Conductive Paste And Method For Producing Solar Cell By Using The Same

A technology of solar cells and conductive paste, which is applied in conductive materials, circuits, photovoltaic power generation and other directions dispersed in non-conductive inorganic materials, can solve the problem of poor energy conversion efficiency of conductive paste of composite glass frit, and conductive paste of composite glass frit. Problems such as unclear proportions and components, to achieve the effect of excellent photoelectric conversion efficiency and excellent conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

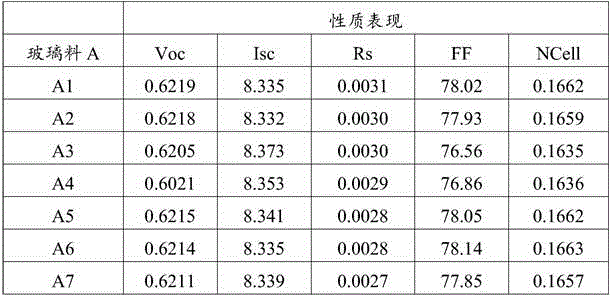

[0031] In the following, the embodiments of the present application have better photoelectric conversion efficiency than conventional conductive pastes.

[0032] Composite glass frit preparation

[0033] 1. Preparation of the first type of sub-frit

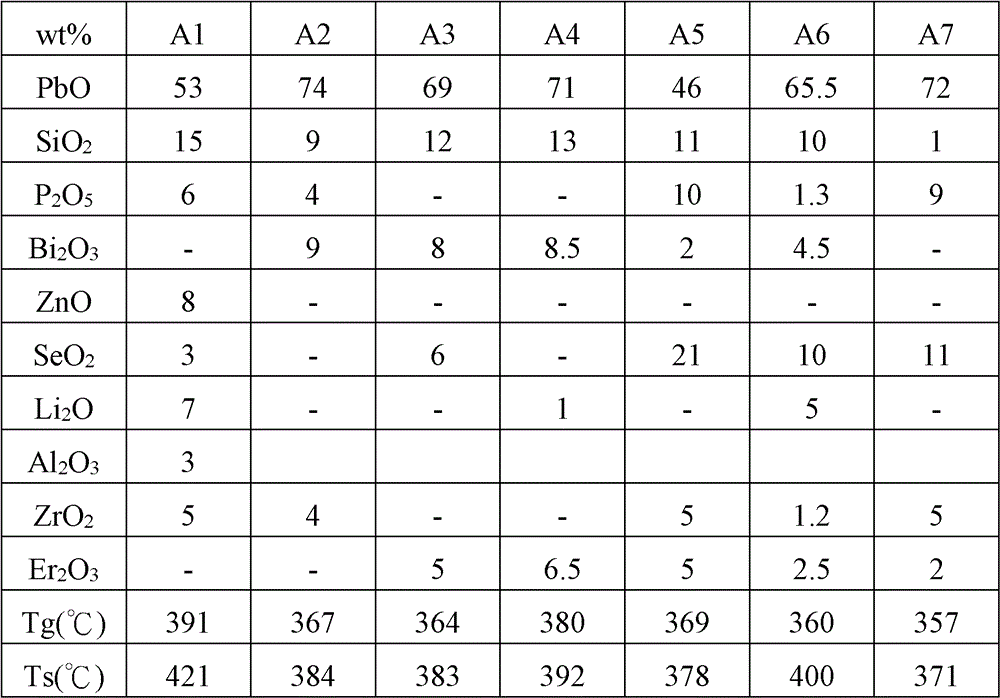

[0034] The first type of sub-glass frit mainly includes lead oxide compound and silicon oxide compound, and the first type of sub-glass frit sample is prepared according to the composition ratio in Table 1 below.

[0035] 【Table I】

[0036]

[0037]It can be seen from Table 1 that the glass transition temperature (Tg) and glass softening temperature (Ts) of the first type of sub-glass frit samples range from 357°C to 391°C and from 371°C to 421°C, respectively.

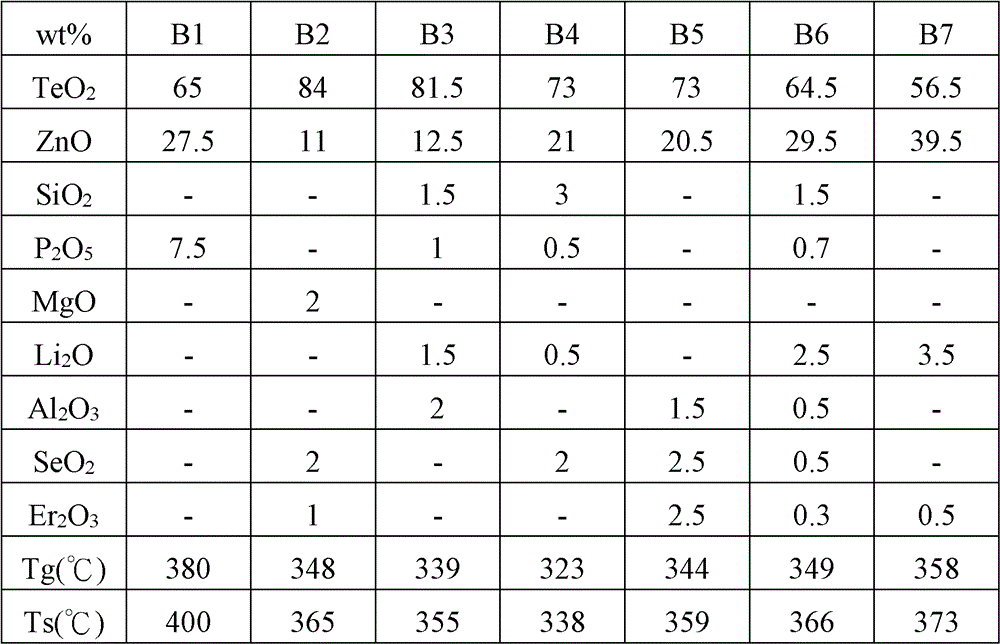

[0038] 2. Preparation of the second type of sub-frit

[0039] The second type of sub-glass frit mainly includes tellurium oxide compound and zinc oxide compound, and the second type of sub-glass frit sample is prepared according to the composition ratio in Table 2 b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com