Efficient light-emitting sulfur selenium tellurium zinc cadmium/zinc sulfide quinary alloy core-shell structure quantum dot material and preparation method

A core-shell structure, zinc sulfide technology, used in luminescent materials, chemical instruments and methods, nanotechnology for materials and surface science, etc. Instability and other problems, to achieve the effect of safe storage and use, stable chemical structure, and reduction of gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

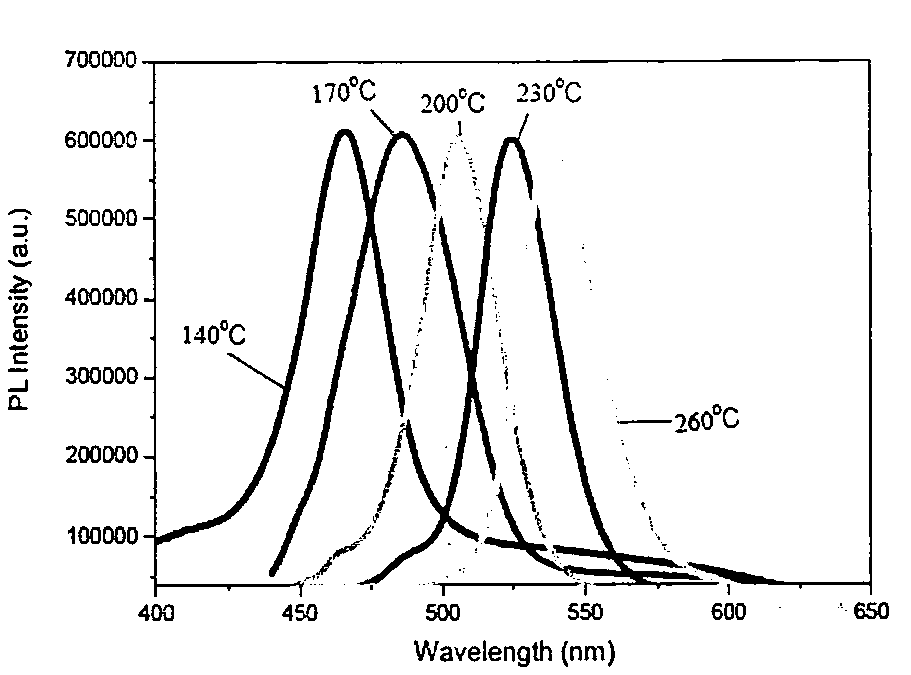

[0042] Example 1: Preparation of blue ZnCdSSeTe / ZnS core-shell quantum dots

[0043] (1) Add 1 mmol S, 1 mmol SeO 2 , 1 mmol TeO 2 Mix with 60 mmol dodecyl mercaptan and 60 mmol liquid paraffin at room temperature. The system was evacuated, stirred and heated to 150 °C under this condition, and the reaction temperature was maintained for 30 min to prepare an anion precursor.

[0044](2) Prepare a solution of 60 mmol oleic acid, 60 mmol oleylamine, 60 mmol isooctanoic acid and 60 mmol liquid paraffin with 1 mmol ZnO and 1 mmol CdO, stir and heat the solution to 200 °C under vacuum conditions, and maintain the The temperature is 2 h, and the cationic precursor is prepared.

[0045] (3) Inject an inert gas into the reaction bottle containing the cation precursor solution, and keep the system temperature at 200°C, quickly inject the anion precursor, and keep the cations (Zn, Cd) and anions (S, Se and Te) The range of the molar ratio is 1, and the temperature is maintained for ...

Embodiment 2

[0053] Example 2: Preparation of green ZnCdSSeTe / ZnS core-shell quantum dots

[0054] (1) Add 1 mmol S, 1 mmol SeO 2 , 1 mmol TeO 2 Mix with 60 mmol dodecyl mercaptan and 60 mmol liquid paraffin at room temperature. The system was evacuated, stirred and heated to 150 °C under this condition, and the reaction temperature was maintained for 30 min to prepare an anion precursor.

[0055] (2) Prepare a solution of 60 mmol oleic acid, 60 mmol oleylamine, 60 mmol isooctanoic acid and 60 mmol liquid paraffin with 1 mmol ZnO and 2 mmol CdO, stir and heat the solution to 200 ° C under vacuum conditions, and maintain the The temperature is 2 h, and the cationic precursor is prepared.

[0056] (3) Inject an inert gas into the reaction bottle containing the cation precursor solution, raise the system temperature to 250°C, quickly inject the anion precursor, and keep the cations (Zn, Cd) and anions (S, Se and Te ) in the range of 2 molar ratios, maintaining the temperature for 20 min. ...

Embodiment 3

[0064] Example 3: Preparation of red ZnCdSSeTe / ZnS core-shell quantum dots

[0065] 1 mmol S, 2 mmol SeO 2 , 2 mmol TeO 2 Mix with 60 mmol dodecyl mercaptan and 60 mmol liquid paraffin at room temperature. The system was evacuated, stirred and heated to 150 °C under this condition, and the reaction temperature was maintained for 30 min to prepare an anion precursor.

[0066] Prepare a solution of 1 mmol ZnO and 3 mmol CdO in 60 mmol oleic acid, 60 mmol oleylamine, 60 mmol isooctanoic acid and 60 mmol liquid paraffin, stir and heat the solution to 150-250 °C under vacuum conditions, and maintain the temperature for 2 h, Preparation of cationic precursors.

[0067] Inject an inert gas into the reaction flask containing the cation precursor solution, raise the system temperature to 300°C, quickly inject the anion precursor, and maintain the moles of cations (Zn, Cd) and anions (S, Se, and Te) The range of the ratio is 3, and the temperature is maintained for 20 min.

[0068]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com