Novel bismuth smelting separation method

A new method, the technology of bismuth oxide, is applied in the direction of elements such as selenium/tellurium, which can solve the problems of low recovery rate, high cost, and environmental pollution, and achieve the effects of increasing bismuth content, reducing energy consumption, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

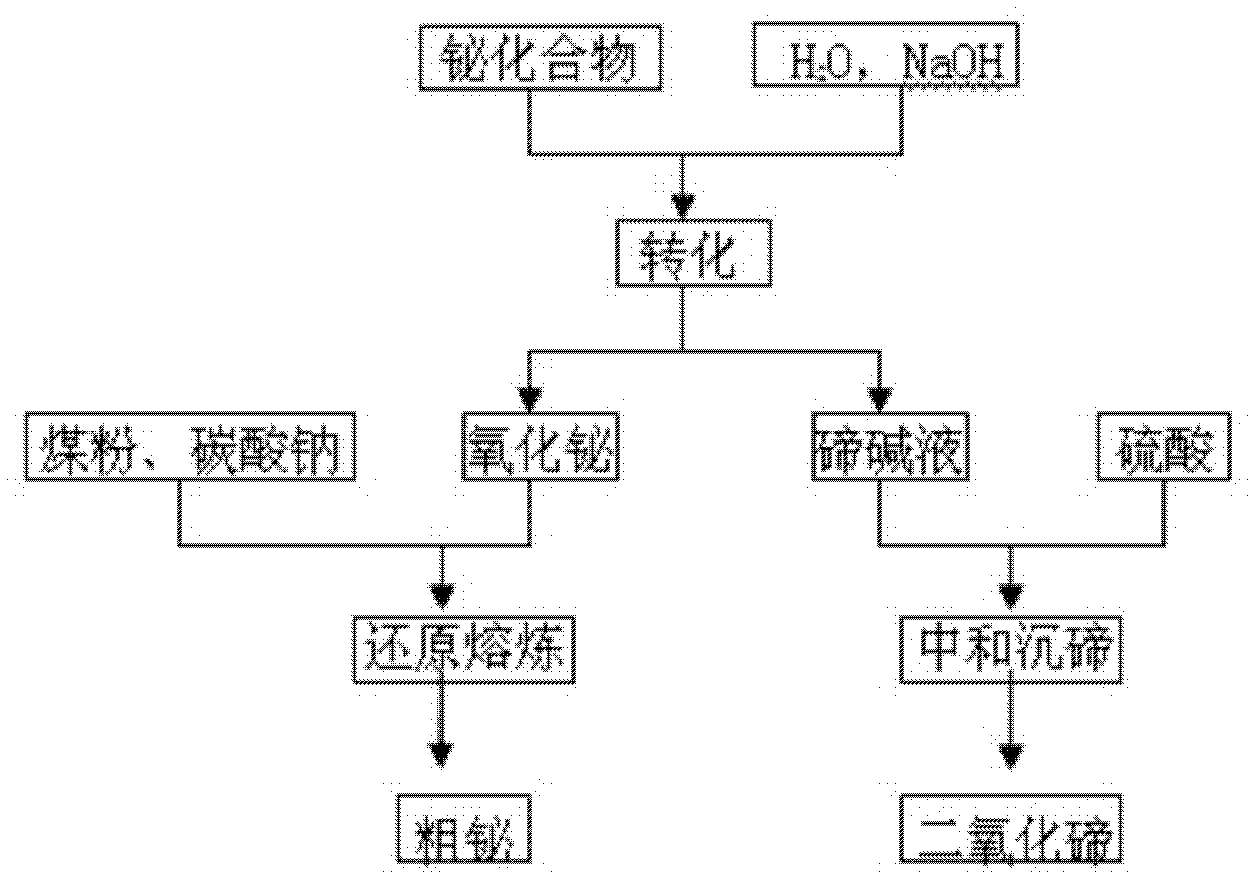

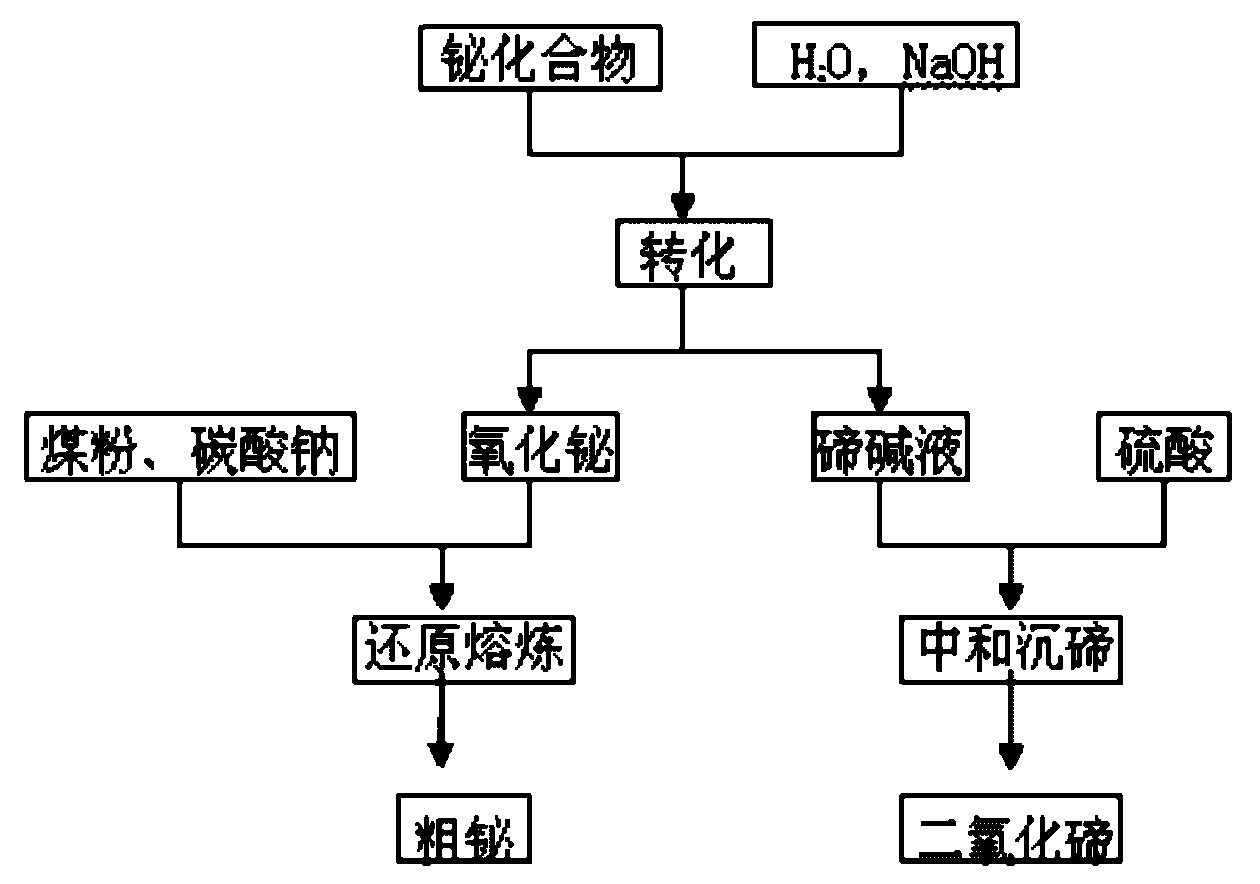

Image

Examples

Embodiment 1

[0013] 8 tons of bismuth compound, its composition is: bismuth 56.40wt%, tellurium 1.51wt%, moisture 35.22wt%.

[0014] (1) Add the bismuth compound to the stirred reactor, add tap water according to the solid-to-liquid mass ratio of 1:1, start the machine and stir until the bismuth compound becomes a slurry, and add it to the reactor according to the ratio of mass ratio bismuth: sodium hydroxide = 1:0.5 Solid sodium hydroxide, after adding alkali, control the reaction temperature at 90-95°C, stir and react for 1 hour, so that bismuth is converted into bismuth oxide, tellurium is dissolved into the alkali solution, and then bismuth oxide and tellurium-containing alkali solution are separated by pressure filtration Obtain bismuth oxide and tellurium lye respectively, and wash the bismuth oxide with water.

[0015] (2) The main components of the bismuth oxide obtained by adding alkali are: bismuth 78.45wt%, tellurium 0.10wt%, water 13.41wt%. Bismuth oxide is uniformly mixed acc...

Embodiment 2

[0018] 10 tons of bismuth compound, its composition is: bismuth 54.64wt%, tellurium 1.43wt%, water 30.25wt%.

[0019] (1) Add the bismuth compound to the stirred reactor, add tap water according to the solid-to-liquid mass ratio of 1:1.5, start the machine and stir until the bismuth compound becomes a slurry, and add it to the reactor according to the mass ratio of bismuth: sodium hydroxide = 1:0.6 Solid sodium hydroxide, after adding alkali, control the reaction temperature at 90-95°C, stir and react for 1.4 hours to convert bismuth into bismuth oxide, tellurium dissolves into the alkali solution, and then separate the bismuth oxide and tellurium-containing alkali solution through pressure filtration Obtain bismuth oxide and tellurium lye respectively, and wash the bismuth oxide with water.

[0020] (2) The main components of the bismuth oxide obtained by adding alkali are: bismuth 77.13wt%, tellurium 0.10wt%, water 14.81wt%. Bismuth oxide is uniformly mixed according to the...

Embodiment 3

[0023] 9.5 tons of bismuth compound, its composition is: bismuth 53.10wt%, tellurium 1.02wt%, water 27.32wt%.

[0024] (1) Add the bismuth compound to the stirred reactor, add tap water according to the solid-to-liquid mass ratio of 1:2, start the machine and stir until the bismuth compound becomes a slurry, and add it to the reactor according to the mass ratio of bismuth: sodium hydroxide = 1:0.8 Solid sodium hydroxide, after adding alkali, control the reaction temperature at 90-95°C, and stir for 2 hours to convert bismuth into bismuth oxide, tellurium dissolves into the alkali solution, and then separate bismuth oxide and tellurium-containing alkali solution through pressure filtration Obtain bismuth oxide and tellurium lye respectively, and wash the bismuth oxide with water.

[0025] (2) The main components of the bismuth oxide obtained by adding alkali are: bismuth 75.69wt%, tellurium 0.08wt%, water 14.85wt%. Bismuth oxide is uniformly mixed according to the mass ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com