Glass frit, composition for solar cell electrodes including the same, and electrode fabricated using the same

A solar cell and glass frit technology, applied to conductive materials dispersed in non-conductive inorganic materials, circuits, photovoltaic power generation, etc., can solve problems such as efficiency degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 5 and comparative example 1 to 2

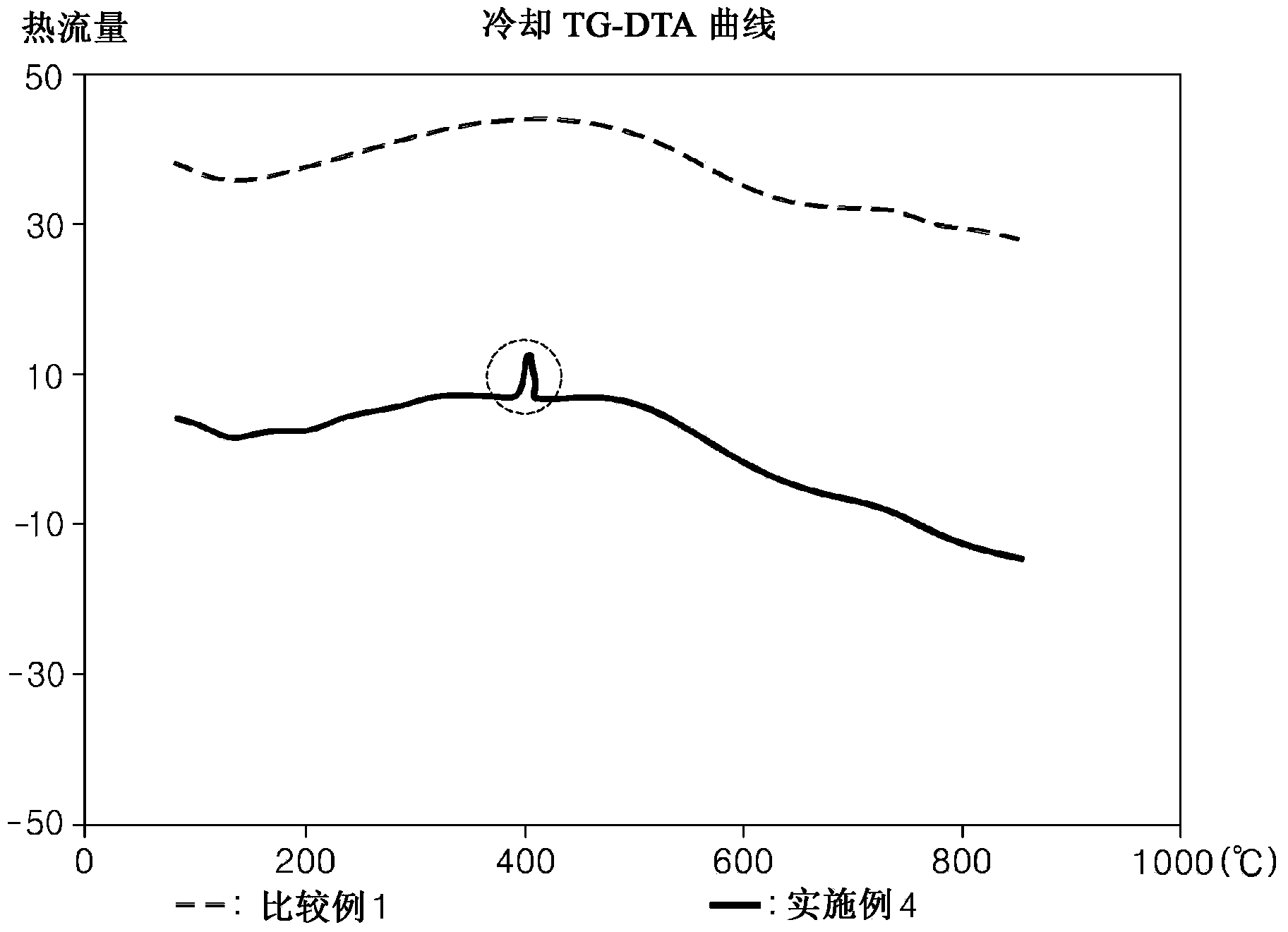

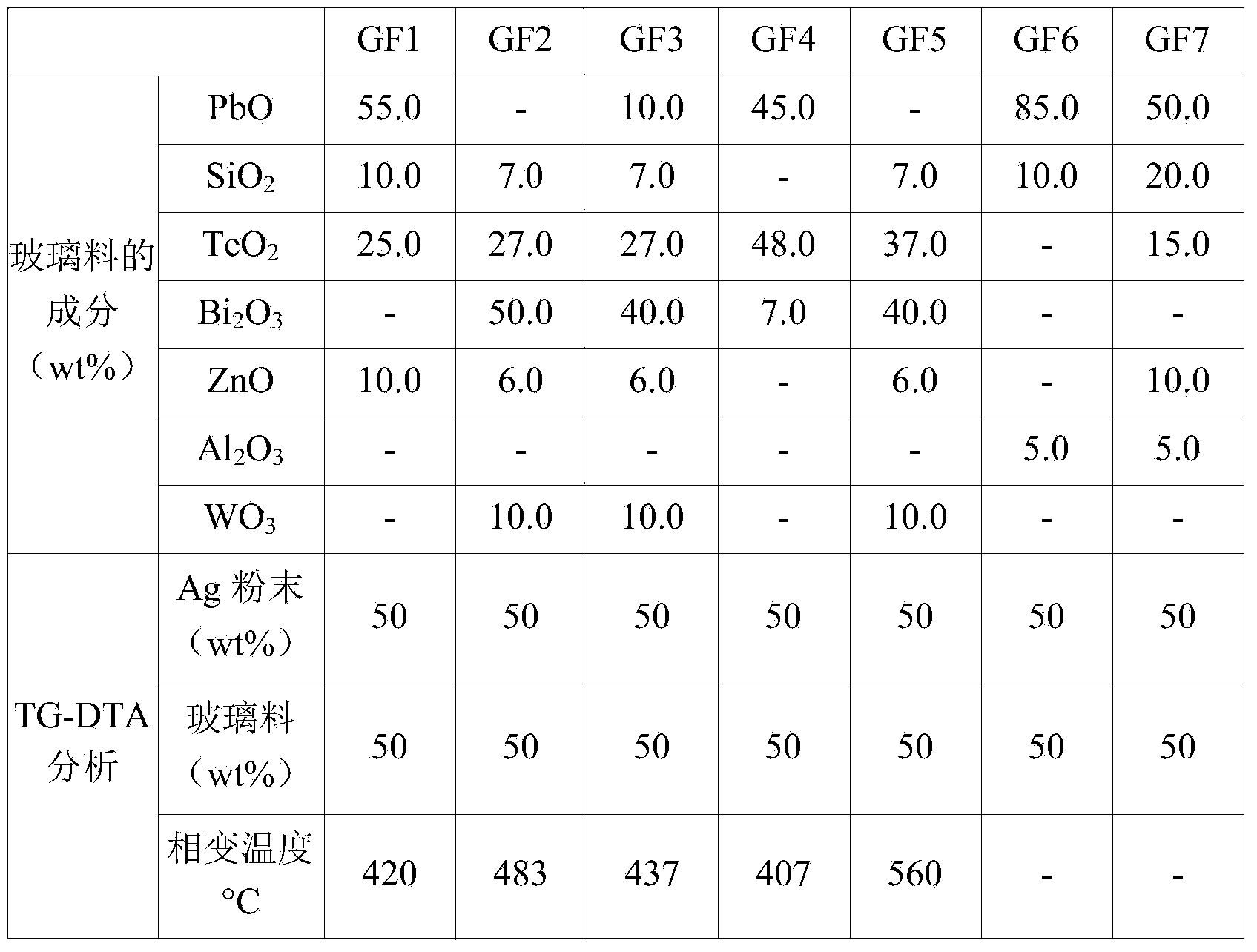

[0053] Examples 1 to 5 and Comparative Examples 1 to 2: Preparation of compositions for solar cell electrodes

[0054] As shown in Table 2, 9 g of organic vehicle obtained by dissolving 1 g of ethyl cellulose in 8 g of butyl carbitol and 89 g of silver powder (Dowa5-11F, Dowa Hightech Co., Ltd.) were added to the 2 g of the prepared glass frits GF1 to GF7 were mixed and kneaded in a 3-roll kneader, thereby preparing a composition for a solar cell electrode.

[0055] Electrode Performance Evaluation

[0056] Each prepared composition was deposited on a screen print plate by rotating a scrapper on it. Each composition was printed on a mono-crystalline wafer with an average sheet resistance of 65Ω while extruding the paste composition onto the image area of the screen printing plate. The printed wafers were dried at 300°C for 20-30 seconds and then subjected to firing in a BTU oven at a 6-zone temperature of 950°C and a belt speed of 250 rpm. After firing, measure the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com