Lead-free sealing glass, sealing device and production method of lead-free sealing glass

A manufacturing method and glass technology, applied in glass manufacturing equipment, glass molding, glass reshaping, etc., can solve problems such as large expansion coefficient of lead-free sealing glass, lead containing, and reduced packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

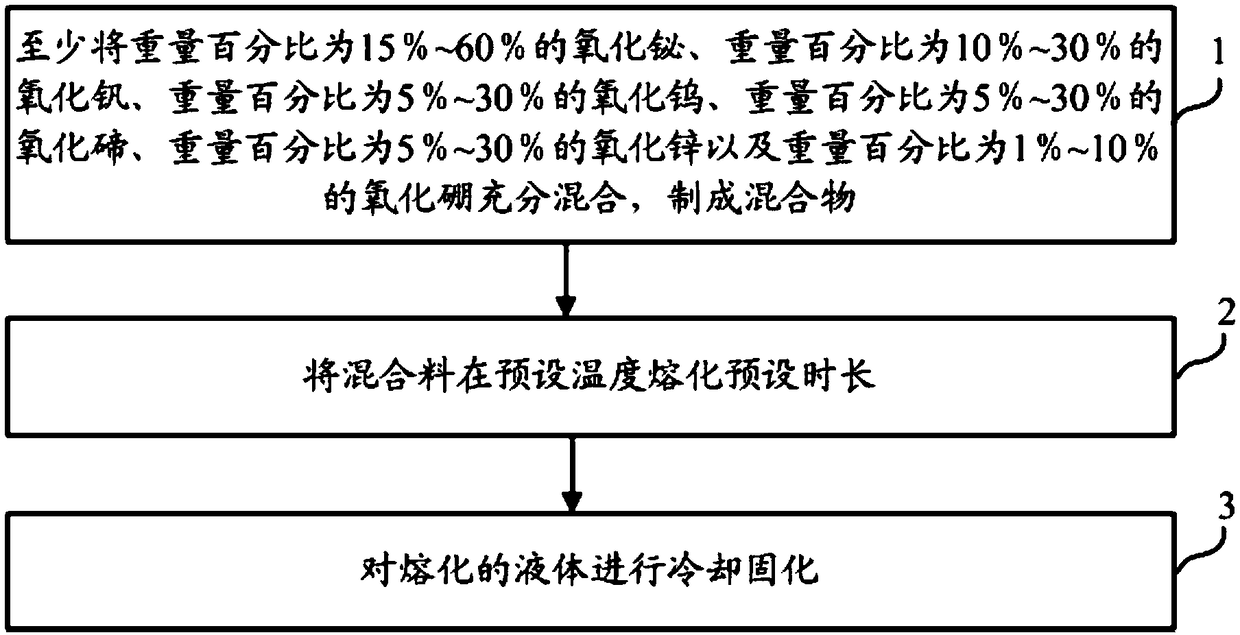

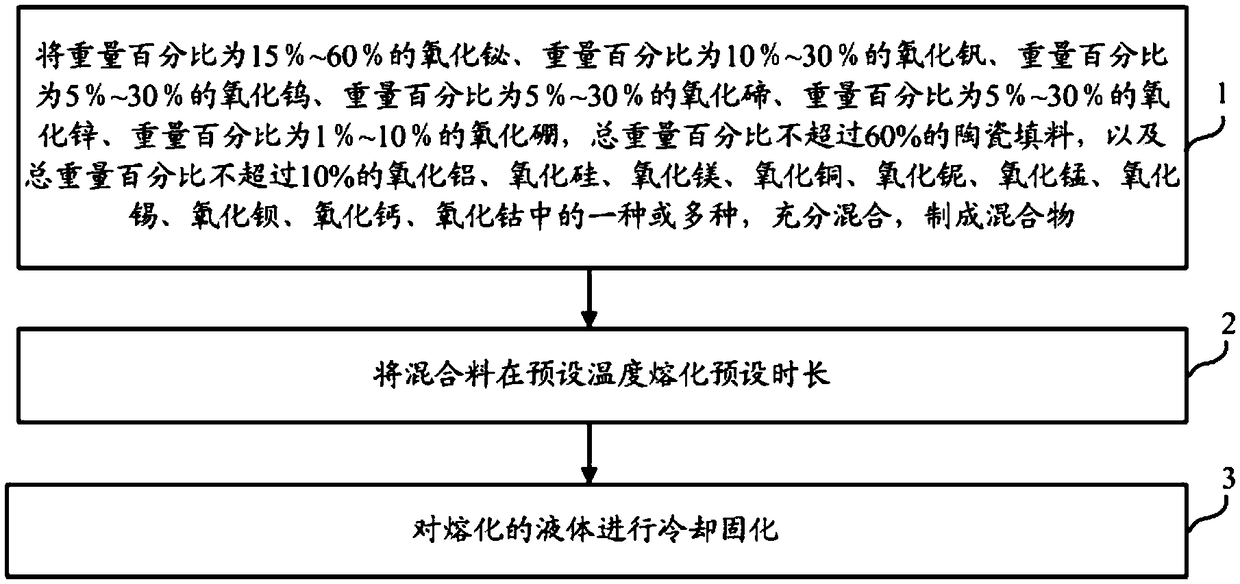

Method used

Image

Examples

Embodiment 1

[0055] In specific implementation, in order to obtain lead-free sealing glass with lower softening temperature and lower expansion coefficient, the composition of lead-free sealing glass can include bismuth oxide, vanadium oxide, tungsten oxide, tellurium oxide, zinc oxide , and boron oxide, and a ceramic filler made of aluminum titanate is added therein. Wherein, the weight percentage of bismuth oxide can be 20%-25%, the weight percentage of vanadium oxide can be 25%-30%, the weight percentage of tungsten oxide can be 15%-20%, and the weight percentage of tellurium oxide can be 15% -20%, the weight percentage of zinc oxide can be 10%-15%, the weight percentage of boron oxide can be 1%-5%, wherein the weight percentage of aluminum titanate is 30%-50% of the total weight. More specifically, corresponding to the first type in Table 1, an expansion coefficient of 49×10 is provided -7 / ° C, softening temperature is 345 ° C, sealing temperature is 480 ° C to 520 ° C glass frit. ...

Embodiment 2

[0065] In specific implementation, in order to obtain lead-free sealing glass with lower softening temperature and better chemical stability, the composition of lead-free sealing glass can include bismuth oxide, vanadium oxide, tungsten oxide, tellurium oxide, Zinc oxide and boron oxide, and a ceramic filler made of eucryptite is added thereto. Wherein, the weight percentage of bismuth oxide is 25%-30%, the weight percentage of vanadium oxide is 20%-25%, the weight percentage of tungsten oxide is 10%-15%, and the weight percentage of tellurium oxide is 20%-25%, The weight percentage of zinc oxide is 5%-10%, the weight percentage of boron oxide is 5%-10%, and the weight percentage of eucryptite is 20%-40% of the total weight. More specifically, corresponding to the second type in Table 1, an expansion coefficient of 65×10 is provided -7 / ° C, glass powder with a softening temperature of 365 ° C.

[0066] The composition of the glass powder is as follows:

[0067]

[0068...

Embodiment 3

[0075] In specific implementation, in order to obtain a lead-free sealing glass with high chemical stability, the composition of the lead-free sealing glass can include bismuth oxide, vanadium oxide, tungsten oxide, tellurium oxide, zinc oxide and boron oxide, A ceramic filler made of cordierite is added therein. Wherein, the weight percentage of bismuth oxide is 18%-23%, the weight percentage of vanadium oxide is 20%-25%, the weight percentage of tungsten oxide is 20%-25%, and the weight percentage of tellurium oxide is 18%-22%, The weight percentage of zinc oxide is 15%-20%, the weight percentage of boron oxide is 1%-5%, and the weight percentage of cordierite is 30%-50% of the total weight. More specifically, corresponding to the third type in Table 1, an expansion coefficient of 61×10 is provided -7 / °C, glass powder with a softening temperature of 352°C.

[0076] The composition of the glass powder is as follows:

[0077]

[0078]

[0079] In manufacturing, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| sealing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com