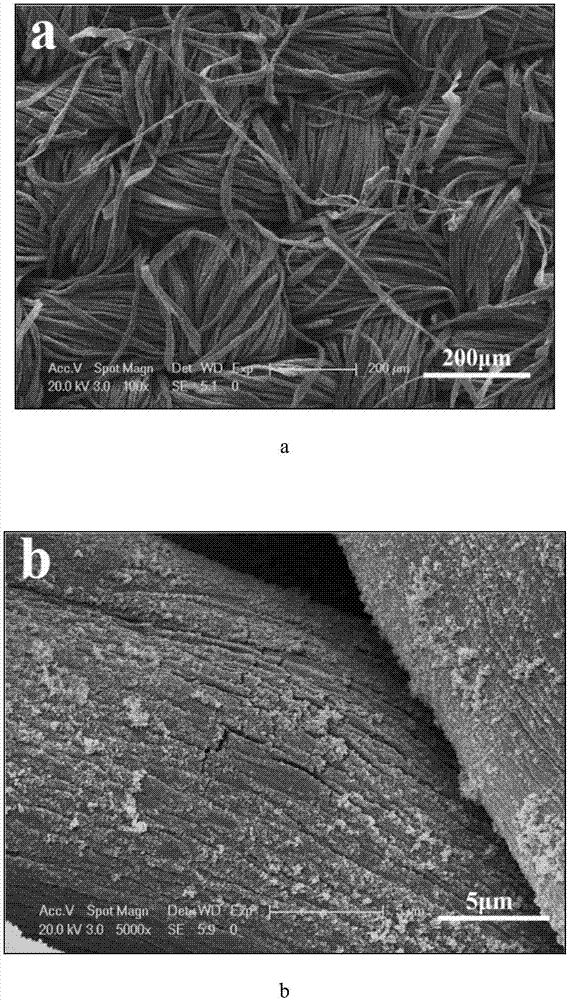

[0032] figure 1 a and b are the ...

Embodiment 2

[0034] Bi 2 Te 3 / PEDOT:PSS / Fabric Flexible Composite Thermoelectric Material

[0035] (1) Ingredients: firstly mix 0.025 mol C 4 h 4 Na 2 o 6 , 0.004 mol Bi(NO 3 )3 ·5H 2 O, 0.006 molTeO 2 , 0.12 mol KOH, put into a beaker containing 100mL deionized water, stir until dissolved, put a cotton fabric with a size of 2.5cm*2.5cm into the solution and continue to stir for 2h. Add 0.04 mol KBH 4 After that, the stirring was continued for 2h. After stopping the stirring, control the temperature of the water bath to 80°C and react for 36 hours;

[0036] (2) Washing: Alternately wash with deionized water and absolute ethanol 3 times each;

[0037] (3) Drying: Bi 2 Te 3 / The fabric is vacuum dried at 60°C for 12 hours;

[0038] (4) Treatment: use DMSO-doped PEDOT:PSS solution (the mass ratio of DMSO and PEDOT:PSS is 1:18) to Bi 2 Te 3 / The fabric is soaked for 0.2h;

[0039] (5) Drying: Bi 2 Te 3 / PEDOT:PSS / The fabric was vacuum dried at 130°C for 1h.

[0040] ...

Embodiment 3

[0042] Bi 2 Te 3 / PEDOT:PSS / Fabric Flexible Composite Thermoelectric Material

[0043] (1) Ingredients: Firstly mix 0.01 mol C 4 h 4 Na 2 o 6 , 0.002 mol Bi(NO 3 ) 3 ·5H 2 O, 0.003 molTeO 2 , 0.04 mol KOH, put into a beaker containing 80mL deionized water, stir until dissolved, put a cotton fabric with a size of 0.1cm*0.1cm into the solution and continue to stir for 1.5h. Add 0.02mol KBH 4 After that, stirring was continued for 1 h. After stopping the stirring, control the temperature of the water bath to 70°C and react for 12 hours;

[0044] (2) Washing: Alternately wash with deionized water and absolute ethanol 3 times each;

[0045] (3) Drying: Bi 2 Te 3 / The fabric is vacuum dried at 60°C for 6 hours;

[0046] (4) Treatment: use DMSO-doped PEDOT:PSS solution (the mass ratio of DMSO and PEDOT:PSS is 1:49) to Bi 2 Te 3 / The fabric is soaked for 0.2h;

[0047] (5) Drying: Bi 2 Te 3 / PEDOT:PSS / The fabric was vacuum dried at 120°C for 0.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com