Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84 results about "Ethylene-maleic anhydride copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

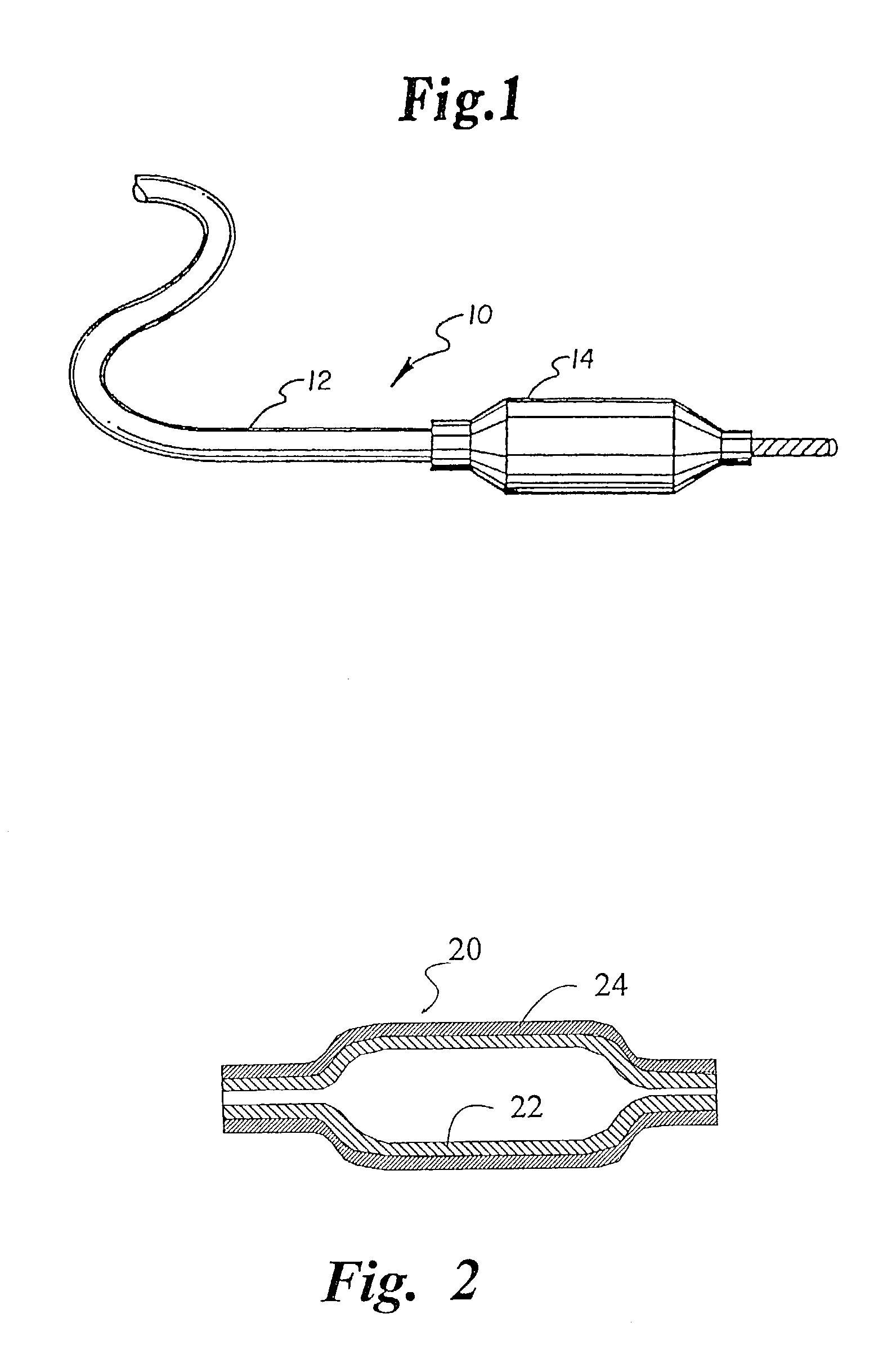

Balloons made from liquid crystal polymer blends

Balloons for use on medical devices such as catheter balloons are formed from polymer blend products which include a liquid crystal polymer (LCP), a crystallizable thermoplastic polymer, especially thermoplastic polyesters such as PET, and a compatabilizer. The compatabilizer may be an ethylene-maleic anhydride copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate-maleic anhydride terpolymer, an ethylene-methyl-methacrylic acid terpolymer, an acrylic rubber, an ethylene-ethyl acrylate-glycidyl methacrylate terpolymer or a mixture of two or more such polymers.

Owner:BOSTON SCI SCIMED INC

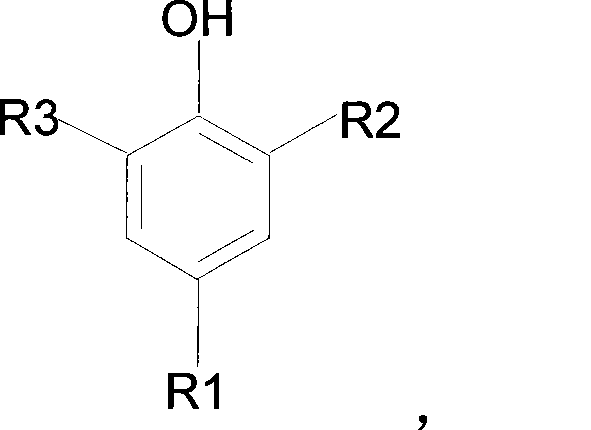

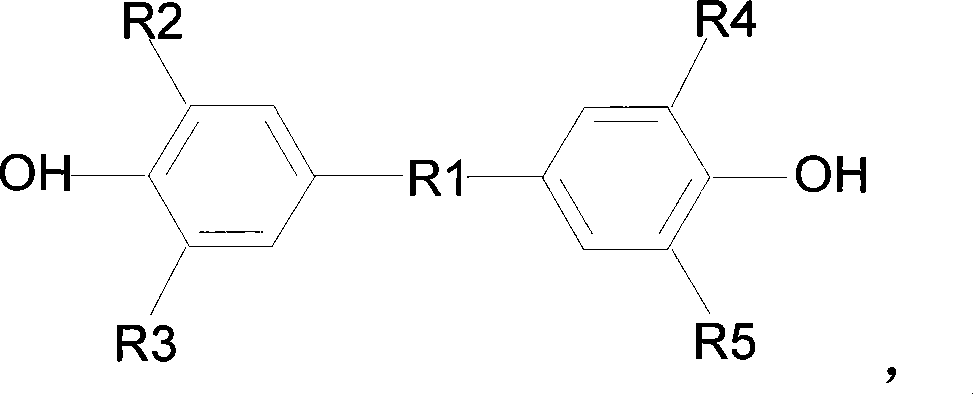

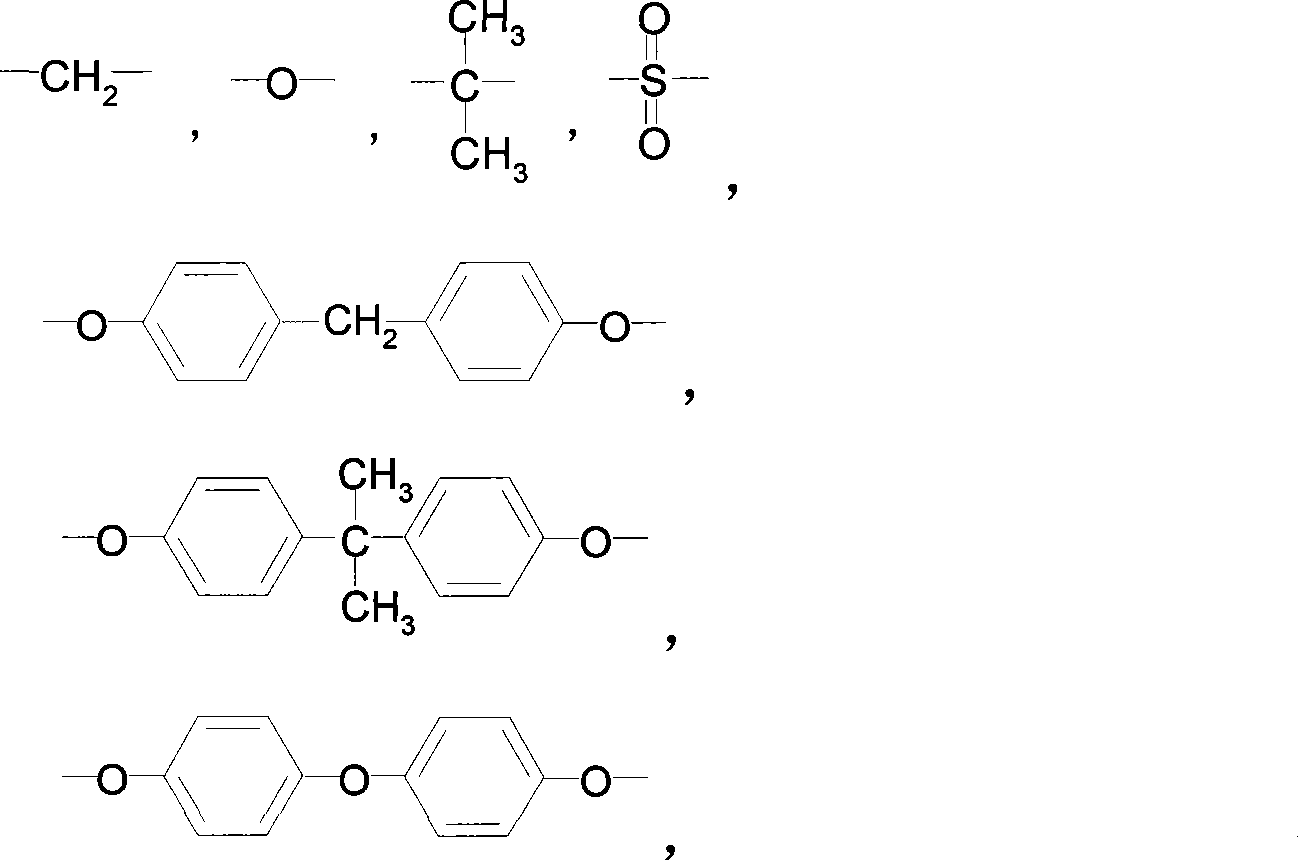

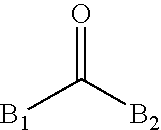

Thermosetting resin composition and use

InactiveCN101481490AImprove heat resistanceExcellent dielectric propertiesCircuit susbtrate materialsMetal layered productsGlass fiberTetrabromobisphenol A

The invention discloses a thermoset resin composition, comprising the following ingredients of: bifunctional groups or polyfunctional group epoxy resin, phenylethylene-maleic anhydride copolymer (SMA) as a curing agent, diallyl bisphenol A-like allylphenol as a co-curing agent and a toughening agent, low-bromine or high-bromine BPA-type epoxy resin or tetrabromobisphenol A (TBBPA or TBBA) as a fire retardant, a proper accelerator and a solvent. The inventive resin composition has, after being cured, relatively low dielectric property and superior thermal reliability and toughness, includes, in contrast to a cooper clad laminate manufactured by reinforcing materials such as glass fiber cloth, relatively low dielectric constant (called Dk for short) and electric loss tangent (called Df for short), high Tg, high thermal cracking temperature (called Td for short), excellent toughness and favorable PCB processibility, is quite suitable for manufacturing the cooper clad laminate for PCB and prepreg, and can also applied to general uses of the epoxy resin, such as molding plastics and the like, and to composite materials for construction, automobile and aviation.

Owner:ITEQ DONGGUAN +1

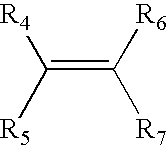

Miscible blends of ethylene copolymers with improved temperature resistance

The present invention is a composition useful as an impact modifier for polyamide compositions. In one embodiment, impact modifiers of the present invention are ethylene maleic anhydride copolymers having at least 3% maleic anhydride functionality. Compositions comprising copolymers of ethylene and maleic anhydride or its functional equivalents and ethylene copolymers with polar comonomers are disclosed. The compositions provide miscible blends and exhibit improved properties, such as increased temperature resistance and mechanical strength, compared to pure ethylene copolymers with polar comonomers.

Owner:PERFORMANCE MATERIALS NA INC

Two-part sizing composition for reinforcement fibers

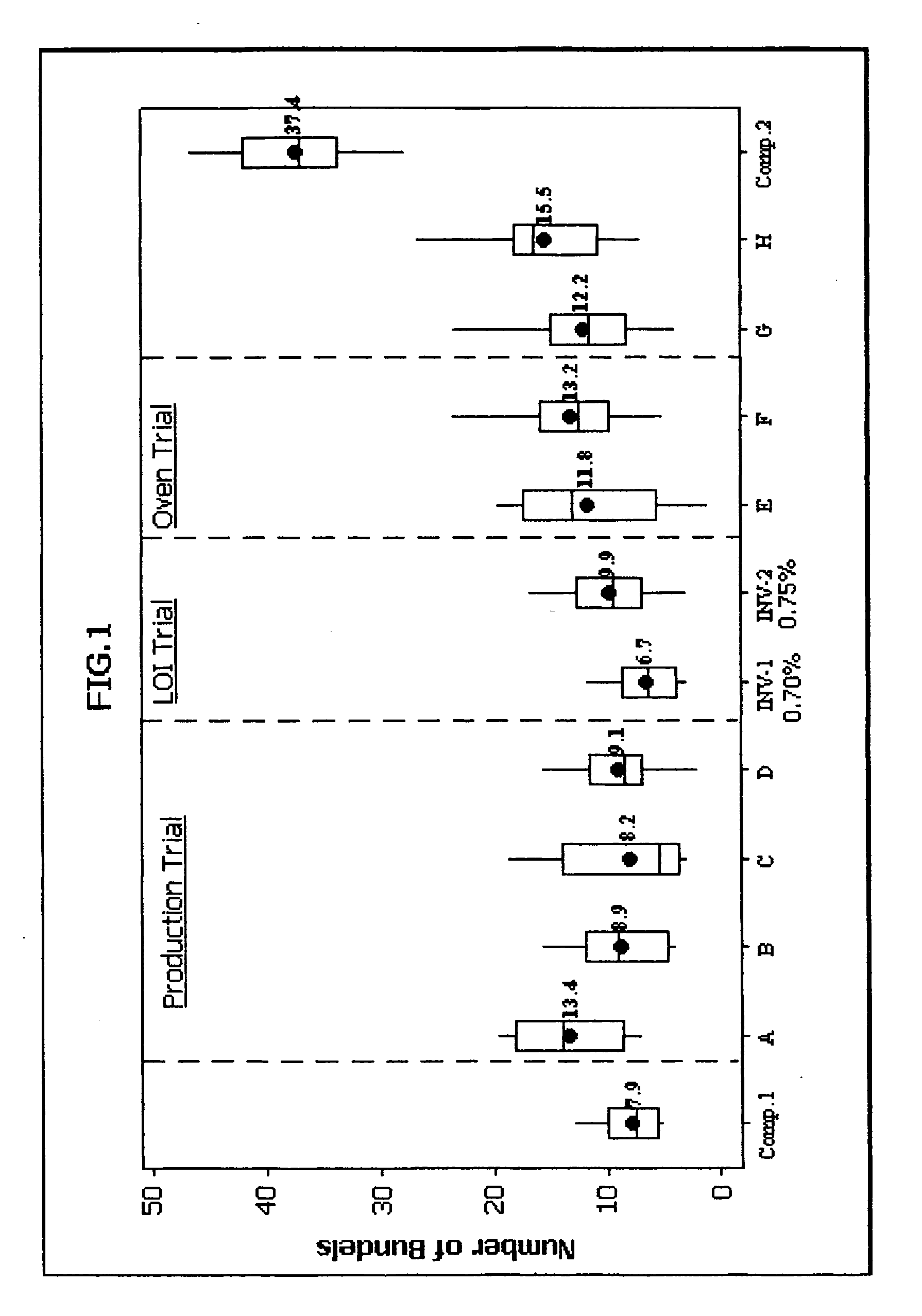

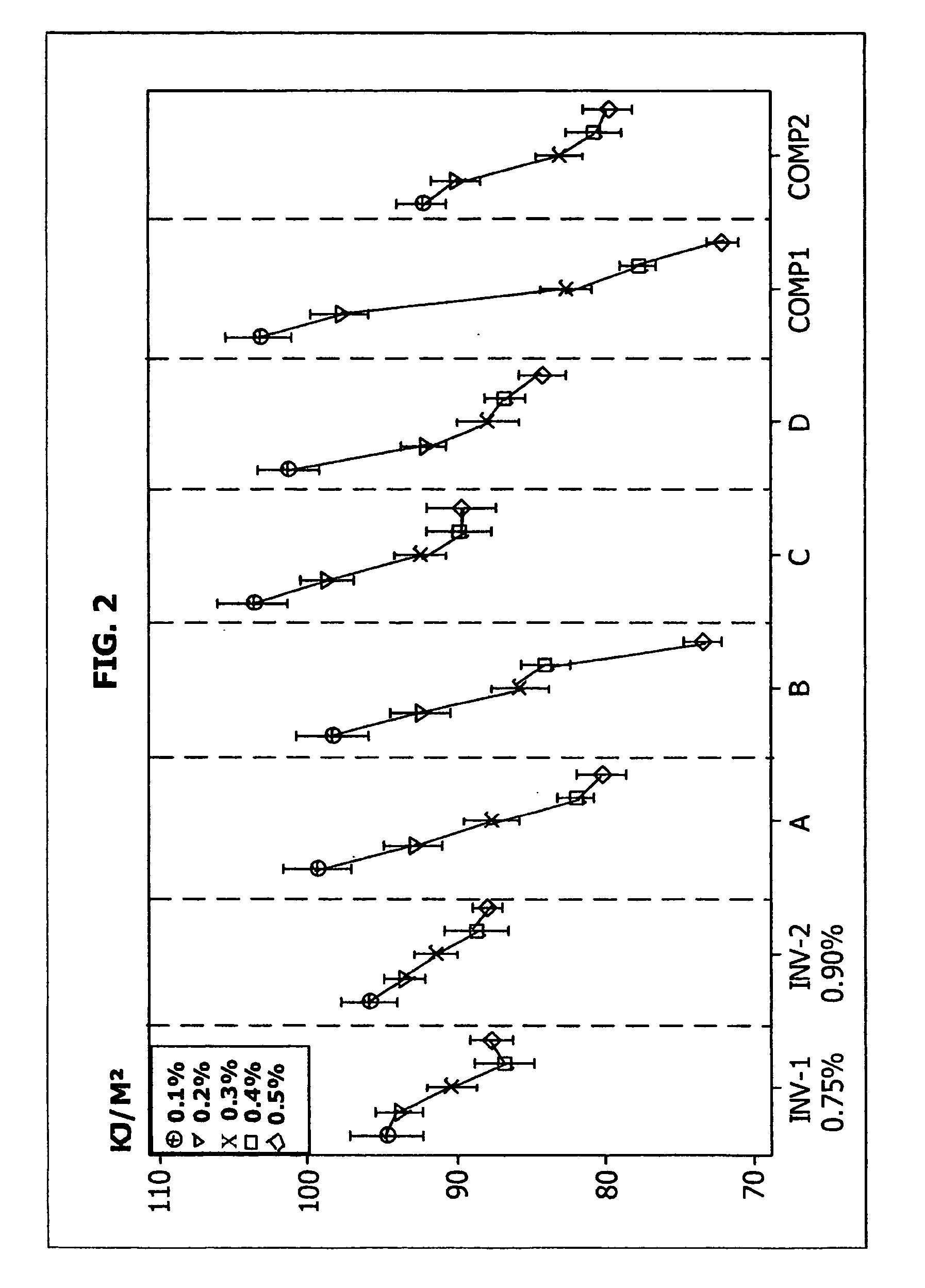

InactiveUS20070072989A1Reduce subsequent chemical corrosionReduce interfilament abrasionSynthetic resin layered productsSpecial tyresFiberFilm-forming agent

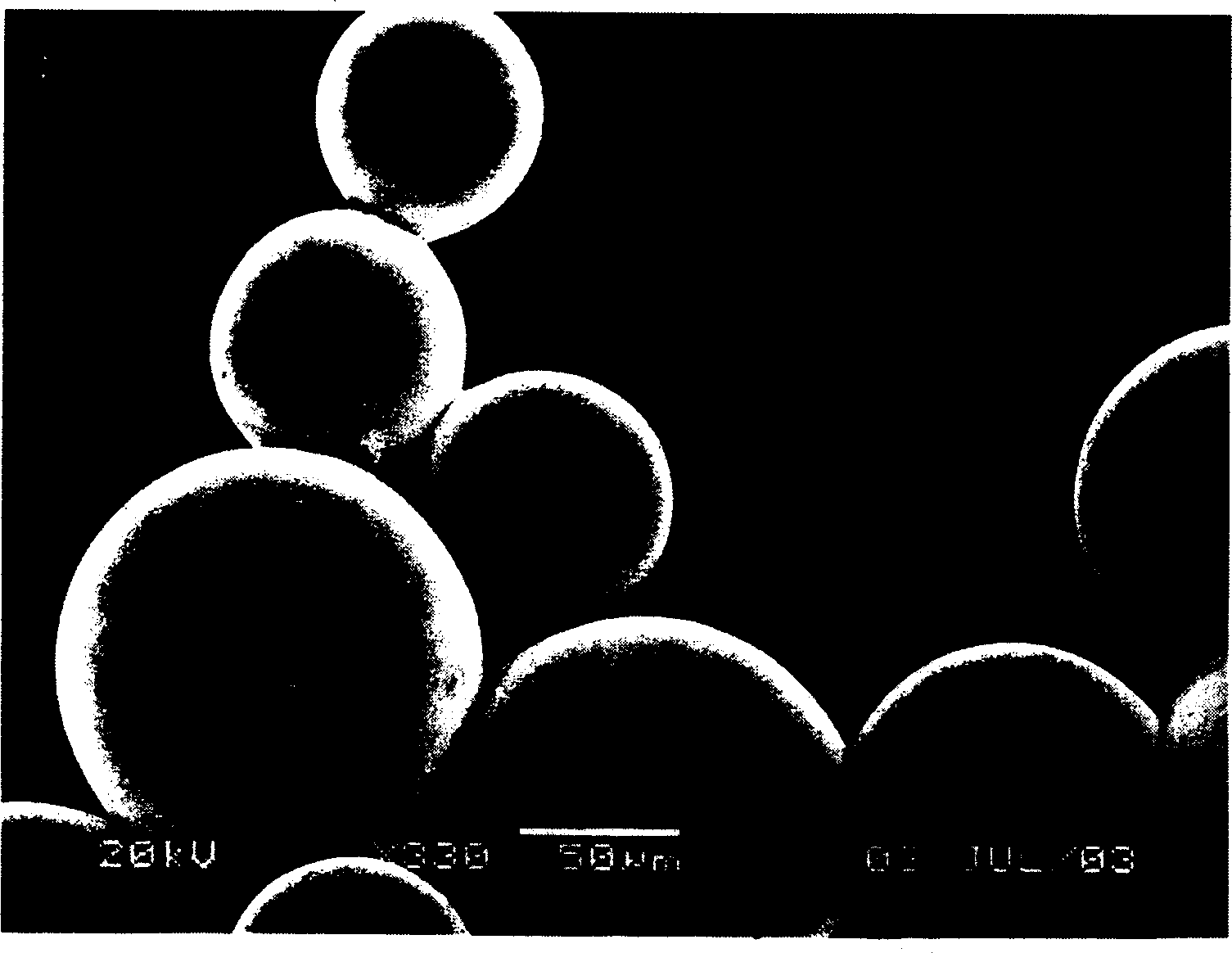

A two-part sizing formulation that imparts improved strength of reinforced composites including a size composition and a binder composition is provided. The size composition may include one or more coupling agents and one or more film forming agents. The binder composition includes a blocked isocyanate and a copolymer formed of a maleic anhydride and at least one other monomer copolymerizable therewith. In a preferred embodiment, the binder composition includes an ethylene-maleic acid copolymer formed by the hydrolysis of an ethylene-maleic anhydride copolymer. In an alternate embodiment, the size composition includes a coupling agent, a lubricant, and a wetting agent. The size composition may be applied to a reinforcing fiber material before the binder size material is applied. The two-part size composition may be applied to a reinforcing fiber which may then be densified or compacted to form a densified reinforcing fiber product, such as a pellet.

Owner:OWENS CORNING FIBERGLAS TECH II

Preparation method of microcapsule for electrophoretic display

InactiveCN1544141AOvercoming performance shortcomingsUniform particle size distributionMicroballoon preparationNon-linear opticsHydrolysateElectrophoresis

The invention discloses an electrophoresis-displaying microcapsule and its preparing method, which recondenses hydrolysate of styrene-maleic anhydride copolymer and glutin to prepare the microcapsule. By the proper technique, it firstly emulsifies the encapsulated matter in the styrene-maleic anhydride copolymer solution, adds in the gultin, and then recondenses them by adding acid and / or water. Its advantages: provision of synthetic high-molecular styrene-maleic anhydride copolymer overcomes the disadvantage that the natural gum Arabic high molecule is easy to degrade so as to affect performance of the microcapsule, and reduces the cost. And by proper technique, it can prepare circular microcapsules which are stable, sealed and have more uniform particle size distribution.

Owner:ZHEJIANG UNIV

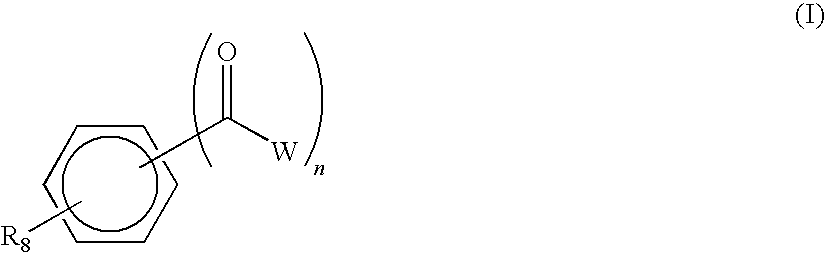

Polymer laminated film and solar panel using laminated film

ActiveCN101823355ANanotechSynthetic resin layered productsMethyl groupEthylene-maleic anhydride copolymer

The invention discloses a laminated film which comprises (a) a base layer and (b) a bonding layer on a main surface of the base layer, wherein the bonding layer is selected from (i) ethylene-(methyl) acrylic acid C1-4 alkyl ester copolymer, and ethylene-(methyl) acrylic acid copolymer or ethylene-maleic anhydride copolymer; (ii) multi-copolymer formed by ethylene and at least two comonomers selected from (methyl) acrylic acid C1-4 alkyl ester copolymer and the ethylene-(methyl) acrylic acid copolymer or the ethylene-maleic anhydride copolymer; (iii) copolymer containing glycidyl methacrylate formed by the ethylene, the glycidyl methacrylate and at least one comonomer selected from the (methyl) acrylic acid C1-4 alkyl ester copolymer, the ethylene-(methyl) acrylic acid copolymer or the ethylene-maleic anhydride copolymer; or (iv) blend of two or more of the copolymers, wherein the bonding layer is directly placed on the base plate or a base coating with the thickness of less than 0.99 mu m is arranged between the base layer and the bonding layer.

Owner:DUPONT ELECTRONICS INC

Controlled-Release Agricultural Chemical Formulation

InactiveUS20070224233A1Improve photostabilityControl dispersivityBiocideAnimal repellantsSalicylic acidStyrene maleic anhydride

An object of the present invention is to provide an agricultural chemical formulation which is able to control release of an agricultural chemical active ingredient. This agricultural chemical formulation includes a composition, containing an agricultural chemical active ingredient, styrene-maleic anhydride copolymer or mixture of styrene-maleic anhydride copolymer and polymer having repeating units derived from rosin or derivative thereof or salicylic acid or derivative thereof, and a release controller (a water-soluble polymer, a hydrophobically-treated silicon oxide, or a surfactant), forming a compatible state or matrix.

Owner:NIPPON SODA CO LTD

Two-part sizing composition for reinforcement fibers

InactiveUS20070154697A1High loss-on-ignition (LOI)Improve mechanical propertiesFibre treatmentNon-woven fabricsFiberCarboxylic acid

A two-part sizing formulation that imparts improved strength of reinforced composites including a size composition and a binder composition is provided. The size composition may include one or more coupling agents and one or more film forming agents. The binder composition includes a high acid number copolymer formed from the polymerization of maleic anhydride or maleic acid and at least one other desired monomer and / or a high acid number polycarboxylic acid. In a preferred embodiment, the binder composition includes an ethylene-maleic acid copolymer formed by the hydrolysis of an ethylene-maleic anhydride copolymer. The size composition may be applied to a reinforcing fiber material before the binder size material is applied. The two-part size composition may be applied to a reinforcing fiber material to form a reinforcing fiber product which may then be densified or compacted to form a densified reinforcing fiber product, such as a pellet.

Owner:OCV INTELLECTUAL CAPITAL LLC

Toughened thermoplastic polyamide compositions

The present invention is a composition useful as an impact modifier for polyamide compositions. In one embodiment, impact modifiers of the present invention are ethylene maleic anhydride copolymers having at least 3% maleic anhydride functionality.

Owner:PERFORMANCE MATERIALS NA INC

Anti-back-staining agent used in jeans enzyme washing

InactiveCN102392374AQuality improvementIncrease added valueFibre treatmentDyeing processHydrolysateActive agent

The invention relates to an assistant for textile dyeing and finishing and discloses an anti-back-staining agent used in jeans enzyme washing. The agent comprises 10-35% of alkaline hydrolysate of styrene / maleic anhydride copolymer, 2-10% of polyvinylpyrrolidone, 2-10% of fatty amine polyoxyethylene ether, 5-25% of fatty alcohol polyoxyethylene ether and the balance of water by mass. The agent has the following advantages: the alkaline hydrolysate of the polymer surfactant styrene / maleic anhydride copolymer is adopted as the main component of the anti-back-staining agent, has excellent effects on adsorbing and dispersing insoluble indigo and can better disperse the dyes generated by enzyme washing in washing liquid, thus achieving the anti-back-staining effect; after the alkaline hydrolysate is compounded with other surfactants, the anti-back-staining effect can be further improved; and the anti-back-staining agent provided by the invention does not have obvious influence on the activity of cellulase, does not reduce the enzyme washing effect, has better biodegradability and is beneficial to environmental protection.

Owner:SUZHOU UNIV

Preparation method for blocked waterborne polyurethane and application of blocked waterborne polyurethane to preparation of digital printing waterborne paint ink

ActiveCN106947049AImprove dispersion stabilityGood dispersionDyeing processFiberDispersion stability

The invention discloses a preparation method for blocked waterborne polyurethane. The method is characterized in that polyurethane is modified by synthesizing a partially-esterified styrene-maleic anhydride copolymer carrying hydroxyl, so that a polyurethane chain plays a role in strongly anchoring organic pigment particles, the dispersion stability of the organic pigment particles in waterborne polyurethane emulsion and the adhesion of a pigment by a waterborne polyurethane adhesive during inkjet curing are facilitated, and the friction resistance and washing fastness are improved. Meanwhile, the polyurethane is subjected to active blocking, so that an unblocked NCO group can react with an OH group on fiber during heating curing after digital printing waterborne paint ink prepared by taking the blocked waterborne polyurethane emulsion prepared by the method as an adhesive is directly jetted onto a fiber fabric, thereby remarkably improving the color fixing firmness and friction resistance. A printed pattern is bright in color, and is soft in handfeel.

Owner:SUN YAT SEN UNIV +1

Natural fiber-reinforced styrene maleic anhydride copolymer composition and preparation method thereof

The invention relates to a natural fiber-reinforced styrene maleic anhydride copolymer composition and a preparation method thereof. The composition comprises the following components in percentage by weight: 10-50 percent of a styrene maleic anhydride copolymer, 10-40 percent of a rubber elastomer, 5-25 percent of a styrene acrylonitrile copolymer, 5-40 percent of natural fibers and 0.1-1.5 percent of a processing aid. The preparation method comprises the following steps of: premixing the components in a high-speed mixer for 3-10 minutes according a certain proportion; leading out; and putting into a screw compressor for extruding and granulating to obtain a product. Compared with the prior art, the invention has the advantages that: a natural fiber-reinforced styrene maleic anhydride copolymer is adopted, so that a prepared product has excellent mechanical performance; and compared with a glass fiber-reinforced product, the prepared product has the advantages of light weight, safety, comfort and degradability.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Laser directly moulded resin composition with improved impact resistance, and preparation method and application thereof

The invention relates to a laser directly moulded resin composition with improved impact resistance as well as a preparation method and application thereof, and mainly solves the problems of low impact strength and low toughness of a polymer composite material capable of being used for laser direct moulding in the prior art. The laser directly moulded resin composition comprises the following components in parts by weight: 50-90 parts of thermoplastic resin; 1-15 parts of a laser activator; 3-15 parts of a toughening compatilizer; 0.1 to 5 parts of a surface modifier; and 1-20 parts of an auxiliary agent; wherein the toughening compatilizer is selected from at least one of a maleic anhydride grafted copolymer, an ethylene-maleic anhydride copolymer, an ethylene-propylene-maleic anhydride copolymer, an ethylene-octene-maleic anhydride copolymer, an ethylene-vinyl acetate-maleic anhydride copolymer and an ethylene-acrylate-maleic anhydride copolymer. The problems are well solved, and thecomposition can be applied to fields such as communication, electronics, automobiles, medicines, spaceflight, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermosetting resin composition and application thereof

ActiveCN103740055AImprove adhesionHigh glass transition temperatureSynthetic resin layered productsCircuit susbtrate materialsMetal foilBromine

The invention provides a thermosetting resin composition, comprising bromized epoxy resin, biphenyl-type and / or naphthalene-type epoxy resin, styrene-maleic anhydride copolymer and cyanate ester resin, wherein the bromine element content in a molecular structure of the bromized epoxy resin is 36-60% based on weight content; the weight of the bromine element in the bromized epoxy resin is 10-23% of total weight of the thermosetting resin composition. The thermosetting resin composition has good heat stability and humidity resistance, good tenacity, adhesive force and fire resistance, and low dielectric constant and dielectric loss angle tangent. The embodiment of the invention also provides application of the thermosetting resin composition in a resin sheet, a resin composite metal foil, a prepreg, a laminated plate, a coated metal foil pressure plate and a printed circuit board.

Owner:HONOR DEVICE CO LTD

Miscible Blends of Ethylene Copolymers With Improved Temperature Resistance

The present invention is a composition useful as an impact modifier for polyamide compositions. In one embodiment, impact modifiers of the present invention are ethylene maleic anhydride copolymers having at least 3% maleic anhydride functionality. Compositions comprising copolymers of ethylene and maleic anhydride or its functional equivalents and ethylene copolymers with polar comonomers are disclosed. The compositions provide miscible blends and exhibit improved properties, such as increased temperature resistance and mechanical strength, compared to pure ethylene copolymers with polar comonomers.

Owner:PERFORMANCE MATERIALS NA INC

Esterfying polycarboxylic acid type ceramic water-reducing agent and preparation method thereof

The invention relates to a ceramic water-reducing agent, in particular to an esterfying polycarboxylic acid type ceramic water-reducing agent and a preparation method thereof. The invention adopts the technical scheme as follows: carrying out polymerization reaction to obtain a high-polymer main chain, and introducing a certain proportion of functional group on the main chain through the esterification reaction to form a comb-pattern molecule structure so as to keep high water-reducing rate and not to cause obvious slow release, thereby an esterfying styrene maleic anhydride copolymer is obtained, the copolymer is prepared into solution by self or compounding with inorganic salts, and the solution can be used as the ceramic water-reducing agent. The method has easily-obtained materials, simple process, convenient operation as well as easy marketability and industrial production. The obtained water-reducing agent can obtain high polymer with the comb-pattern structure by esterfying styrene maleic anhydride. A polyether lateral chain has better hydrophilcity and can also play a steric exclusion role and remarkably improve the dispersing performance of the water-reducing agent to mud particles. The efficiency of the compounded water-reducing agent can be further improved.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

High-rigidity high-toughness composite material applied to periphery of automobile engine and preparation method thereof

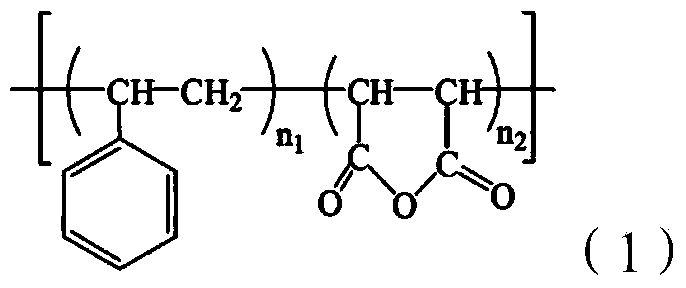

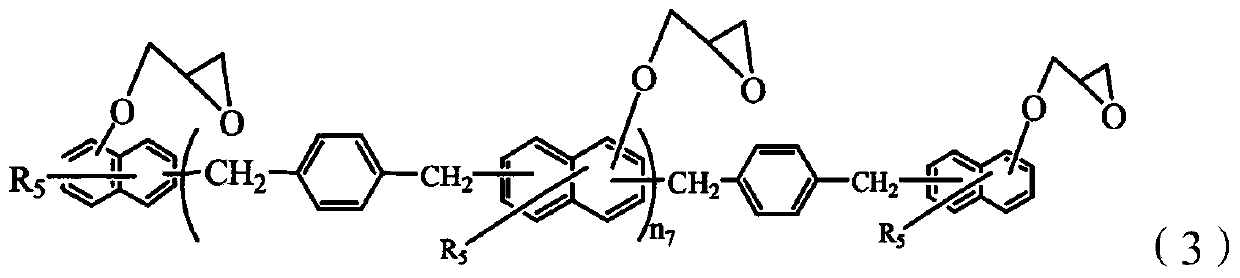

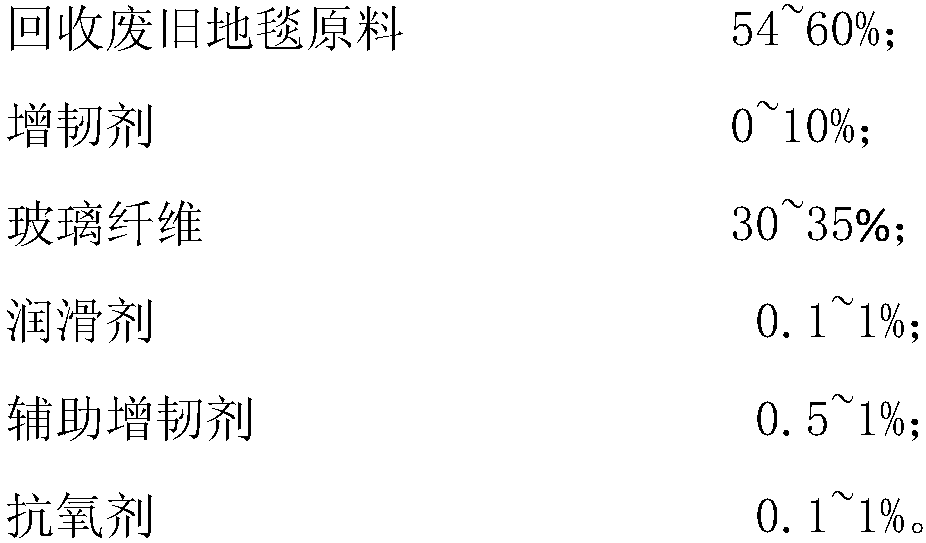

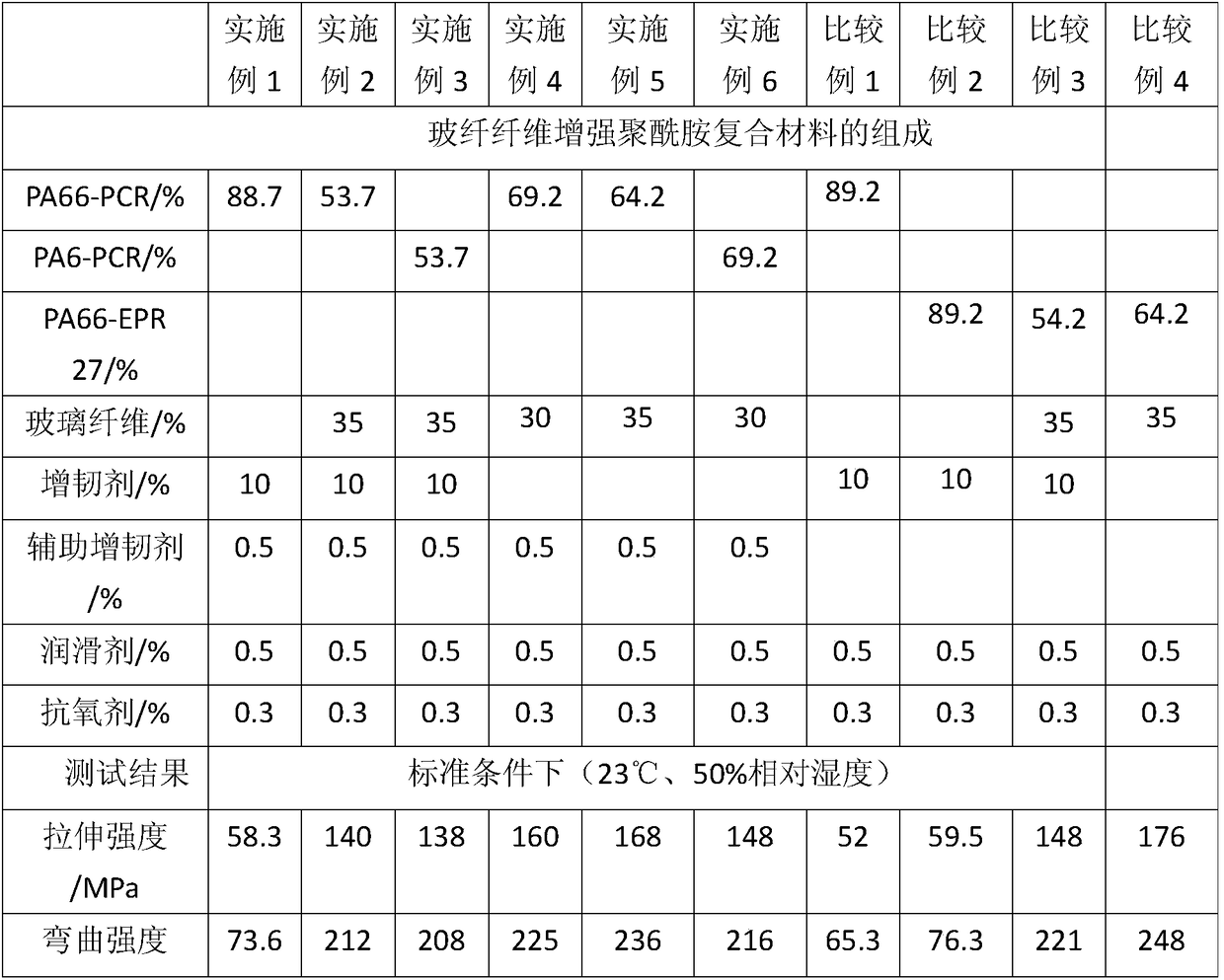

The invention discloses a high-rigidity high-toughness composite material applied to the periphery of an automobile engine and a preparation method thereof. The high-rigidity high-toughness compositematerial comprises the following raw materials by weight: 54 to 60% of recovered waste carpet material, 0 to 10% of a toughening agent, 30 to 35% of glass fibers, 0.1 to 1% of a lubricant, 0.5 to 1% of an auxiliary toughening agent and 0.1 to 1% of an anti-oxidant. Compared with the prior art, the high-rigidity high-toughness composite material provided by the invention has the following advantages: an ethylene maleic anhydride copolymer is used as the auxiliary toughening agent, and reactive functional groups in the copolymer of ethylene and maleic anhydride are reacted with maleic anhydrideused as the toughening agent of, a silane coupling agent on the surfaces of the glass fibers and a terminal functional group of nylon so as to form a micro-crosslinked structure; and thus, the material is endowed with mechanical properties, aging properties, freezing liquid resistance and the like equivalent to a newly-prepared material, and is allowed to meet the harsh requirements of the periphery of the automobile engine on nylon materials.

Owner:ZHEJIANG PRET NEW MATERIALS +4

Preparation method of epoxy soybean oil compatilizer for polyolefin composite material

The invention provides a preparation method of an epoxy soybean oil compatilizer for a polyolefin composite material. Epoxy soybean oil acrylate serves as a main raw material; a soybean oil-styrene-maleic anhydride copolymer is prepared by changing the consumption of the styrene, the maleic anhydride and polyethylene glycol and using a free radical polymerization method; the polymer can serve as a compatilizer of a polyolefin / calcium carbonate composite material. Since soybean oil and polyethylene glycol long flexible chain contained in the copolymer play a role of compatibilizing polyolefin, and carboxyl and hydroxyl in a copolymer molecule play a role of anchoring polar hydroxyl on the surface of calcium carbonate powder, so that interfacial compatibility and bonding strength of the polyolefin and the calcium carbonate can be effectively improved, further the rigidity and the toughness of the composite material are improved, and the requirements of engineering materials can be met. The method has the advantages of simple process, low cost, low environmental pollution, high applicability, easiness for large-scale popularization and application and the like; the prepared polyolefin composite material is widely applied to the fields of pipes, plates, various formed products, wires and cables, package, automobiles, machinery, daily groceries and the like.

Owner:唐桂珍

Polyethylene and polystyrene compound radiating coating and preparation method therefor

InactiveCN105111840AImprove impact resistanceImprove corrosion resistanceAnti-corrosive paintsDiacetone alcoholSodium ascorbate

The invention discloses a polyethylene and polystyrene compound radiating coating which is prepared from the following raw materials in parts by weight: 10-17 parts of brominated polystyrene, 12-15 parts of a styrene-maleic anhydride copolymer, 6-10 parts of propynol, 90-100 parts of copolymer, 4-7 parts of graphene, 16-20 parts of nano silicon dioxide, 0.2-0.3 part of a saline coupling agent KH560, 700-800 parts of dimethylformamide, 4-5 parts of sodium nitride, 0.04-0.05 part of aluminum trichloride, 1.6-2 parts of a 2-3% sodium ascorbate solution, 1.8-2 parts of a 2-3% copper sulfate solution, 120-130 parts of high density polyethylene, 1-2 parts of diacetone alcohol, 1-2 parts of glycerol triglycerate, 0.6-1 part of diacetone-acryloamide, 0.3-1 part of sp80, 2-4 parts of calcium fluoride and 1-2 parts of magnesium fluoride. The coating disclosed by the invention is blended by polyethylene and polystyrene, so that the surface strength and toughness of the coating are effectively improved and the weather resistance and the antiaging property are improved.

Owner:BENGBU TIMES ELECTRONICS

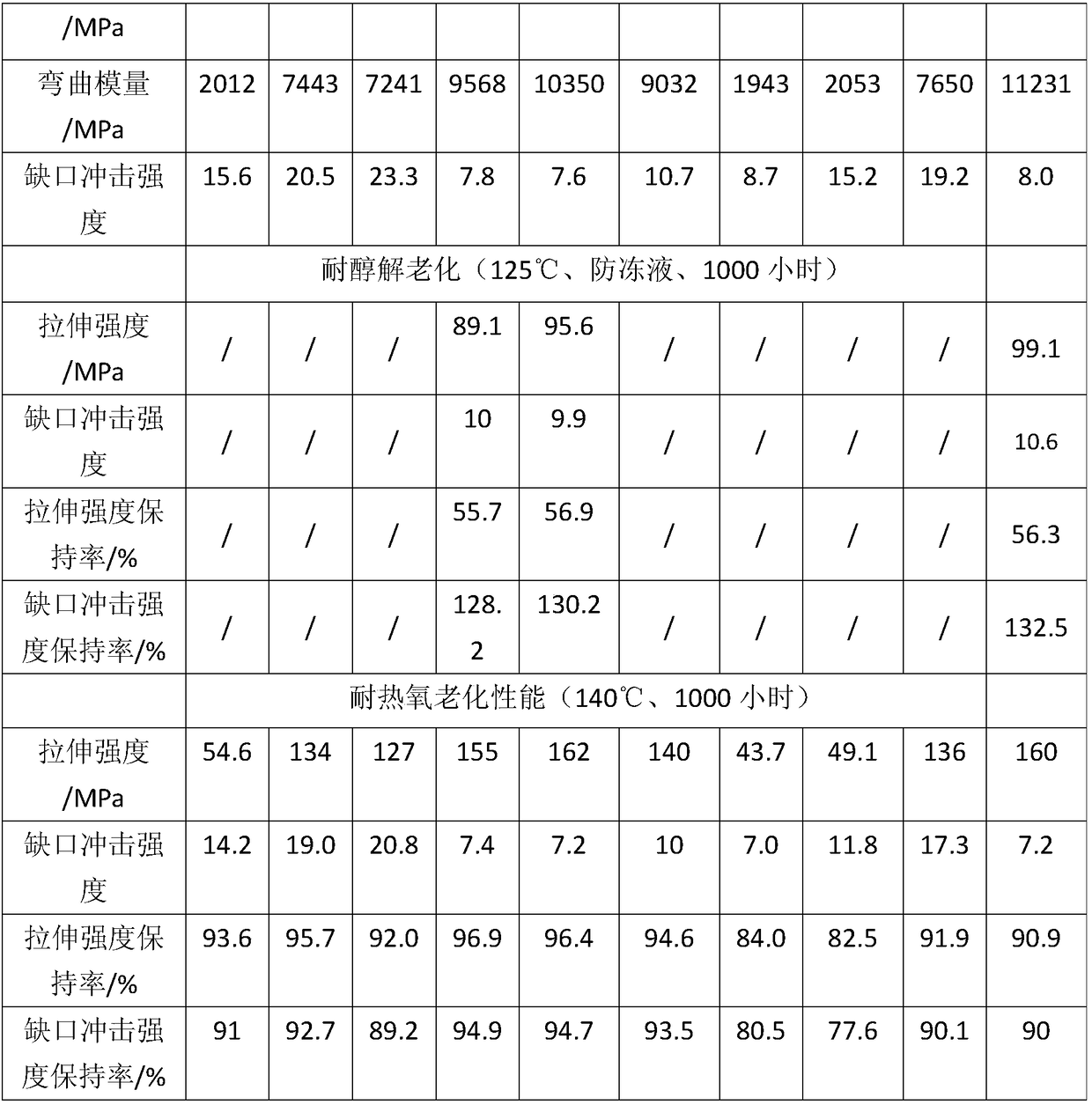

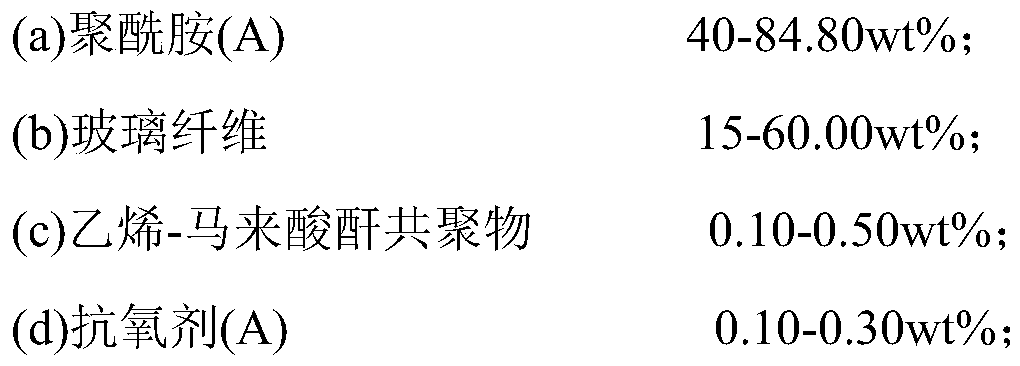

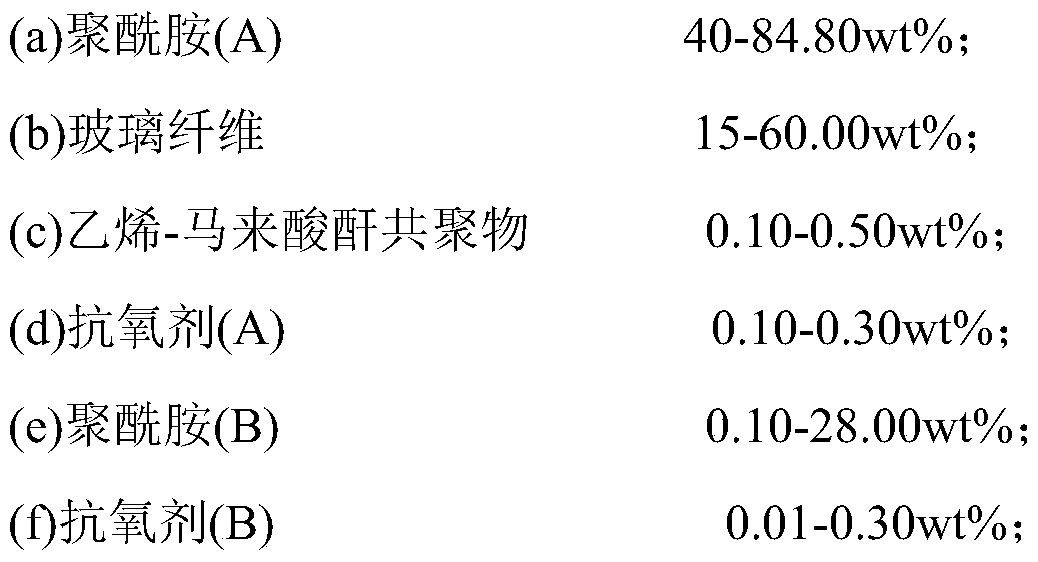

Pure hydrolysis-resistant polyamide composition and preparation method thereof

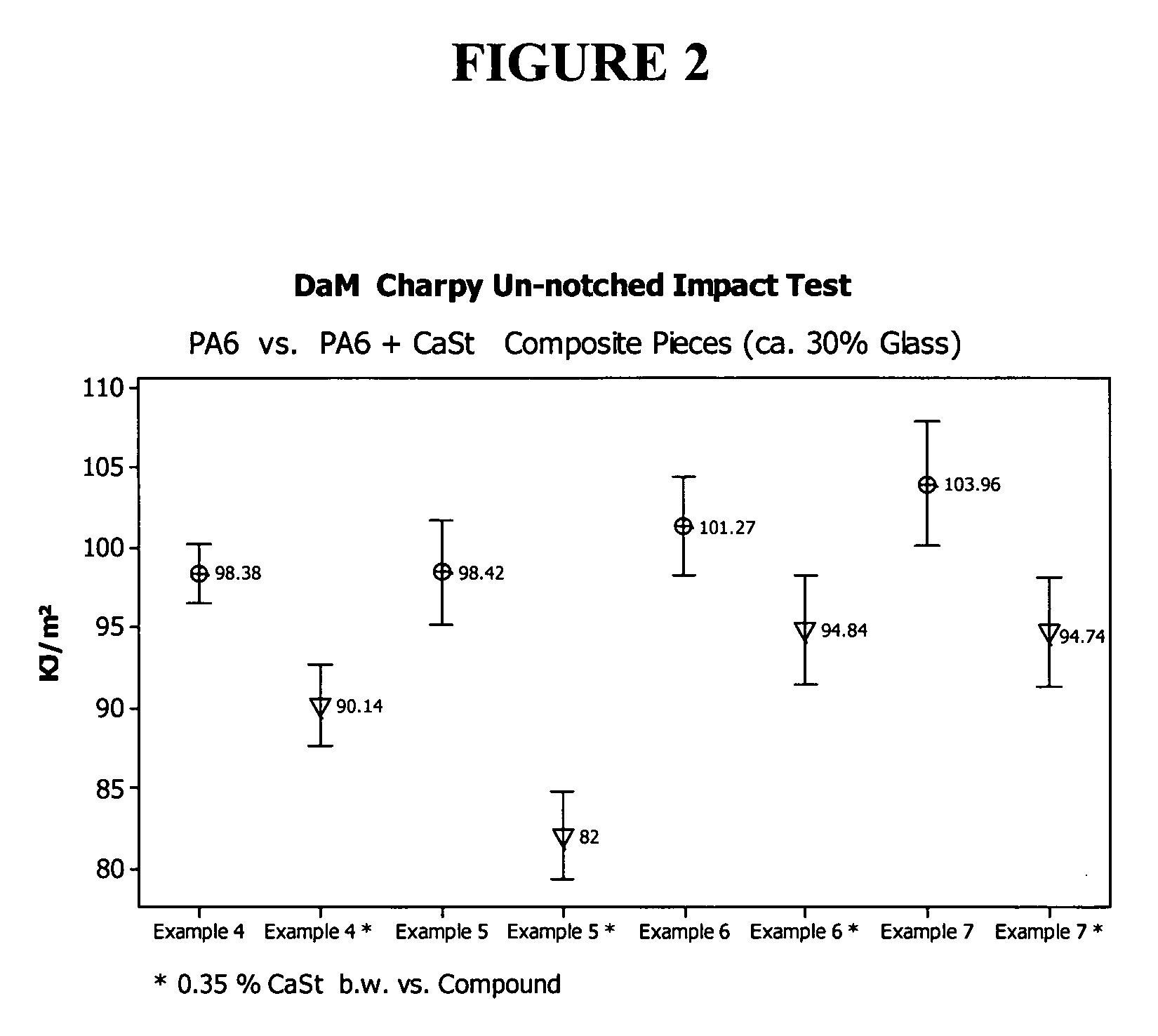

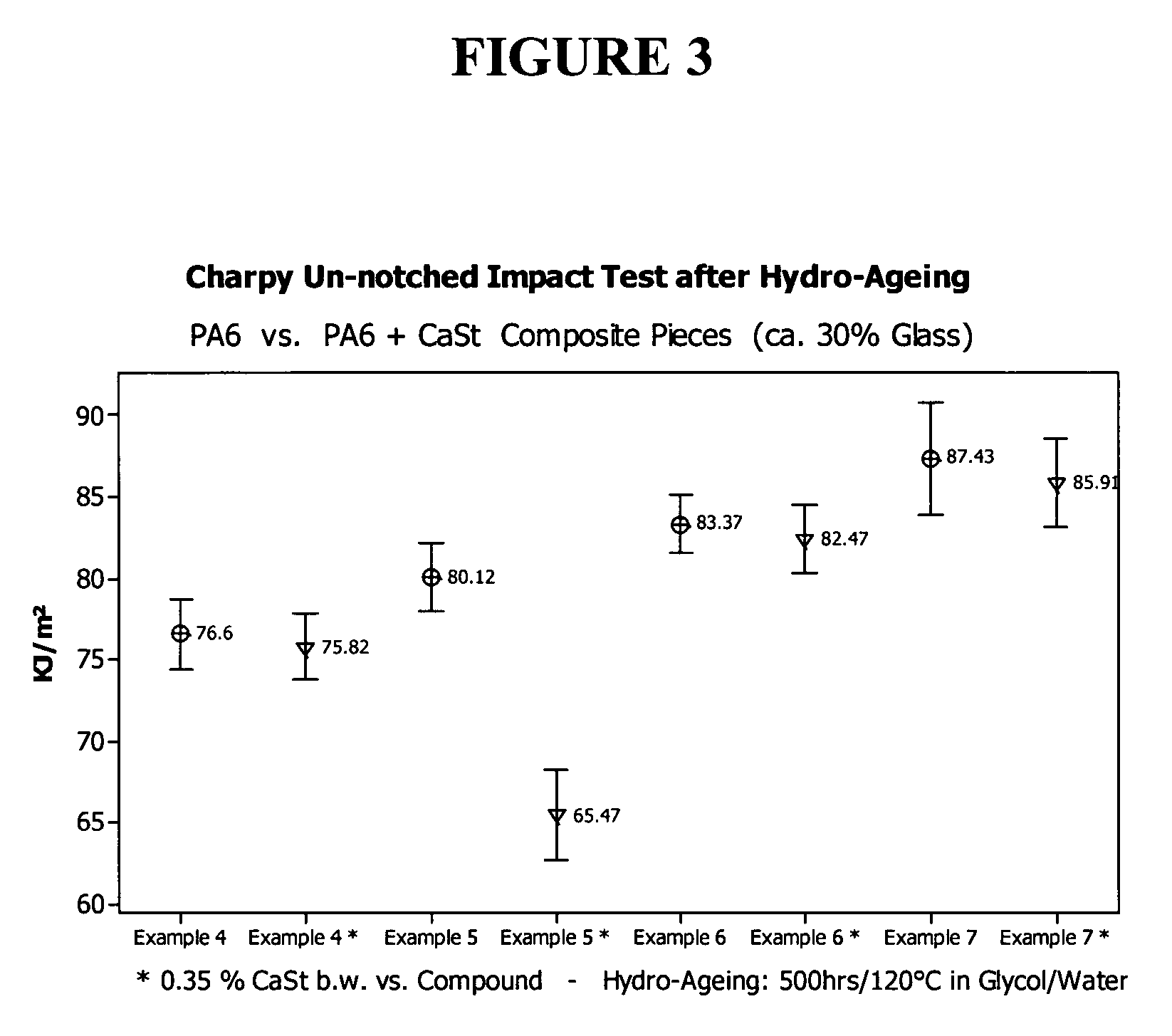

ActiveCN109943067AImproved retention of mechanical propertiesImprove long-term hydrolysis resistanceGlass fiberPolymer science

The invention discloses a pure hydrolysis-resistant polyamide composition and a preparation method thereof, and the pure hydrolysis-resistant polyamide composition comprises the following components in percentage by mass: 40-84.80 wt% of polyamide (A), 15-60.00 wt% of glass fiber, 0.10-0.50 wt% of ethylene-maleic anhydride copolymer and 0.10-0.30 wt% of antioxidant (A), wherein the polyamide (A) is polyhexamethylene adipate and has more than 70 mmol / kg of terminal amino group or less than 60 mmol / kg of terminal carboxyl group; the polyamide and the functional auxiliary agent are added into themain feeding port of an extruder; the glass fiber is added into the feeding port at the middle section side; the pure polyamide composition with long-term heat-resistant chlorine water is obtained through screw extrusion drawing, granulation and drying; the polyamide composition has a tensile strength retention rate of at least 50% after being soaked in hot chlorine water (Cl content of 5 ppm) at90 DEG C / 1000 hours.

Owner:江苏晋伦塑料科技有限公司

Toughened thermoplastic polamide compositions

InactiveUS20050239964A1Synthetic resin layered productsThin material handlingPolyamideEthylene-maleic anhydride copolymer

The present invention is a composition useful as an impact modifier for polyamide compositions. In one embodiment, impact modifiers of the present invention are ethylene maleic anhydride copolymers having at least 3% maleic anhydride functionality.

Owner:PERFORMANCE MATERIALS NA INC

Blended graphene and silicon dioxide dispersing and heat-dispersion paint and preparation method therefor

InactiveCN105111838AImprove impact resistanceImprove corrosion resistanceCoatingsSodium bicarbonateCopper sulfate

The present invention disclose blended graphene and silicon dioxide dispersiing and heat-dispersion paint. The blended graphene and silicon dioxide dispersiing and heat-dispersion paint consists of the following raw materials in parts by weight: 2-4 parts of calcium aluminate, 1-2 parts of magnesium stearate, 12-15 parts of styrene-maleic anhydride copolymer, 6-10 parts of propargyl alcohol, 90-100 parts of tetrahydrofuran, 4-7 parts of graphene, 16-20 parts of nano silica, 0.3-0.4 part of a silane coupling agent KH560, 700-800 parts of dimethylformamide, 4-5 parts of sodium nitride, 0.04-0.05 part of aluminium trichloride, 1.6-2 parts of a 2-3% sodium ascorbate solution, 1.8-2 parts of a 2-3% copper sulfate solution, 120-130 parts of high density polyethylene, 2-3 parts of propylene glycol alginate, 0.8-1 part of polyacrylamide, 0.5-1 part of sodium bicarbonate, 6-10 part of polyvinylidene chloride, and 2-3 parts of microcrystalline wax. According to the blended graphene and silicon dioxide dispersiing and heat-dispersion paint, a thermal conductivity network formed by a graphene two-dimensional planar structure and a nano silica dioxide three-dimensional network structure is dsitributed in resin, so that the heat radiating effect is achieved.

Owner:BENGBU NANZI INSTR

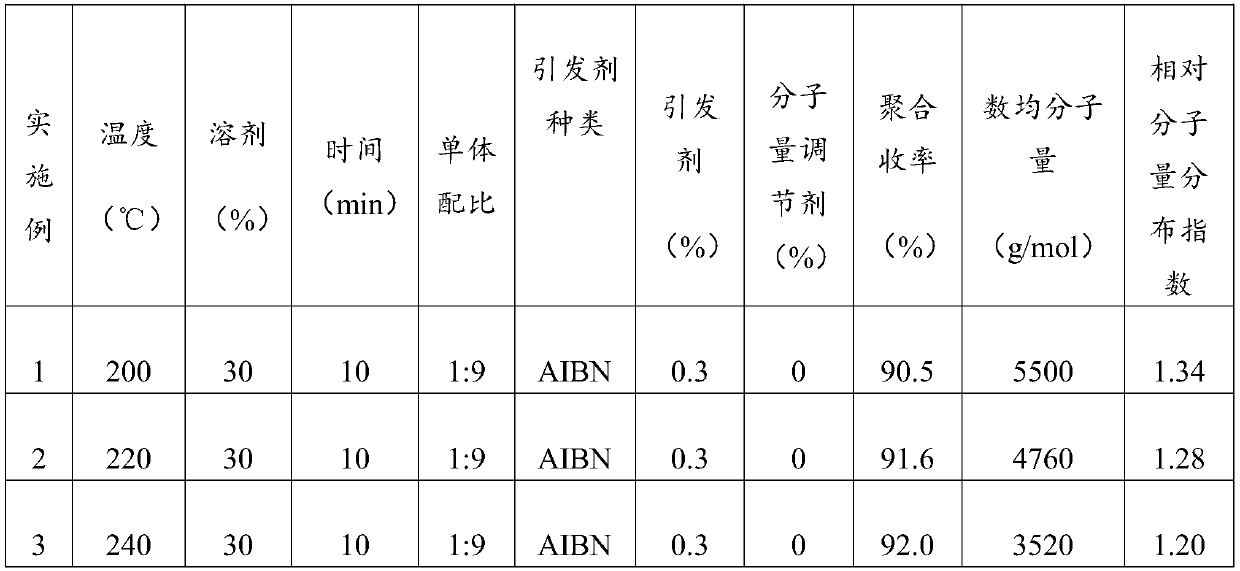

Low molecular weight styrene maleic anhydride copolymer and preparation method thereof

The invention provides a low molecular weight styrene maleic anhydride copolymer and a preparation method thereof, and relates to the field of polymer material synthesis. The copolymer is obtained byfree radical copolymerization of monomers, and the monomers comprise the following components according to the mole fraction: 45-50% of styrene; 45-50% maleic anhydride; 5-10% of C12-C18 monounsaturated fatty acids; and 0-5% of unsaturated monomers, wherein the unsaturated monomers do not comprise styrene, maleic anhydride and C12-C18 monounsaturated fatty acids. The invention further provides a preparation method of the copolymer. The copolymer has the characteristics of light color, high acid value, low molecular weight and uniform structure, and can be respectively used as a surface sizingagent, an organic pigment dispersant, an emulsion polymerization protective colloid, a photoresist and the like of paper in the industries of papermaking, textile, printing and dyeing, coating, chemical industry, photoelectricity and the like.

Owner:上海深竹化工科技有限公司

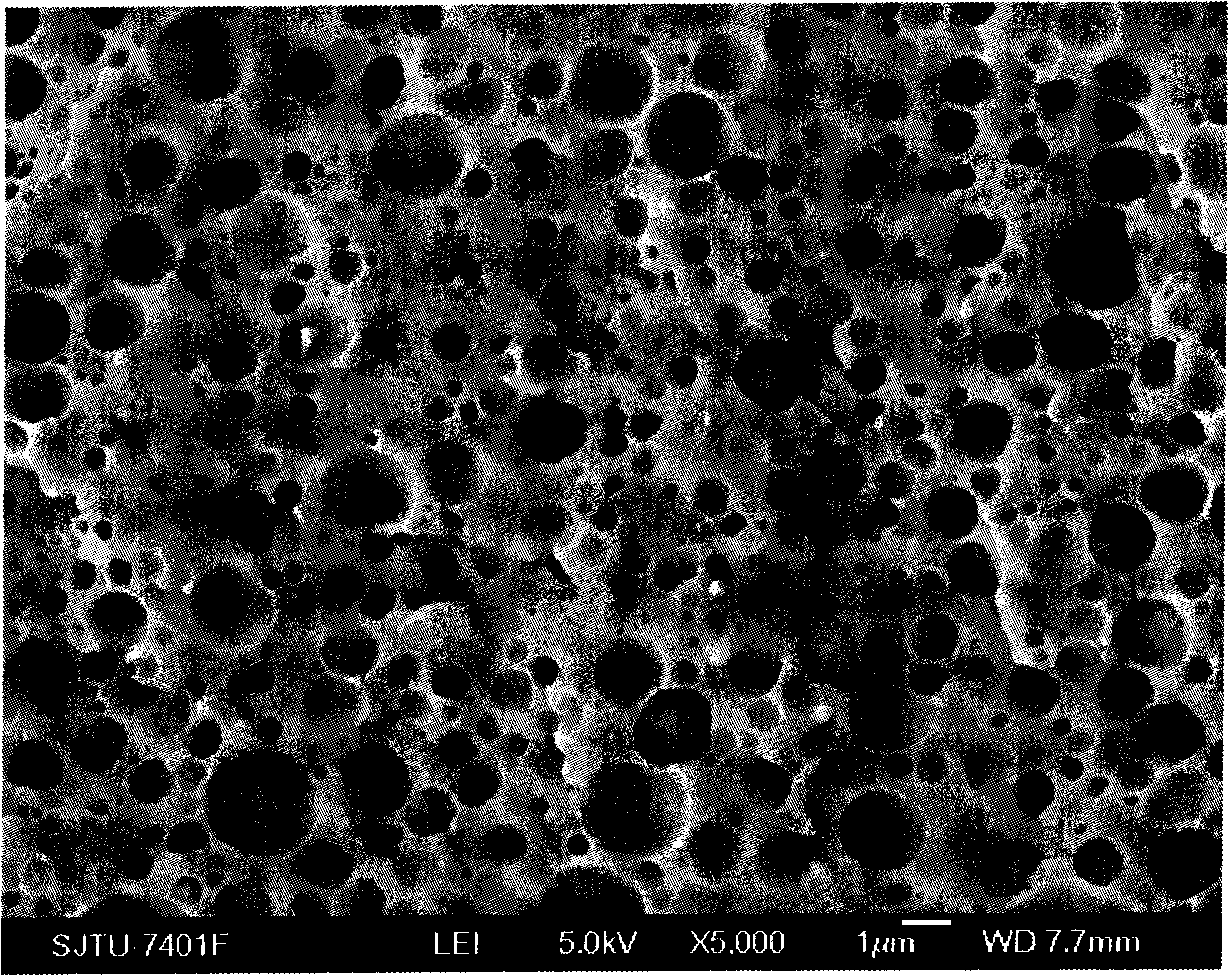

Capacity increasing modifying method for polyphenylene oxide / nylon 6 alloy

The invention discloses a polyphenylether / nylon 6 alloy compatibilizing and modifying method which comprises the following steps: nylon 6 and styrene-maleic anhydride copolymer are dried in a vacuum state, and then 30-50 portions of styrene-maleic anhydride copolymer and 50-70 portions of nylon 6 are added in a double-screw extruder to be extruded and granulated so that the blend of nylon 6 / styrene-maleic anhydride copolymer is prepared; and 50-80 portions of nylon 6 dried in a vacuum state, 20-50 portions of polyphenylether and 2-20 portions of nylon 6 and styrene-maleic anhydride copolymer are extruded and granulated so that polyphenylether / nylon 6 alloy compatibilizing and modifying material is prepared. Compared with the simple blend of polyphenylether / nylon 6, the polyphenylether / nylon 6 alloy compatibilizing and modifying material has the tensile strength of 76 Mpa and the notch impact strength of 33.5 J / m which are respectively improved by 50 percent and 40 percent.

Owner:SHANGHAI JIAO TONG UNIV

Reaction type water-based color paste and preparation method thereof

InactiveCN110845913AAid in solubilityGuaranteed SolubilityPigment pastesPolymer scienceOrganic chemistry

The invention relates to reaction type water-based color paste and a preparation method thereof. The reaction type water-based color paste is prepared from the following raw material components in parts by weight: styrene-maleic anhydride copolymer polyether ester, a hydroxylated pigment and a neutralizer, wherein the addition amount of the styrene-maleic anhydride copolymer polyether ester and the hydroxylated pigment is that the ratio of the molar weight of maleic anhydride to the molar weight of hydroxyl is (1: 1)-(1: 2), and the addition amount of the neutralizer is that the pH value of the color paste is adjusted to be 6-8. By uniformly stirring and mixing the styrene-maleic anhydride copolymer polyether ester and the hydroxylated pigment (hydroxylated carbon black and the like); heating to 100-150 DEG C, reacting for 2.0-6.0 hours, adding the neutralizer to neutralize until the pH value is 6-8, and adding a certain amount of water to regulate the viscosity, the reaction type water-based color paste is obtained. Compared with the prior art, the color paste provided by the invention has good water solubility and storage stability, has good dispersibility and color rendering property for other pigments and fillers, can form a color paste system with good performance, and can be widely applied to the fields of water-based paint and water-based ink.

Owner:DONGLAI COATING TECH SHANGHAI

Low-molecular-weight narrow-distribution styrene-maleic anhydride copolymer and preparation method thereof

The invention provides a low-molecular-weight narrow-distribution styrene-maleic anhydride copolymer and a preparation method thereof, and belongs to the technical field of high polymer material preparation. The styrene-maleic anhydride copolymer is prepared by adopting a high-temperature continuous free radical polymerization method, the method is simple in process, low in solvent and initiator consumption, low in cost, capable of realizing continuous production, short in reaction time, high in reaction rate and high in conversion rate; and the low-molecular-weight narrow-distribution styrene-maleic anhydride copolymer prepared by the method is small in molecular weight distribution range, more uniform in product molecular weight distribution and more stable in product performance, and has a good industrial prospect.

Owner:CHANGCHUN UNIV OF TECH

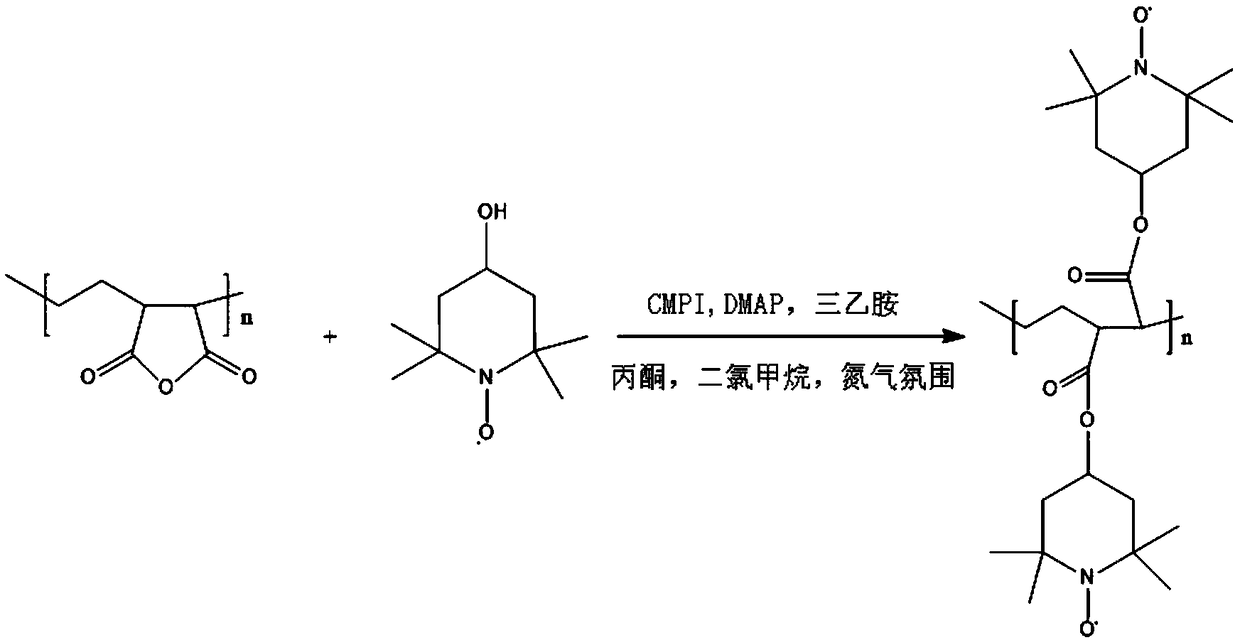

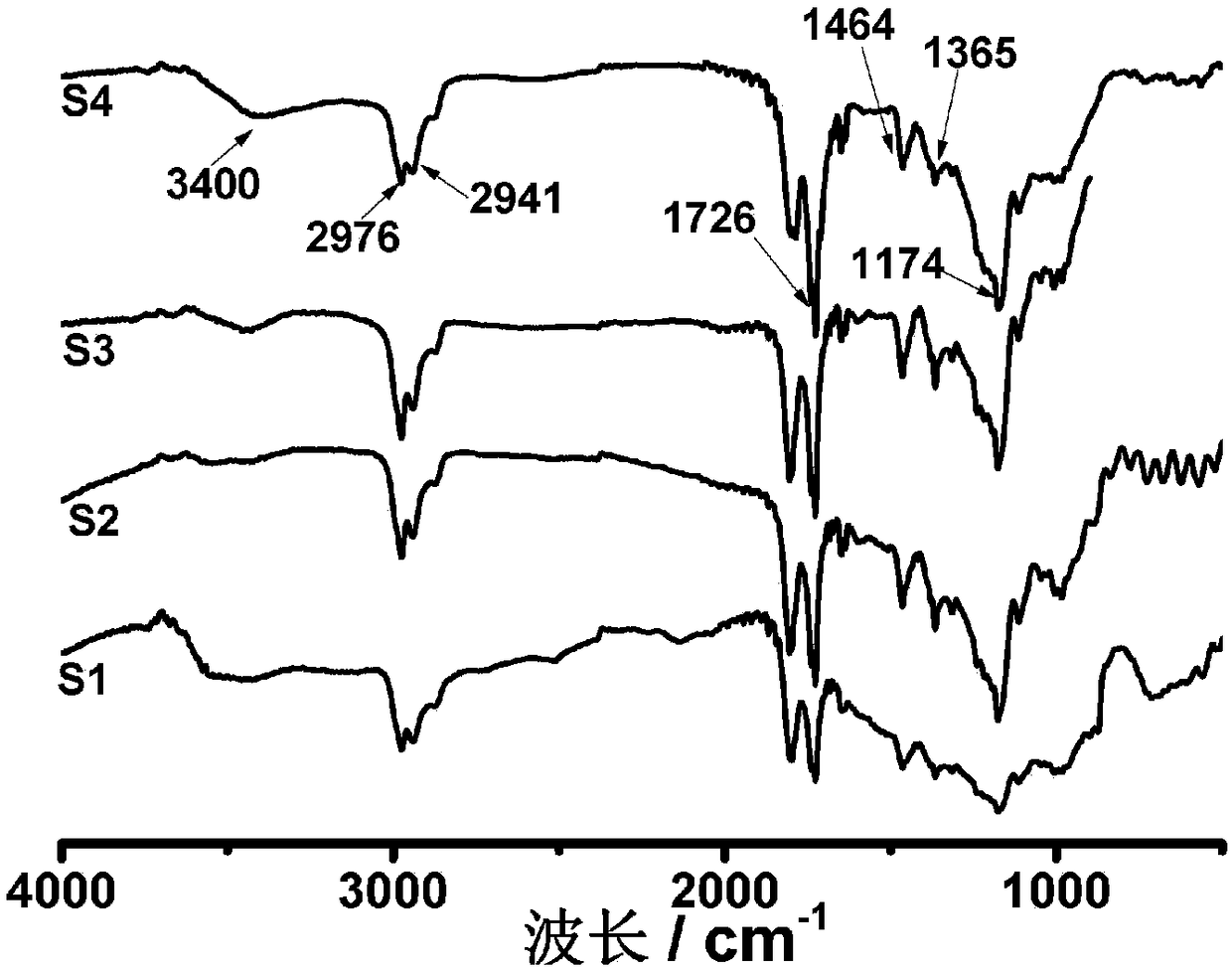

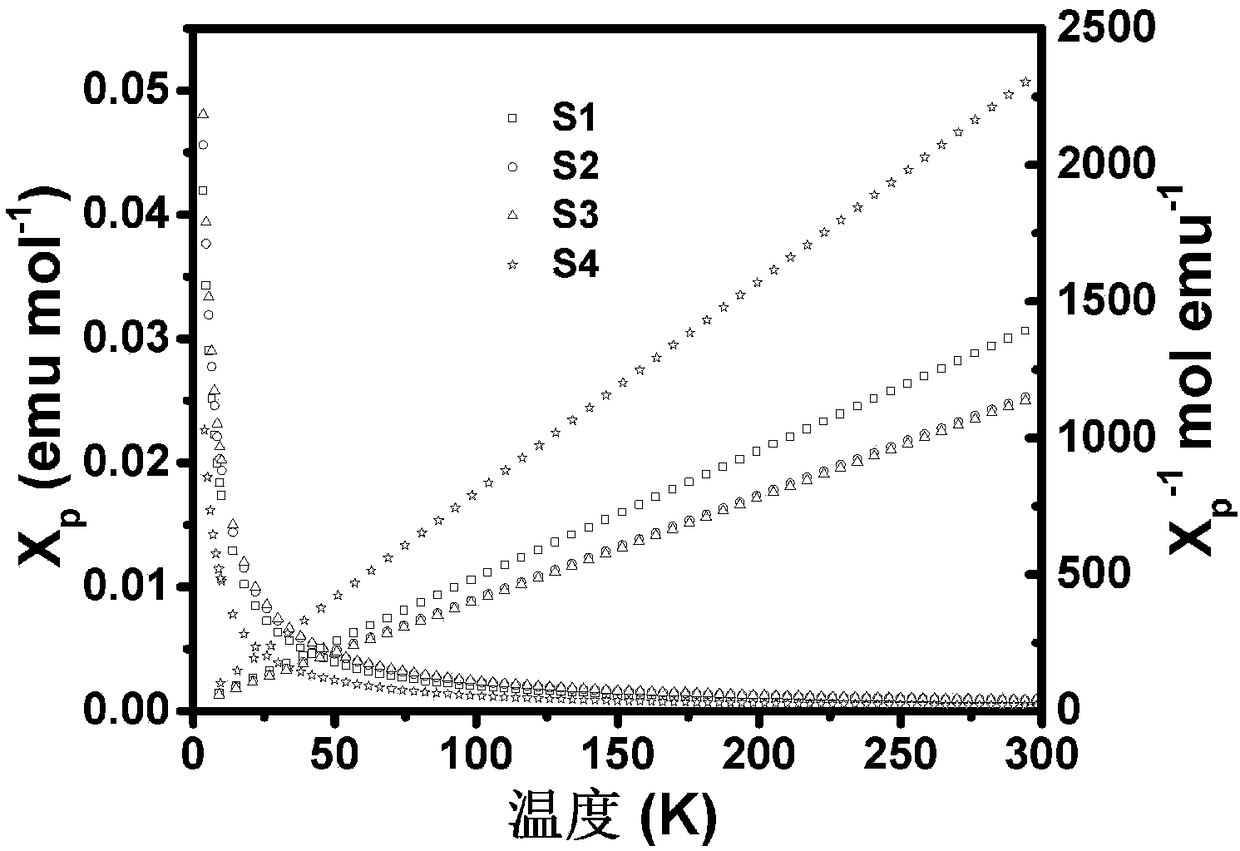

Free radicalized ethylene-maleic anhydride copolymer and synthesis method thereof

The invention provides a synthesis method of a free radicalized ethylene-maleic anhydride copolymer, and belongs to the field of functional high molecular chemistry. An esterification reaction is performed on an ethylene-maleic anhydride copolymer and 4-hydroxy-2, 2, 6, 6-tetramethylpiperidine nitroxide free radicals to obtain the free radicalized ethylene-maleic anhydride copolymer. By the synthesis method, a previous method for preparing a free radicalized polymer by relying on complex and cumbersome monomer polymerization is broken through, only one step of simple esterification reaction isneeded, and the prepared free radicalized ethylene-maleic anhydride copolymer has high molecular weight and relatively high free radical content of per unit mass of repeating units, and the free radical number of each monomer molecule can be as high as 0.97; the electrolyte resistance is good, and the solubility in an electrolyte solution is only 0.59mg / mL; meanwhile, the synthesis method has theadvantages of simple reaction, mild condition, and high reaction degree which can reach 54%.

Owner:SUN YAT SEN UNIV

Radiation crosslinking halogen-free flame retardant ABS/PC (acrylonitrile butadiene styrene/ polycarbonate) composite material and preparation method thereof

The invention relates to a radiation crosslinking halogen-free flame retardant ABS / PC (acrylonitrile butadiene styrene / polycarbonate) composite material and a preparation method thereof. An electronic accelerator can be adopted to perform crosslinking modification on the ABS / PC composite material, and defects of poor heat resistance, liquidity and rigidity of a conventional ABS / PC composite material and the defect that the ABS / PC composite material cannot be used for an automobile, a heat-resisting electronic and electrical apparatus element and a large-size injection molding part are mainly overcome. The radiation crosslinking halogen-free flame retardant ABS / PC composite material is provided, the heat resistance limit is broken through, the heat resisting temperature is increased, meanwhile, the rigidity of the material is improved, the supporting strength of a thin-walled workpiece is ensured, and the market demand is met. A product mainly comprises raw materials of ABS resin, PC, styrene-maleic anhydride copolymer, methyl methacrylate-butadiene-styrene copolymer, trimethylolpropane trimethacrylate, triphenyl phosphate, ammonium polyphosphate, zinc borate, resorcinol bis(diphenyl phosphate), methyl vinyl silicone rubber and the like.

Owner:HUBEI HUACHENG TECH

Method of directing grafting by controlling the location of high vinyl segments in a polymer

A method of producing an engineered plastic selected from the group consisting of high impact polystyrene, styrene-maleic anhydride copolymer, methylmethacrylate-butadiene-styrene copolymer, transparent impact polystyrene, and acrylonitrile butadiene styrene copolymer is provided. The method comprises the steps of: (a) adding a polymer containing at least one high vinyl segment having a 1,2-vinyl bond content of greater than 45% to a solvent comprising at least one vinyl monomer; (b) optionally adding at least one additional inert solvent; (c) optionally adding additives selected from the group consisting of extender oils, modifiers, and antioxidants; and (d) initiating polymerization of the at least one vinyl monomer by the use of an initiator and / or heat, wherein the presence of the at least one high vinyl segment in the polymer allows direction of the grafting site during preparation of the engineered plastic.

Owner:BRIDGESTONE CORP

Check valve casting and machining process thereof

ActiveCN112430404AImprove wear resistanceSpray evenlyLiquid surface applicatorsCoatingsPolymer sciencePtru catalyst

The invention relates to the field of castings, and discloses a check valve casting and a machining process thereof. The surface of the check valve casting is treated by a surface treating agent, andthe surface treating agent comprises the following raw materials in parts by weight: 30-40 parts of styrene-maleic anhydride copolymer; 8-10 parts of Cr3Si; 4-6 parts of 1,6-hexanediol diacrylate; 6-8parts of 4-(benzylthio)phenol; 1-2 parts of a catalyst; and 40-50 parts of isooctyl alcohol polyoxy ether ester. The processing technology comprises the following steps: S1, preparing the surface treating agent; S2, conducting thermal spraying; and S3, carrying out post-processing treatment. Compared with the prior art, the invention has the following advantages and effects: Cr3Si is adopted to improve the wear resistance of the surface treating agent, the styrene-maleic anhydride copolymer and Cr3Si are blended to improve the dispersity, and the 1,6-hexanediol diacrylate and 4-(benzylthio)phenol products are further mixed to prepare a copolymerization mixture with large molecular weight and a compact structure; the wear resistance of the check valve casting is improved; and according tothe machining process, the modes of preheating, thermal spraying and hole sealing treatment are adopted, and the performance of the check valve casting is better.

Owner:WENZHOU HAIGE VALVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com